Patents

Literature

54results about How to "Improved particle size composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-effect soil conditioner and preparation method thereof

ActiveCN102925162AImprove water absorption and retention capacityStrong resistance to external physical pressureAgriculture tools and machinesOrganic fertilisersWater holdingFluoride

The invention discloses a multi-effect soil conditioner and a preparation method of the multi-effect soil conditioner. The multi-effect soil conditioner comprises the raw materials, by weight, 600-740 parts of organic solid waste, 150-210 parts of flyash and 110-190 parts of polyamino acid superabsorbent. The 600-740 parts of the organic solid waste, the 150-210 parts of the flyash and the 110-190 parts of the polyamino acid superabsorbent are mixed sufficiently and dried to granulate. The soil conditioner has various advantages of being water-holding and fertilizer-saving, and increasing plant soil nutrient and improving soil physico-chemical property and the like. The soil conditioner can be applied to various qualitative soils and play a crucial role in restoring special soils such as high level of fluoride soil and clayey soil, and also play a crucial role in wind prevention and sand fixation.

Owner:NANJING UNIV OF TECH

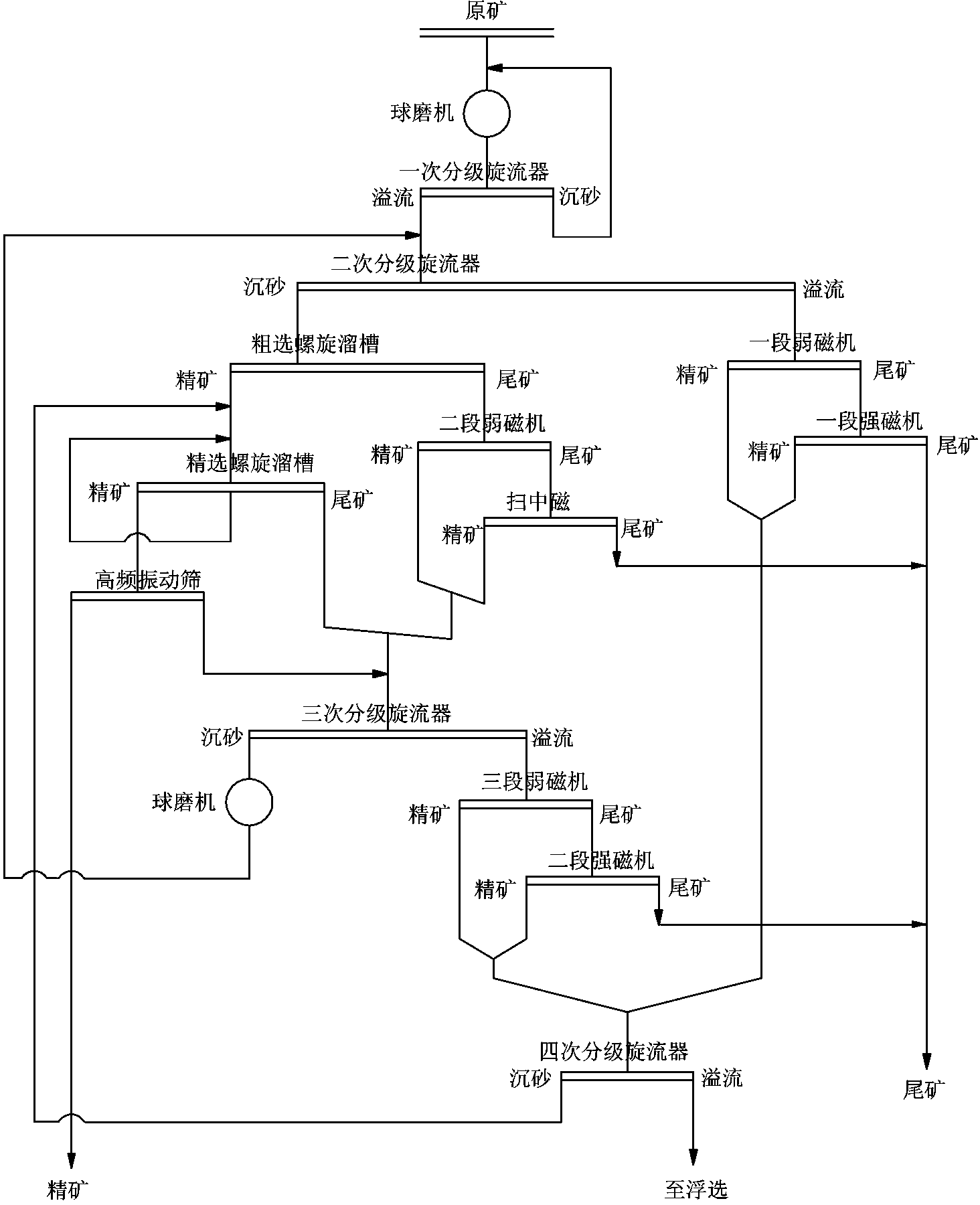

Process method for hematite dressing to increase gravity concentrate yield

InactiveCN103611623AIncrease productionReduce consumptionWet separationThermodynamicsProcess engineering

Owner:ANSTEEL GRP MINING CO LTD

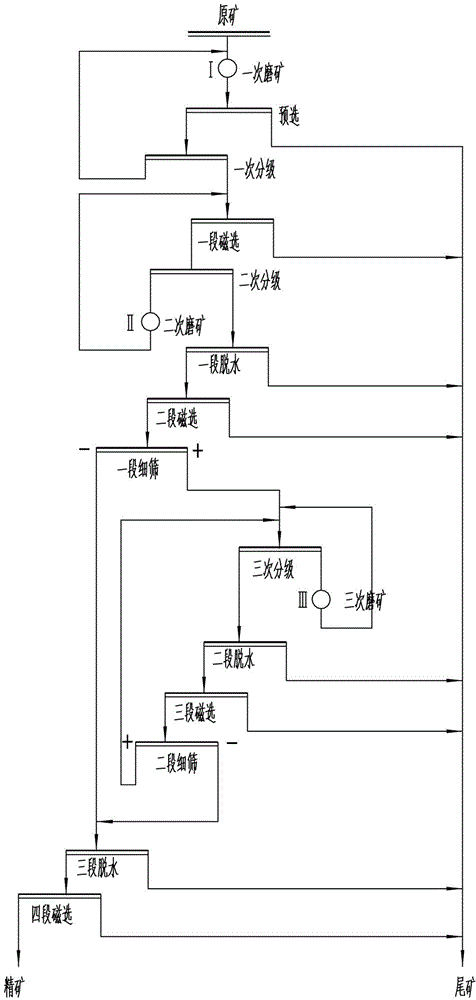

Simple magnetic separation process for Anshan type iron carbonate-containing lean magnetite ore

ActiveCN104128259AEasy to handleImproved particle size compositionMagnetic separationPhysical chemistryMagnetic separator

The invention relates to a simple magnetic separation process for Anshan type iron carbonate-containing lean magnetite ore. The process includes ore grinding, grading and magnetic separation and comprises the following concrete steps: ore grinding three times; presorting with a large-wrap angle medium-intensity magnet separator; grading with a cyclone three times; dehydration in three stages; fine sieving in two stages; and magnetic separation with a magnet separator in four stages. The invention provides the energy-saving, low-carbon, environment-friendly and reliable production process for treatment of iron carbonate-containing lean magnetite ore by using a simple magnetic separation method; the process can further improve treating capability, enhance technical and economic indexes, reduce production cost and greatly increase the utilization efficiency of inferior resources while improving ore grinding, grading and sorting efficiency.

Owner:ANSTEEL GRP MINING CO LTD

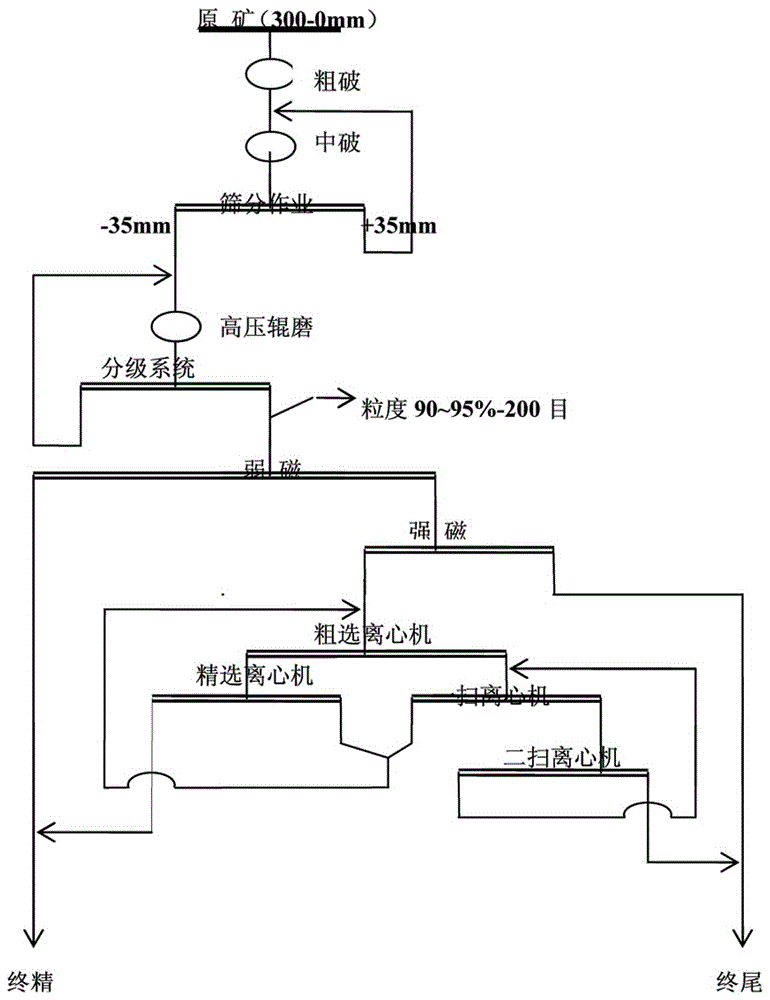

High-pressure rolling and magnetic-gravity separation process for lean hematite

InactiveCN106513163ASimple processReduce the cost of beneficiationWet separationGrade systemHigh pressure

The invention relates to a high-pressure rolling and magnetic-gravity separation process for lean hematite. The high-pressure rolling and magnetic-gravity separation process for lean hematite is characterized by comprising the following steps that after raw ore particles with the particle size of 0-300 mm are subjected to the coarse crushing and intermediate crushing screening operation, the product particle size is 0-35 mm; after the particles pass through a high-pressure roll mill and a wind grading system, the large-particle-size products subjected to wind grading return to the high-pressure roll mill, the small-particle-size products subjected to wind grinding and with the 200-mesh sieve sieving rate being 90%-95% are fed to the technical procedures with low intensity magnetism, high intensity magnetism and a centrifugal machine so as to be graded; concentrate obtained through low intensity magnetic separation and concentrate obtained through the centrifugal machine are combined into final concentrate with the grade being 66.5%-67.5% and the yield being 27%-29%; and the grade of tailings of high intensity magnetic separation is 8.3%-8.8%, the grade of tailings of two-stage scavenging centrifuge is 16%-18%, and the tailings of high intensity magnetic separation and the tailings of two-stage scavenging centrifuge are combined into final tailings with the grade being 10.50%-11% and the yield being 61%-63%. The high-pressure rolling and magnetic-gravity separation process for lean hematite has the advantages that original fine crushing operation and two-stage grinding operation are omitted, the products with the 200-mesh sieve sieving rate being 90%-95% can be directly obtained by the adoption of the high-pressure roll mill and the wind grading system, the process structure is simplified, and the ore separation cost is reduced significantly.

Owner:ANSTEEL GRP MINING CO LTD

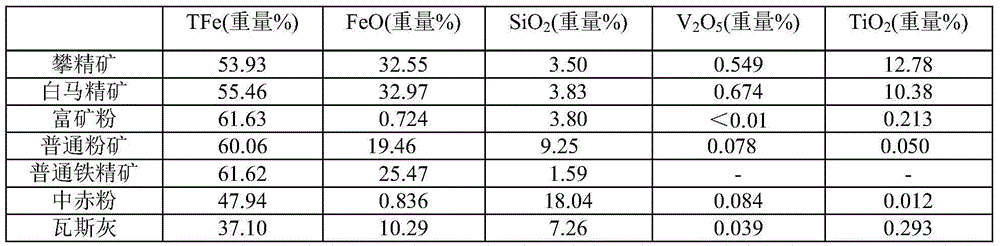

Sintering method for high-grade vanadium titanium iron ore concentrate

ActiveCN103014323AImproved particle size compositionImprove breathabilityBlast furnace detailsGranularityBlast furnace smelting

The invention discloses a sintering method for a high-grade vanadium titanium iron ore concentrate. The method comprises the steps which are sequentially performed as follows: fuel pretreatment, burdening, water adding and mixing, pelletizing, ignition sintering, CaCl2 solution spraying and blast furnace smelting, wherein, in percentage by mass, the particle size of coke powder in the fuel after the pretreatment is 0-3 mm, 20%-29% of the coke powder is provided with the particle size smaller than 0.5 mm, quick lime is added twice, the proportion of a second addition is 25%-75%, a mixture which is formed by adding water and mixing contains 7.3%-7.6% of water, the carbon content of the mixture is 4.6%-4.75%, the material layer height during ignition sintering is 660-740 mm, and the mass concentration of the sprayed CaCl2 solution is 1%-3%. According to the sintering method for the high-grade vanadium titanium iron ore concentrate, the processing steps of optimizing sintering processing parameters, comprehensively applying fuel pretreatment, increasing water of the sintering mixture, appropriately reducing the carbon content of the sintering mixture, increasing the material layer height, separately adding fluxing agents, spraying the CaCl2 solution to a sintering ore and the like are adopted, so that the production quality and the low-temperature reduction degradation performance of the sintering ore are substantially improved, and the fuel consumption is reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Low-cost magnesium gunning material and its preparation method

The invention discloses a low-cost magnesium gunning material and its preparation method. The low-cost magnesium gunning material is prepared from the following components of: by weight, 25-38 parts of recycled magnesia of 1-3mm, 32-42 parts of recycled magnesia of 0.088-1mm, 6-12 parts of a recycled magnesium powder of 200 meshes, 8-12 parts of a sintered magnesium powder, 1-5 parts of sodium silicate, 1-5 parts of calcium hydroxide and 3-10 parts of ultrafine slurry. When in use, the above magnesium gunning material is sprayed onto ladle damaged positions by the use of a spray gun so as to complete the repairing work. The magnesium gunning material has characteristics of low cost, good fluidity, high adhesive rate, rapid reaction, fast hardening, low spring rate, erosion resistance, anti-stripping capacity and the like, is applicable to hot repairing of ladle, especially to hot repairing of slag line portions, and can be used to effectively prolong service life of ladle.

