Non-standard-configured two-stage continuous ore grinding and grading process

A non-standard, grinding technology, applied in the direction of grain processing, etc., can solve the problem of over-grinding of tungsten-containing minerals, achieve the effect of grinding efficiency, avoid sludge problems, and reduce the sand return ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

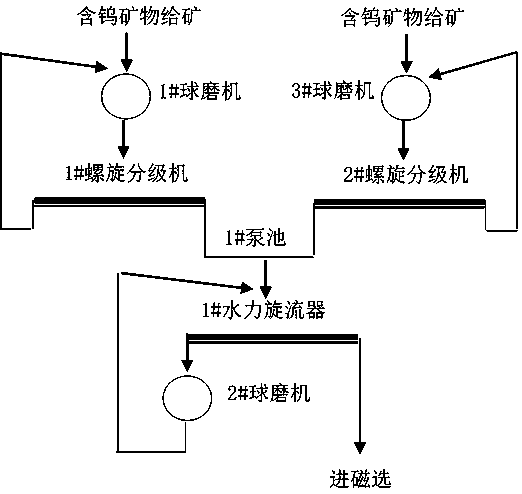

Embodiment 1

[0035] Embodiment 1: a kind of two-stage continuous grinding and classification process of non-standard configuration, it is carried out according to the following steps,

[0036] Step 1: Feed tungsten-containing minerals or tungsten-containing polymetallic minerals into 1# ball mill and 3#M ball mill, the specification is QG2.7×3.6m;

[0037] Step 2: discharge ore pulp from 1# ball mill and 3# ball mill into corresponding 1# spiral classifier and 2# spiral classifier respectively;

[0038] Step 3: The sand returned from 1# spiral classifier and 2# spiral classifier is respectively discharged into the corresponding 1# ball mill and 3# ball mill;

[0039] Step 4: Adjust the -200 mesh content in the overflow of 1# spiral classifier and 2# spiral classifier to 55%, and the pulp is combined and discharged into the 1# pump pool and fed into the 1# hydrocyclone by the slurry pump for classification ;

[0040] Step 5: 1# hydrocyclone graded grit is discharged into 2# ball mill for ...

Embodiment 2

[0043] Embodiment 2: a kind of two-stage continuous grinding and classification process of non-standard configuration, it carries out according to the following steps,

[0044] Step 1: Feed tungsten-containing minerals or tungsten-containing polymetallic minerals into 1# ball mill and 3#M ball mill, the specification is QG2.7×3.6m;

[0045] Step 2: discharge ore pulp from 1# ball mill and 3# ball mill into corresponding 1# spiral classifier and 2# spiral classifier respectively;

[0046] Step 3: The sand returned from 1# spiral classifier and 2# spiral classifier is respectively discharged into the corresponding 1# ball mill and 3# ball mill;

[0047] Step 4: Adjust the -200 mesh content in the overflow of 1# spiral classifier and 2# spiral classifier to 65%, and the pulp is combined and discharged into the 1# pump pool and fed into the 1# hydrocyclone by the slurry pump for classification ;

[0048] Step 5: 1# hydrocyclone graded grit is discharged into 2# ball mill for reg...

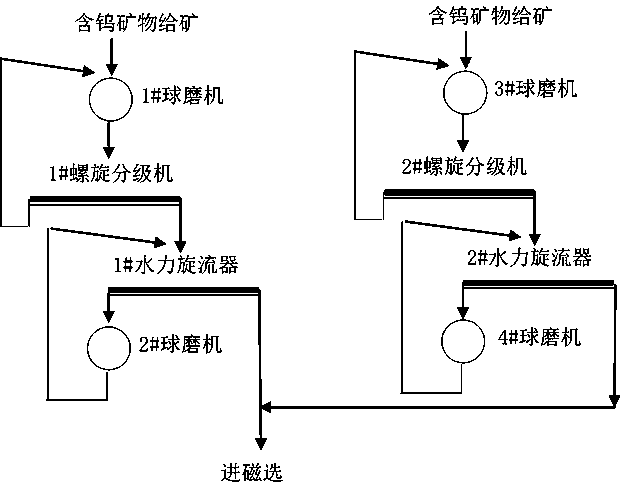

Embodiment 3

[0051] Embodiment 3: a kind of two-stage continuous grinding and classification process of non-standard configuration, it carries out according to the following steps,

[0052] Step 1: Feed tungsten-containing minerals or tungsten-containing polymetallic minerals into 1# ball mill and 3#M ball mill, the specification is QG2.7×3.6m;

[0053] Step 2: discharge ore pulp from 1# ball mill and 3# ball mill into corresponding 1# spiral classifier and 2# spiral classifier respectively;

[0054] Step 3: The sand returned from 1# spiral classifier and 2# spiral classifier is respectively discharged into the corresponding 1# ball mill and 3# ball mill;

[0055] Step 4: Adjust the -200 mesh content in the overflow of 1# spiral classifier and 2# spiral classifier to 60%, and the pulp is combined and discharged into the 1# pump pool and fed into the 1# hydrocyclone by the slurry pump for classification , at this time, the classification mass efficiency and volume efficiency of the hydrocycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com