Sintering mixture and vanadium-titanium sinter as well as preparation method of vanadium-titanium sinter

A technology of sintering mixture and vanadium-titanium iron concentrate, which is applied in the field of sintering mixture, vanadium-titanium sinter and its preparation, can solve the problems of sinter strength and finished product rate to be improved, sinter cost increase, high price of rich ore powder, etc. , to achieve the effects of improving product market competitiveness and economic benefits, improving the quality of sintered ore, and improving mineral composition and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing vanadium-titanium sintered ore. The method includes: sintering the sintered mixture into pellets and sequentially carrying out distributing, pressing and sintering, the distributing makes the material layer thickness 660-750mm, The ignition temperature is 1100-1150° C., and the ignition time for sintering is 2-2.5 minutes, wherein the sintering mixture is the above-mentioned sintering mixture.

[0036] According to the present invention, the pelletizing method may be a conventional pelletizing method. For example, the method of pelletizing the sinter mixture generally includes mixing the sinter mixture with water to pelletize. Preferably, the method of granulating the sintered raw materials is to perform first-mixing and second-mixing granulation of the sintered raw materials in sequence.

[0037] Generally, the homogeneous mixing method includes mixing the sintered mixture with water for 2-4 minutes, with respec...

Embodiment 1

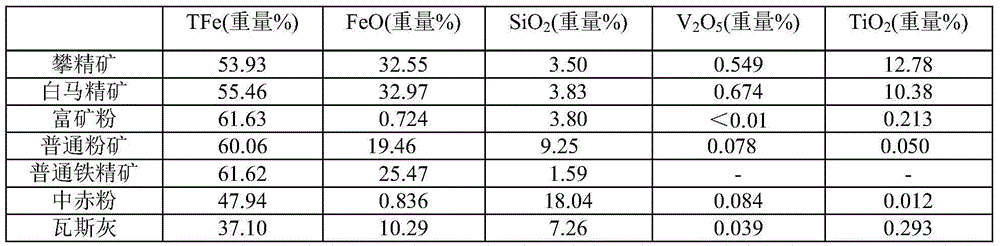

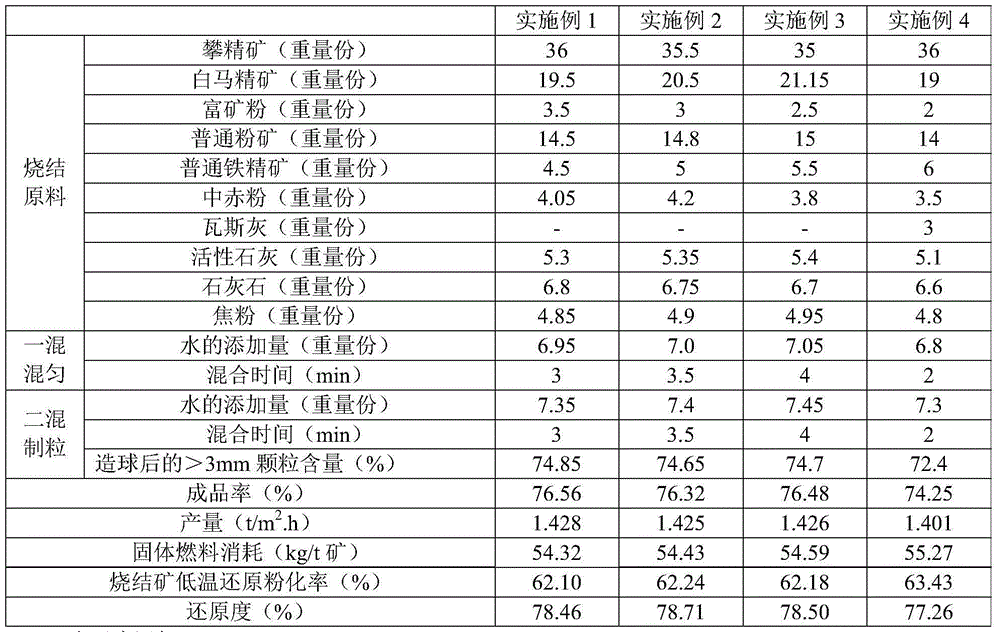

[0055] The sintering raw materials are mixed and pelletized according to the type and amount recorded in Table 1 (the method of first-mixing and second-mixing granulation in sequence), and then the pelletized sintering mixture is added to the sintering machine trolley for distribution , so that the height of the material layer is 690mm, and then press the material layer to press down the material layer by 20mm. At an ignition temperature of 1100° C., ignite for 2.0 minutes to sinter to obtain sintered ore. Among them, the yield, output, solid fuel consumption, sinter low-temperature reduction pulverization rate and reduction degree are shown in Table 1.

Embodiment 2

[0057] The sintering raw materials are mixed and pelletized according to the type and amount recorded in Table 1 (the method of first-mixing and second-mixing granulation in sequence), and then the pelletized sintering mixture is added to the sintering machine trolley for distribution , so that the height of the material layer is 710mm, and then carry out pressing to make the material layer pressed down by 30mm. At the ignition temperature of 1120°C, ignite for 2.1 minutes to sinter to obtain sintered ore. Among them, the yield, output, solid fuel consumption, sinter low-temperature reduction pulverization rate and reduction degree are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com