Advanced slurry mixing and grading method for gravity raw ore and application of advanced slurry mixing and grading method

A technology for slurry mixing and raw ore, which is applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems affecting the utilization rate of the shaking table, affecting the classification effect, and reducing the recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Embodiment 1, check the whole process of experiment

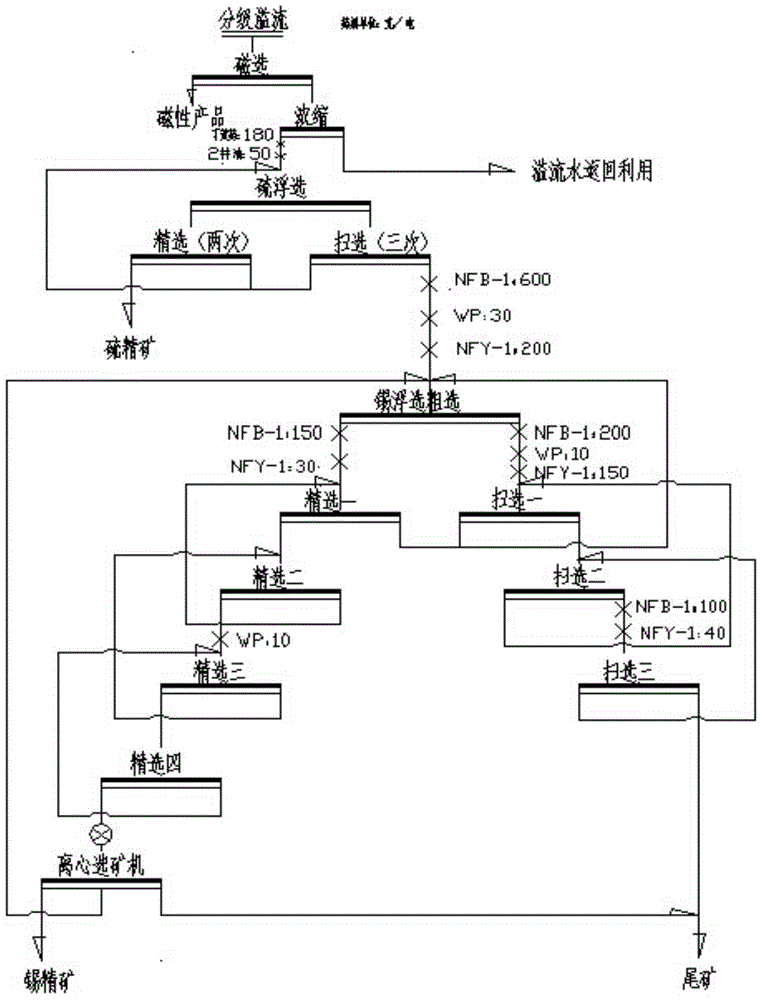

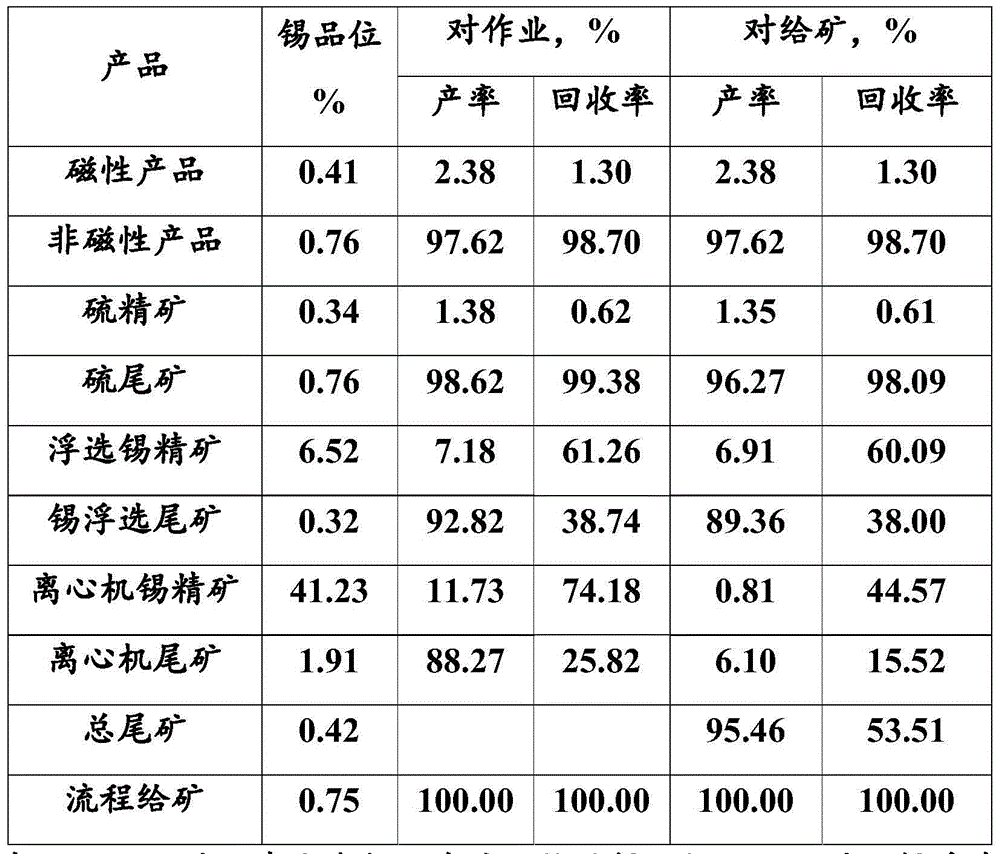

[0080] 1. Reference figure 1 The whole process of re-selection of raw ore is set for industrial application full-process verification. The specific process is as follows:

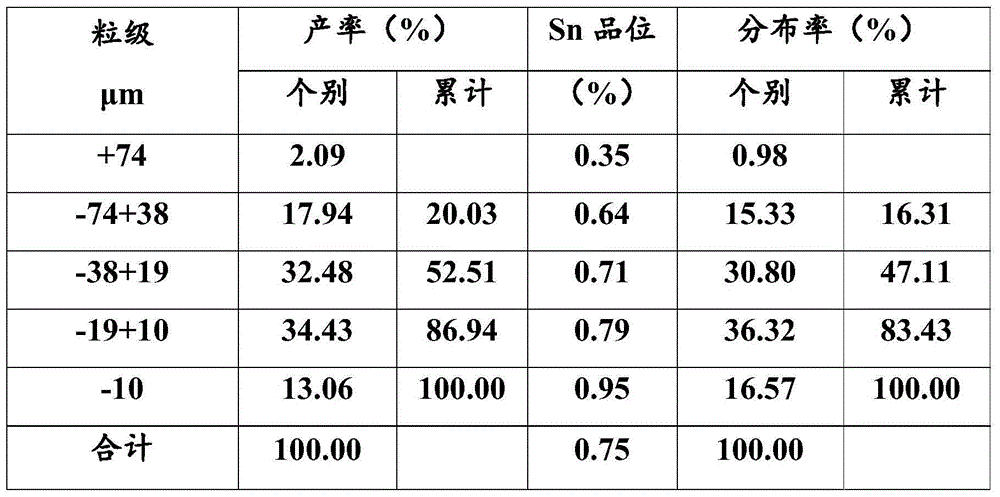

[0081] (1) Slurry grading is carried out in advance on the gravity separation raw ore of Yuling Polymetallic Mine of Linwu County Nanfang Mining Co., Ltd., which is divided into -19μm fine-grained slurry, +38μm shaker optional particle size and +150μm granular The fine-grained sludge enters the flotation as an overflow, the optional particle size of the shaker enters the gravity separation as the underflow, and the +150μm particle size is pre-tailed. The metal distribution rate of +150μm particle size is only 2.15%, but the yield accounts for 9.82%, and most of them are connected organisms; after this level enters the flotation system, it will interfere with the recovery of effective target minerals and affect the selection index; therefore, Pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com