Oxygen-enriched sintering process method

An oxygen-enriched and new process technology, applied in the field of oxygen-enriched sintering process, can solve the problems of poor surface strength of sintered ore, insufficient heat, insufficient oxygen, etc., so as to improve the quality of sintered ore, increase the thickness of the material layer, and promote the smooth removal of sintered ore. the effect of removing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

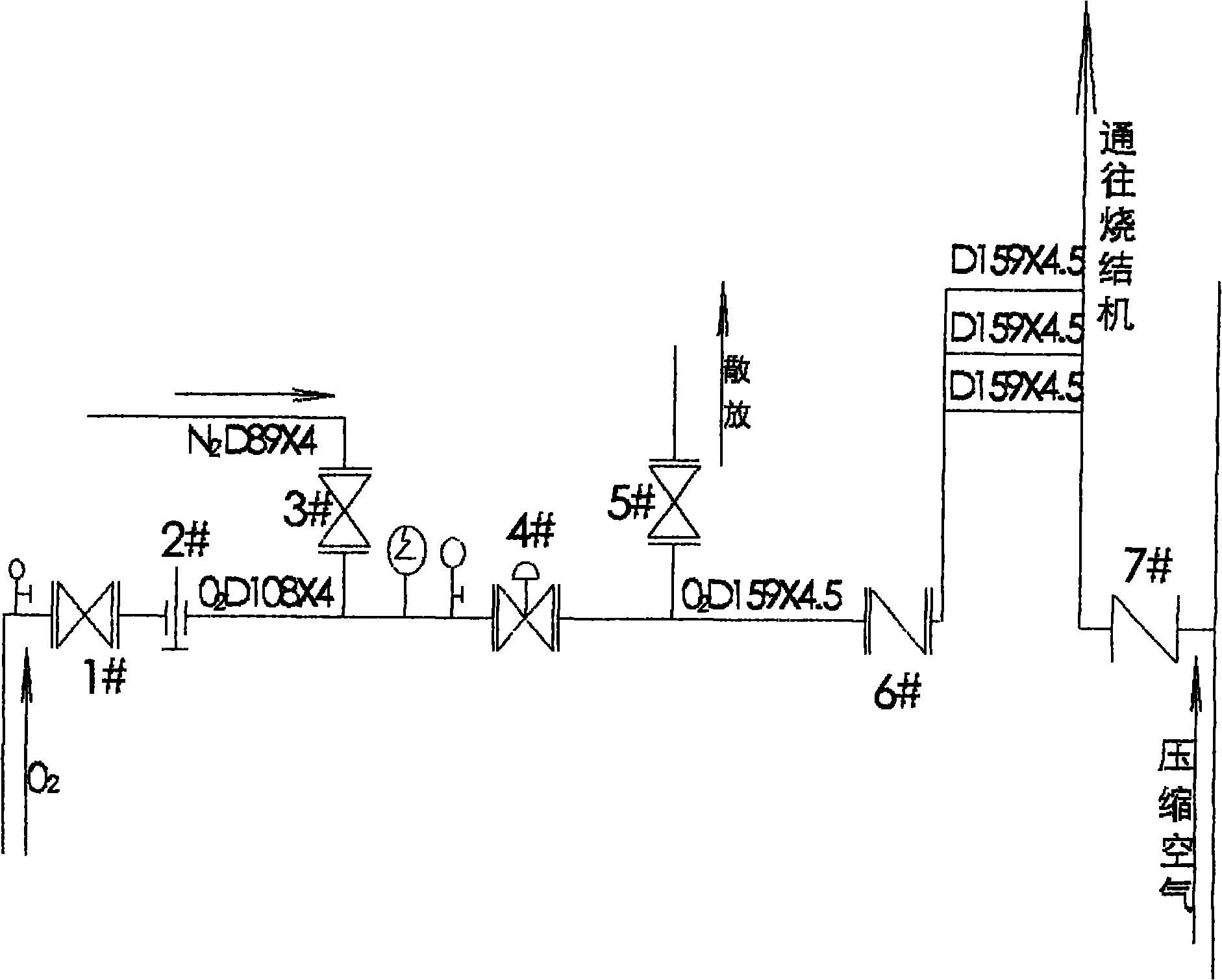

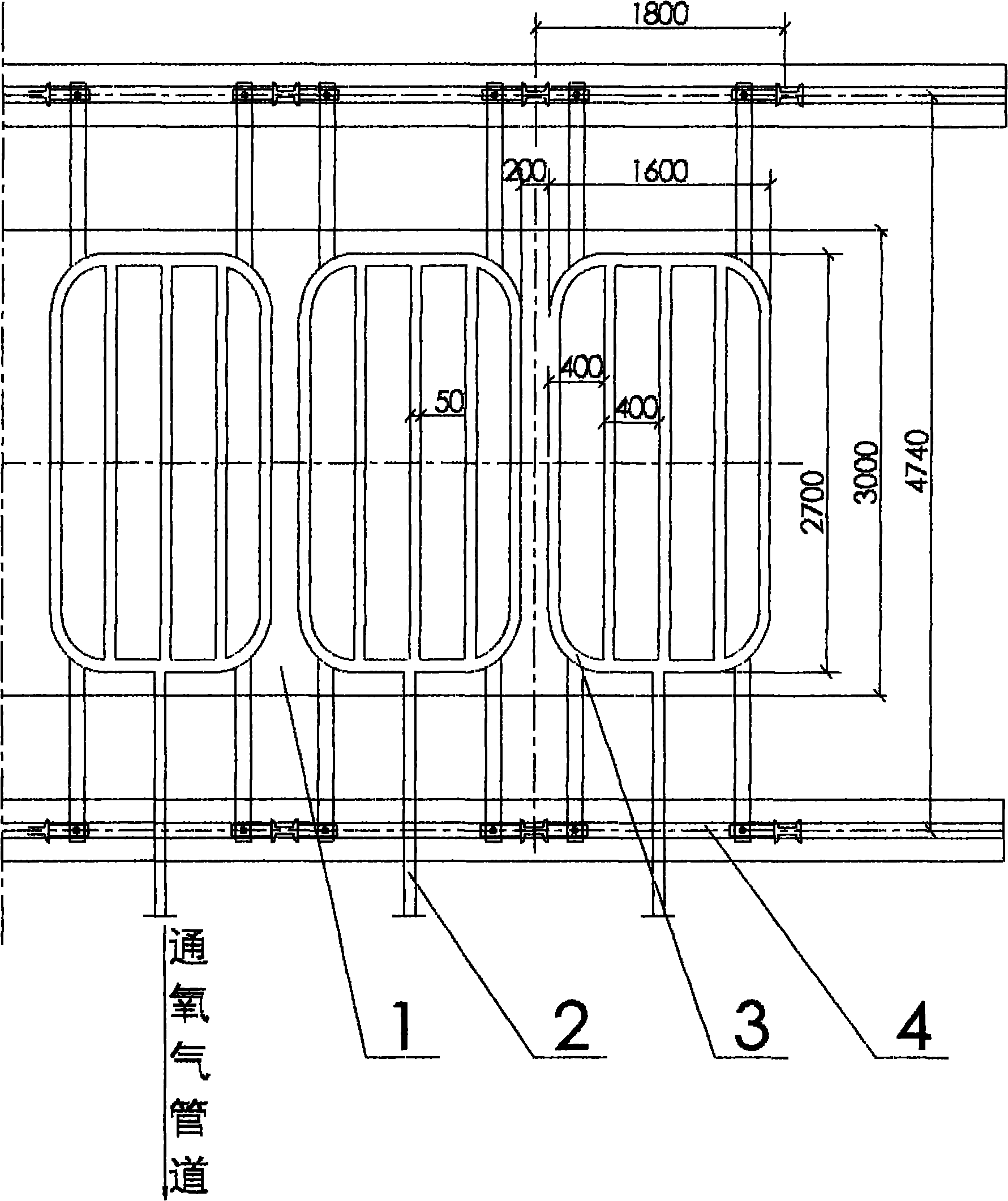