Owner:山西高科耐火材料股份有限公司

Casting-molded large-scale nitride-combined silicon carbide product

ActiveCN103936437AIncrease contact areaFavorable for high temperature nitriding reactionSilicon nitrideAluminium

The invention relates to a casting-molded large-scale nitride-combined silicon carbide product. The product employs silicon carbide particles and powder, silicon carbide micro powder, silicon dioxide micro powder, alumina micro powder, active magnesium oxide and a water reducer as powder materials, employs silica sol as a binder and is molded by employing vibration casting. A molded blank is subjected to maintenance, drying, and high-temperature nitridation processing in nitrogent, so that the nitride-combined silicon carbide product is prepared. By reacting silicon dioxide and silicon carbide in the materials with nitrogen at the conditions of high temperature and nitrogen, silicon nitride is generated and other nitrides are further generated, and thus the combination strength is generated. The products helps to solve the problems and the disadvantages that conventional nitride-combined silicon carbide products generated through nitridation of silicon powder is high in cost and relatively easily have residual silicon, large-scale products cannot be produced, and the like. According to the technical scheme, the large-scale nitride-combined silicon carbide product can be produced and has the advantages of low cost, excellent performances and the like, the prepared silicon carbide product is capable of replacing conventional Si3N4-combined, Si2N2O-combined and Sialon-combined silicon carbide and being applied to fields of steel industry blast furnace air ports and blast furnace cooling wall cast-in bricks, nonferrous metals industry aluminium electrolytic tanks and the like.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

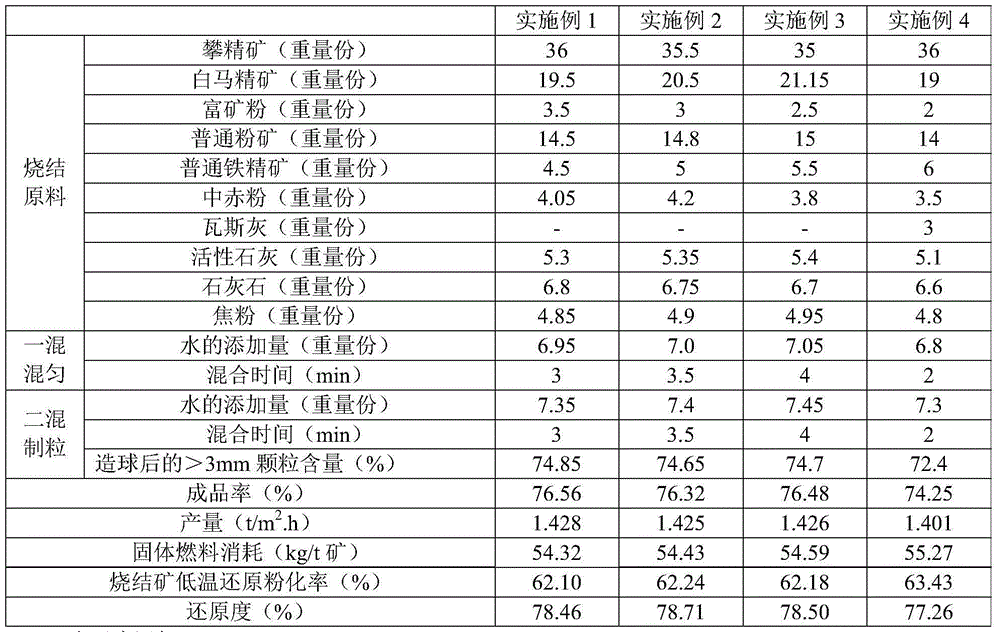

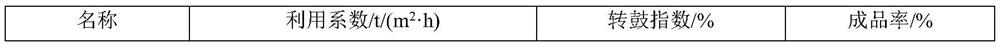

Sintering mixture and vanadium-titanium sinter as well as preparation method of vanadium-titanium sinter

The invention discloses a sintering mixture, a vanadium-titanium sinter prepared from the sintering mixture and a preparation method of the vanadium-titanium sinter. The sintering mixture comprises the following raw materials in percentage by weight: 54-58% of vanadium-titanium-iron concentrate, 2-8% of ordinary iron concentrate, 13-16% of ordinary ore powder, 1-6% of ore-rich powder, 3-5% of medium-sized hematite ore powder, 11-13% of a solvent and 4.5-5.5% of a fuel. The sintering mixture is low in cost; by virtue of the use of the sintering mixture, the sinter ore can be produced at a high yield; the prepared sinter ore is high in strength, high in rate of finished products and excellent in low-temperature reduction pulverization performance.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Sintering method of iron ore with added limonite

The invention provides a sintering method of iron ore with added limonite. The sintering method of the iron ore with the added limonite comprises the steps of limonite fine grinding treatment, limonite roasting treatment, batching, mixing, material distribution, material pressing and sintering with fire, wherein the granularity of the ground limonite is controlled to be below 1mm, the ground limonite is roasted at the temperature of 180-220 DEG C, the water content of the mixed material is controlled to be 7.3-7.6 wt%, and the quantity of the pressed materials in the step of material pressing is controlled to be 20-50 mm. The sintering method of the iron ore with the added limonite is capable of eliminating the explosion phenomenon in the sintering process of the coarse-grain limonite, improves the strength and the yield of sintered ore, improves the quality of the sintered ore, can reduce the content of crystal water in the limonite, is favorable for sintering, can reduce the consumption of fuel, improves the grain composition of the mixed materials, and improves the air permeability of material layers, thereby improving the yield and the quality of the sintered ore. In addition, the sintering method of the iron ore with the added limonite is capable of improving the compactness of the material layers, improves the structure of the sintered ore, controls the sintering speed at the same time, improves the metallurgical performance of the sintered ore, and is favorable for improving the techno-economic indicators of a blast furnace process.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

