Comprehensive utilization method for low-grade complex ferromanganese ore

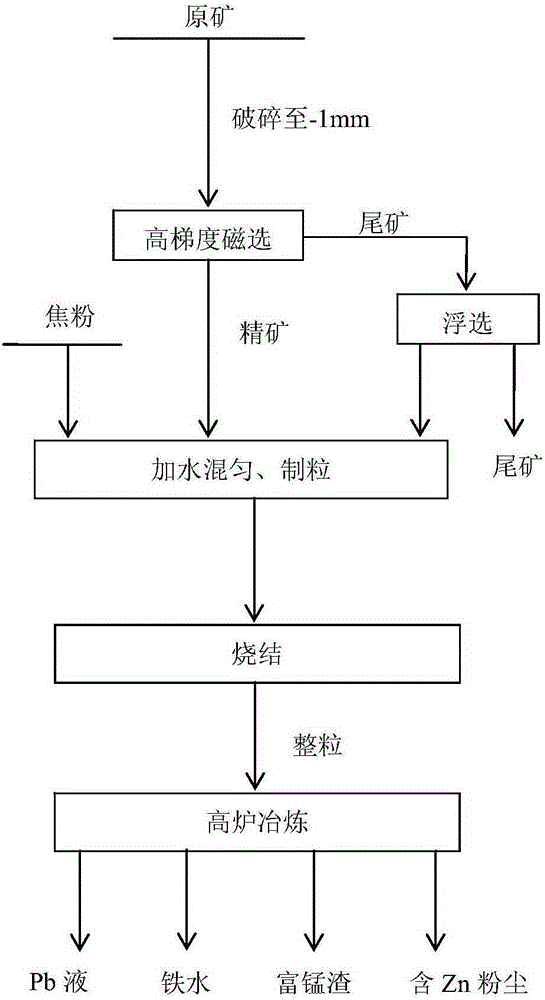

A low-grade iron-manganese ore technology, applied in the field of comprehensive utilization of low-grade complex iron-manganese ore, can solve problems such as the inability to obtain economically valuable products, and the quality of sintered ore cannot meet the requirements of blast furnaces, so as to achieve value improvement and simple operation , the effect of fewer processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: For raw ore powder, when the magnetic field intensity is 1.1T~1.3T, the productive rate of concentrate is more than 88%, the recovery rate of Fe is more than 90%, the recovery rate of Mn is more than 85%, and the recovery rate of Pb is more than 88%. The recovery rate is above 65%, and the recovery rate of Zn is above 76%.

Embodiment 2

[0018] Example 2: Under the condition that the dosage of compound xanthate is 300-600g / t and the dosage of No. 2 oil is 0.03ml-0.04ml / t, the yield of concentrate is 23.87%, the recovery rate of Fe is 22.60%, and the recovery rate of Mn The recovery rate of Pb was 27.35%, the recovery rate of Pb was 83.52%, and the recovery rate of Zn was 69.08%.

Embodiment 3

[0019] Example 3: When the water content of the mixture is about 9%, and the fuel ratio is about 5.5%, the utilization coefficient of the sintering cup is 0.765t / m 2 h, the yield rate is 64.26%, and the drum strength is 63.33%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com