Pelletizing method for improving particle size of sintering mixture

A technology of sintering mixture and mixing system, which is applied in the field of iron and steel metallurgy, can solve the problems affecting the particle size composition of sintering mixture, achieve the effect of improving technical and economic indicators, ensuring uniformity, and improving particle size composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

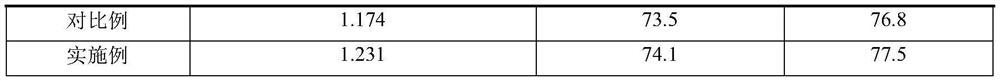

[0031] Take by weighing two parts of dedusting ash and active ash whose quality is 2% and 7.5% of the total weight of sintered new material respectively, the first part of dedusting ash directly enters the first mixing and mixing (i.e. one-stage mixing granulation), and the active ash is digested and mixed (as Comparative example). In the second part, the dedusting ash is screened, the part below 0.25mm is mixed with the dedusting ash, then water is added to digest the active ash, and stirred to make a pulp. After the active ash above 0.25mm is directly digested, add a mix (Example) respectively, and then After two-stage mixing (that is, two-stage mixing granulation). Carry out sintering experiments, control the moisture content of the mixture within the range of 7.5%±0.2%, the first mixing time is 4min, the second mixing time is 4min, the amount of new sintering material is 70kg, the material layer is 700mm, and 30% of the returned ore (returned The ore is specially fired to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com