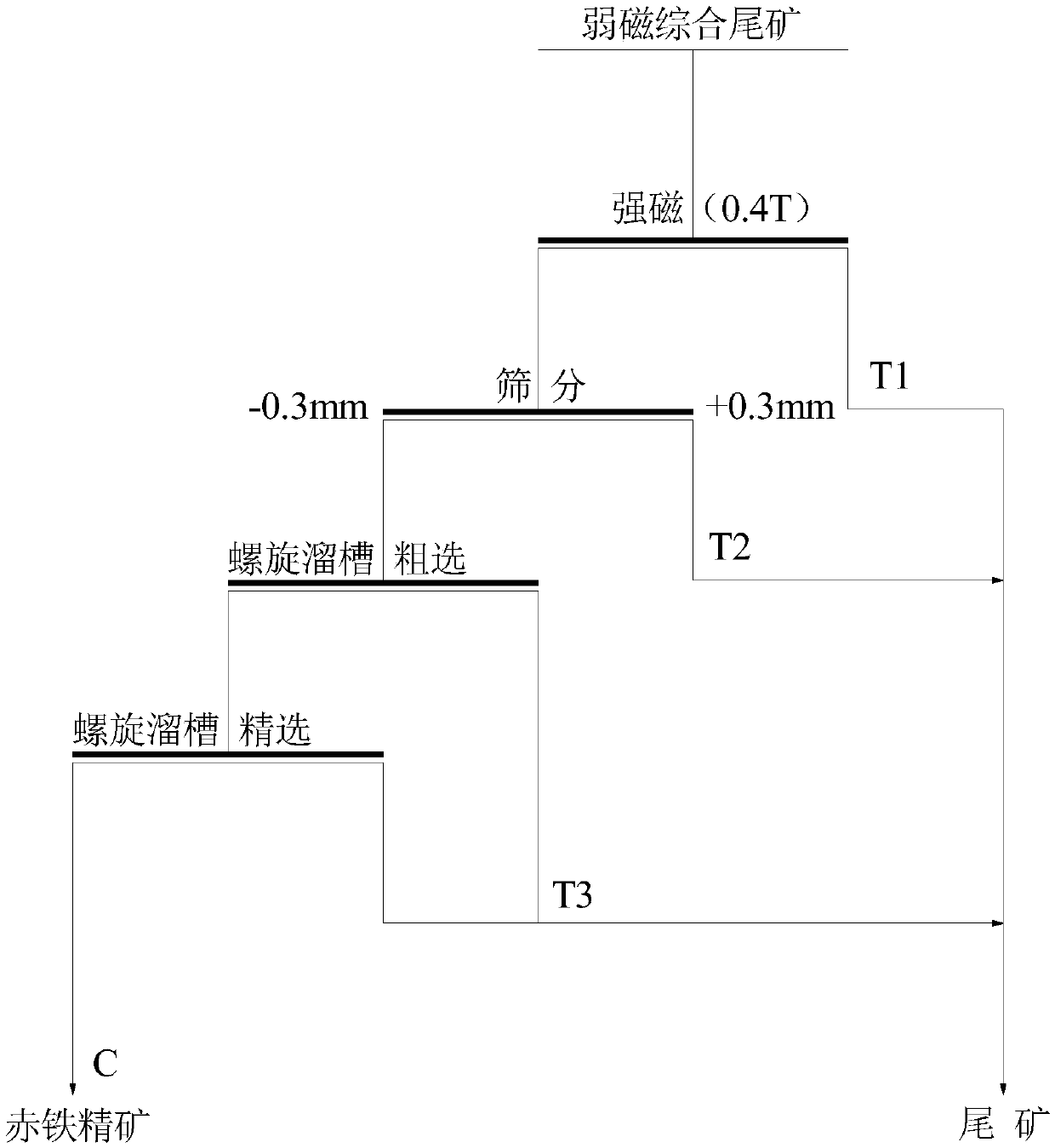

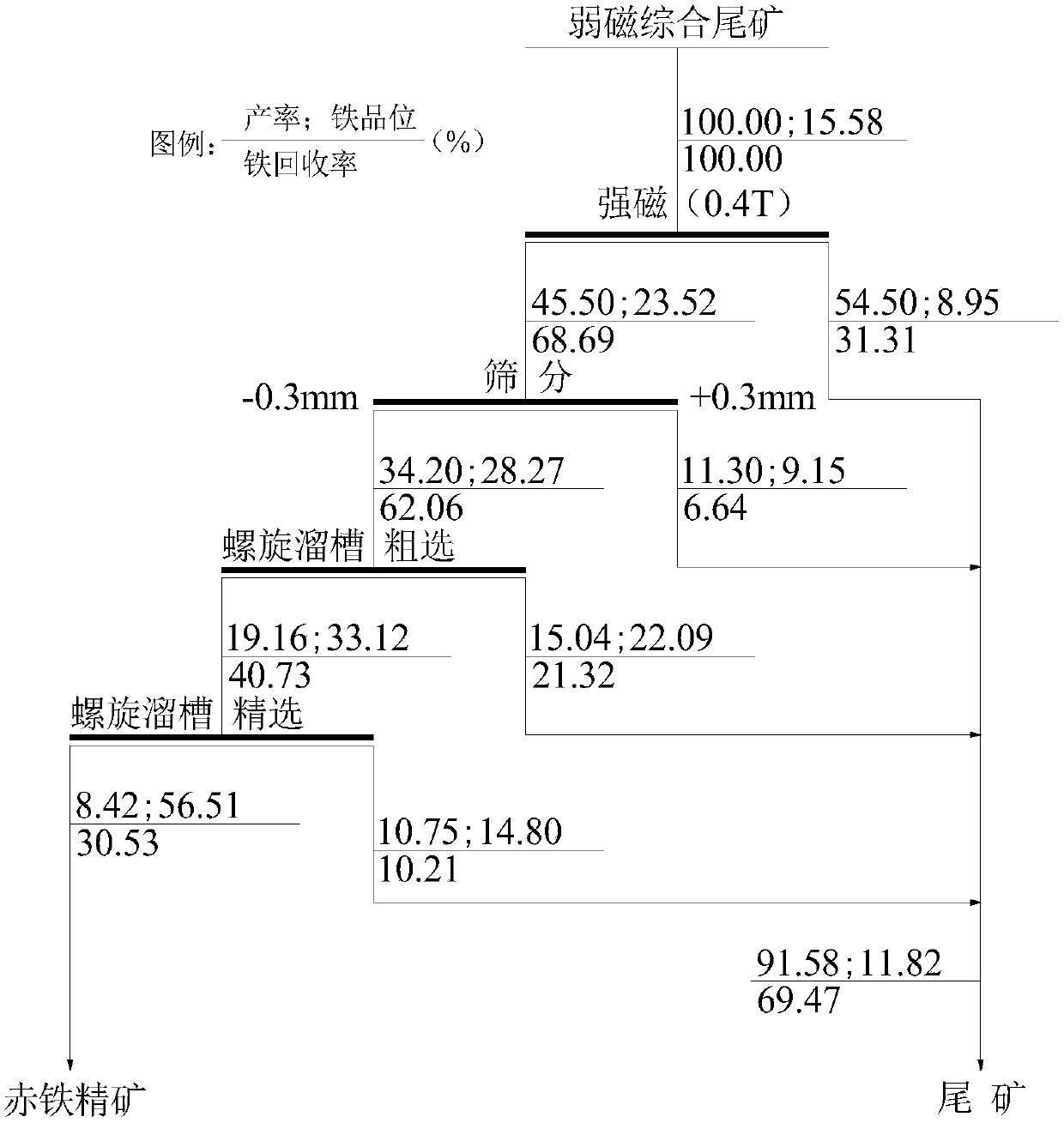

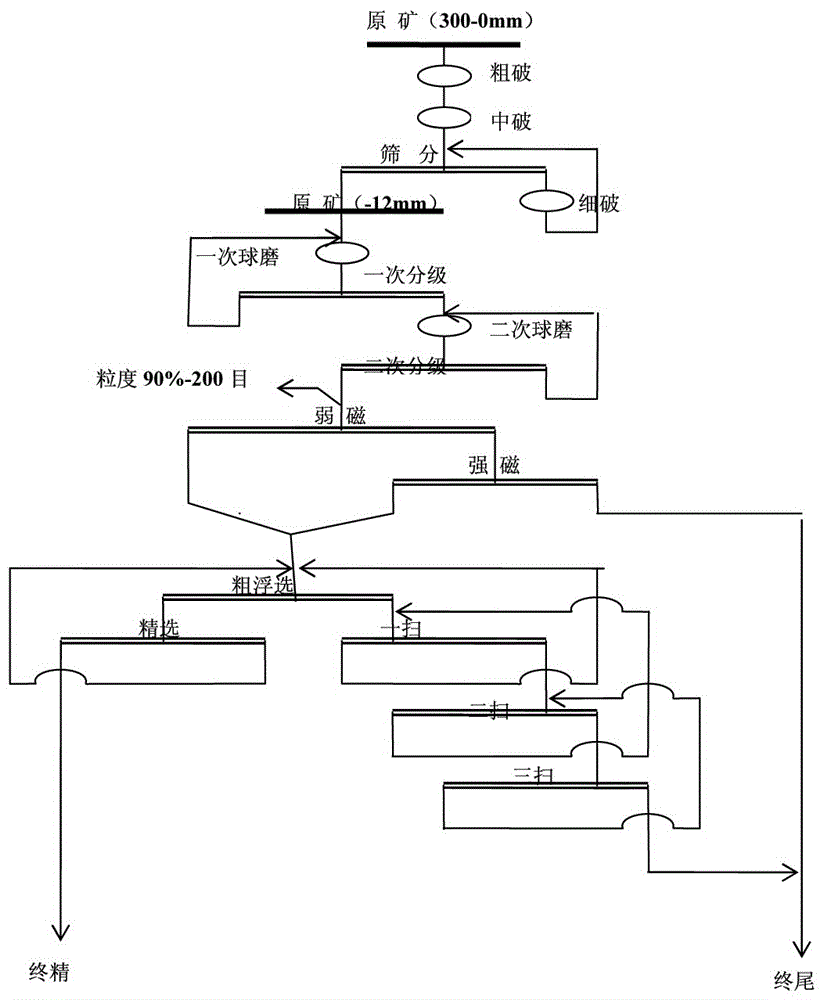

Mineral separation method for improving high-sulfur magnetite and hematite mixed ore separation indexes

The invention discloses a mineral separation method for improving high-sulfur magnetite and hematite mixed ore separation indexes. The method comprises the steps that raw ore is subjected to the processes of stage grinding, flotation sulfur separating and low-intensity magnetic separation, low-intensity magnetic separation tailing is discharged, and qualified sulfur concentrate and magnetite concentrate products are obtained; strong magnetic separation is conducted on the discharged low-intensity magnetic separation tailing, high-intensity magnetic separation tailing T1 is discarded, and thena high-intensity magnetic rough concentrate is obtained; the obtained high-intensity magnetic rough concentrate is subjected to fine-sieve sieving work, and a retained product directly serves as tailing T2 to be discarded; and a fine-sieve through product is fed into a spiral chute gravity separation technology, spiral chute gravity separation tailing T3 is discarded, and a spiral chute gravity separation iron concentrate C is obtained, wherein the spiral chute gravity separation technology comprises the primary spiral chute rough separation step and the primary spiral chute fine separation step. The mineral separation method for improving the high-sulfur magnetite and hematite mixed ore separation indexes has the advantages that the grade of hematite concentrate TFe is high, the operationrecovery rate is high, the technological process is simple and easy to carry out, the indexes are stable, and operation and management are easy to achieve on the site.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

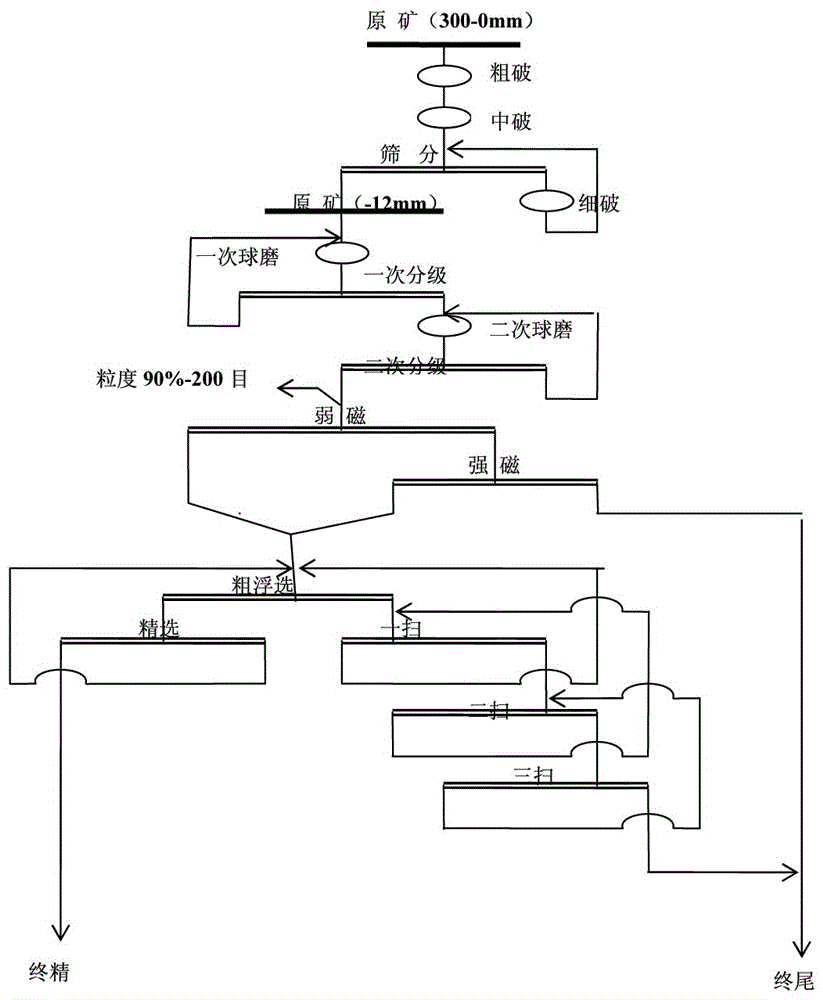

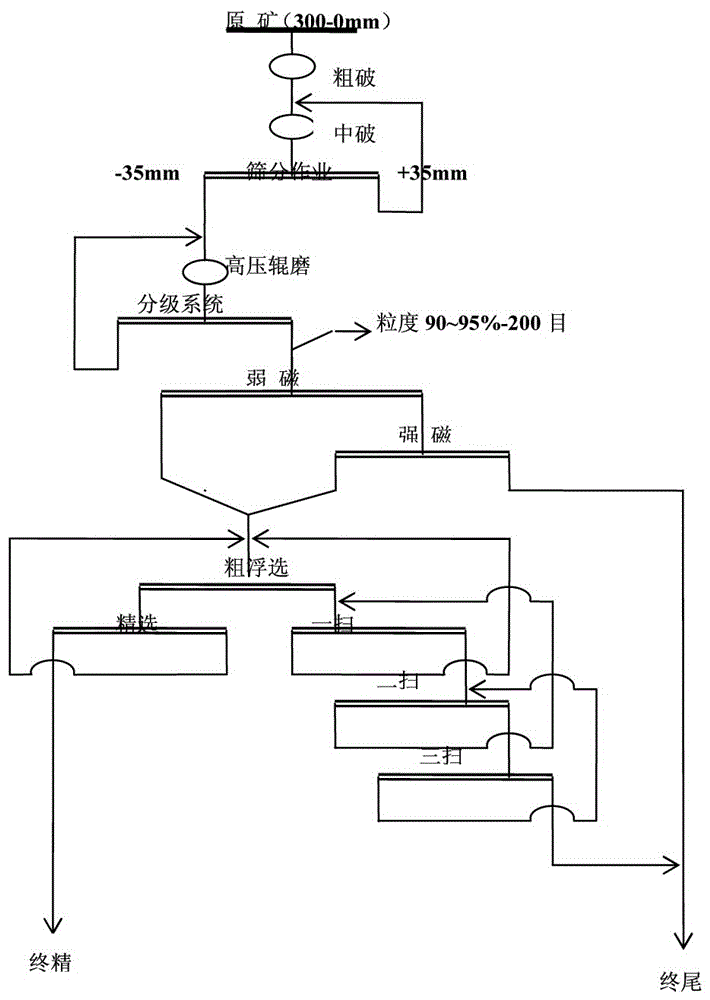

High-pressure roller grinding, weak magnet-strong magnet-reverse flotation technology for poor hematite

InactiveCN106492977ASimple processReduce the cost of beneficiationWet separationEngineeringReverse flotation

The invention relates to a high-pressure roller grinding, weak magnet-strong magnet-reverse flotation technology for poor hematite. The technology includes the step that the poor hematite is subjected to rough crushing and medium crushing and is characterized by further including the following steps that after raw ore with the particle size being 300-0mm is subjected to rough crushing and medium crushing screening operations, the product particle size is 35-0mm; by the adoption of a high-pressure roller grinding device and an air classification system, coarse-grained products suffering from air classification return to the high-pressure roller grinding device, and fine-grained products with the air classification particle size being -200 meshes and the content being 90%-95% are fed into the weak magnet-strong magnet-anion reverse flotation technology. By the adoption of the technology, an original fine crushing operation and a two-section ore grinding operation are omitted in the technological process, the high-pressure roller grinding device and the air classification system are adopted so that the fine-grained products with the particle size being -200 meshes and the content being 90%-95% can be obtained directly, the flowage structure is simplified, short-process sorting is realized, beneficiation cost is greatly reduced, and economical benefits are remarkable.

