Patents

Literature

72results about How to "Reduce production errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

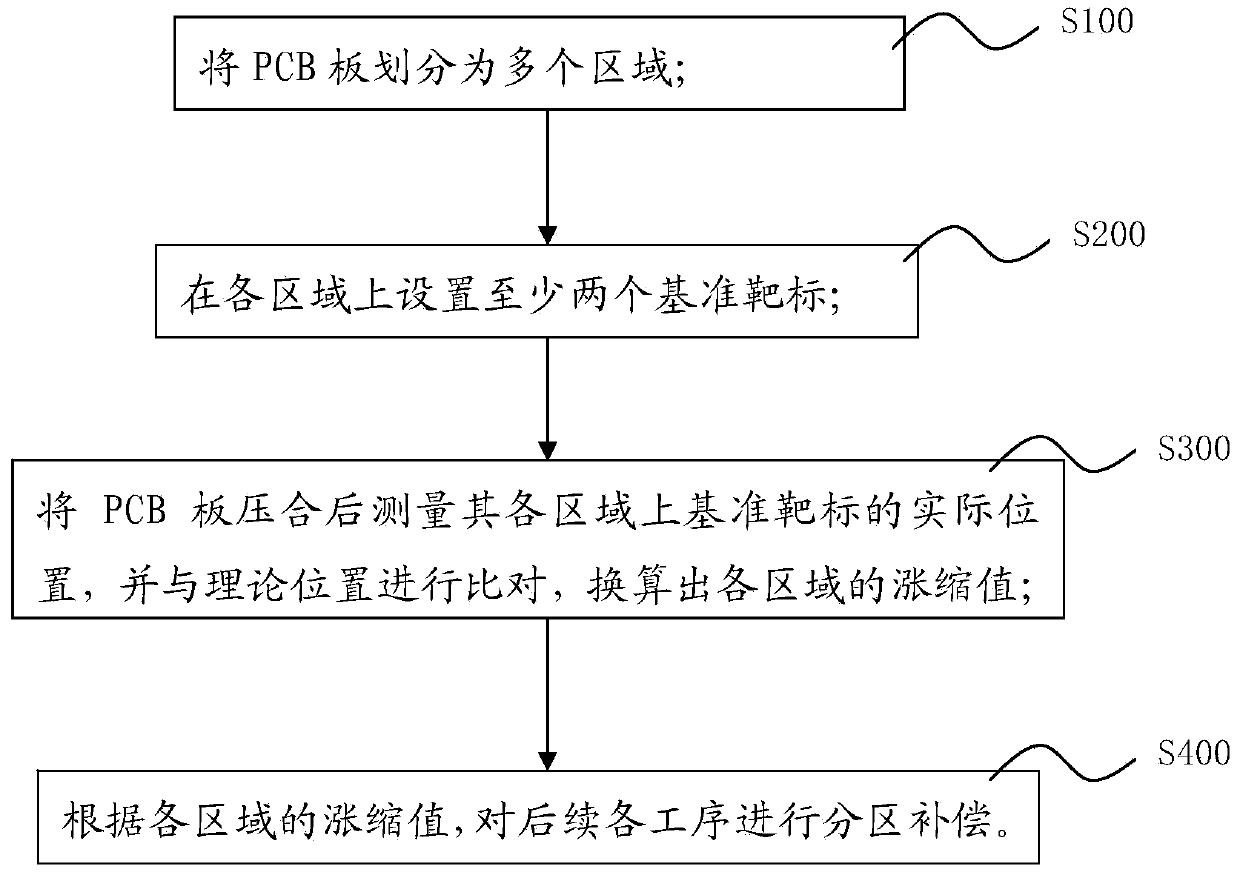

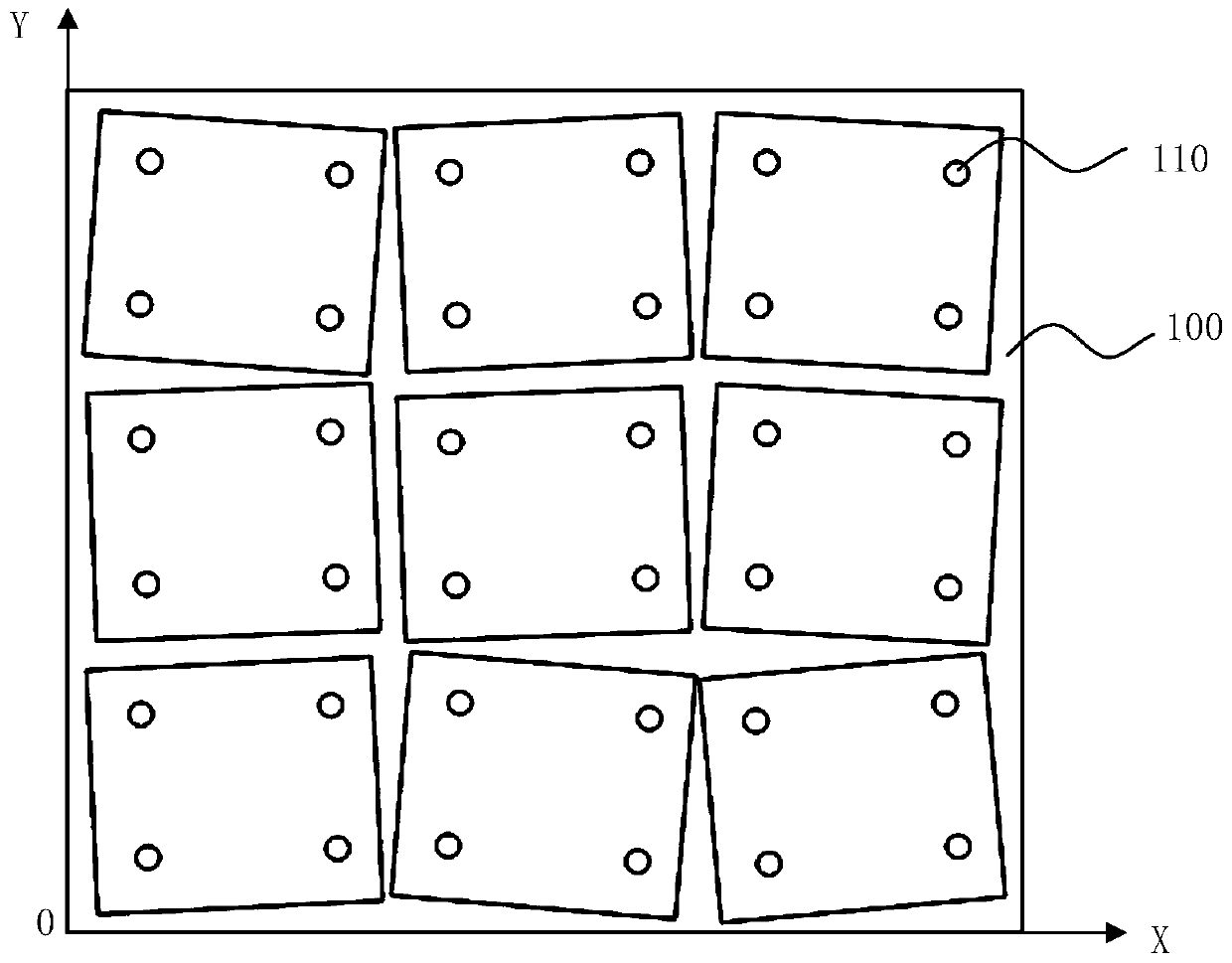

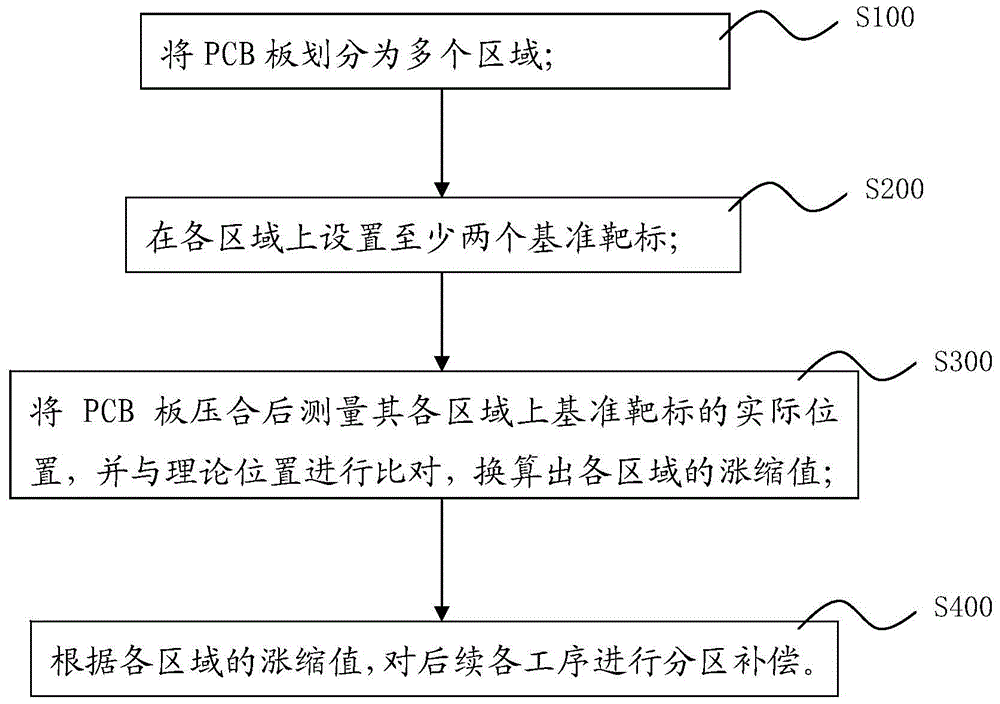

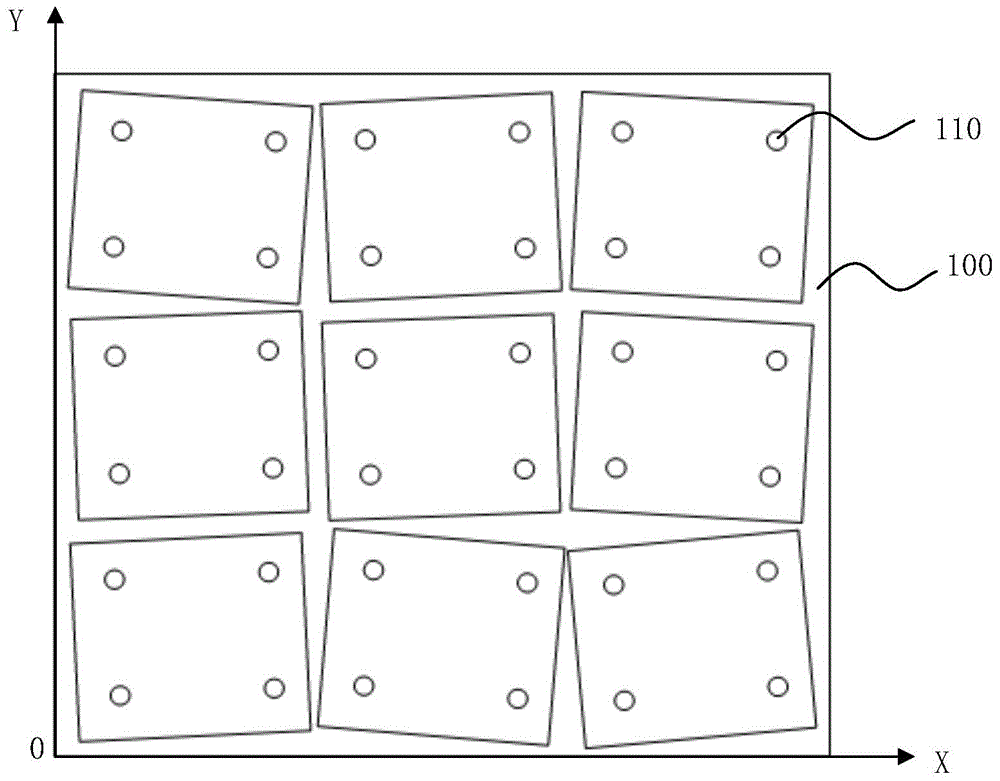

PCB expansion compensation method

ActiveCN103747617AReduce expansion and contraction deviationImprove manufacturing precisionPrinted circuits stress/warp reductionPrinted circuit manufactureEngineeringCompensation methods

