Winnowing and magnetic separation method and device for reclaimed foundry sand

A technology of wind magnetic separation and regenerated sand, applied in foundry molding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of large dust content, too much fine sand in regenerated sand, unable to meet the particle size of foundry sand, and sand mold permeability. Quality requirements and other issues to achieve the effect of reducing usage, improving quality, and optimizing particle size composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

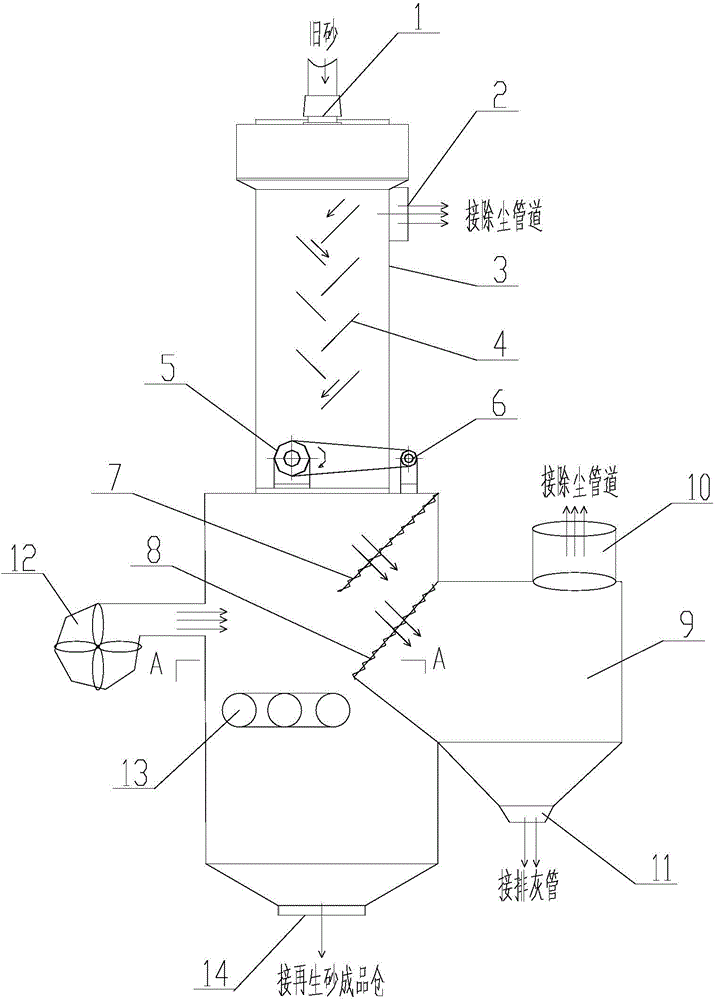

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

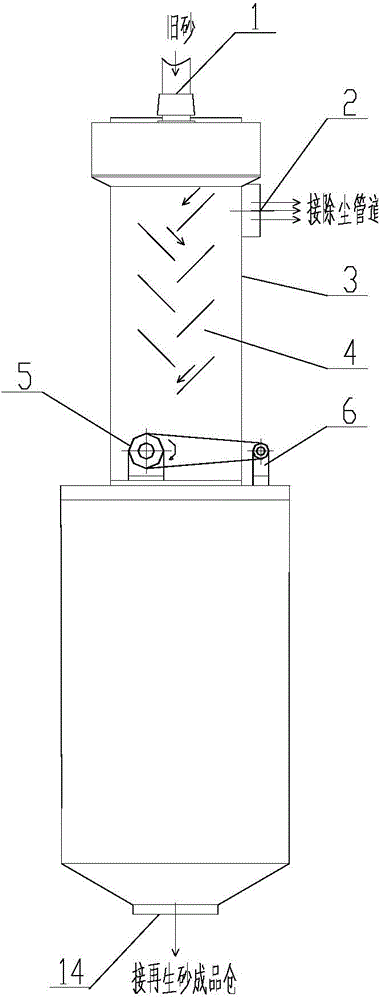

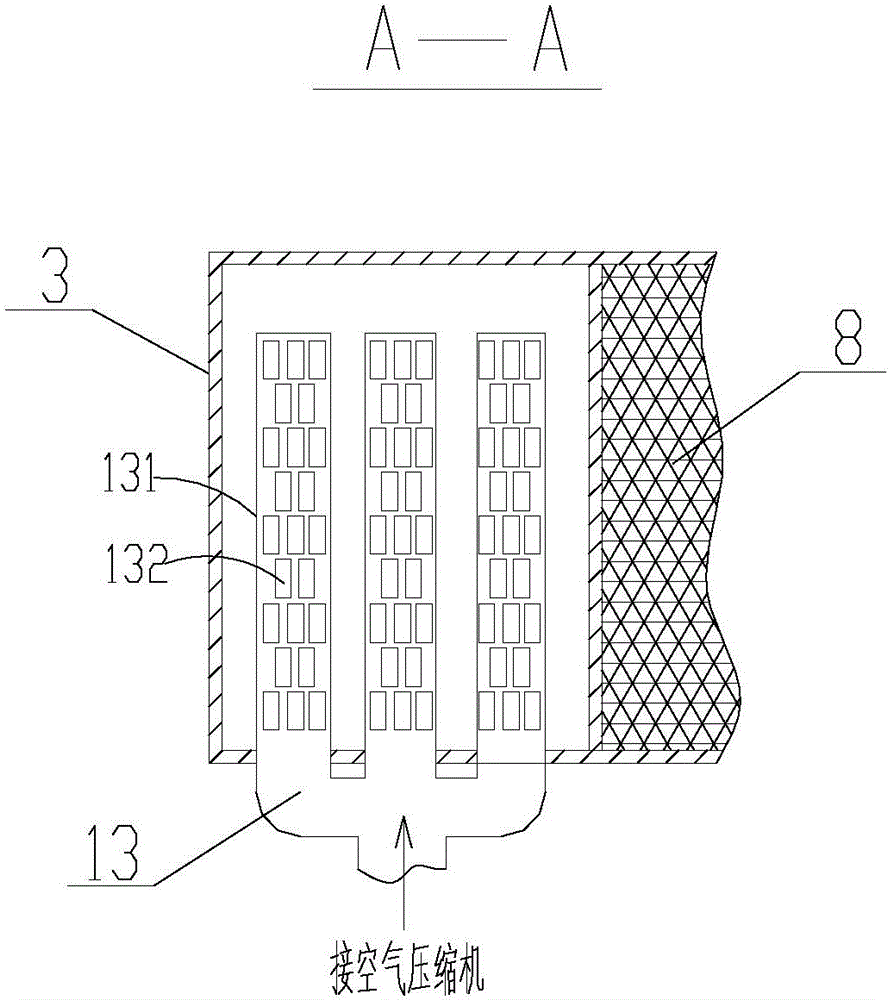

[0023] A method of air-magnetic separation of foundry regenerated sand according to the present invention, the old molding sand containing sand grains, dust and ferrochrome particles undergoes magnetic separation, winnowing and screening respectively in the cylinder body 3, and the ferrochrome particles are separated by the magnetic separation process, and the ferrochrome particles are separated by wind. The dust is separated during the selection process, and the sand particles with a particle size smaller than the specified requirements are separated during the screening process.

[0024] Specifically include the following steps:

[0025] 1) The old molding sand containing sand, dust and ferrochrome particles enters the cylinder body 3 from the upper part, and falls on the dry magnetic separation cylinder 5 after passing through the turn-back def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com