Owner:ANSTEEL GRP MINING CO LTD

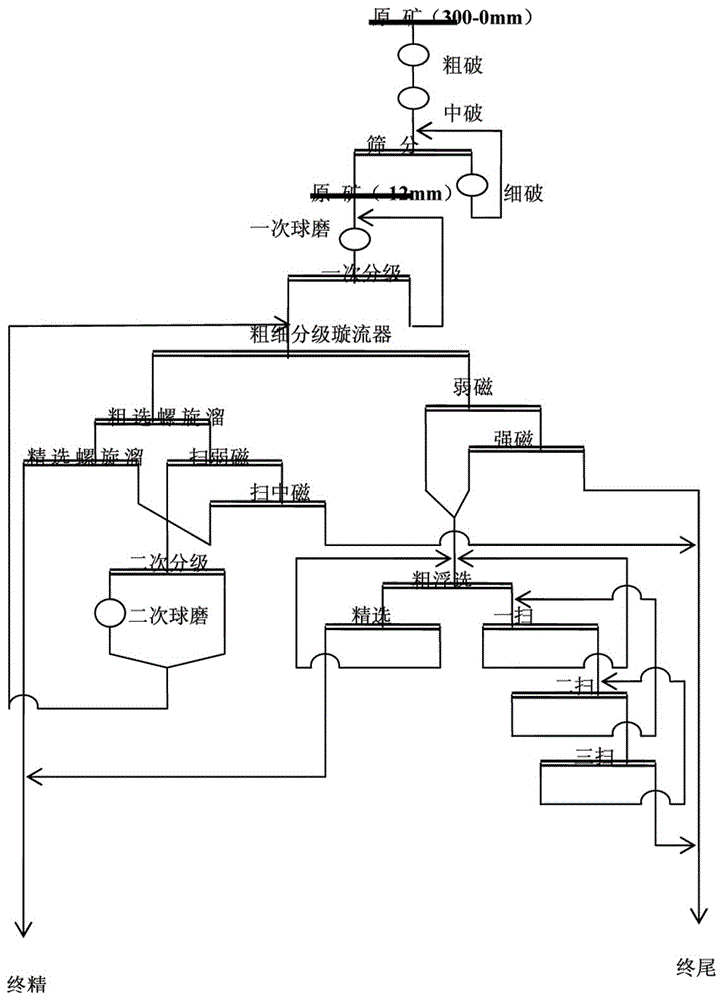

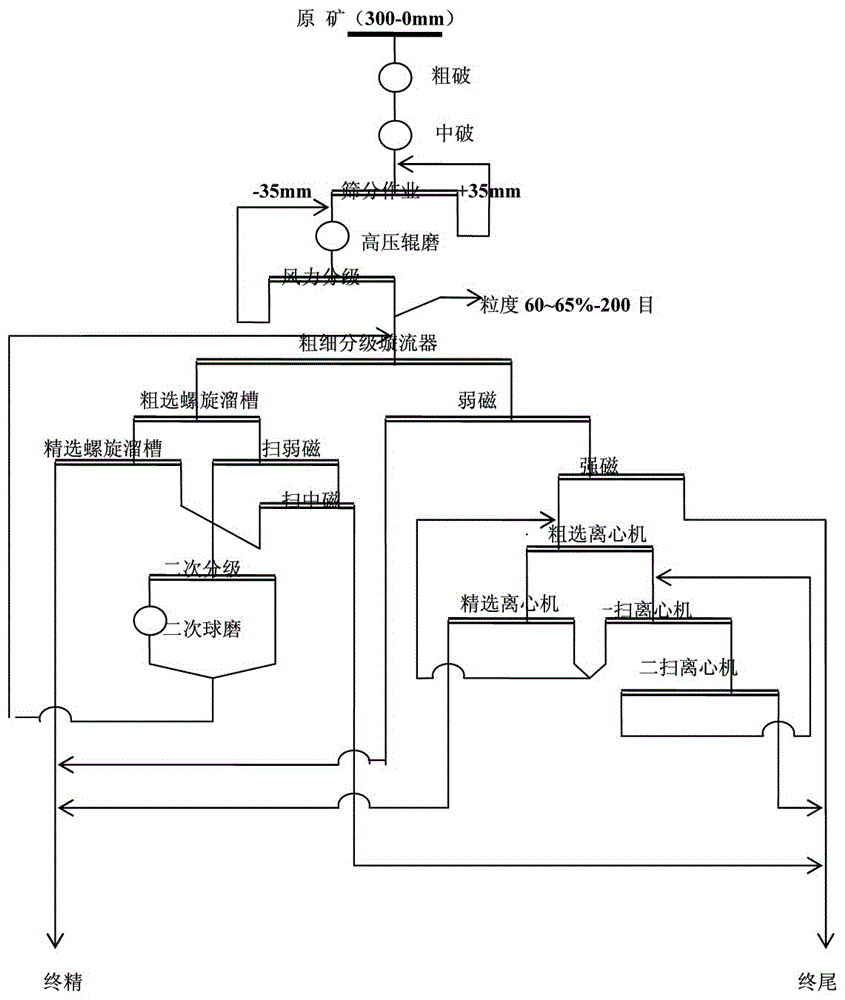

Poor hematite high pressure roller milling, thickness grading and reselection-magnetic separation-centrifugal machine sorting process

InactiveCN106423534ASimple processReduce the cost of beneficiationWet separationEngineeringHigh pressure

The invention relates to a poor hematite high pressure roller milling, thickness grading and reselection-magnetic separation-centrifugal machine sorting process. The process is characterized in that raw ore passes through coarse breaking, medium breaking screening, high pressure roller milling and air classification systems to be fed into a thickness grading hydrocyclones to be subject to classification operation, reselection, magnetic separation and centrifugal machine sorting are then carried out, and concentrates with the grade ranging from 67.5% to 67.8% and the yield ranging from 31.33% to 32% and tailings with the grade ranging from 10.5% to 11.5% and the yield ranging from 67.5% to 68.5% are sorted. According to the technological process, fine breaking operation in original three-stage breaking and first-stage ore grinding operation are omitted, a product with the granularity being 200 meshes and the content ranging from 60%-65% can be obtained directly through high pressure roller milling and thickness grading, the flowage structure is simplified, short process sorting is achieved, the ore separation cost is greatly reduced, and economical benefits are remarkable.

Owner:ANSTEEL GRP MINING CO LTD

Advanced slurry mixing and grading method for gravity raw ore and application of advanced slurry mixing and grading method

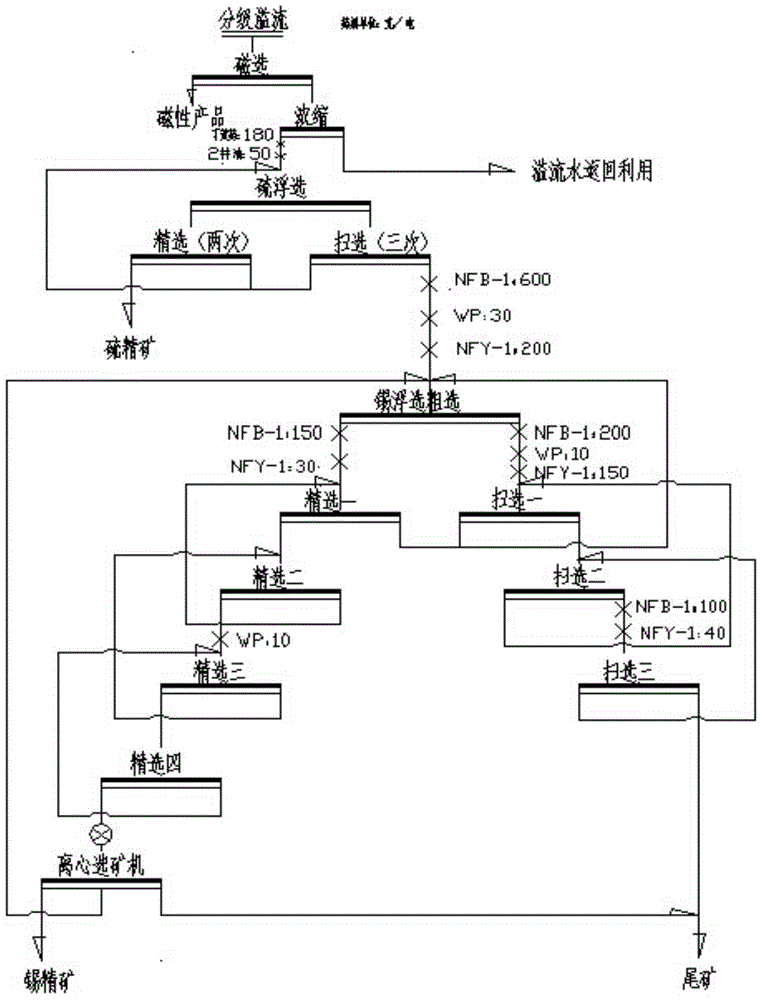

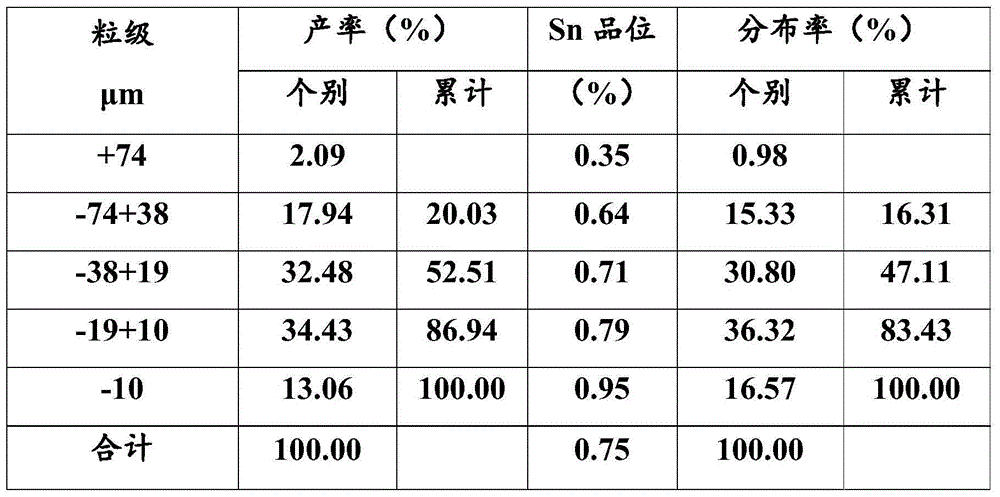

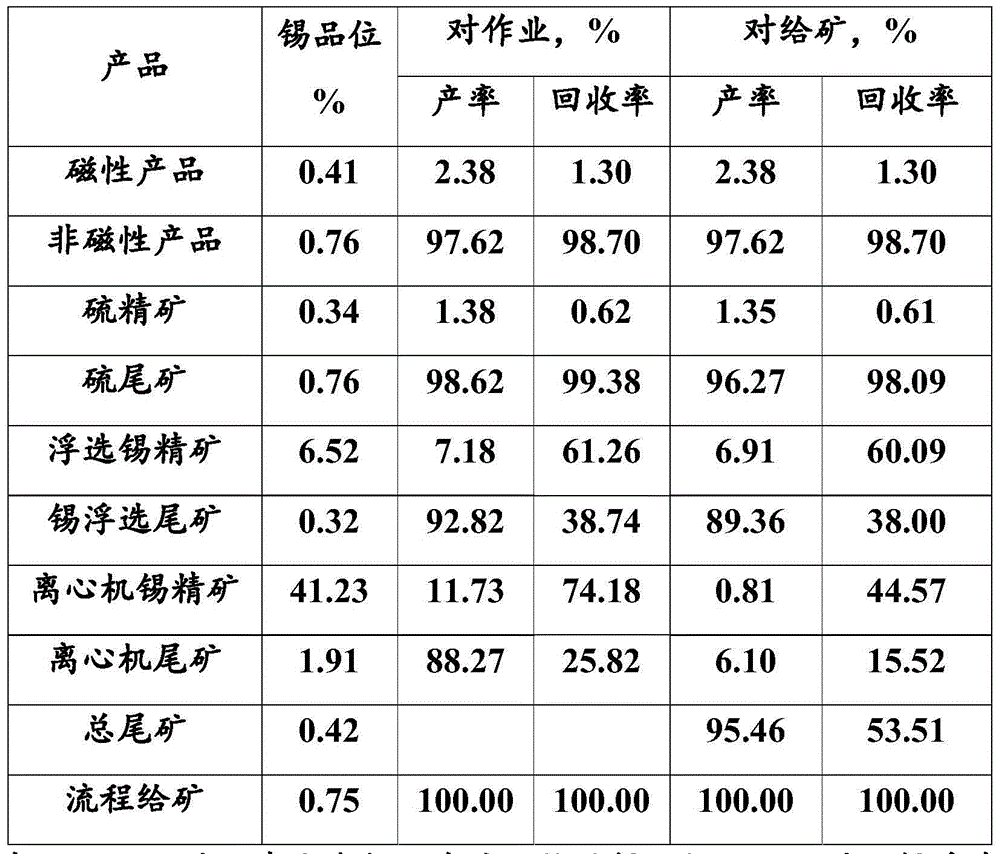

ActiveCN104588201AOvercoming technical difficulties in recyclingTo achieve the expected purpose of deslimingWet separationCassiteriteSlurry

The invention provides a technological method for recycling fine-particle cassiterite from gravity raw ore. The method is characterized by comprising advanced slurry mixing and grading steps on the gravity raw ore; the advanced slurry mixing and grading steps comprise technologies for carrying out gravity concentration on underflow and carrying out flotation on overflow, and comprise separation of fine-particle slime from the particle capable of being sepatated by a table concentrator; the fine-particle slime is fed to flotation as overflow; the particle capable of being sepatated by the table concentrator is fed to gravity concentration as the underflow. According to the advanced slurry mixing and grading method, effective recovery of the fine-particle cassiterite in the overflow which is subjected to advanced slurry mixing and grading is achieved; the technical problem of recovery of the fine-particle cassiterite is overcome; new idea and exploration direction are provided for ore dressing workers for solving fine-particle cassiterite recovery research; the ore feeding mode of a traditional cassiterite gravity-recovery process is broken through; with respect to the overflow which is subjected to advanced slurry mixing and grading overflow, when the grade of tin in the ore feeding process is 0.75%, the grade of tin concentrate which is obtained by tin flotation is 6.52%, the operation recovery rate is 61.26% and the recovery rate in the ore feeding process is 60.09%.

Owner:临武县南方矿业有限责任公司

Sintering method of fine Baima vanadium-titanium magnetite concentrate

The invention discloses a sintering method of fine Baima vanadium-titanium magnetite concentrate. The sintering method comprises the sequential steps of burdening, mixing with water, pelletizing, igniting and sintering, spraying CaCl2 solution and blast furnace processing, wherein based on mass, the water content in the mixed material in the water mixing step is 7.2-7.5%; the carbon content in the mixed material is 4.8-5.0%; the material layer height when igniting and sintering is 640-700 mm; and the mass concentration of the sprayed CaCl2 solution is 1.5-3%. Through optimizing of the sintering technical parameters, comprehensively improving of the water content of the sintering mixed material, the carbon content in the mixed material and the height of the material layer, the grain composition and the sinter components of the mixed material when the fine Baima vanadium-titanium magnetite concentrate is sintered are greatly improved; the sintering atmosphere, flux mineralization, sintering heat system and mineral crystallization in the sintering process are effectively strengthened, so as to improve the sinter product yield and quality, and enable the yield and the quality of the sinter and the metallurgical performance to be greatly improved.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Method for producing sintering ore with iron ore concentrate as main iron materials

InactiveCN105714103AImproved particle size compositionImprove breathabilityGranularityMaterial distribution

The invention provides a method for producing sintered ore with iron concentrate as the main iron material. The iron concentrate, the returned ore with a particle size of 3-5 mm, and coke powder, limestone, magnesium stone, and quicklime with a particle size of less than 1 mm are added with water and then mixed vigorously. Machine-made mixture ball A; after adding water with iron concentrate, returned ore with a particle size of less than 3mm, coke powder with a particle size of 1-5mm, limestone with a particle size of 1-2mm, magnesium stone with a particle size of 1-2mm and quicklime, it is made by a strong mixer Mixture ball B: Mix mixture ball A, mixture ball B and coke powder with a particle size of less than 1mm evenly to form sinter mixture C, which is distributed on sintering equipment and sintered to obtain a finished sintered ore. The invention can improve the gas permeability and sintering speed of the sintering material layer, thereby increasing the output of iron concentrate sintering and reducing the fuel consumption of iron concentrate sintering; at the same time, it is beneficial to strengthen the mineralization performance of iron-containing raw materials and the generation of calcium ferrite, Improve the strength and yield of sintered ore.