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

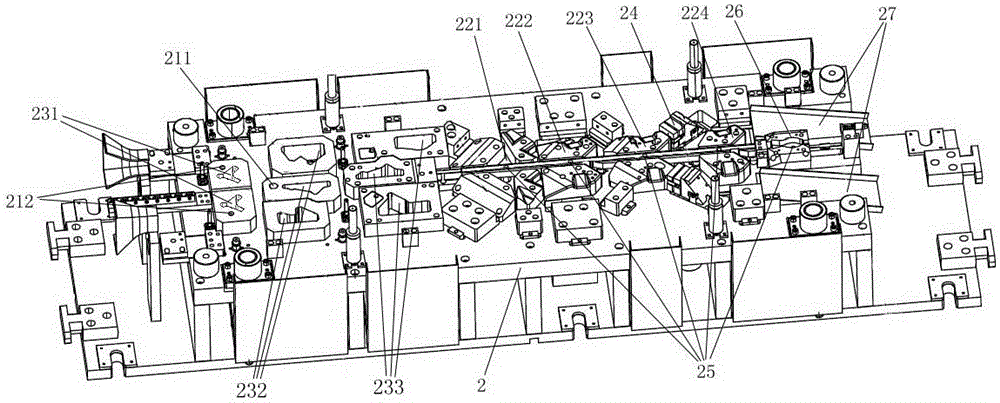

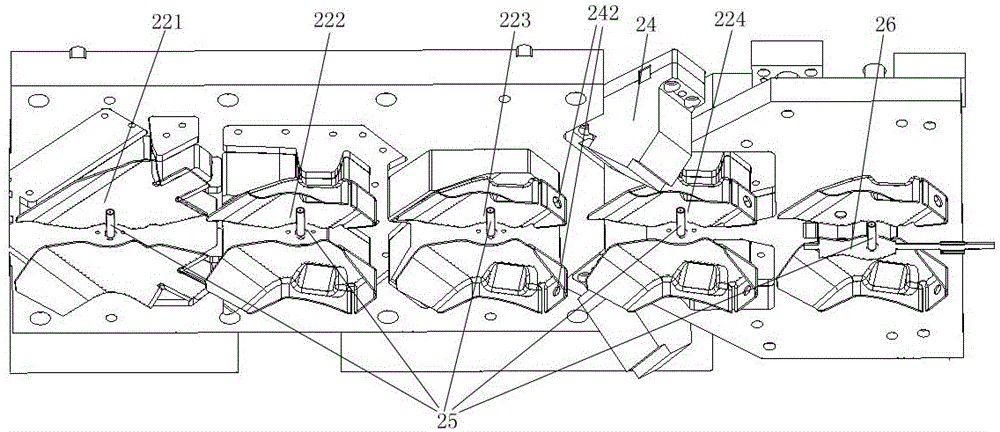

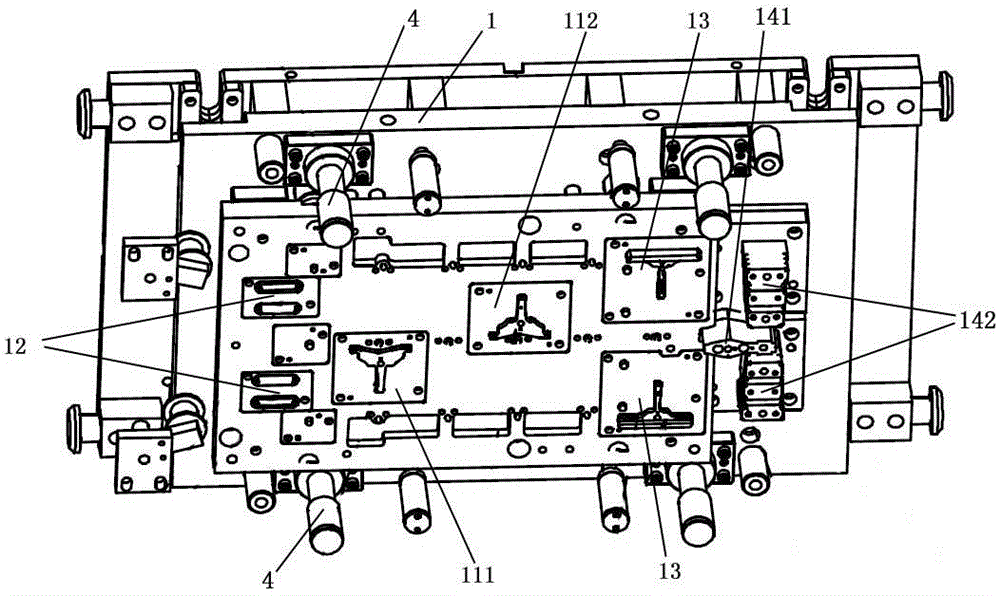

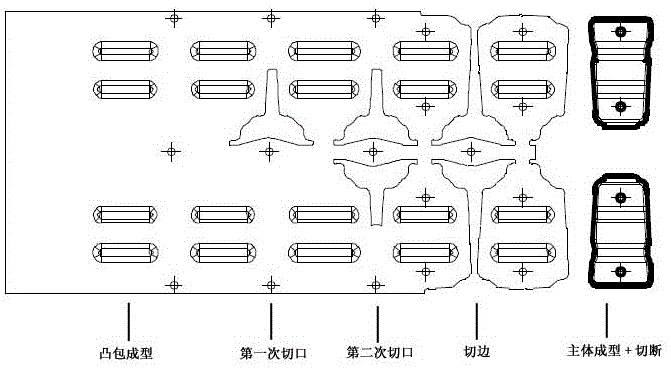

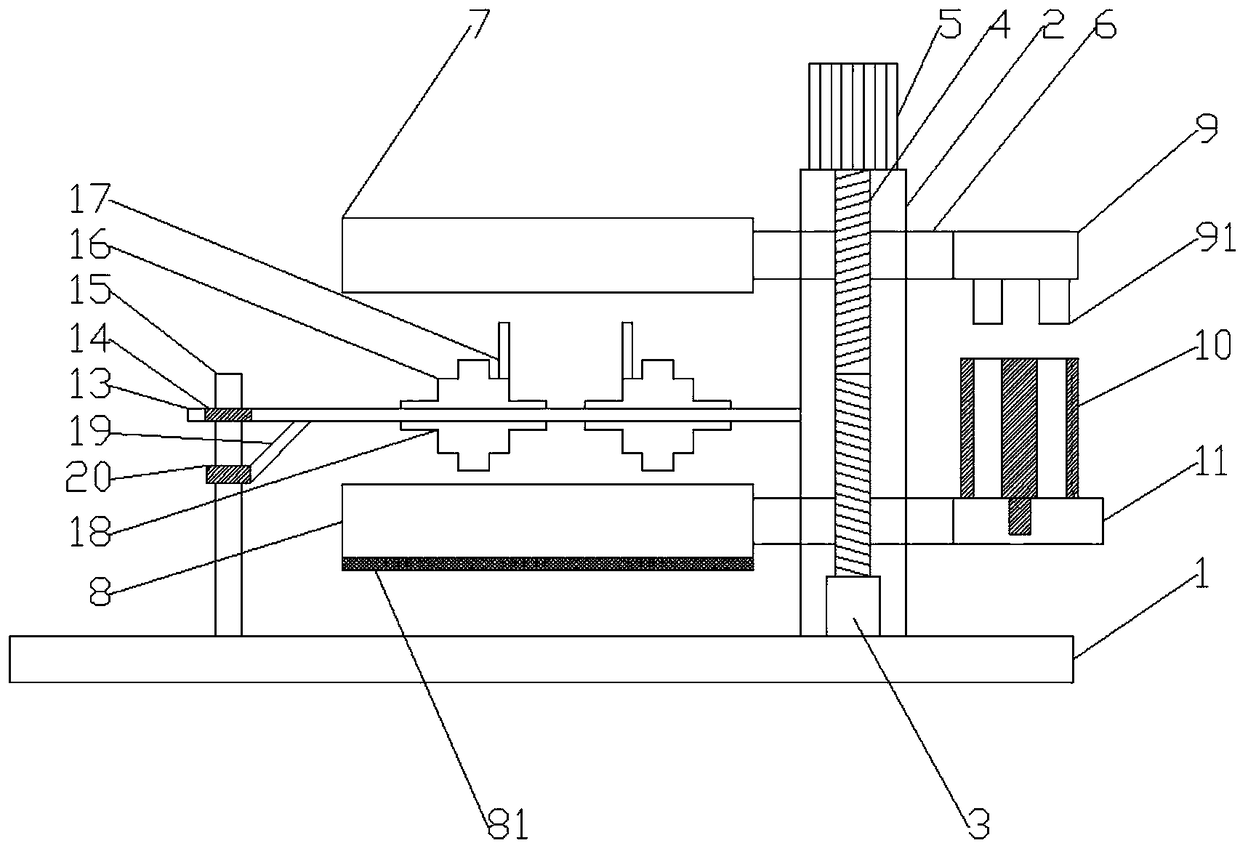

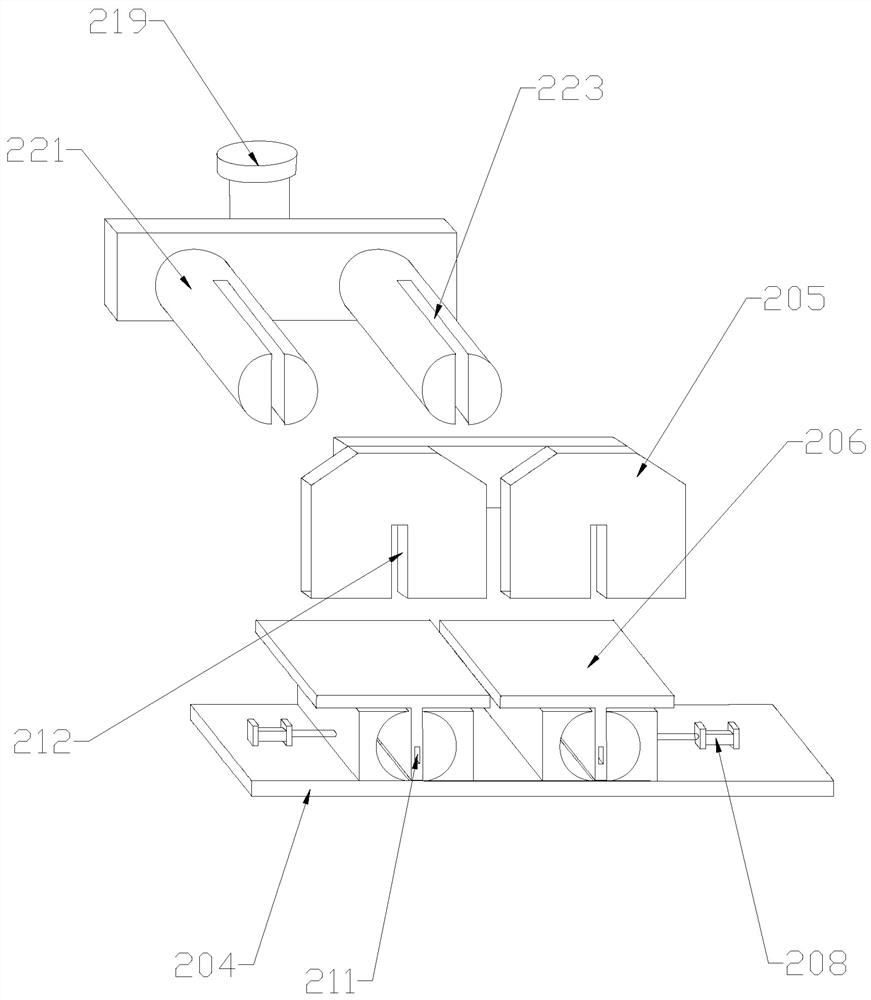

Continuous die for manufacturing vehicle connecting plate and continuous manufacture method of vehicle connecting plate

ActiveCN104998969AAvoid the phenomenon of position deviationGuaranteed quality pass rateShaping toolsVehicle componentsPunchingEngineering

The invention aims to provide a continuous die for manufacturing a vehicle connecting plate. The continuous die comprises an upper die and a lower die, wherein mutually corresponding guide poles and guide tables are respectively arranged on the upper die and the lower die; the upper die is provided with a punch set, a forming male die set, an edging knife set, a side punching inclined wedge and a cut-off tool; corresponding to the upper die, the lower die is correspondingly provided with a punch female die set, a forming female die set, an edging female die set, a side punching slider and a cut-off groove; the side punching inclined wedge is fixedly mounted on the upper die, and the lower end surface of the side punching inclined wedge is an inclined face; the side punching slider is arranged on the lower die through a slide rail, and a side punching fixing female die is arranged at the tail end of the slide rail; and during die assembly, the inclined face of the side punching slider and the inclined face of the side punching inclined wedge mutually extrude in a contact manner, and the side punching slider performs feed movement toward side punch female dies. The invention also provides a continuous manufacture method of a vehicle connecting plate. The continuous die and the continuous manufacture method have the characteristics of being simple in structure, simple and convenient to operate, high in efficiency and low in cost.