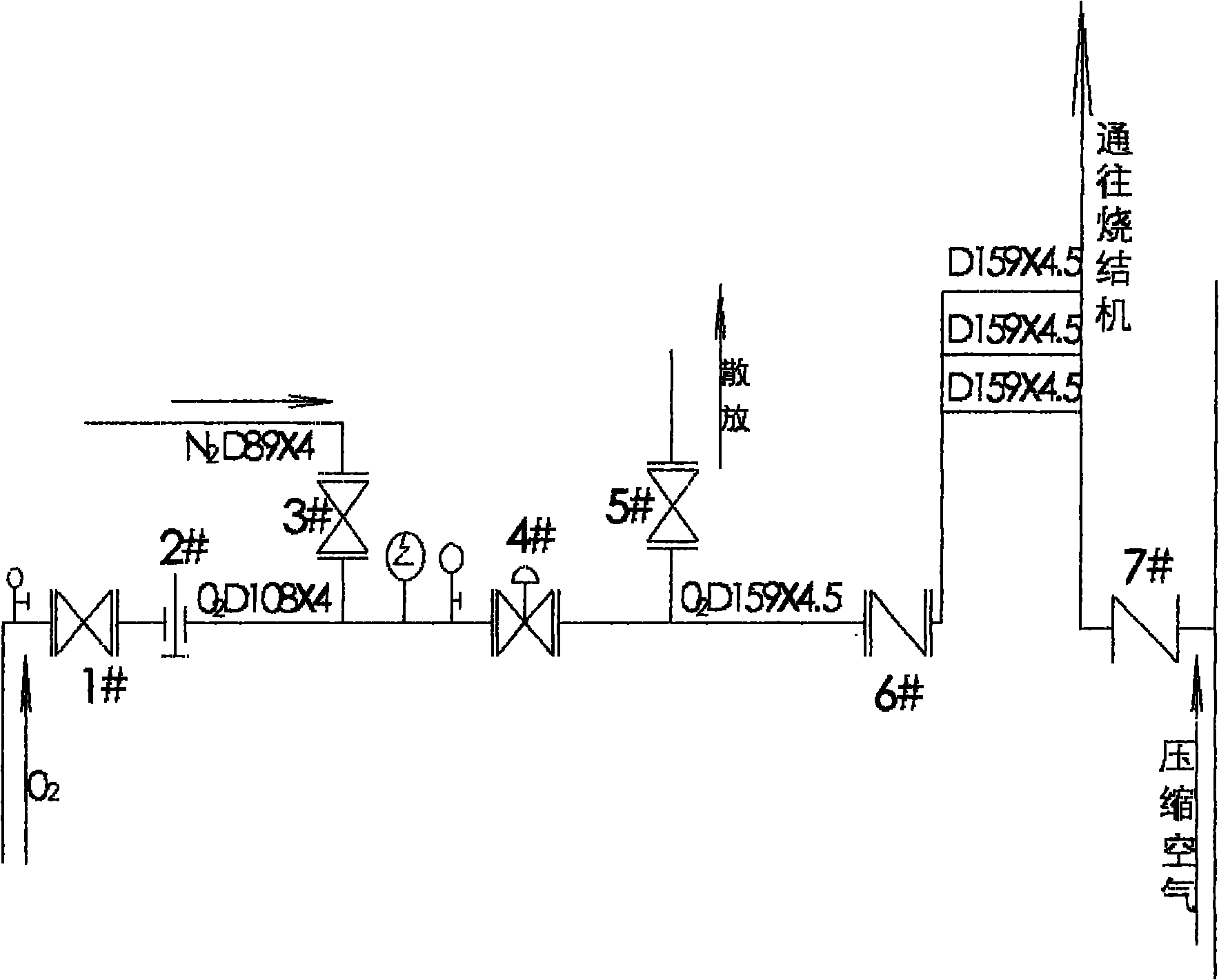

[0010] Oxygen-enriched oxygen is fed into the pipeline leading to the top of the sintering machine through the carefully designed sintering oxygen supply process, and is blown vertically into the sintering layer through several rows of pipelines arranged horizontally above the sintering machine. The specific operation of stopping the oxygen supply is: after the pipeline is purged, send the oxygen to the front of the 1# oxygen stop valve, and the pressure should be 0.2MPa~0.4MPa. Open the 7# butterfly valve. Slowly open the 1# cut-off valve, 6# cut-off check valve, open the 2# quick cut-off valve, and then gradually open the 4# flow regulating valve, and calculate the oxygen enrichment rate according to the compressed air flow and oxygen enrichment after sintering oxygen enrichment (X 02 ) Oxygen enrichment rate: X 02 ---It refers to the percentage increase of the oxygen volume content in the blast after oxygen enrichment.

[0011] x 02 =0.788×Q(oxygen)÷60 / Q(mixed)×100%

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com