Owner:ANGANG STEEL CO LTD

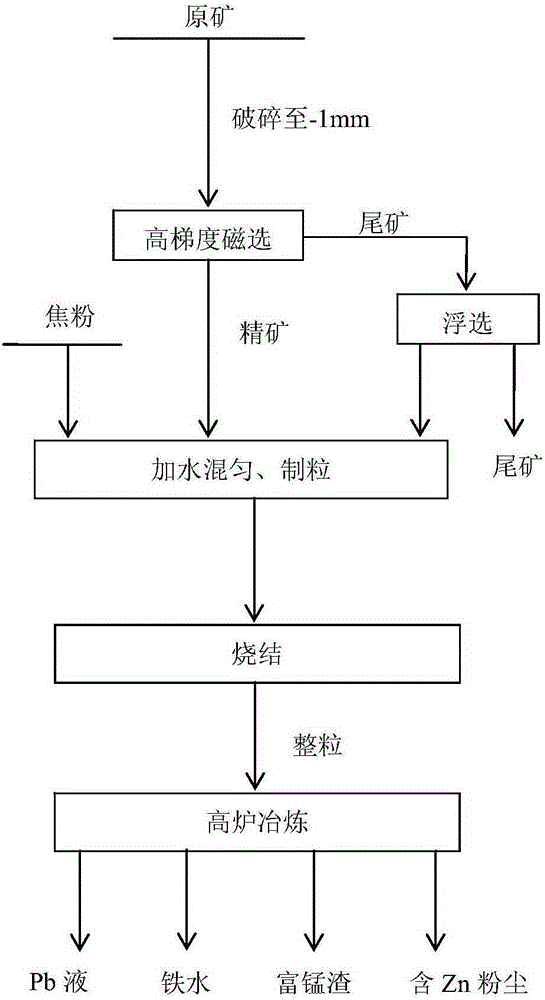

Comprehensive utilization method for low-grade complex ferromanganese ore

ActiveCN105296747ARaise the gradeReduce processingBlast furnace detailsFlotationMaterials scienceMagnetic separation

The invention discloses a comprehensive utilization method for low-grade complex ferromanganese ore. The comprehensive utilization method comprises the steps that raw ore is crushed to a certain particle size, and magnetic separation is conducted through a high-gradient magnetic separator; valuable elements such as Pb and Zn in tailings are recycled through flotation; sintering is conducted after flotation concentrate and magnetic concentrate are mixed uniformly; the sintered ore enters a blast furnace for smelting; and in the blast furnace smelting process, Pb deposits at the bottom of the blast furnace as liquid phases, Pb and molten iron are separated and recycled, Zn is enriched in blast furnace dust, Fe enters the next working procedure as molten iron, and Mn enters the slag phase and forms manganese-rich slag. In this way, various valuable elements in the complex refractory ferromanganese ore are utilized sufficiently. The method is easy to implement and reliable, energy consumption is low, various valuable elements in the raw ore can be recycled, and accordingly the economic benefits of mineral products are greatly increased. By means of the comprehensive utilization method, a feasible method and a reliable theoretical foundation are provided for the development and utilization of the low-grade ferromanganese ore.

Owner:CENT SOUTH UNIV

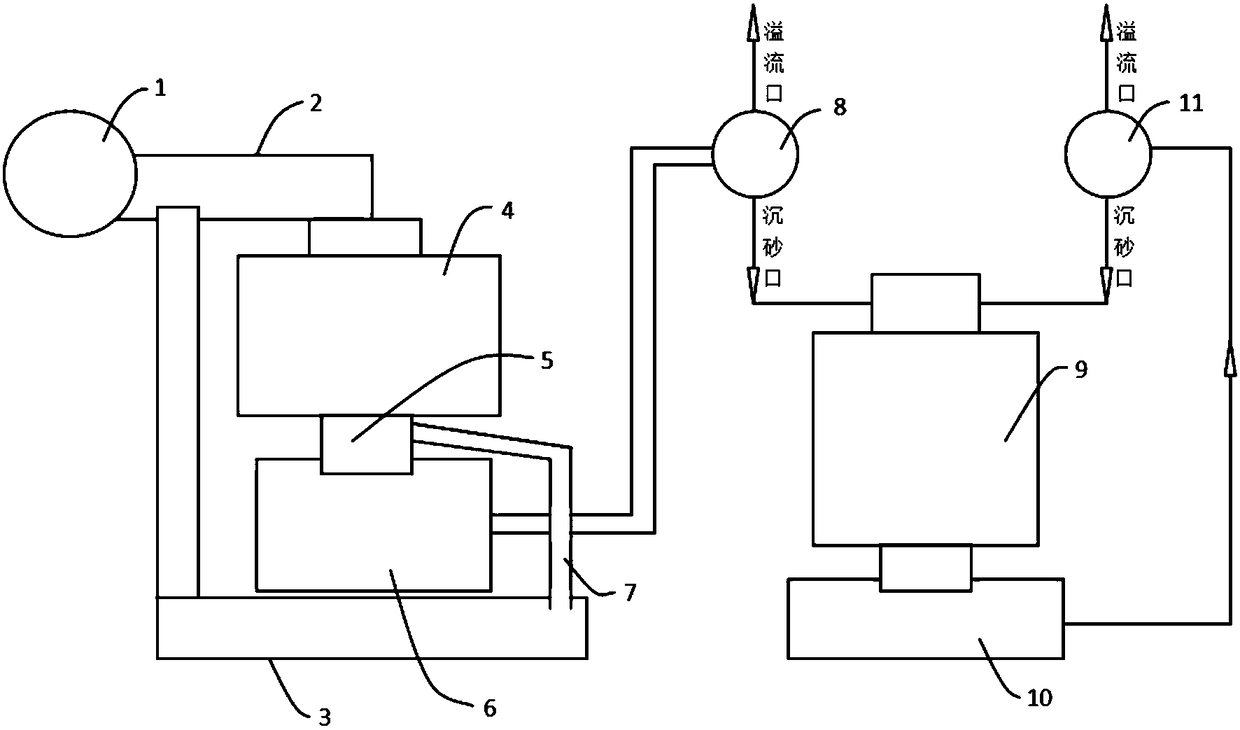

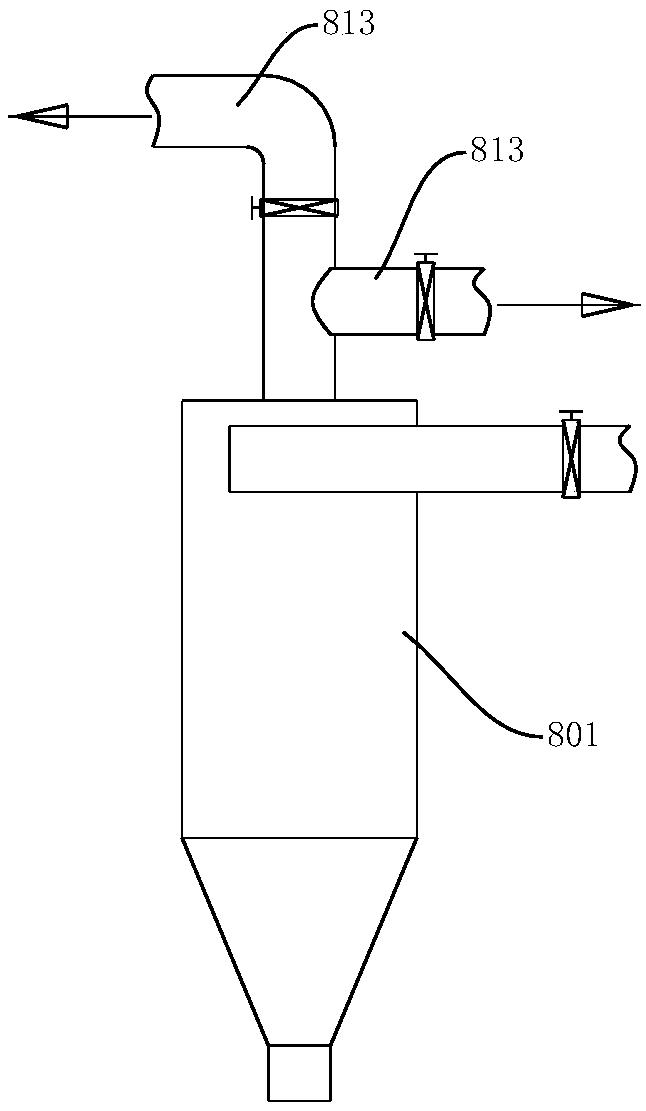

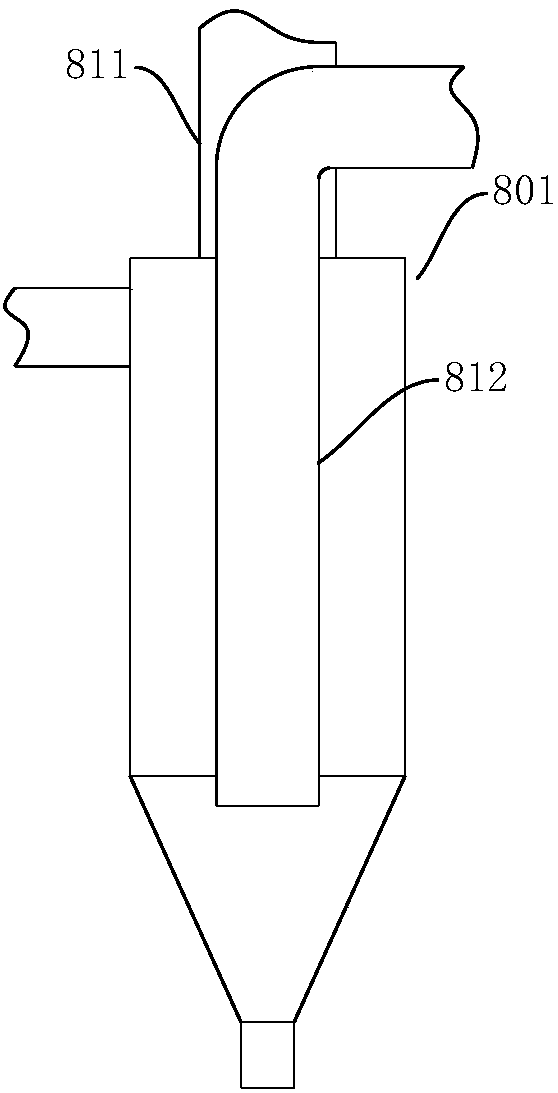

Gold ore grinding classification system and grinding classification processing technology

PendingCN108927281AOptimize structure layoutEasy to handleGrain treatmentsWet separationReturn ratioEngineering

The invention discloses a gold ore grinding classification system and grinding classification processing technology. The grinding classification system includes a first section grinding classificationsystem and a second section grinding classification system. The first section grinding classification system comprises a semi-autogenous mill, a cylinder screen, a first classification pump pool andan inspection classification hydrocyclone group, and the second section grinding classification system comprises a ball grinding mill, a second classification pump pool and a control classification hydrocyclone group. Compared with original one-time screening processing, the gold ore grinding classification system reduces the sand-returning ratio of the semi-autogenous mill and improves the sand-returning ratio of the ball grinding mill, part of qualified materials in ore discharge of the semi-autogenous mill performs flotation operation in advance, the load of the two-stage ore grinding millsis optimized, the particle size composition of grinding products is optimized, the argillation problem caused by over-grinding is avoided, and the recovery rate of the ore dressing is improved.