Owner:柳州市楷都汽车零部件有限公司

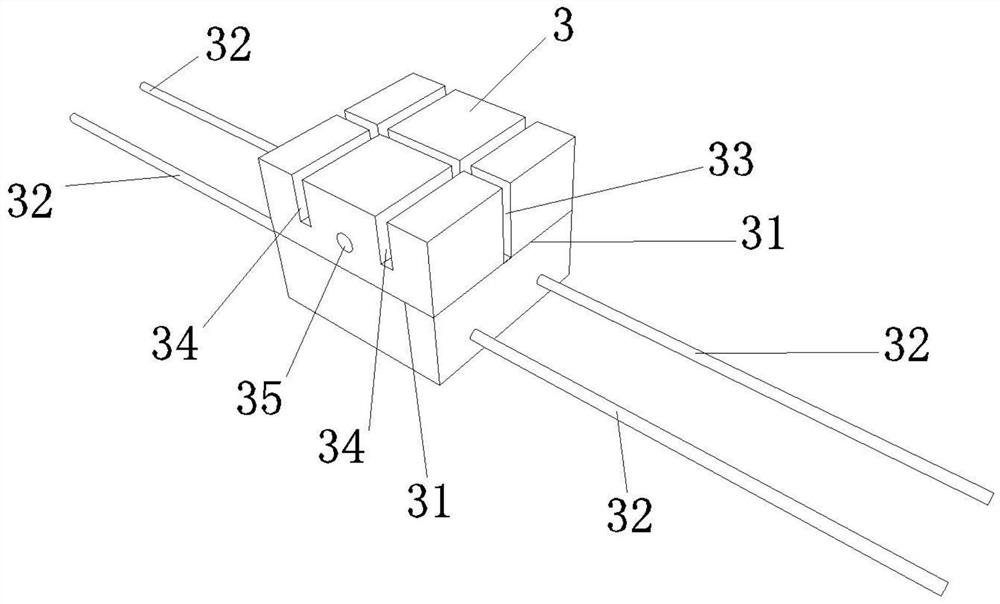

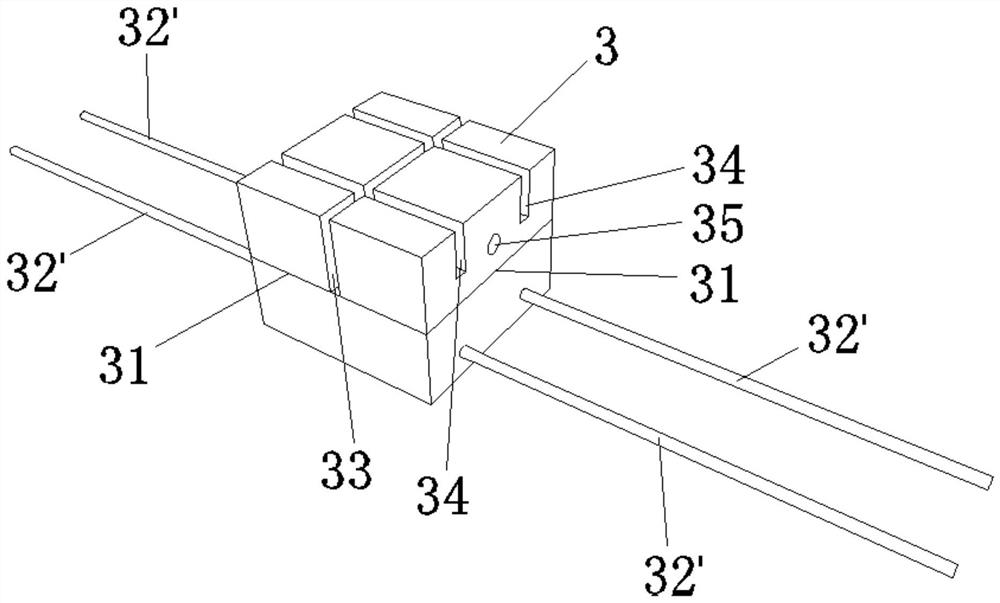

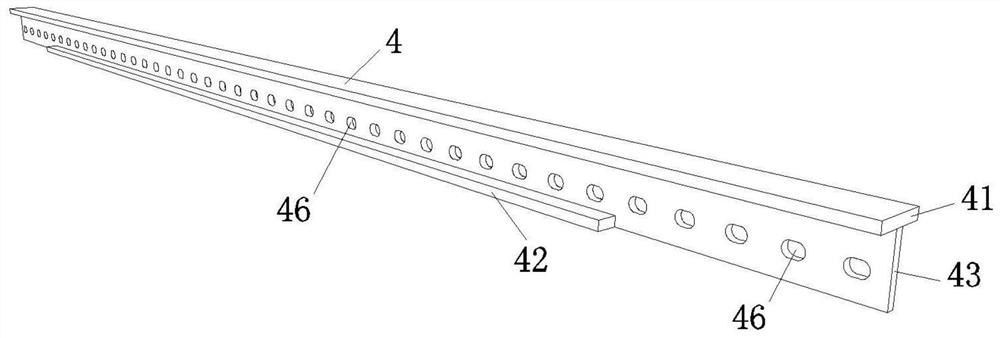

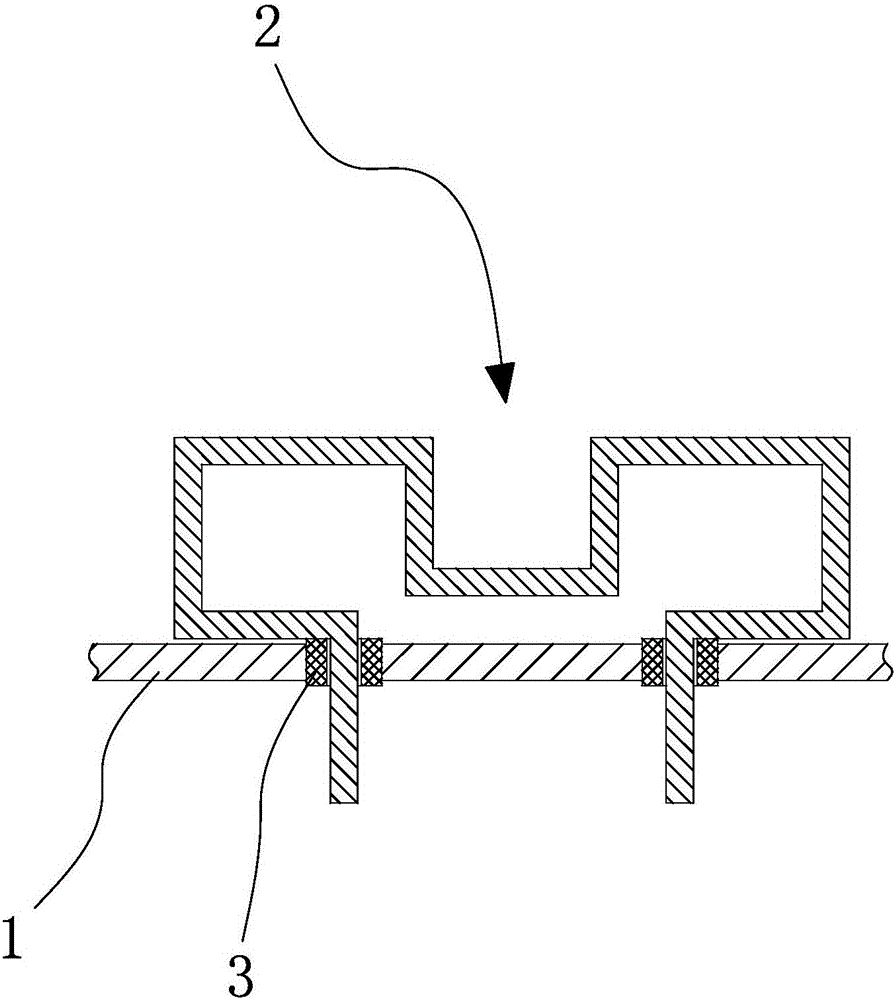

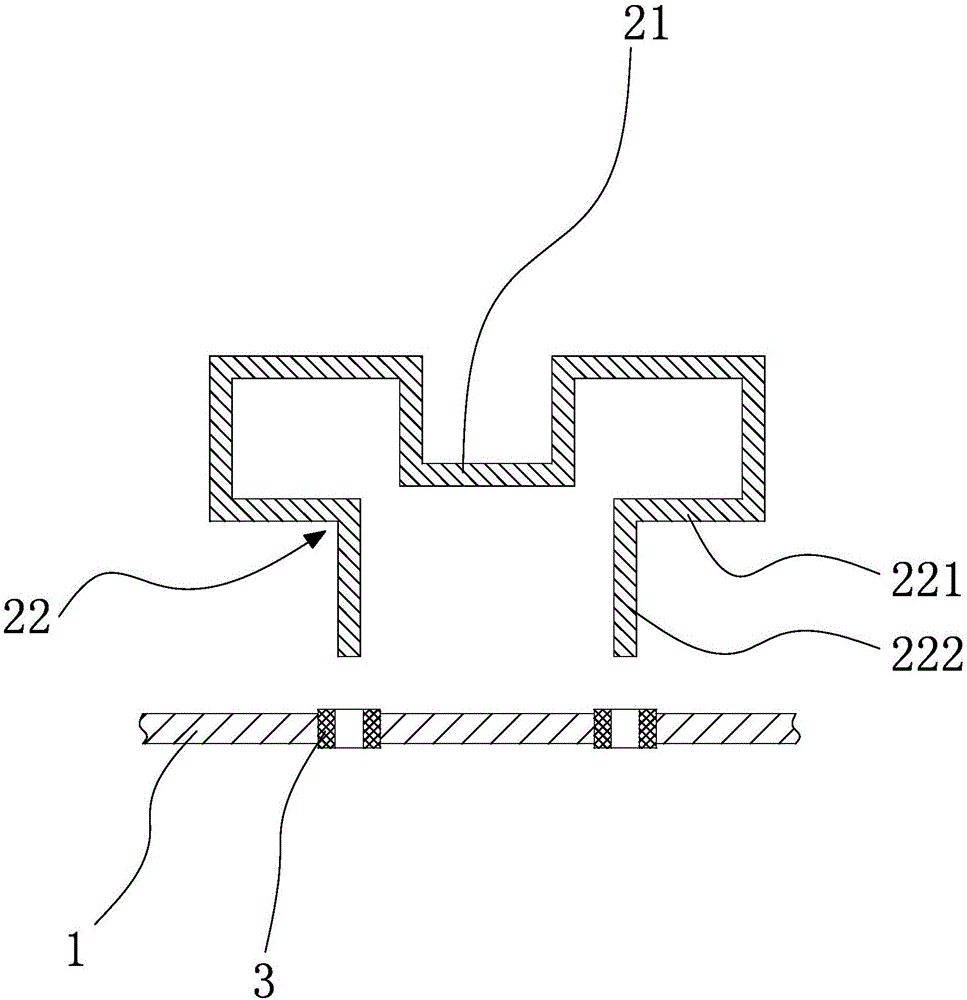

