High-pressure rolling and magnetic-gravity separation process for lean hematite

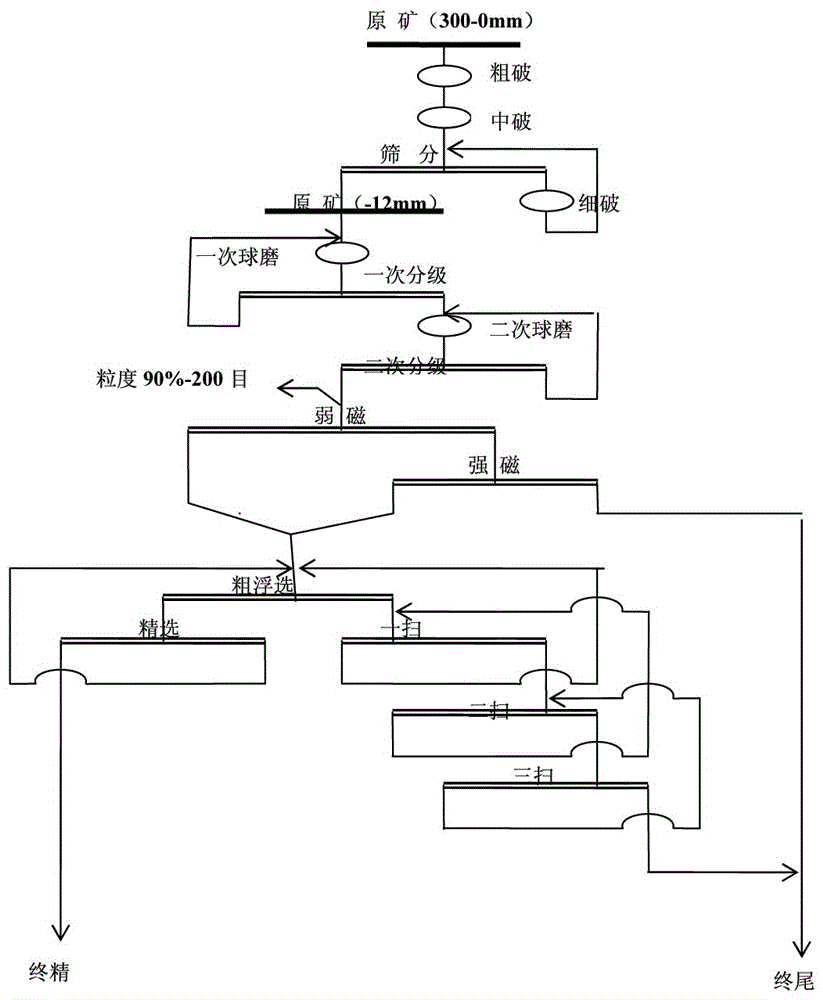

A high-pressure roller mill and hematite technology, applied in the field of beneficiation, can solve the problems of high beneficiation cost, many beneficiation stages, complicated processes, etc., and achieve the effects of significant economic benefits, simplified process flow, and reduced beneficiation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

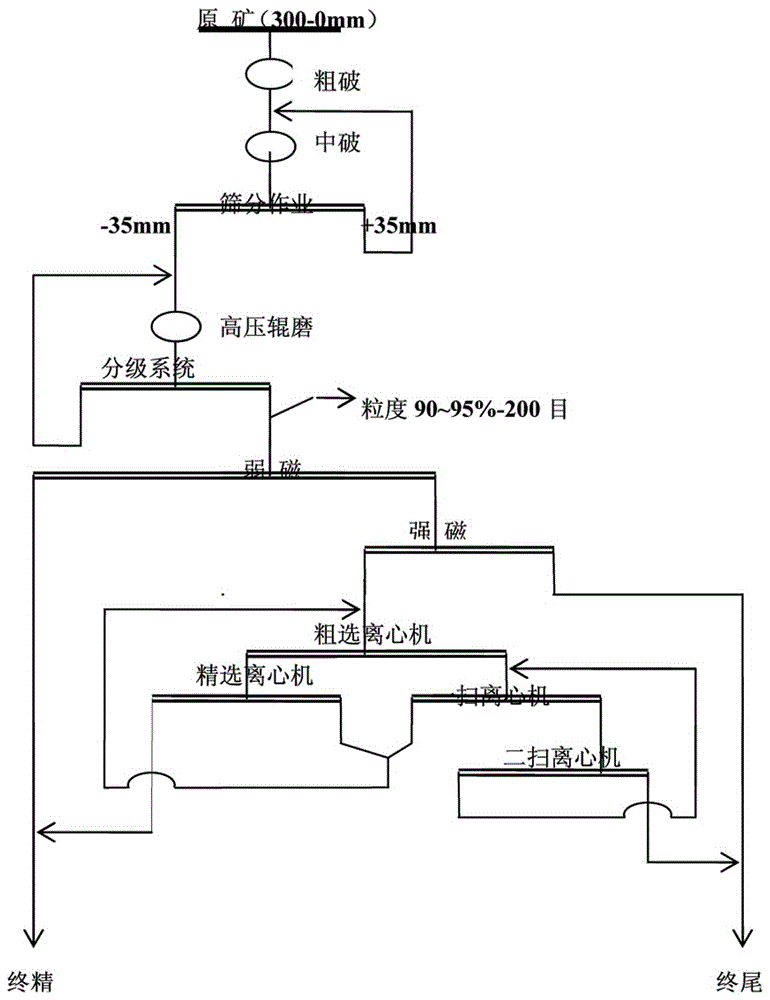

[0013] The present invention will be further described below in conjunction with the drawings.

[0014] Such as figure 2 As shown, a high-pressure roller mill and magnetic-gravity separation process for lean hematite of the present invention is characterized in that it includes the following steps: the raw ore with a particle size of 300 to 0 mm is subjected to coarse crushing and medium crushing screening operations. , The product size is 35~0mm. After the high-pressure roller mill and the wind classification system, the coarse-grained products classified by the wind are returned to the high-pressure roller mill, and the fine-grained products with 90%-95% of the -200 mesh content of the wind classification are fed into the weak magnetic field— Strong magnetic-centrifuge process flow is sorted, weak magnetic separation concentrate and selected centrifuge concentrate are combined into the final concentrate, grade 66.5%~67.5%, yield 27%~29%, strong magnetic tailing grade 8.3 %~8....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com