Owner:DULAN JINHUI MINE CO LTD

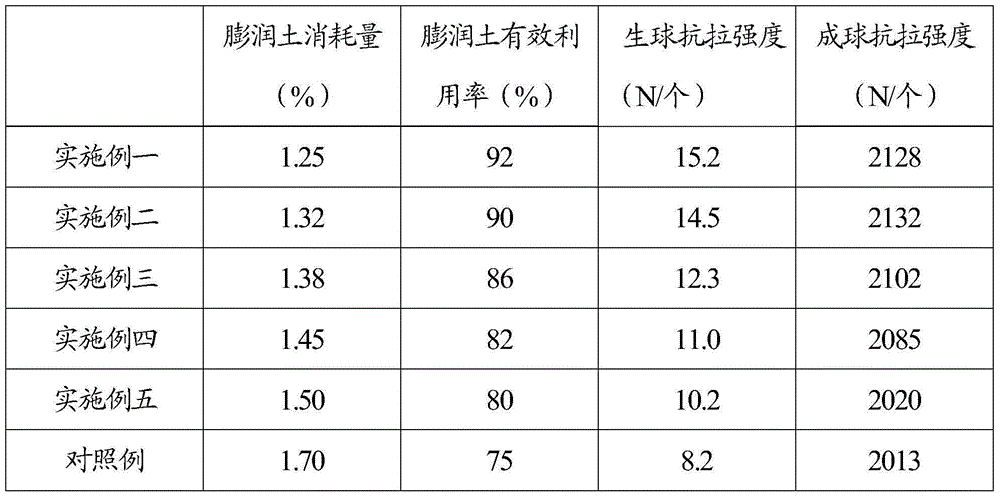

Pelletizing method for reducing bentonite consumption

The invention discloses a pelletizing method for reducing bentonite consumption. Bentonite is adopted as a binding agent. The pelletizing method comprises the steps of mixing, pelletizing, drying and preheating and roasting. In the step of mixing, a mixture of Qing Gangping concentrate powder with the weight ratio of 50%-70% and XiChang South concentrate powder with the weight ratio of 30%-50% is adopted as pelletizing concentrate powder; and during mixing, water is firstly added to the bentonite to wet the bentonite, and then the bentonite is mixed with the pelletizing concentrate powder to form mixed powder. The bentonite is fully expanded through selective treatment on concrete powder raw materials and control over parameters in the bentonite mixing step, the concentrate power is in full contact with the bentonite, the effective utilization rate of the bentonite is improved, and therefore pelletizing quality is improved.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

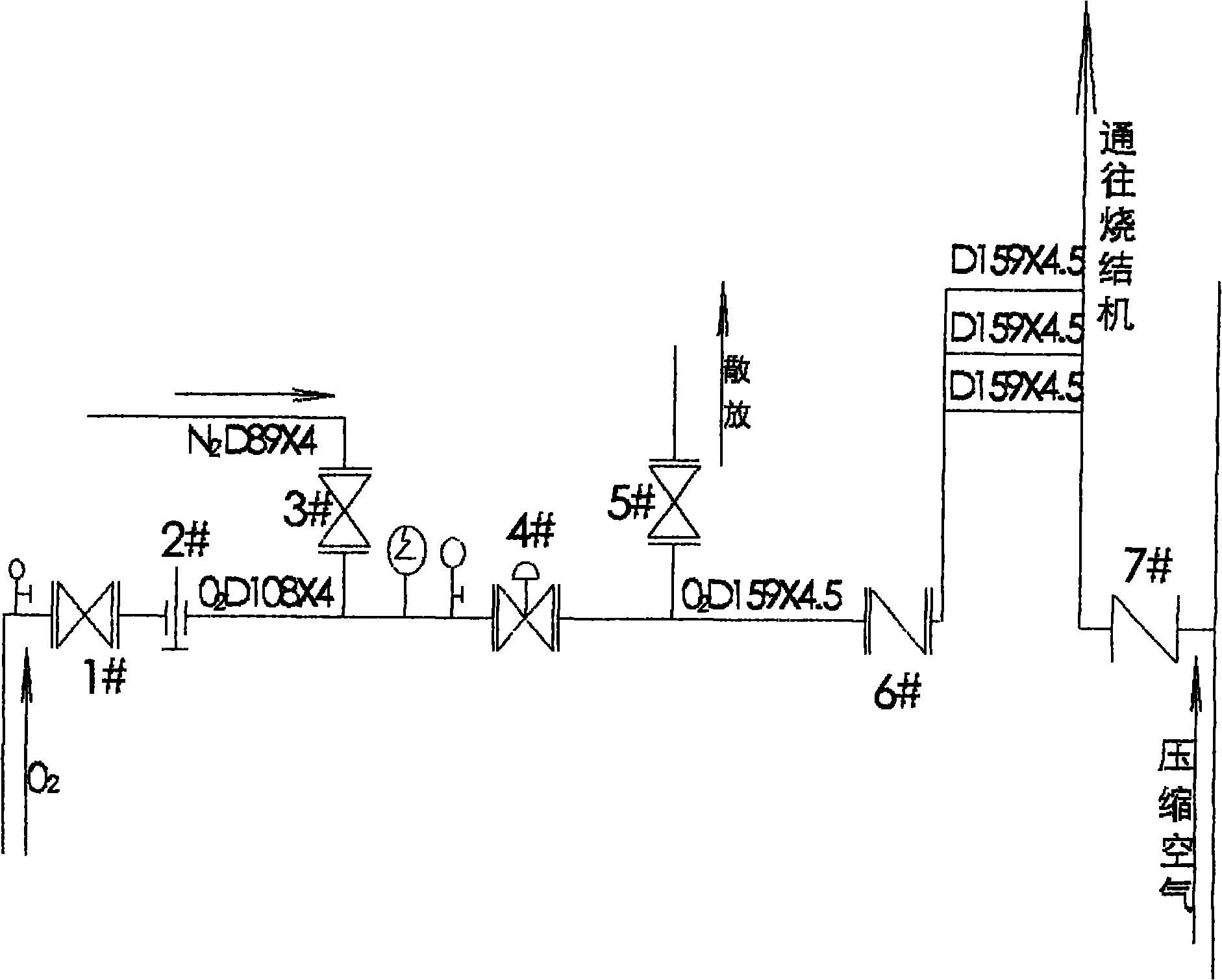

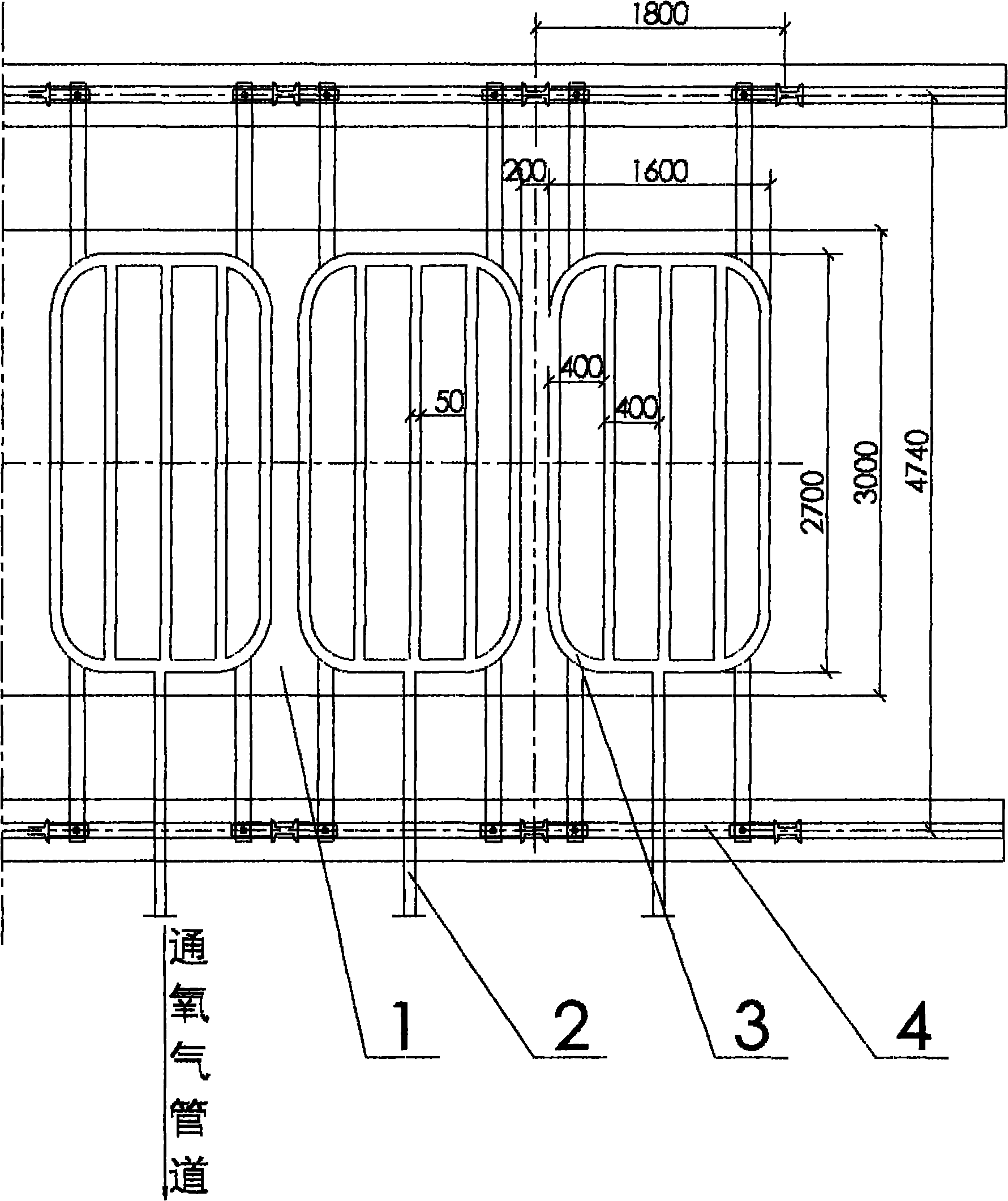

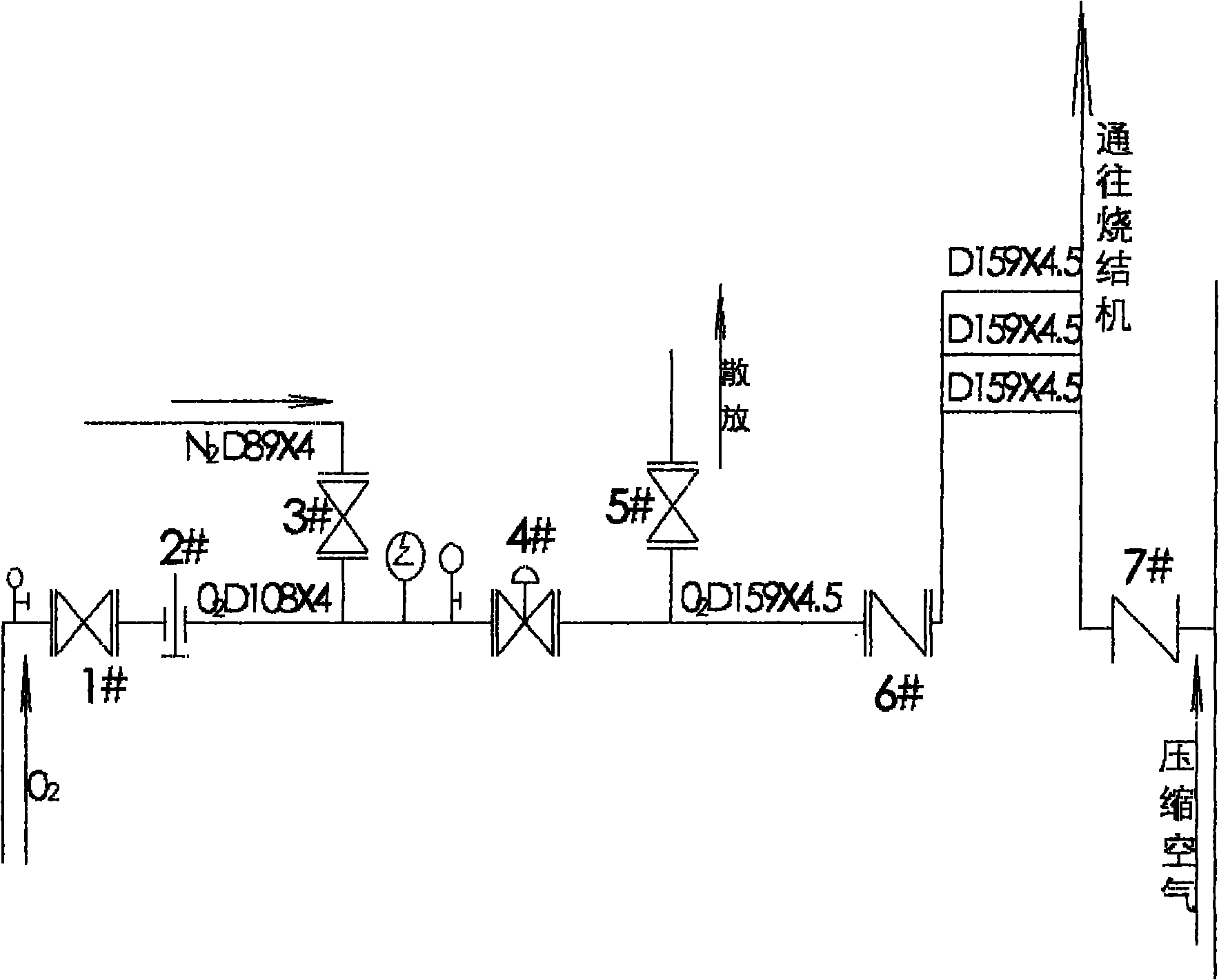

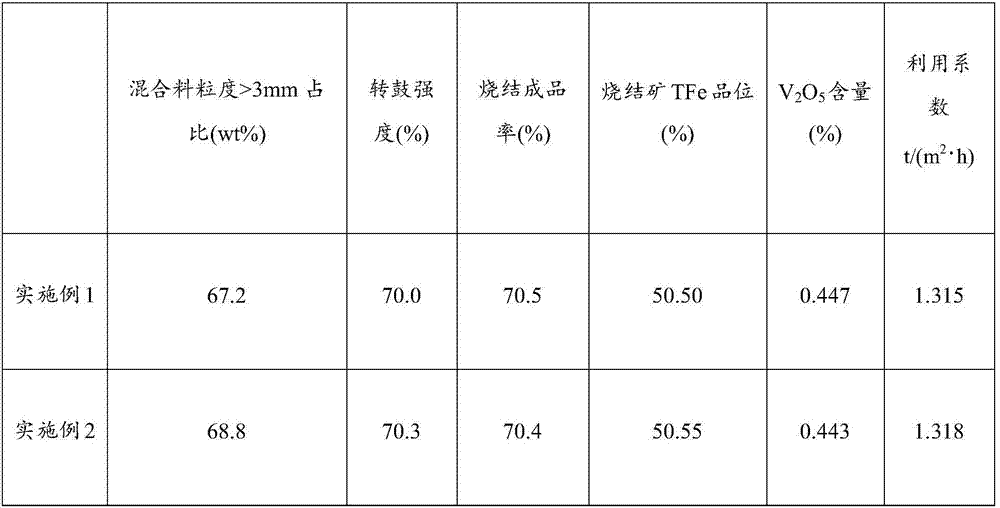

Oxygen-enriched sintering process method

The invention discloses an oxygen-enriched sintering process method. In the sintering production process, air with a certain concentration is blown to the upper part of a sintering machine, and the continuous production of oxygen-enriched sintering is performed by increasing the oxygen content in the air so as to fulfill the aims of improving the quality of sintered minerals and reducing solid fuel consumption. A novel sintering process production method can improve the thickness of material layers, improve the granularity composition of the sintered minerals, reduce the solid fuel consumption and facilitate smooth desulfuration. The oxygen-enriched sintering process is a novel process and novel method for effectively improving the quality of the sintered minerals.