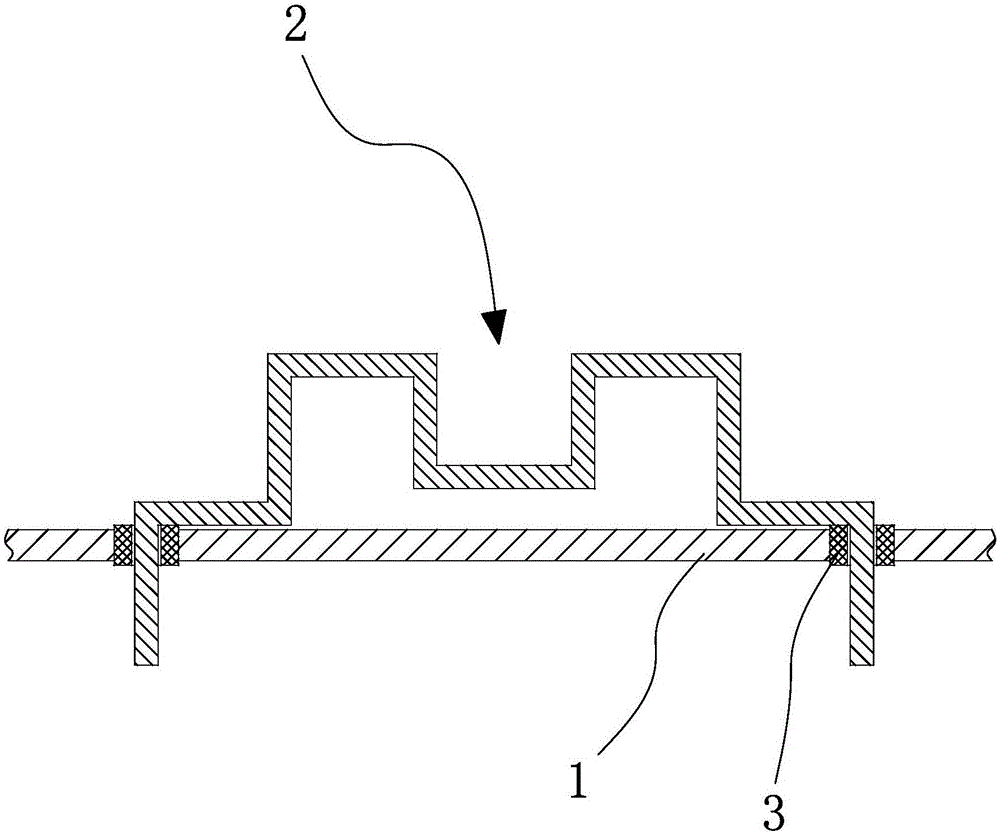

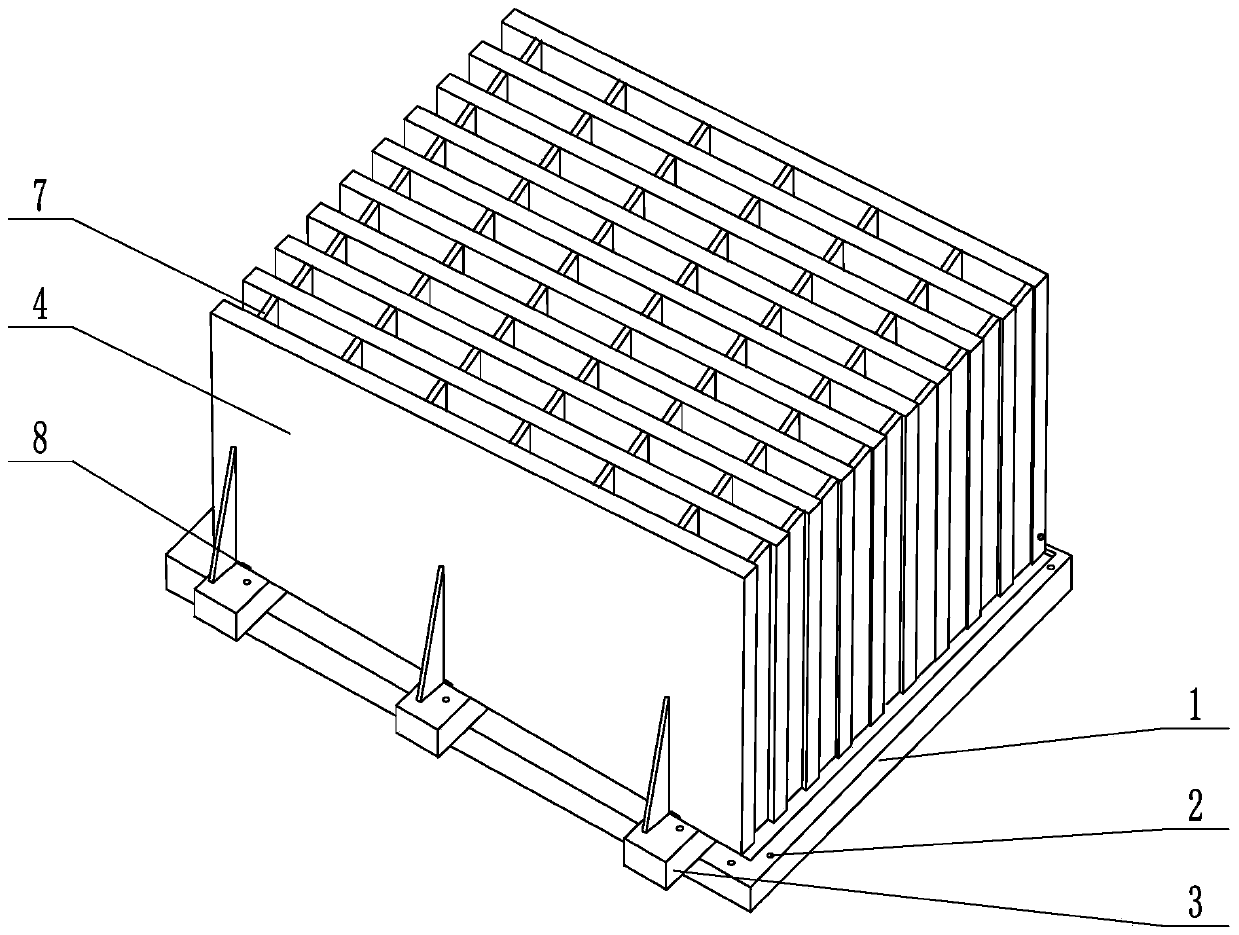

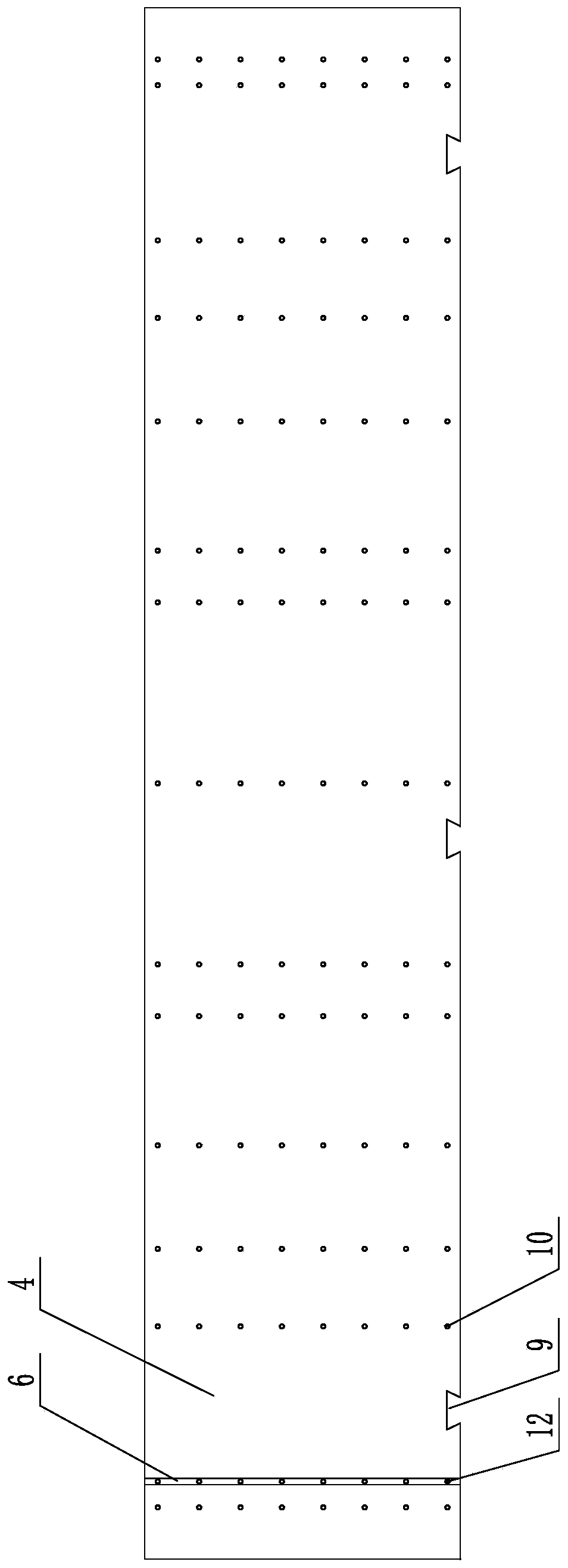

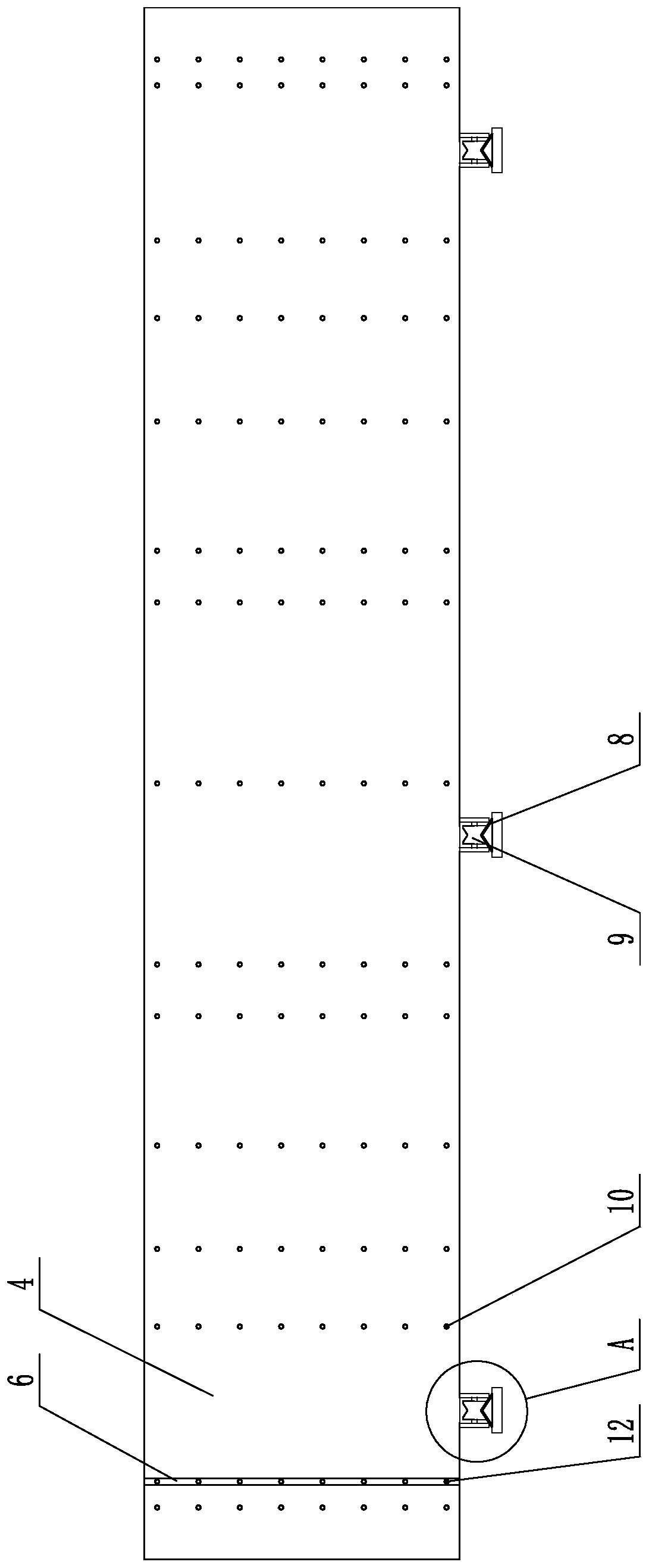

Prefabricated bottom plate of laminated slab, laminated slab, and preparation method of laminated slab

