Preparation method of anti-erosion silica brick for carbon calcination furnace

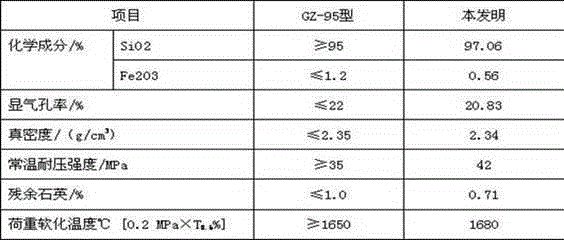

An anti-erosion and calcining furnace technology, applied in the field of refractory materials, can solve the problems of kiln life and safety impact, technical performance cannot be satisfied, etc., to achieve the effect of superior high temperature performance of products, enhanced corrosion resistance, and change of pore shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing an anti-corrosion silica brick for a carbon calciner, the raw materials are proportioned according to the following parts by weight:

[0035] Calcined silica material, particle size 1-2.36mm28%, particle size 0.5-1mm21%, particle size 0.2-0.5mm18%, particle size 0.075-0.1mm24%, particle size 0-0.045mm9%, sintering aid 4%, compound Admixture 1.5%, reinforcing agent 2%, binder 3.8%,

[0036] Mixing: Add the above-mentioned calcined silica material and reinforcing agent into the wet mill, mix for 2 minutes, then add the sintering aid and compound admixture and mix for 3 minutes, add the binder and mix for 15 minutes, and mix until the mud is uniform It can be rolled out softly;

[0037] Molding: Weigh the mixed mud according to a fixed weight and pour it into the mould, and shape it under a pressure of 630 tons;

[0038] Drying: Dry the adobe at 100°C until the residual moisture is 0.6%.

[0039] Firing: Put the obtained bricks into a kiln at 1400...

Embodiment 2

[0041] A method for preparing an anti-corrosion silica brick for a carbon calciner, the raw materials are proportioned according to the following parts by weight:

[0042] Calcined silica material, particle size 1-2.36mm35%, particle size 0.5-1mm15%, particle size 0.2-0.5mm13%, particle size 0.075-0.1mm30%, particle size 0-0.045mm7%, sintering aid 4%, compound Admixture 2.0%, reinforcing agent 1.0%, binder 4%,

[0043] Mixing: add the above-mentioned calcined silica material and reinforcing agent into the wet mill, mix for 2 minutes, then add the sintering aid and compound admixture and mix for 3 minutes, add the binder, mix and roll for 20 minutes, and mix until the mud is uniform It can be rolled out softly;

[0044] Molding: Weigh the mixed mud according to a fixed weight and pour it into the mould, and shape it under a pressure of 630 tons;

[0045] Drying: Dry the adobe at 150°C until the residual moisture is 0.7%.

[0046] Firing: Put the obtained bricks into a kiln a...

Embodiment 3

[0048] A method for preparing an anti-corrosion silica brick for a carbon calciner, the raw materials are proportioned according to the following parts by weight:

[0049] Calcined silica material, particle size 1-2.36mm25%, particle size 0.5-1mm25%, particle size 0.2-0.5mm23%, particle size 0.075-0.1mm20%, particle size 0-0.045mm7%, sintering aid 8%, compound Admixture 1.0%, reinforcing agent 1.2%, binder 6.0%,

[0050] Mixing: add the above-mentioned calcined silica material and reinforcing agent into the wet mill, mix for 2 minutes, then add the sintering aid and compound admixture and mix for 3 minutes, add the binder, mix and roll for 18 minutes, and mix until the mud is uniform It can be rolled out softly;

[0051] Molding: Weigh the mixed mud according to a fixed weight and pour it into the mould, and shape it under a pressure of 630 tons;

[0052] Drying: Dry the adobe at 120°C until the residual moisture is 0.8%.

[0053] Firing: Put the obtained bricks into a kiln...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com