Owner:TIANJIN TIANTIE METALLURGICAL GRP

Recovery method of blast furnace dedusting ash and blast furnace dedusting ash sintering material

InactiveCN107419045AImproved particle size compositionImprove breathabilityRecycling and recovery technologiesProcess efficiency improvementPelletizingRecovery method

The invention relates to the metallurgical field, in particular to a recovery method of blast furnace dedusting ash and a blast furnace dedusting ash sintering material. According to the method, the blast furnace dedusting ash and sintering mixing water are mixed, and blast furnace dedusting ash mortar is made. The blast furnace dedusting ash mortar, an iron-containing material, a fluxing agent, fuel and return mine are subjected to mixing granulation, and a mixed material is made; and finally, the mixed material is sintered. The blast furnace dedusting ash mortar is adopted to perform sintering, the mixed material grain composition can be remarkably improved, the proportion of the +3 mm part in the sintered mixed material is increased, an obvious effect is achieved for improving the breathability of a mixed material layer, and therefore the sintering utilizing coefficient is improved, the sintering mine yield is increased, and therefore the utilizing rate of the blast furnace dedusting ash is greatly increased. The blast furnace dedusting ash sintering material made through the recovery method of the blast furnace dedusting ash is good in breathability and high in sintering utilizing rate.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

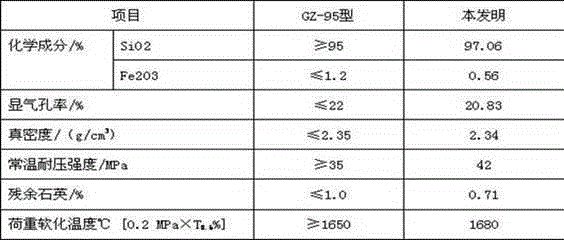

Preparation method of anti-erosion silica brick for carbon calcination furnace

The invention discloses a preparation method of an anti-erosion silica brick for a carbon calcination furnace. Calcined silica materials with different granularities are taken as main raw materials, a combustion aid, a compound additive, an enhancer and a binding agent are added, the raw materials are mulled, pressed, dried, then put into a kiln, and sintered under the thermal insulation condition for 24-30 hours at the temperature of 1,380 DEG C-1,440 DEG C, a finished product is formed and cooled to the normal temperature, and the anti-erosion silica brick is prepared. The high-temperature performance of the product is excellent, the compactness and the yield of finished products are improved, the erosion resistance is improved, and the service life of the carbon calcination furnace is greatly prolonged.

Owner:REFRACTORY MATERIAL OF SINOSTEEL CORP

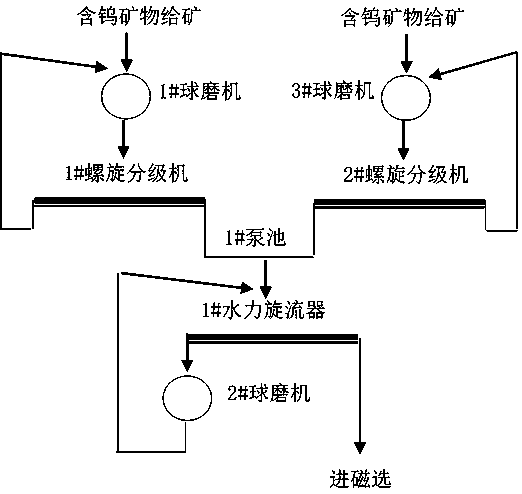

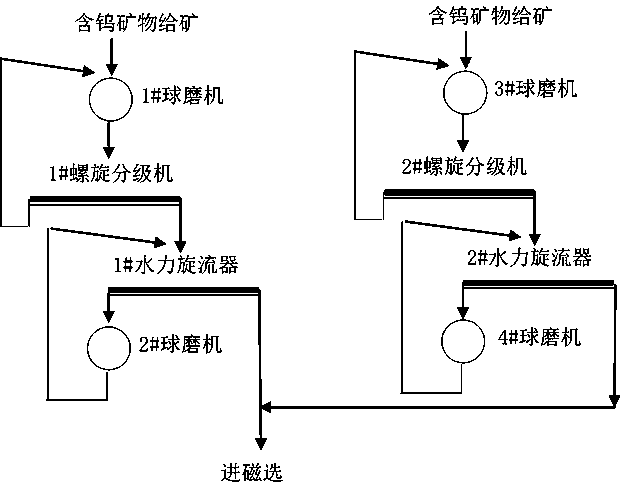

Non-standard-configured two-stage continuous ore grinding and grading process

InactiveCN110052321AUniform particle size distributionLow total grinding energy consumptionGrain treatmentsEngineeringBall mill

The invention discloses a non-standard-configured two-stage continuous ore grinding and grading process. Tungsten-containing raw ore is fed into two ball mills at the same time, ground products of each ball mill are fed into a corresponding spiral classifier for grading, graded returned sand returns to the corresponding ball mill for grinding again, each ball mill and the corresponding spiral classifier form closed-circuit grinding, graded overflow of the two spiral classifiers is fed into a same pump tank, ore pulp in the pump tank is fed into a hydrocyclone for grading, a graded overflow sample is obtained as a final product after grinding and grading, obtained grading grit is fed into a third ball mill for regrinding, and reground ore pulp is discharged into the pump tank to form closed-circuit grinding. The process has the advantages that for brittle and fragile tungsten-containing substances, not only total grinding energy consumption is low, the operation cost is low, process improvement is convenient, but also the graded overflow product has uniform particle size distribution, and the grade of tungsten-containing flotation tailings can be continuously reduced based on the prior art. The process is suitable for popularization and application of metallic mineral rich in tungsten.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL +1

Casting-molded large-scale nitride-combined silicon carbide product

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Pelletizing method for improving particle size of sintering mixture

The invention discloses a pelletizing method for improving the particle size of a sintering mixture and belongs to the field of ferrous metallurgy. Dedusting ash is mixed with fine-particle active lime to form a mixture; water is added for slaking; full stirring and slurrying are carried out, the mixture, coarse-particle active lime after slaking through adding water and other sintering materialsare mixed and pelletized to obtain the sintering mixture; the mixing, water adding and slaking process pre-wets the dedusting ash, at the same time, heat released through slaking of the active lime can raise the temperature of dedusting ash particles to increase the water absorption speed, and the the adverse impact of the hydrophobicity of the dedusting ash to sintering pelletizing is compensatedto certain degree. In addition, as the particles of the dedusting ash and the fine-particle active lime are smaller, core particles for pelletizing are not provided, and aggregation after mixing is avoided, slurry uniformity is ensured; and in addition, the active lime after slaking has viscousness and can be adhered to the dedusting ash particles, the pelletizing capacity is improved, and size composition of the sintering mixture is improved to improve the technical-economic indicator of sintered ore.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

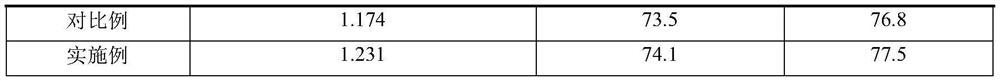

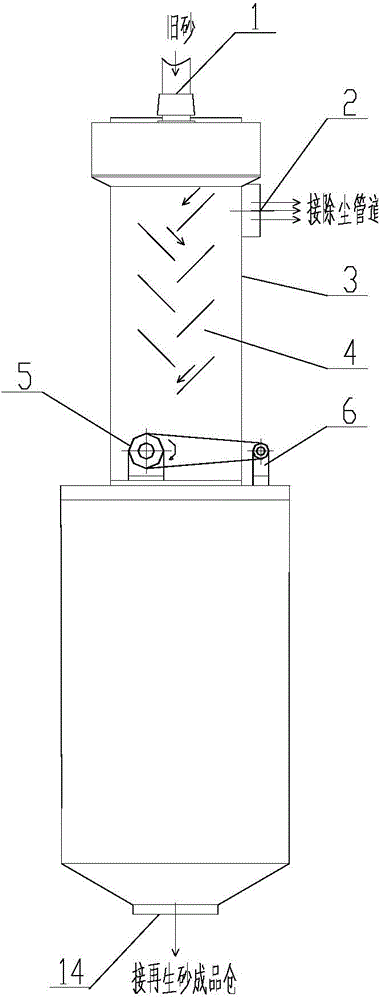

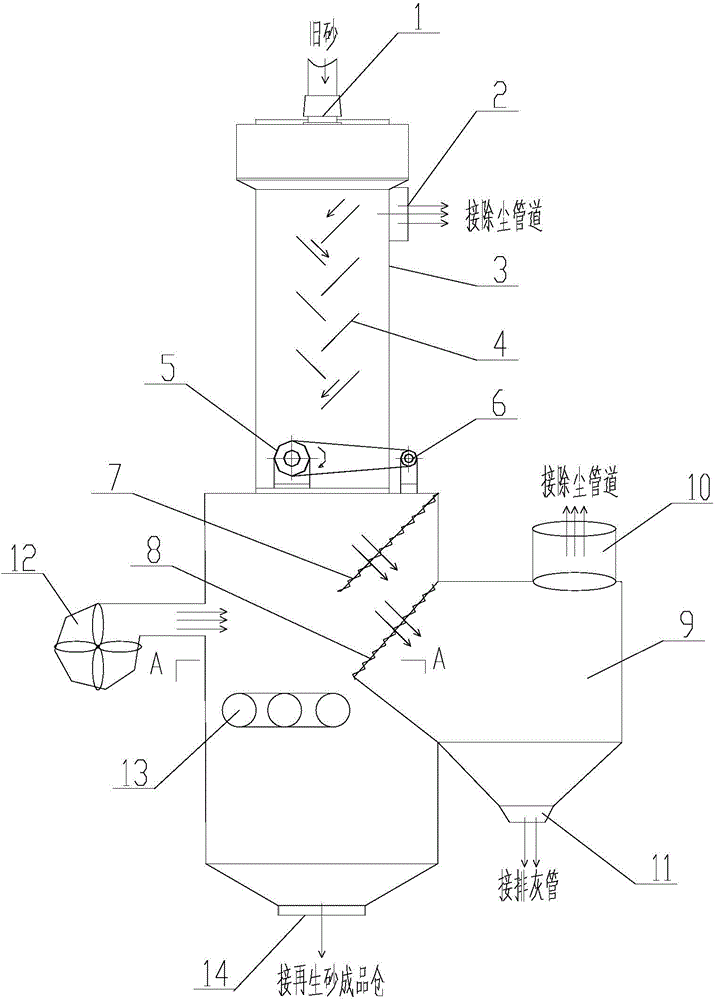

Winnowing and magnetic separation method and device for reclaimed foundry sand

ActiveCN104815951AImproved particle size compositionReduce usageMould handling/dressing devicesFoundryAir blower

The invention relates to a winnowing and magnetic separation method and device for reclaimed foundry sand. Old molding sand containing sand grains, dust and ferrochrome particles are respectively subjected to magnetic separation, winnowing and screening in a cylinder, the ferrochrome particles are separated out of in the magnetic separation process, dust is separated out in the winnowing process, and sand grains with the grain size meeting the specified requirement are separated out in the screening process. A dry type magnetic separation cylinder is fixed to the middle of the cylinder and can rotate around a rotating shaft, and a backflow type guide plate is arranged in the cylinder at the upper portion of the dry type magnetic separation cylinder. At least two screens are arranged in the throwing-out direction of the dry type magnetic separation cylinder, a blower nozzle is formed in the cylinder corresponding to the lower end of the upper-portion screen I and connected with an air blower, a compressed air purge device is arranged in the cylinder under the lower-portion screen II, and a sand discharging port is formed in the bottom of the cylinder. An ash discharge bin is arranged under the screen II, and an ash discharge port is formed in the bottom of the ash discharge bin. The winnowing and magnetic separation method and device can optimize the grain size composition of reclaimed sand while magnetic separation, the phenolic resin and curing agent liquid using amount can be decreased and the quality of the molding sand can be improved during repeated usage.