ActiveCN112012386AEasy to disassembleConvenient positioning and bindingFloorsCeramic shaping apparatusEngineeringRebar

The invention discloses a prefabricated bottom plate of a laminated slab, the laminated slab, and a preparation method of the laminated slab, and belongs to the field of prefabricated buildings. The prefabricated bottom plate of the laminated slab comprises connecting part groups, a first composite steel bar layer, and a concrete bottom plate. Each of connecting parts comprises a connecting blockand positioning steel bars horizontally penetrating through the lower part of the connecting block; the upper part of each of the connecting blocks is provided with a downwards concave connecting groove and penetrated plug pin holes vertical to the connecting groove; and the connecting grooves are used for inserting webs, with inserted holes, of profile steel parts. The first composite steel bar layer comprises an upper steel bar layer and a lower steel bar layer; the positioning steel bars of the connecting parts and the lower steel bar layer are located on the same plane; the connecting blocks penetrate through meshes of the first composite steel bar layer; and the plug pin holes are located above the concrete bottom plate. Due to the design of the connecting grooves and the plug pin holes in the upper side of the prefabricated bottom plate, the profile steel parts can be detached, hoisting and stacking are convenient, and the positioning steel bars of the prefabricated bottom platecan also prevent the risk that the multifunctional concrete block connecting parts are pulled out of the prefabricated bottom plate in the lifting and hoisting process.

Owner:上海凯汇建筑设计有限公司

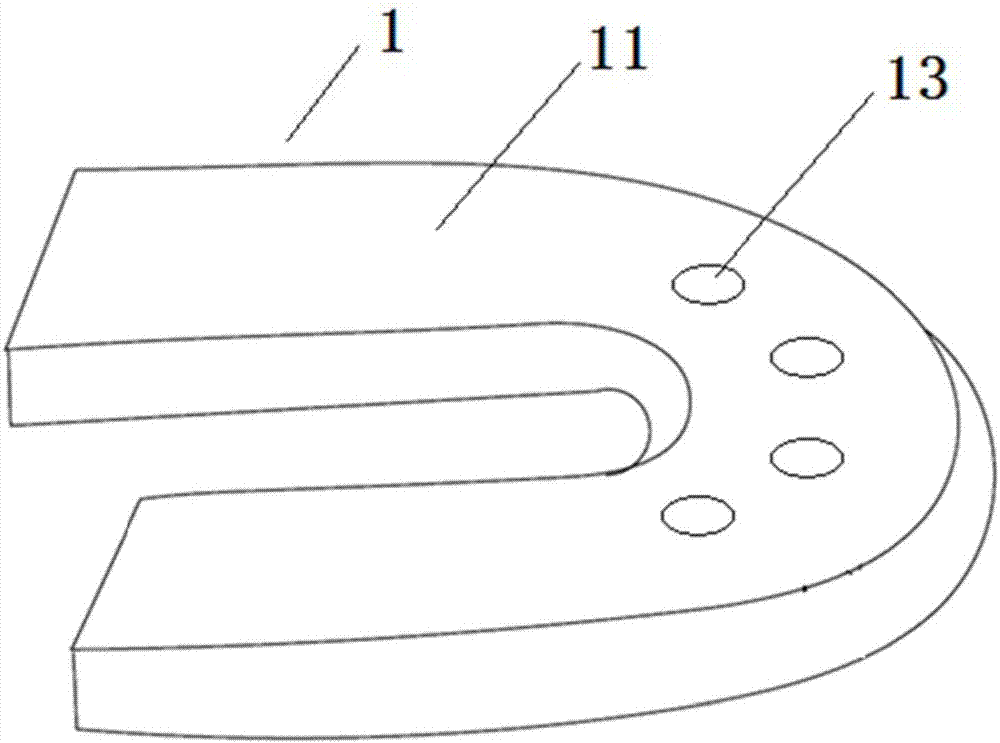

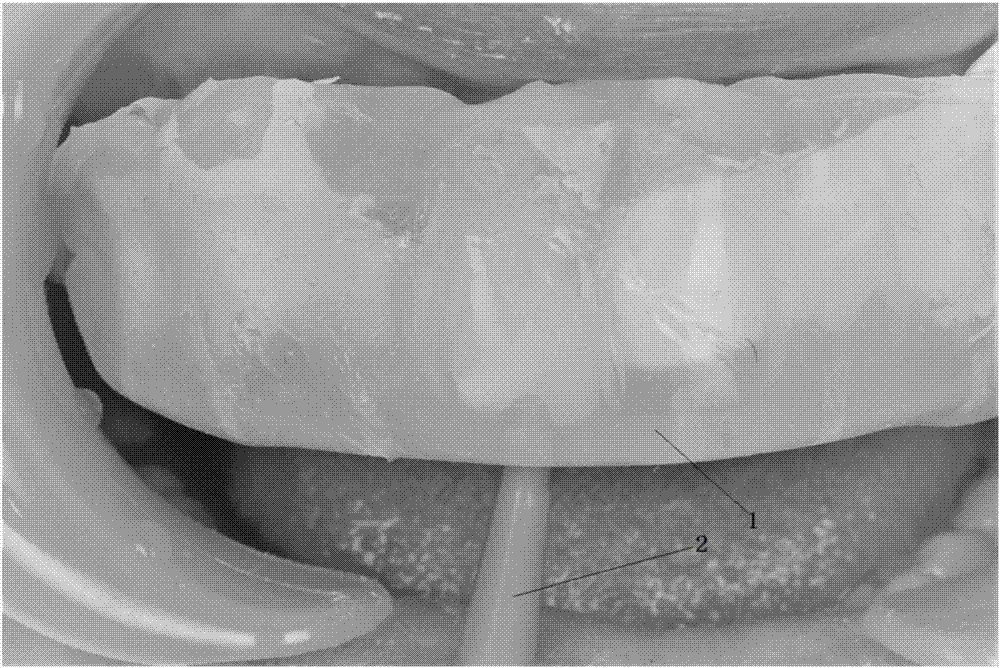

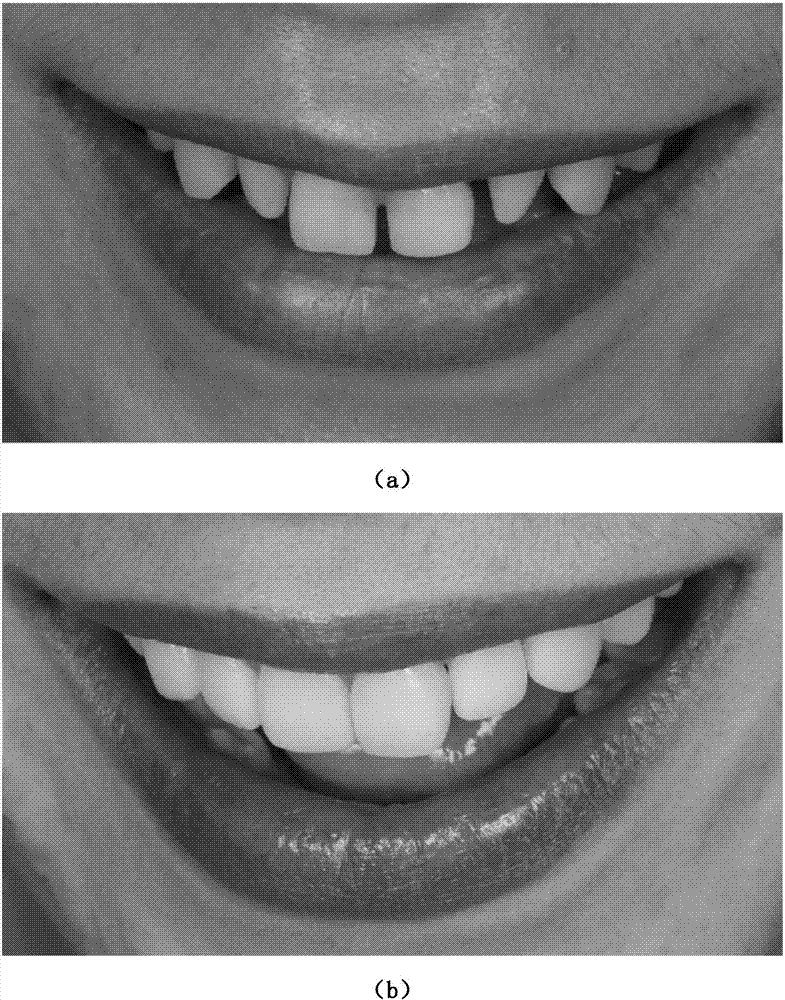

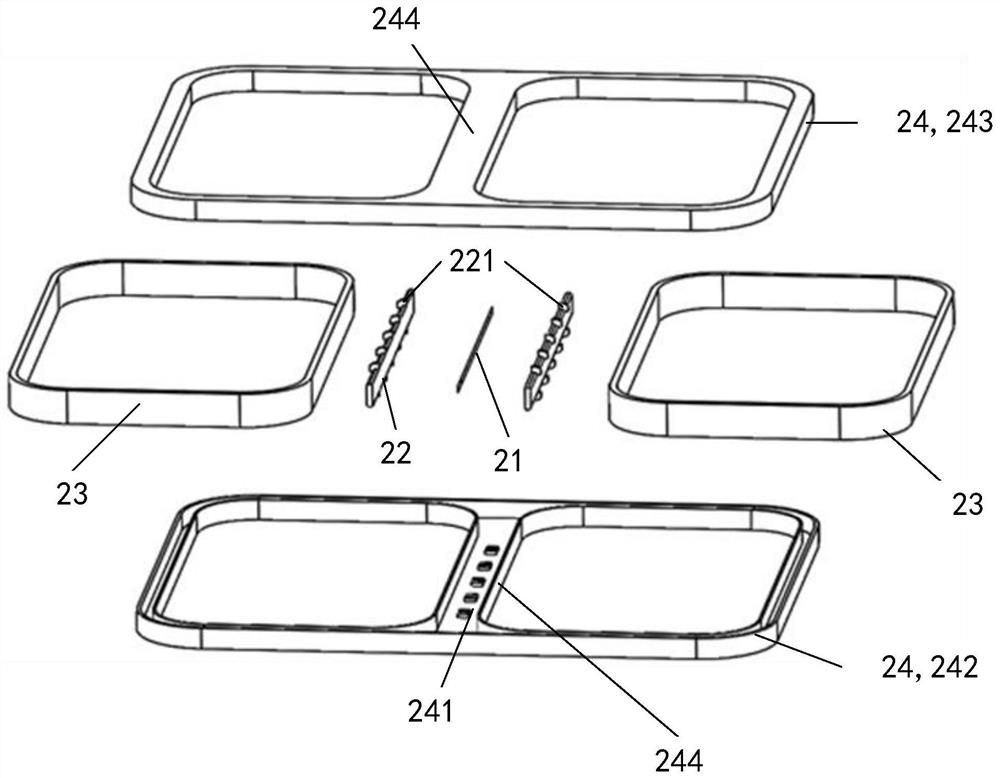

Device and method for molding resin veneer

ActiveCN107126272AWork lessShape adjustableTeeth fillingTeeth cappingEngineeringAtmospheric pressure

The invention discloses a molding device for a resin veneer for dental cosmetics, and a method for preparing the resin veneer by using the molding device. The molding device for the resin veneer comprises an outer-layer thermoplastic membrane guide plate, an inner-layer transparent silicon rubber female mold and a high-filler fluid resin injection hole. When the molding device is operated inside a mouth of a patient, an improved molding injection technique is implemented according to an atmospheric pressure principle, so that bubbles can be reduced to the maximum extent, and in addition, the resin veneer can be relatively efficiently molded.

