Board overturning device for circuit board production

A circuit board and turning board technology, which is applied in the field of turning board devices for circuit board production, can solve the problems of inconvenient handling or stable placement, no height adjustment function, and inconvenient placement position adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

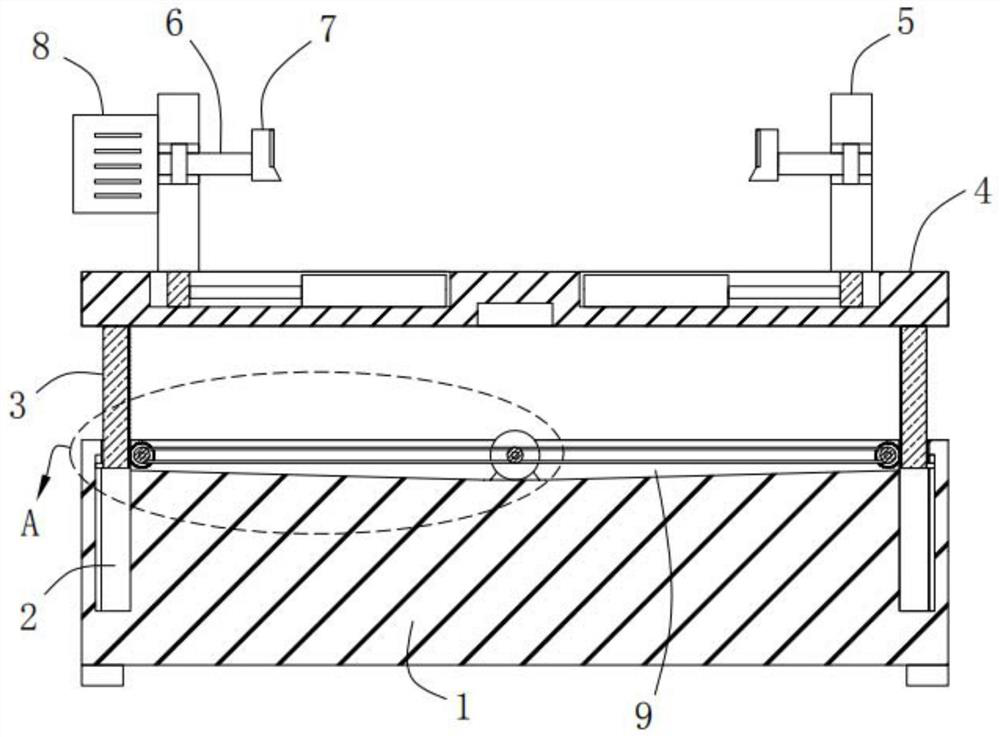

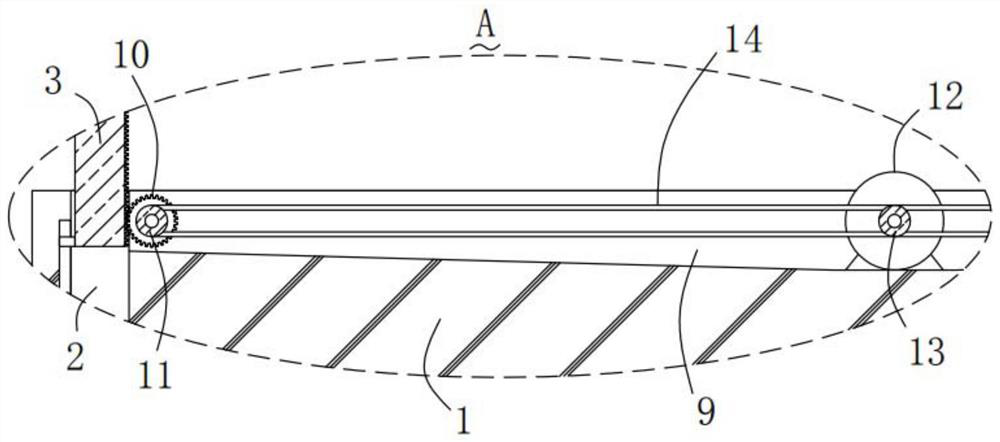

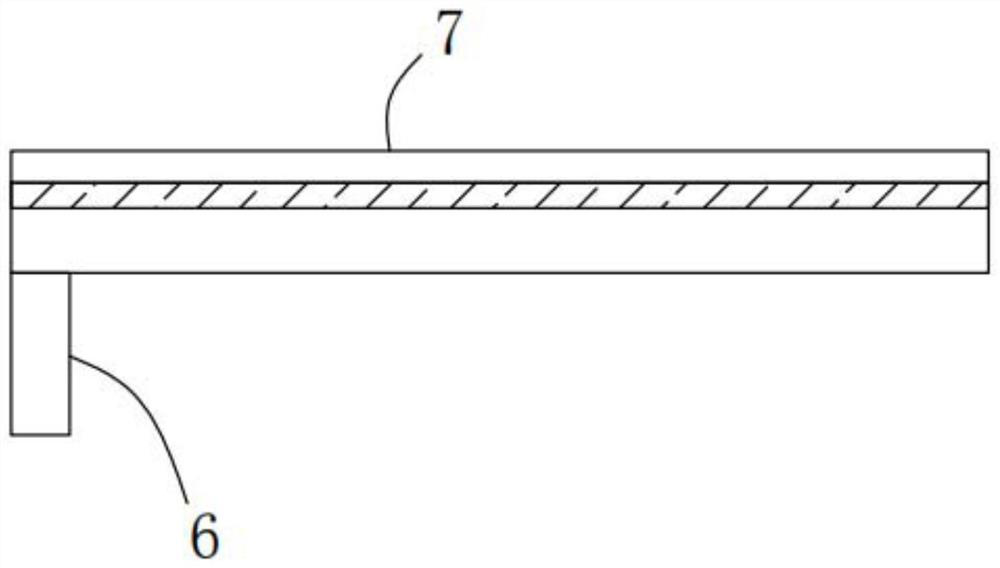

[0027] Please refer to Figure 1-4 , in the first embodiment of the present invention, the turning device for circuit board production includes: a base 1; two first grooves 2, and the two first grooves 2 are opened on the top of the base 1; two Rack 3, the two racks 3 are slidably installed in the corresponding first groove 2, the top of the rack 3 extends outside the corresponding first groove 2; horizontal plate 4, the horizontal plate 4 is fixed Installed on the top of the two racks 3; two slide plates 5, the two slide plates 5 are all slidably installed on the top of the horizontal plate 4; two first rotating shafts 6, the two first rotating shafts 6 are respectively installed on On the corresponding slide plate 5; two splints 7, the two splints 7 are respectively fixedly installed on the ends of the two first rotating shafts 6 close to each other, and the two splints 7 are located between the two slide plates 5; the first motor 8, the The first motor 8 is fixedly install...

no. 2 example

[0039] Based on the panel turnover device for circuit board production provided in the first embodiment of the present application, the second embodiment of the present application proposes another panel turnover device for circuit board production. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0040] The second embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

[0041] Please refer to Figure 5-6 The turnover device for circuit board production also includes a storage room 15, the storage room 15 is opened at the bottom of the base 1, the storage room 15 is equipped with an internal thread sleeve 16, and the internal thread sleeve 16 is internally threaded with a screw rod 17 , the screw 17 runs through the internally threaded sleeve 16, and both sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com