Owner:LIAONING FU-AN HEAVY INDUSTRY CO LTD

Low-cost magnesium gunning material and its preparation method

Owner:山西高科耐火材料股份有限公司

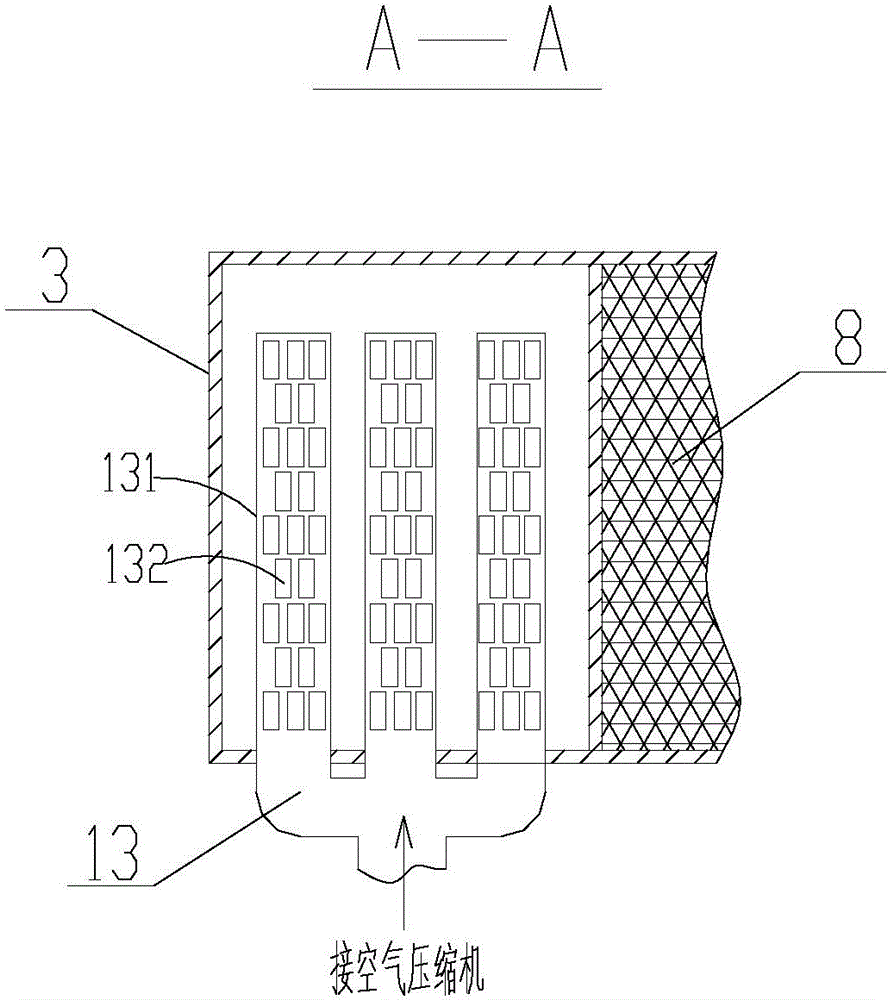

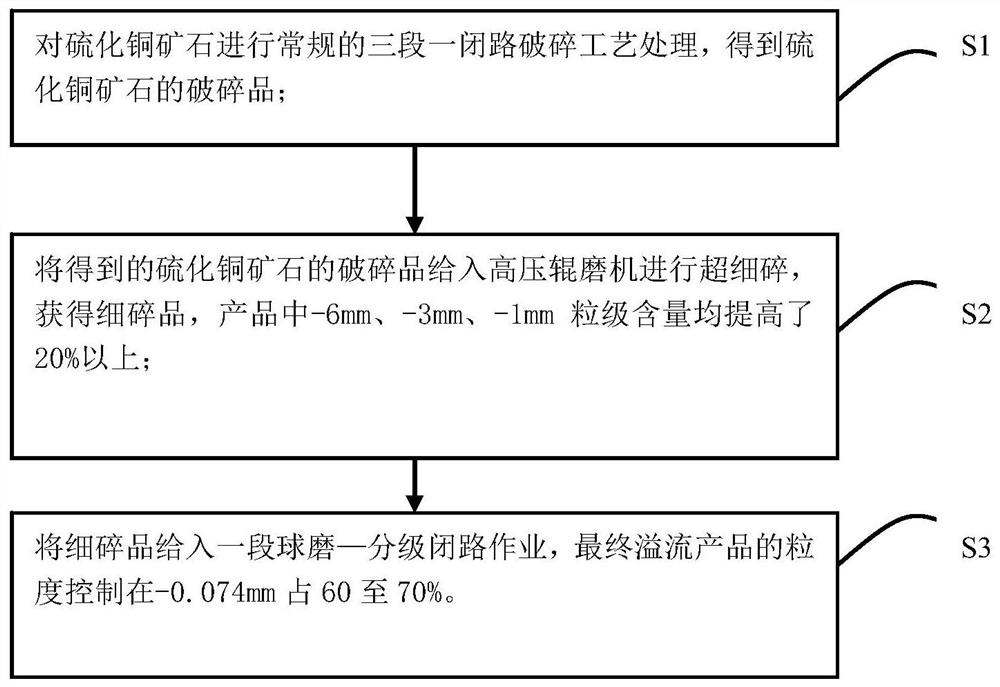

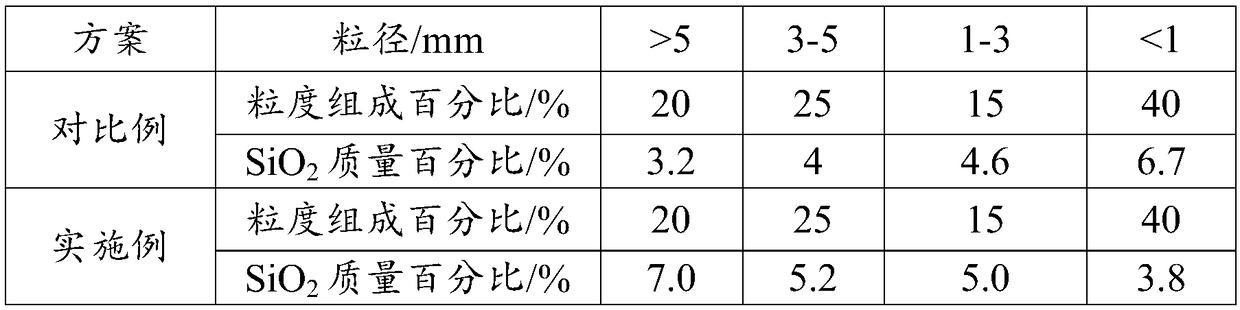

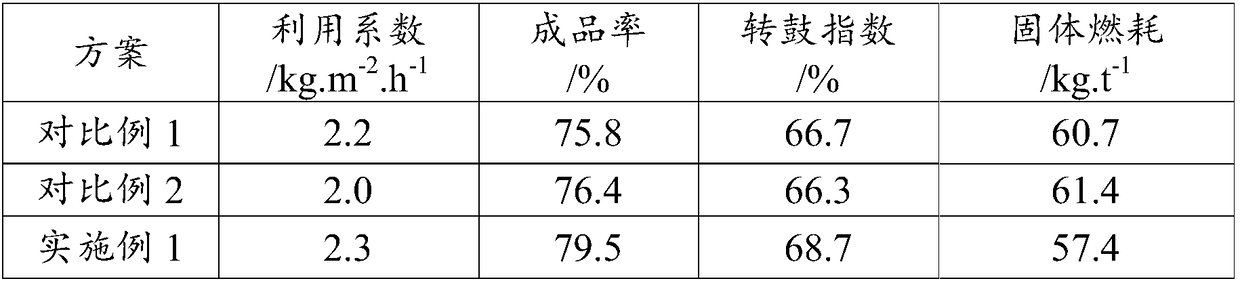

Efficient and energy-saving comminuting process for copper sulfide ore

InactiveCN111974526ASmall granularityImproved particle size compositionGrain treatmentsPhysical chemistryEngineering

The invention belongs to the technical field of copper ore treatment, and particularly relates to an efficient and energy-saving comminuting process for copper sulfide ore. The efficient and energy-saving comminuting process comprises the following steps: conventional process treatment of three-stage crushing with a single closed circuit stage is conducted on the ore, and thus a crushed product isobtained, wherein the maximum granularity of the crushed product is 15 mm, the content of the grain size less than 6 mm accounts for 50 to 65% of the total quantity of the whole grain size, the content of the grain size less than 3 mm accounts for 30 to 45% of the total quantity of the whole grain size, and the content of the grain size less than 1 mm accounts for 15 to 30% of the total quantityof the whole grain size. According to the efficient and energy-saving comminuting process for the copper sulfide ore, a one-stage high-pressure roller mill ultrafine grinding link is added on the basis of a conventional process of three-stage crushing with the single closed circuit stage, the lamination crushing effect of a high-pressure roller mill is fully utilized, the granularity of the product entering the mill is greatly decreased, the grain composition is optimized, the content of the grain sizes of minus 6 mm, minus 3 mm and minus 1 mm in the products is increased by 20% or above, and'more crushing and less grinding' is achieved.

Owner:JIANGXI COPPER +1

Segregation and ore matching sintering method of iron ore

The invention discloses a segregation and ore matching sintering method of iron ore. The segregation and ore matching sintering method of the iron ore comprises the following steps: S1, selecting 2 to4 kinds of an iron ore powder with different SiO2 mass percentage ratios, wherein the difference value of the SiO2 mass percentage ratio between two of the 2 to 4 kinds of iron ore powder is 3.0 to 10.0 percent; S2, controlling the SiO2 mass percentage ratio of the mixed ore to be 5.0+ / -0.5 percent, controlling the mixed ore to account for 30 to 50 percent of the total weight of a rich ore powder, a concentrate powder, auxiliary materials and the mixed ore, and adjusting the ratio of the 2 to 4 kinds of iron ore powder to realize segregation of the SiO2 between crude particles and fine particles; and S3, mixing with the rich ore powder, the concentrate powder, the auxiliary materials, a flux and fuel uniformly and then sintering. The segregation and ore matching sintering method of the iron ore has the advantages of improving the physical strength of the sintered ore, improving the graded composition of the sintered ore, reducing energy consumption and increasing the production rate.

Owner:ZHANGJIAGANG HONGCHANG STEEL PLATE CO LTD +2

Metallurgy sintering synergist as well as preparation method and application thereof

ActiveCN114438312ASuppress generationReduce chalkingRecycling and recovery technologiesActivated carbonSlag

The invention discloses a metallurgical sintering synergist as well as a preparation method and application thereof. The synergist is prepared from the following raw materials in percentage by weight: 35-65% of steel slag, 0.1-2% of polyethylene glycol, 2-8% of fluorite, 0.05-2.5% of potassium permanganate, 0.5-8% of hydrogen peroxide, 1-5% of ammonium metavanadate, 0.5-2% of waste activated carbon and the balance of water. By optimizing the compound substances and using the synergist, the rotary drum quality of the sintered ore can be improved, the vertical sintering speed can be increased, the particle size composition of the sintered ore can be improved, RDI + 3.15 can be improved, the reduction degree and the molten drop performance can be improved, and the energy consumption can be reduced.

Owner:云南科兴环保科技有限公司

Method for improving strength and size composition of sinter

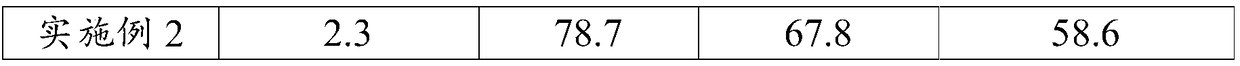

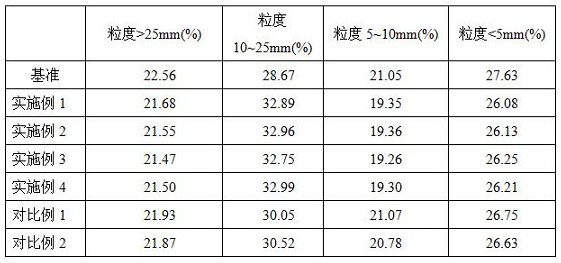

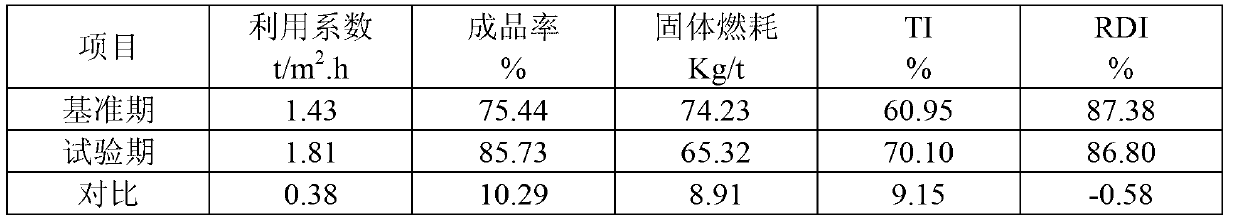

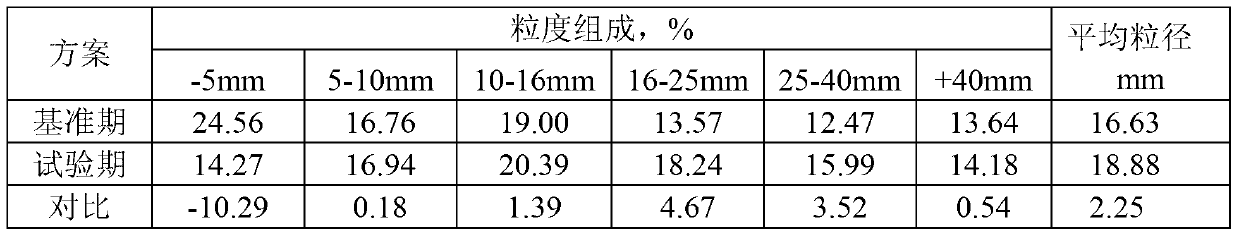

The invention discloses a method for improving the strength and the size composition of a sinter. The method is characterized in that when fluxes are added in a dosing chamber, a brucite fiber accounting for 0.90-0.95 % of the total mass of a sintered material is also added besides a calcium flux and a magnesium flux; after dosing, the brucite fiber, the calcium flux, the magnesium flux, an iron material and fuel are thoroughly mixed, and then water is added to wet the material to be subjected to a sintering process. Under the situation that the neutralized material structure, the fuel ratio and the sinter basicity remain unchanged, the brucite fiber is added, the sintering time is shortened from the original 24.2min to 21.9min, the productivity is increased by 26.6%, the sinter tumbler strength is improved by 9.15%, the average sinter size composition is improved by 2.25mm, the sinter solid fuel is decreased by 8.91kg / t, and the economic benefits are obvious, and the popularization and application values are great.

Owner:JIGANG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com