Owner:西安知北信息技术有限公司

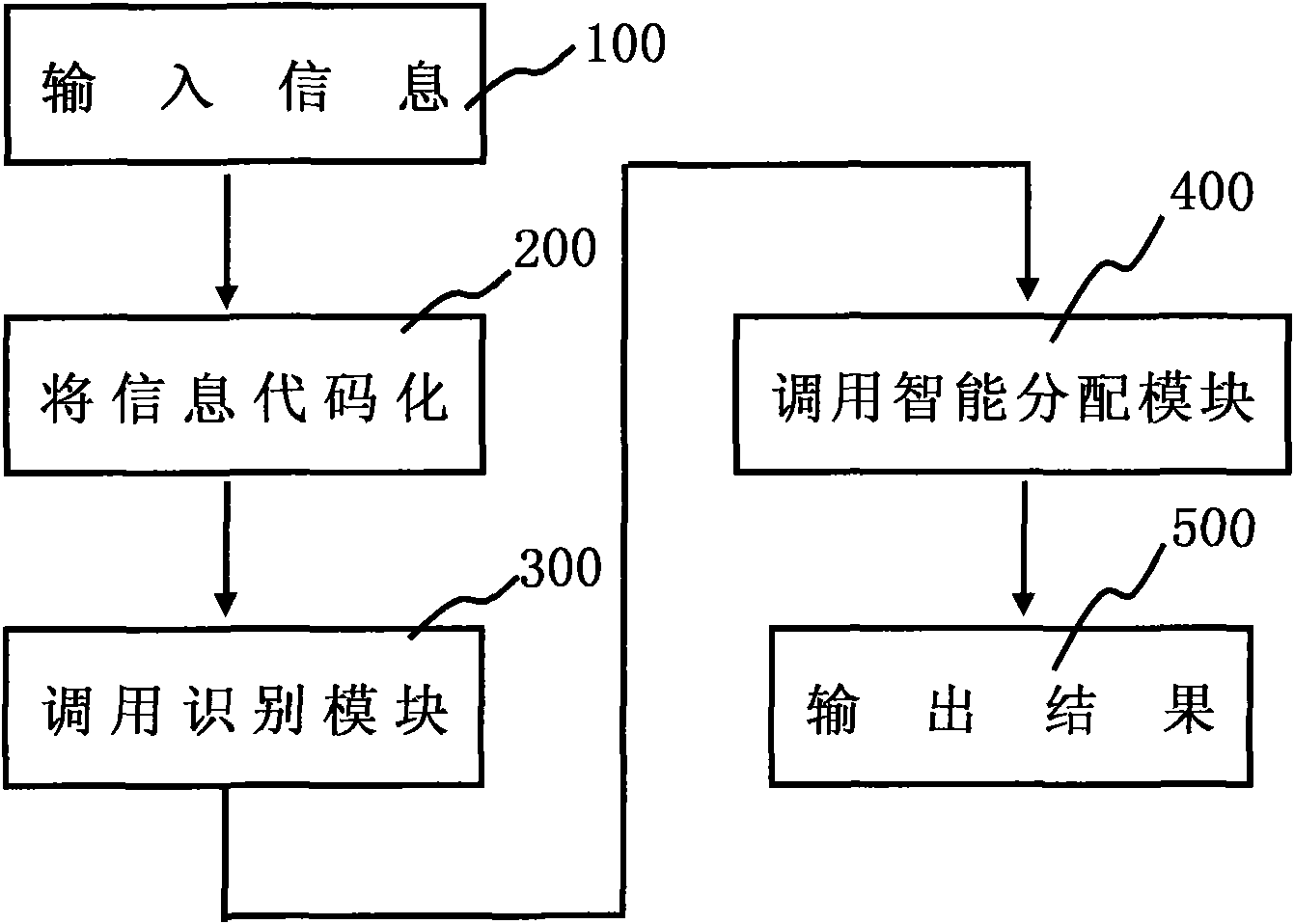

Distribution method of optical cable chromatography

InactiveCN101644803AShorten the timeReduce production errorsFibre mechanical structuresDistribution methodComputer module

The invention relates to the technical field of cables, in particular to a distribution method of optical cable chromatography, comprising the following steps: A. inputting information which comprisesan optical cable structure, a chromatography distribution method, and the like; B. coding the information; C. calling an identification module; D. calling an intelligent distribution module to execute the following steps according to identified information: automatically calling a working procedure document, drawing a chromatography distribution table, a section sketch map, a detection report table, and the like, and distributing to the each working procedure machine; and E. outputting a result. The method has the following advantages of: (1) reducing the master degree requirement for information recorders on optical cable professional knowledge, and saving training time; (2) simplifying the training of the structure knowledge to staffs and reducing error rate; (3) saving paper cost, printing cost and labor cost; (4) accelerating the complete time of a detection report and alleviating the workload of detecting staffs, so that the detecting staffs have more time to detect products.

