Grinding device for small-diameter optical lens

An optical lens and small-diameter technology, which is applied in the mechanical field, can solve the problems of slow production efficiency, broken corners of the lens, and inconvenient grinding of edges and corners, and achieve the effect of easy removal, avoiding reprocessing, and saving procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

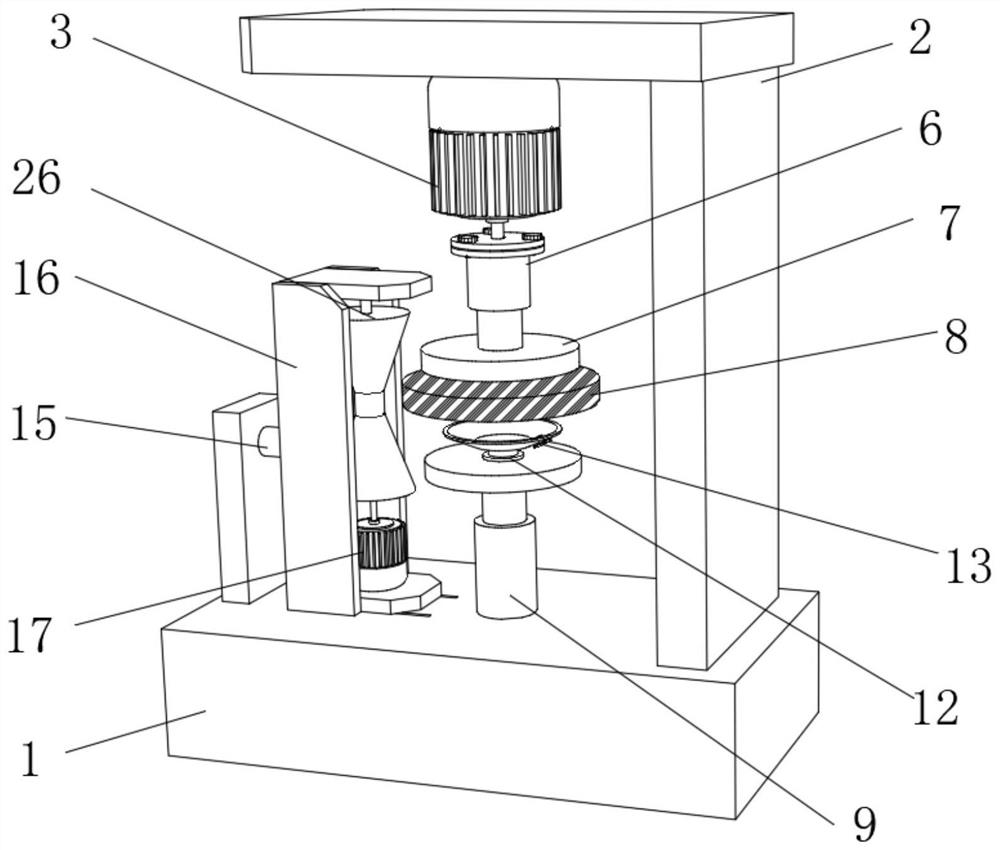

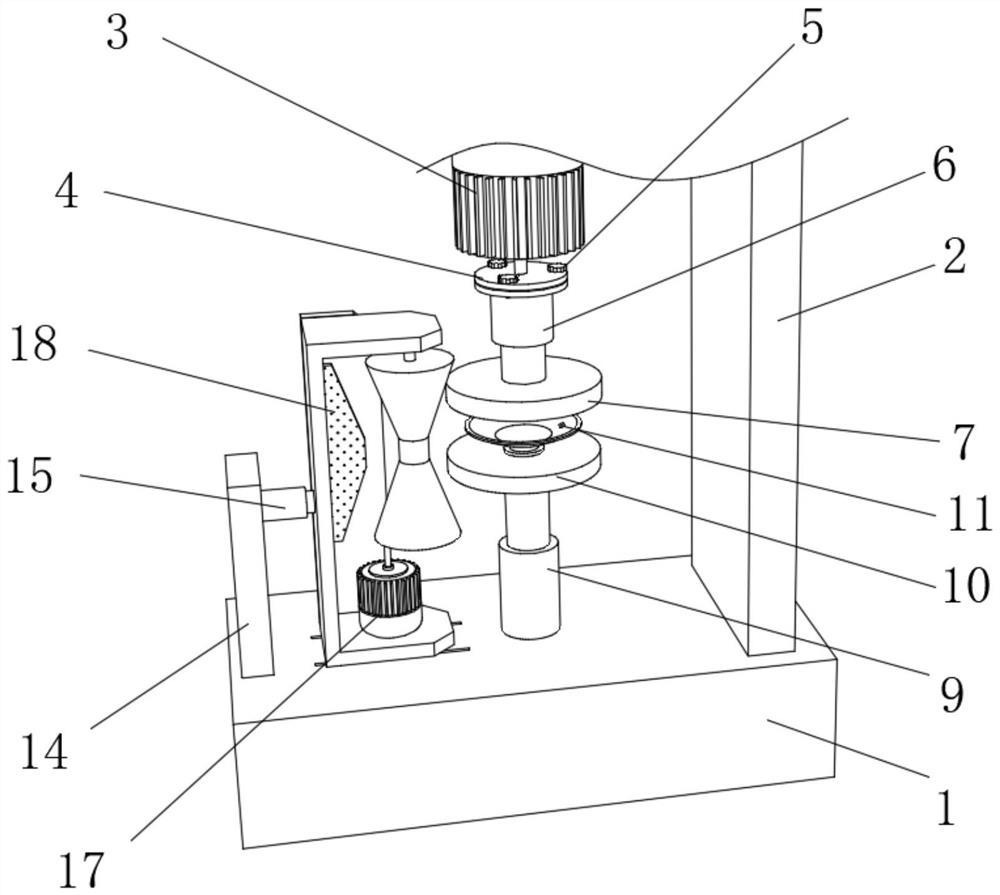

Method used

Image

Examples

Embodiment 2

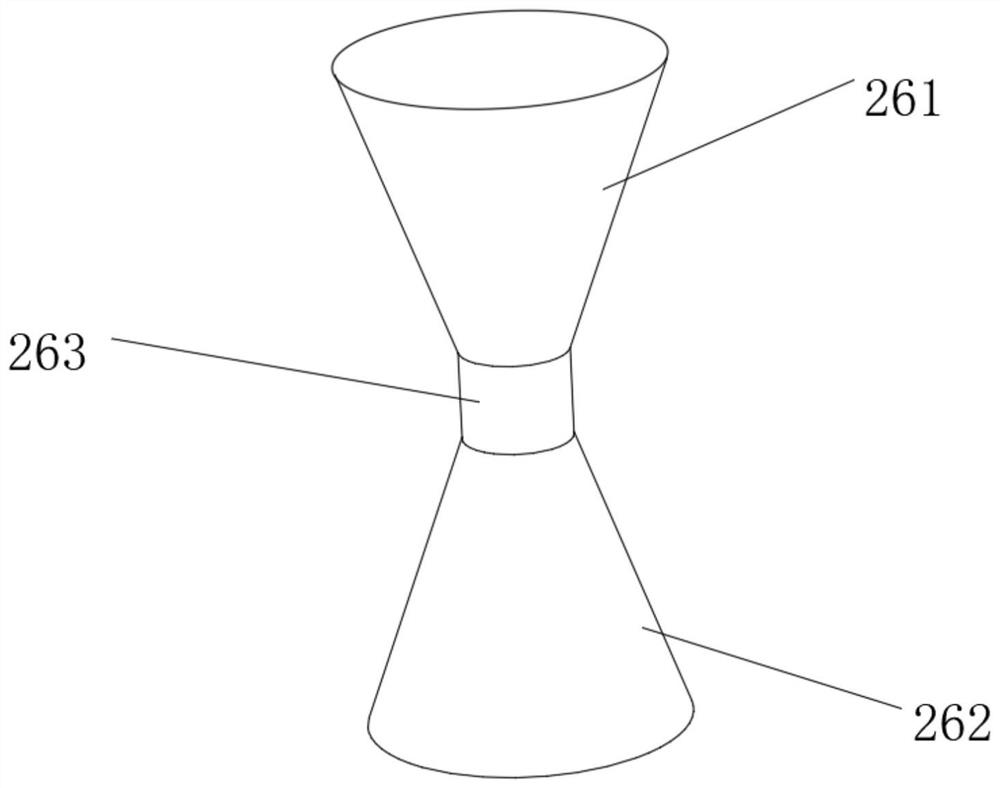

[0041] refer to Figure 4-5 , a grinding device for small-diameter optical lenses. Compared with Embodiment 1, in this embodiment, a through hole 28 is provided at the center of the inner bottom end of the suction cup seat 19 and the rubber layer 20, and the lower end of the suction cup seat 19 is fixedly connected with a rectangular The sealing tube 21, the side end of the rectangular sealing tube 21 is provided with a second air hole 23, the upper end of the second clip 10 is rotatably connected with a fixed cylinder 29, and the side end of the fixed cylinder 29 is provided with a first air hole 22 matching the second air hole 23, A tension spring 24 is fixedly connected between the lower end of the rectangular sealing tube 21 and the inner bottom end of the fixed tube 29, a pair of T-shaped limit sliders 25 are integrated at the side end of the rectangular sealing tube 21, and a pair of T-shaped limit sliders 25 are arranged on the inner wall of the fixed tube 29. Type limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com