Recovery method of blast furnace dedusting ash and blast furnace dedusting ash sintering material

A technology of blast furnace dust removal and recovery method, applied in the field of metallurgy, can solve the problem of low utilization degree of blast furnace dust dust, and achieve the effects of improving the sintering utilization coefficient, increasing the output, and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

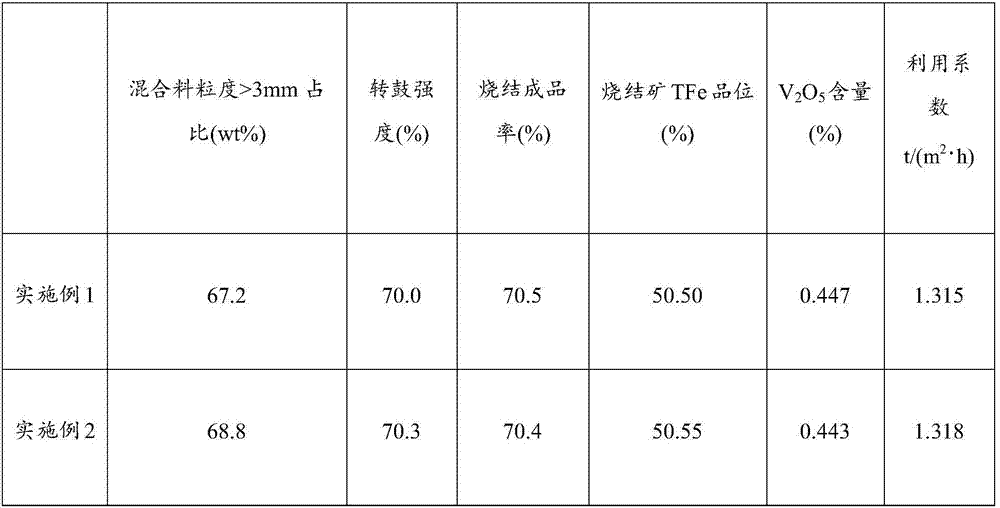

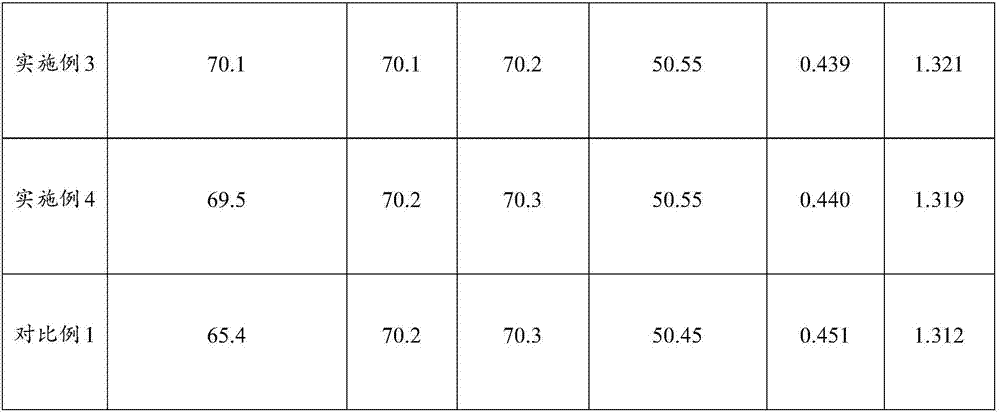

Embodiment 1

[0043] A kind of blast furnace dedusting ash sintered material provided in this embodiment is prepared in the following way:

[0044] The composition of selected blast furnace dust is: ω(TFe)>55%, ω(FeO)>10%, ω(CaO)>9.5%, ω(SiO 2 )>6.0%, ω(MgO)>2.5%, ω(Al 2 o 3 )>3.0%, ω(V 2 o 5 )>0.04%, ω (particle size less than 0.074mm>90%.

[0045]Mechanically mix blast furnace dedusting ash and mixed water to make blast furnace dedusting mortar, then put the dedusting mortar into the mixer for mixing and granulation, control the moisture content of the sintering mixture at 7.5±0.2%, and then pass the grading sieve to test the mixture Material particle size composition. Among them, blast furnace dedusting mortar accounts for 1wt% of the mixture.

[0046] The mixture is put into a sintering cup for sintering by ignition and ventilation. The particle size of the bottoming material for the sintering cup is 10 mm, the thickness of the bottoming material is 18 mm, and the total thickness ...

Embodiment 2

[0048] A kind of blast furnace dedusting ash sintered material provided in this embodiment is prepared in the following way:

[0049] The composition of selected blast furnace dust is: ω(TFe)>55%, ω(FeO)>10%, ω(CaO)>9.5%, ω(SiO 2 )>6.0%, ω(MgO)>2.5%, ω(Al 2 o 3 )>3.0%, ω(V 2 o 5 )>0.04%, ω (particle size less than 0.074mm>90%.

[0050] Mechanically mix blast furnace dedusting ash and mixed water to make blast furnace dedusting mortar, then put the dedusting mortar into the mixer for mixing and granulation, control the moisture content of the sintering mixture at 7.5±0.2%, and then pass the grading sieve to test the mixture Material particle size composition. Among them, blast furnace dedusting mortar accounts for 2wt% of the mixture.

[0051] The mixture is put into a sintering cup for sintering by ignition and ventilation. The particle size of the bottoming material for the sintering cup is 16mm, the thickness of the bottoming material is 22mm, and the total thickness o...

Embodiment 3

[0053] A kind of blast furnace dedusting ash sintered material provided in this embodiment is prepared in the following way:

[0054] The composition of selected blast furnace dust is: ω(TFe)>55%, ω(FeO)>10%, ω(CaO)>9.5%, ω(SiO 2 )>6.0%, ω(MgO)>2.5%, ω(Al 2 o 3 )>3.0%, ω(V 2 o 5 )>0.04%, ω (particle size less than 0.074mm>90%.

[0055] Mechanically mix blast furnace dedusting ash and mixed water to make blast furnace dedusting mortar, then put the dedusting mortar into the mixer for mixing and granulation, control the moisture content of the sintering mixture at 7.5±0.2%, and then pass the grading sieve to test the mixture Material particle size composition. Among them, blast furnace dedusting mortar accounts for 3wt% of the mixture.

[0056] The mixture is put into a sintering cup for sintering by ignition and ventilation. The particle size of the bottoming material for the sintering cup is 12 mm, the thickness of the bottoming material is 20 mm, and the total thickness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com