Owner:蒋菊生

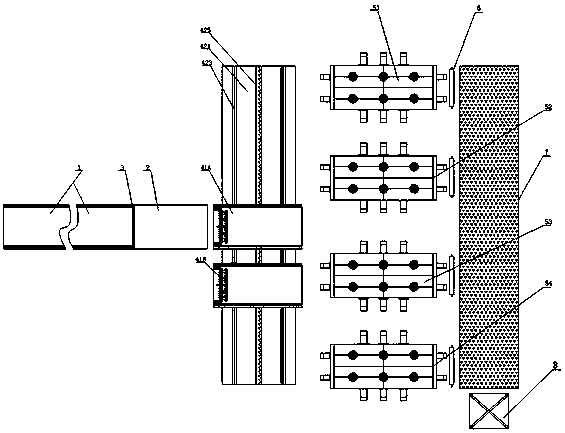

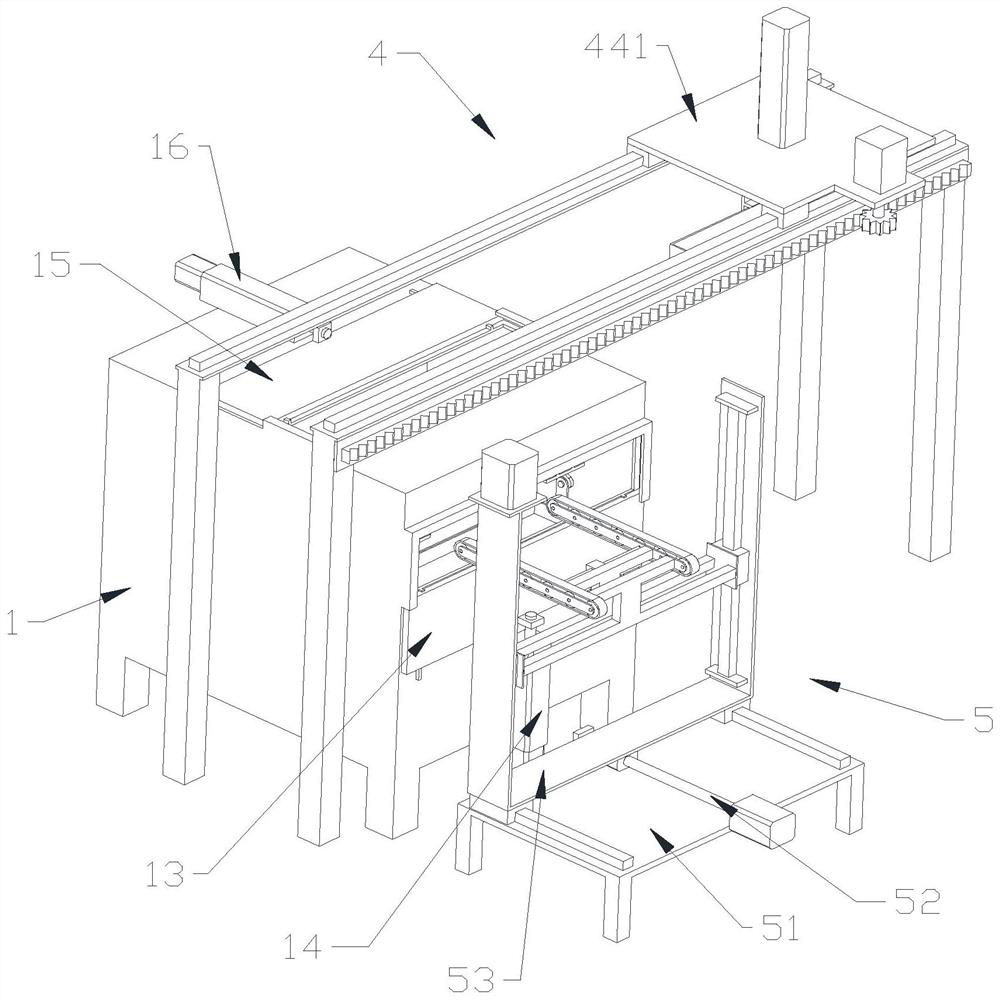

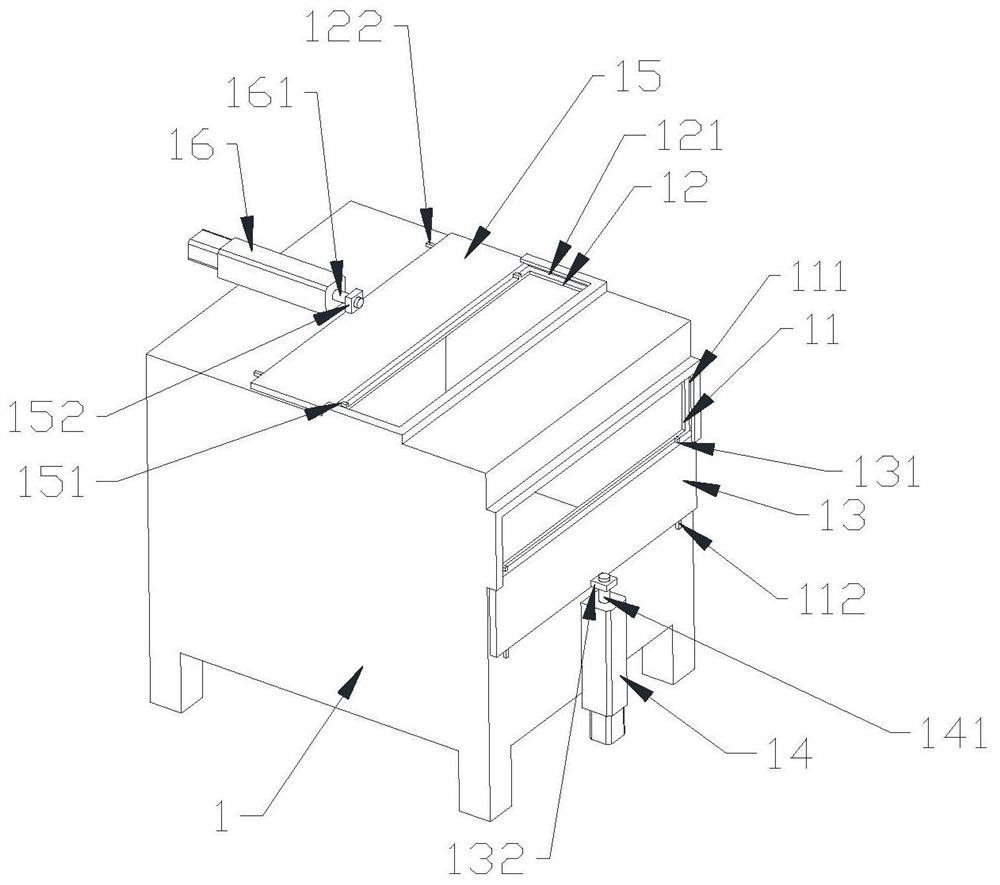

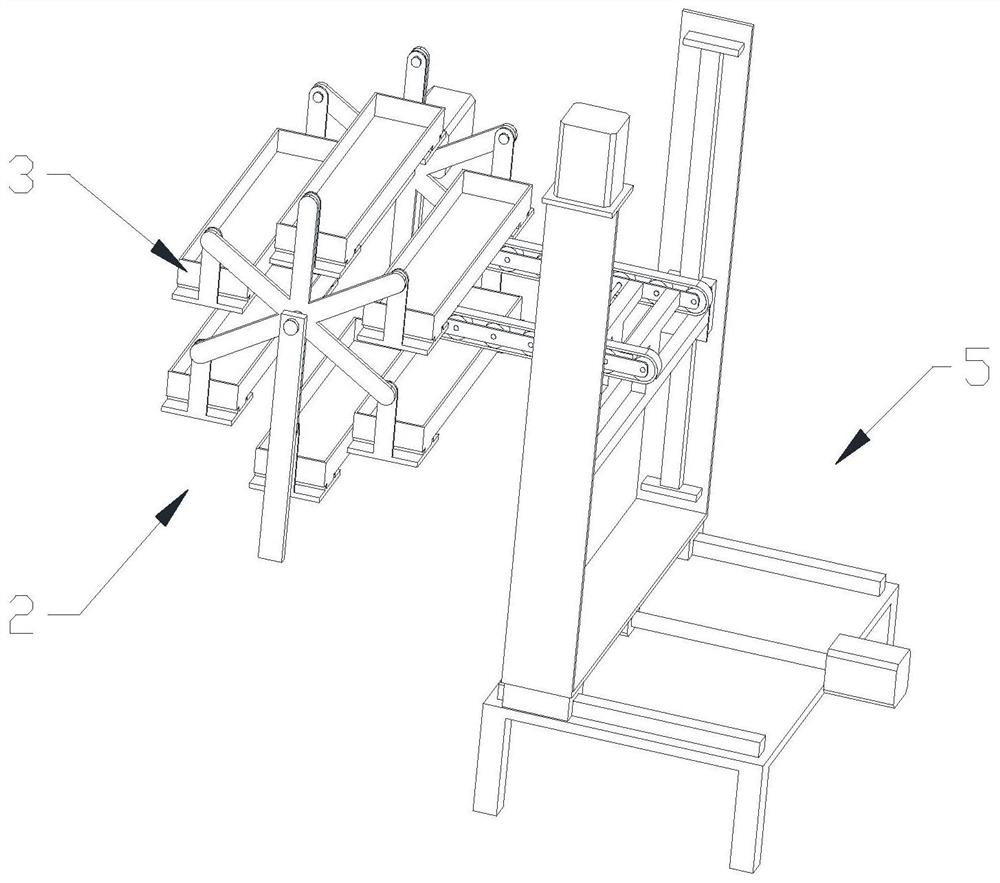

Automatic laminated wood board core processing method and device

ActiveCN107718181ARealize automatic precise cuttingRealize automatic fillingPlywood pressesLaminationHot pressManufacturing engineering

The invention discloses an automatic laminated wood board core processing device which comprises a board blank conveying assembly, a displacement adjusting mechanism, a hot-pressing unit and a finished product board conveying mechanism. The board blank conveying assembly comprises a conveying belt I, a loading platform and a cutting mechanism, the displacement adjusting mechanism comprises ferry trolleys, a ferry track and a pushing platform, the hot-pressing unit include two or more hot-pressing machines, and the hot-pressing machines use the conveying belt I as the axis and are longitudinally and symmetrically arranged at the tail end of the displacement adjusting mechanism. The finished product board conveying mechanism comprises a conveying belt II, a conveying pair roller set and a board blanking machine. Compared with the prior art, the automatic laminated wood board core processing device achieves automatic board blank loading through matched work of two ferry trolleys and fourhot-pressing machines, and fully utilizes the time difference of pressure maintaining in an instant pressing and alternative execution working mode. In addition, all the operations including board blank conveying, cutting, displacement and loading and finished product board recovery are automatic, and the working efficiency is greatly improved.

Owner:樊荣武

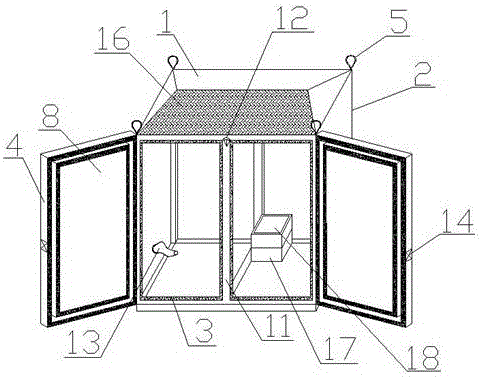

Convenient-to-mount intelligent dustproof power distribution cabinet

ActiveCN106785975AWon't scratchReasonable structural designSubstation/switching arrangement casingsVertical edgeAbnormal shaped

The invention relates to electric equipment and in particular relates to a convenient-to-mount intelligent dustproof power distribution cabinet. The convenient-to-mount intelligent dustproof power distribution cabinet comprises a cover body and a rectangular power distribution cabinet body, wherein the power distribution cabinet body is formed by detachably connecting stainless steel plates and edge frames; each edge frame is of a square pipe with a square-shaped longitudinal section; turning edges I are arranged at the inner edge of the edge frame on the front surface of the power distribution cabinet body; door bodies are arranged on the front surface of the power distribution cabinet; each door body is formed by splicing a door edge and a stainless steel plate; each door edge is formed by welding abnormal-shaped pipes with a concave longitudinal section; grooves of the concave door edges are matched with the turning edges on the front surface of the power distribution cabinet body; hoisting buckles are arranged at the tops of the vertical edge frames of the power distribution cabinet body; an intelligent controller is arranged at one side edge of the power distribution cabinet body. The convenient-to-mount intelligent dustproof power distribution cabinet has the advantages that the power distribution cabinet body is formed by detachably connecting the stainless steel plates and the edge frames and the convenient-to-mount intelligent dustproof power distribution cabinet is simple and convenient to assemble and firm in structure.

Owner:JIANGSU HAITONG ELECTRICAL APPLIANCE CO LTD

PCB expansion and contraction compensation method

ActiveCN103747617BReduce expansion and contraction deviationImprove manufacturing precisionPrinted circuits stress/warp reductionPrinted circuit manufactureEngineeringArea measurement

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

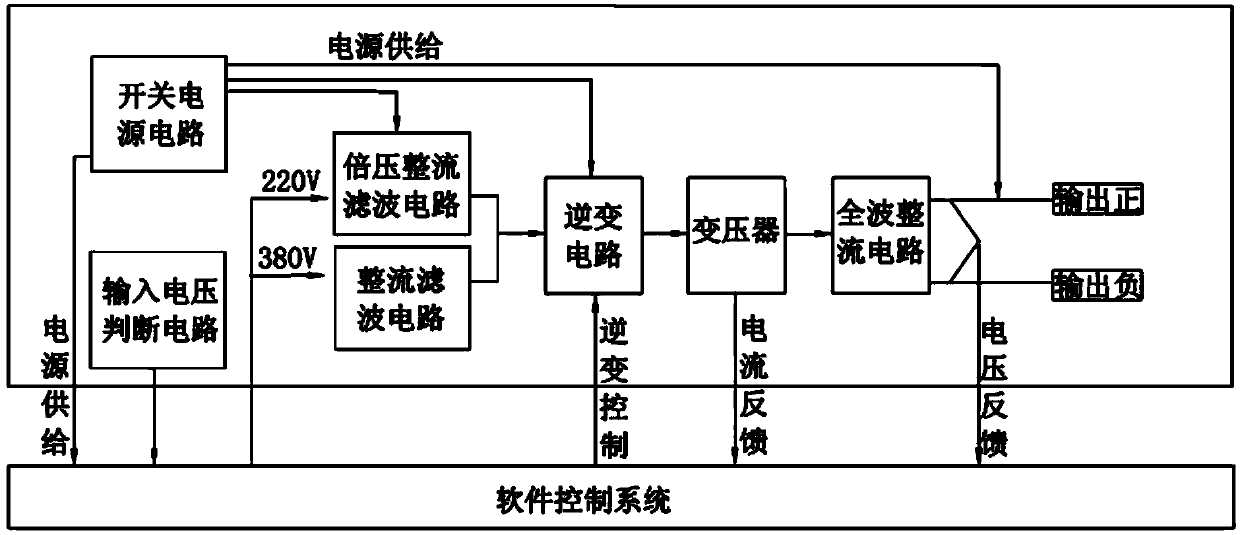

Electric welding machine and circuit control board system thereof

ActiveCN103722319AClear structureSimple production processDc-dc conversionWelding/cutting auxillary devicesPower flowFull wave

The invention provides a circuit control board system of an electric welding machine. The circuit control board system comprises a control board and a master board, and the control board and the master board are connected through a flat cable; the master board comprises a switch power supply circuit, an input voltage judging circuit, a voltage doubling rectifying filter circuit, a rectifying filter circuit, an inverter circuit, a transformer, a full-wave rectifying circuit, a current feedback circuit and a voltage feedback circuit. The invention further provides the electric welding machine. The electric welding machine and the circuit control board system thereof have the advantages that the electric welding machine is simple and clear in structure; production process is simplified, production hours are shortened, and production cost is reduced; connection relation is simple, and some key connection leads are replaced by copper foils, so that a fool-proof function can be achieved, and the probability of production errors is reduced; interferences by clustering of traditional connection leads are reduced by the simple connection relation; functional modules are individually laid out, so that test and maintenance are facilitated; the whole system of the electric welding machine is modularized, so that operations such as improving and upgrading of the electric welding machine are facilitated.

