Efficient and energy-saving comminuting process for copper sulfide ore

A technology of copper sulfide and ore, which is applied in the direction of grain processing, etc., can solve the problems of large grinding medium loss, large grinding capacity, and high grinding energy consumption, and achieve the effect of improving processing capacity, improving processing capacity, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

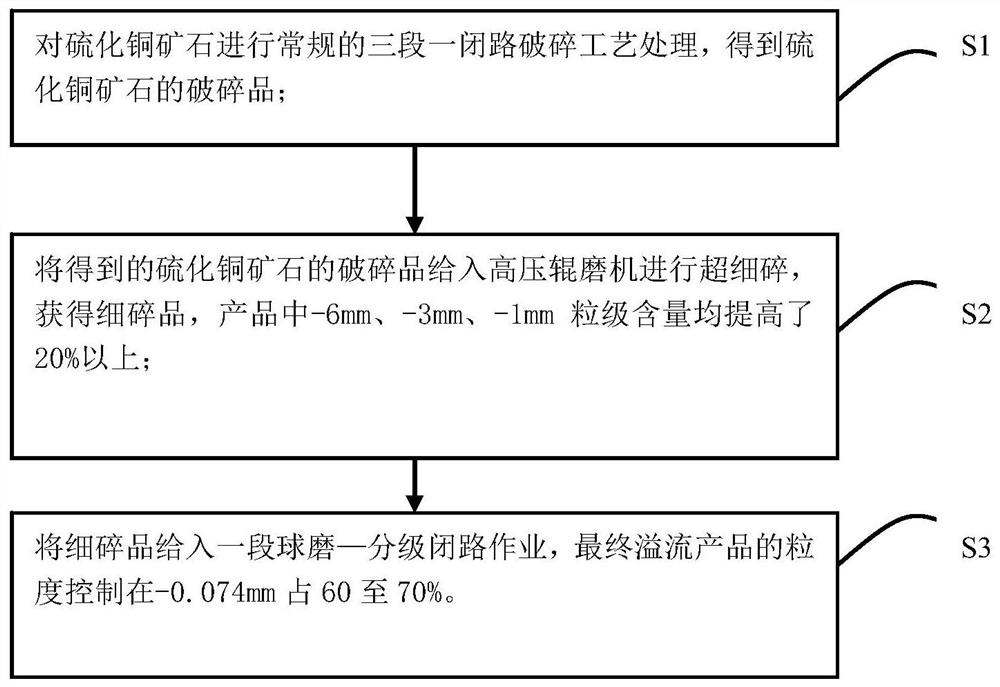

Embodiment 1

[0047] The crushed products of the existing conventional three-stage-one-closed-circuit crushing process are fed into the GM100 / 30 high-pressure roller mill, and the open circuit is used for ultra-fine crushing. The initial pressure of the high-pressure roller mill is 5.0MPa, and the roller gap is 10mm. The content of -6mm in ultra-fine open-circuit products increased by 23.15%, the content of -3mm increased by 25.71%, and the content of -1mm increased by 20.29%. The open-circuit product of the high-pressure roller mill is fed into the ball mill, and the grinding medium is steel balls. The ratio of the initial balls is: φ80mm:φ70mm:φ60mm is 20:20:60, and the filling rate is 42%. The cyclone, the grit is returned to the ball mill, and finally the overflow product enters the next operation. See the process flow figure 1 . The processing capacity of the ball mill increased from 60.82t / h to 82.95t / h, the energy consumption per ton of ore grinding decreased from 12.84kWh / t to 9.5...

Embodiment 2

[0049] The crushed products of the existing conventional three-stage-one-closed-circuit crushing process are fed into the GM100 / 30 high-pressure roller mill, and the open circuit is used for ultra-fine crushing. The initial pressure of the high-pressure roller mill is 5.5MPa, and the roller gap is 16mm. The content of -6mm increased by 23.56%, the content of -3mm increased by 30.25%, and the content of -1mm increased by 24.62%. The open-circuit product of the high-pressure roller mill is fed into the ball mill, and the grinding medium is steel balls. The ratio of the initial balls is: φ80mm:φ70mm:φ60mm is 25:25:50, and the filling rate is 45%. The cyclone, the grit is returned to the ball mill, and finally the overflow product enters the next operation. See the process flow figure 1 . The processing capacity of the ball mill increased from 60.82t / h to 86.58t / h, the energy consumption per ton of ore grinding decreased from 12.84kWh / t to 9.15kWh / t, and the unit consumption of ...

Embodiment 3

[0051] The crushed products of the existing conventional three-stage one closed-circuit crushing process are fed into the GM100 / 30 high-pressure roller mill, and the closed-circuit is used for ultra-fine crushing. The mesh size of the high-frequency vibrating screen is 4mm, and the initial pressure of the high-pressure roller mill is 5.5MPa, roller gap 16mm, -6mm content increased by 26.10%, -3mm content increased by 34.59%, -1mm content increased by 27.27% in the ultra-fine closed circuit product of high pressure roller mill. The closed-circuit product of the high-pressure roller mill is fed into the pre-graded hydrocyclone, and the grit enters the ball mill. The ratio of the initial balls is: φ80mm:φ70mm:φ60mm is 25:20:55, and the filling rate is 40%. The ball mill product enters the Check the graded hydrocyclones, the final overflow product goes to the next operation. The processing capacity of the ball mill increased from 60.82t / h to 85.12t / h, the energy consumption per to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com