Owner:SHANGHAI GREATWAY WELDING EQUIP

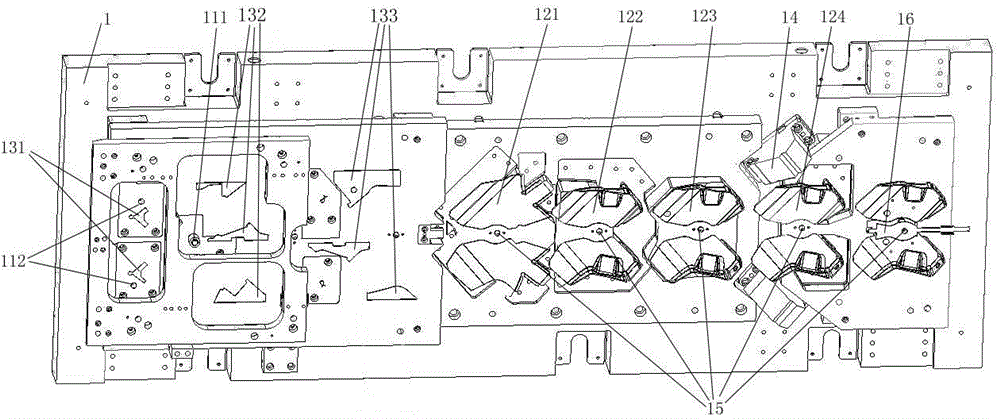

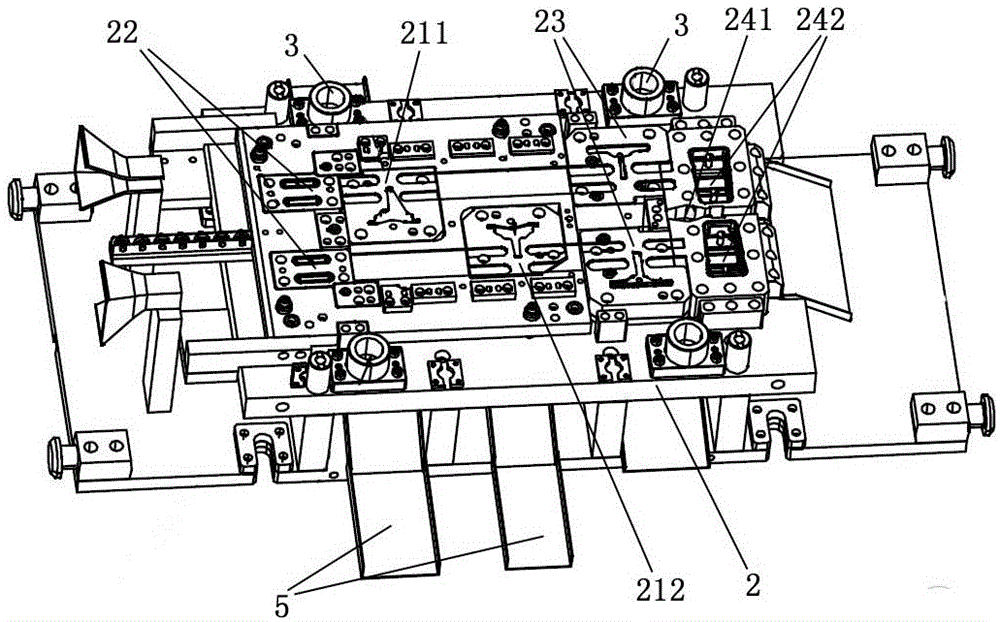

Continuous mold for manufacturing vehicle partition boards, and continuous manufacturing method

InactiveCN104998968AGuarantee processing qualityIntegrity guaranteedShaping toolsVehicle componentsEngineeringContinuous manufacturing

The invention aims to provide a continuous mold for manufacturing vehicle partition boards. The continuous mold comprises an upper mold and a lower mold, wherein guide tables and guide pillars, which mutually correspond, are respectively arranged on the upper mold and the lower mold; the upper mold is provided with an incision cutter group, two forming convex molds, two edge trimming cutters and a cut-off bending convex mold; the two forming convex molds are distributed in mirror symmetry on both sides in the transverse direction of the upper mold; the two edge trimming cutters are distributed in mirror symmetry on both sides in the transverse direction of the upper mold; the lower mold is provided with incision concave molds, forming concave molds, edge trimming concave molds and cut-off bending concave molds, corresponding to the upper mold. The invention further provides a continuous manufacturing method of the vehicle partition boards, which utilizes the continuous mold. The continuous mold and the manufacturing method, which are provided by the invention, have the characteristics of being simple in structure, simple and convenient to operate, high in efficiency and low in cost.

Owner:柳州市楷都汽车零部件有限公司

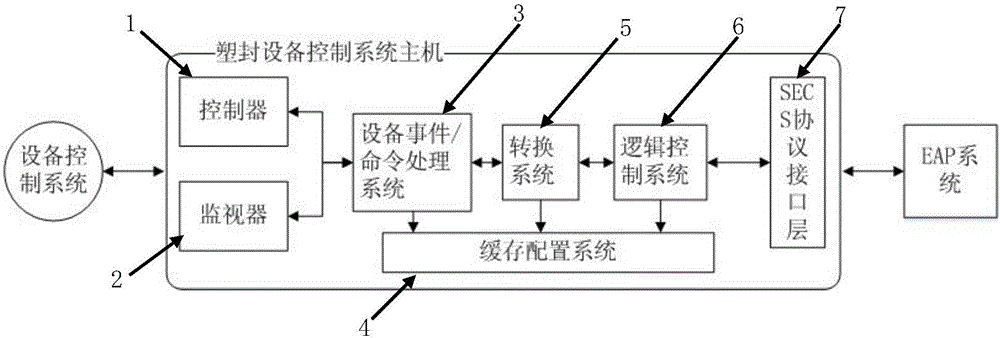

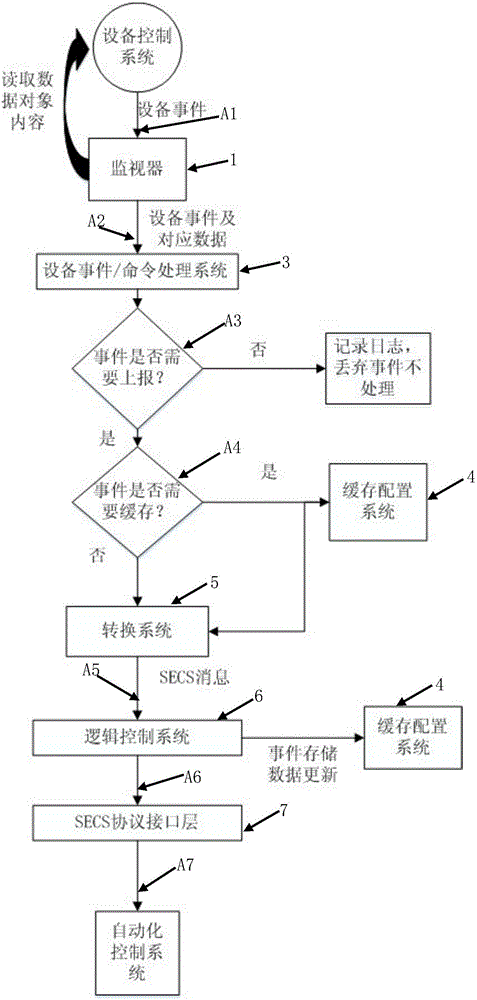

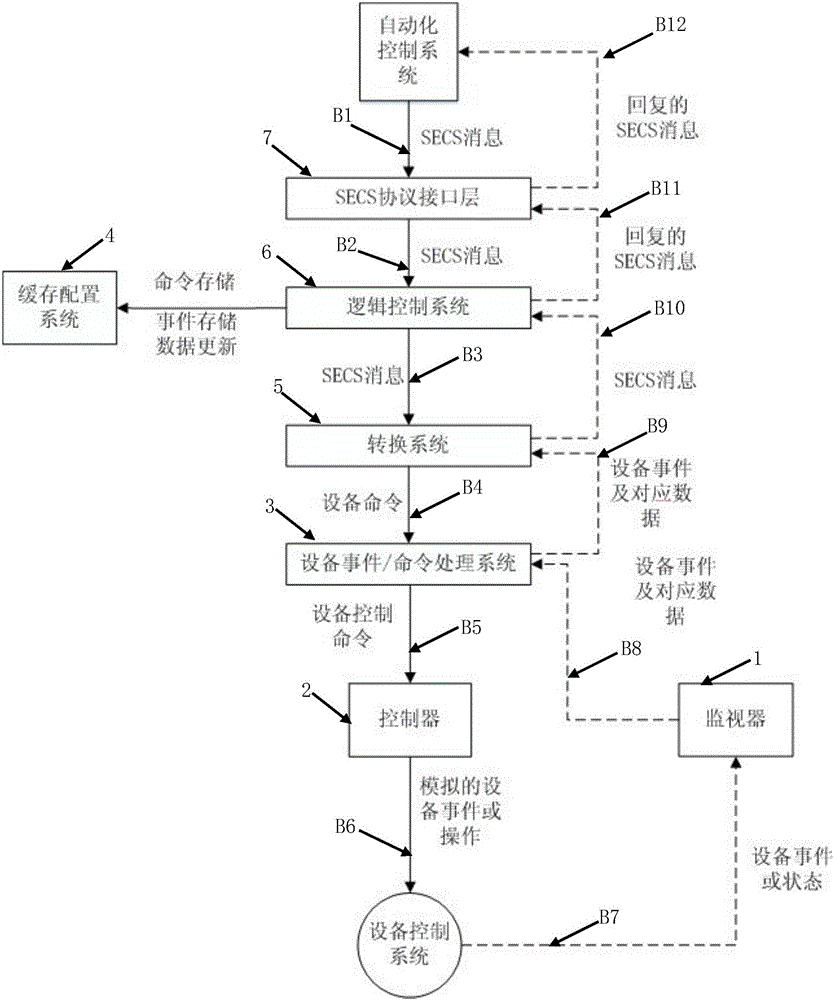

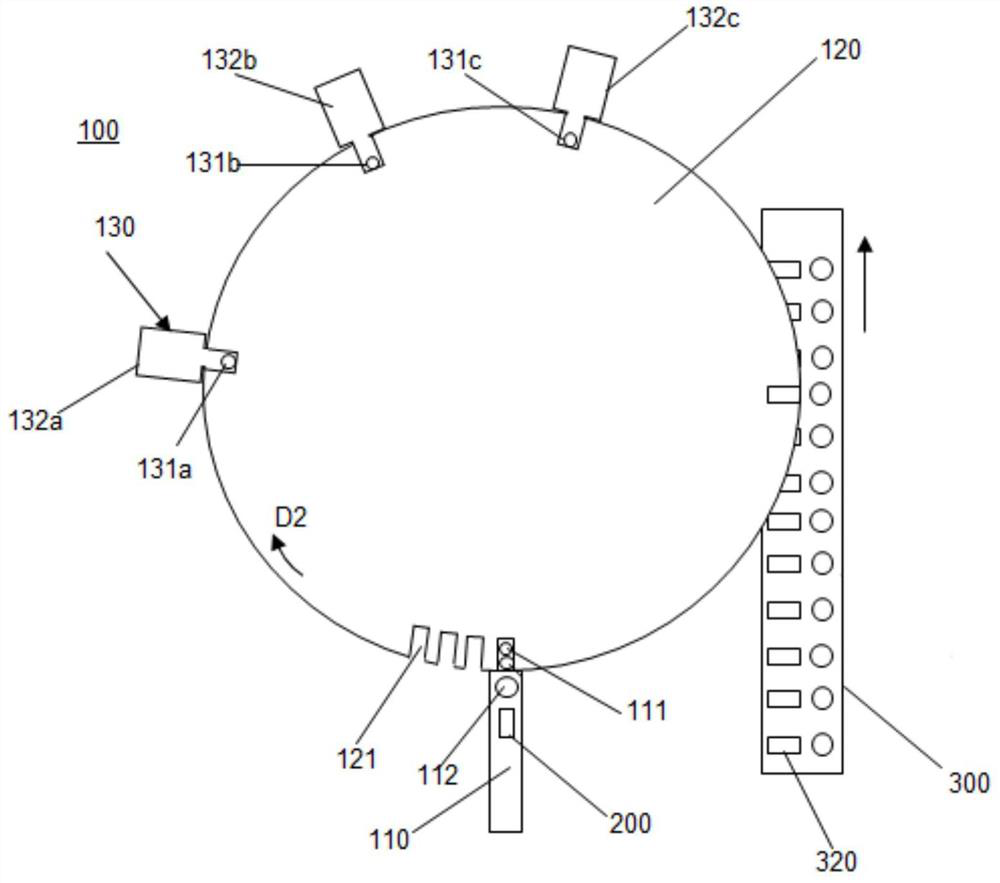

Monitoring conversion control system

ActiveCN106468880AReduce discrepancyIncrease productivityAdaptive controlControl systemInterface layer

The invention provides a monitoring conversion control system, which is characterized by comprising a monitor, a controller, an equipment event / command processing system, a cache configuration system, a conversion system, a logic control system and an SECS protocol interface layer, and is characterized in that the monitor monitors events, operations and data objects of an equipment control system; the controller converts an equipment command into an operation or an event corresponding to the equipment control system, and sends the operation or the event to the equipment control system; the equipment event / command processing system is connected with the monitor and the controller, receives variations of the events, the operations and the data objects reported by the monitor, and receives an equipment command sent by the monitoring conversion control system; the cache configuration system is connected with the equipment event / command processing system, and stores configuration and system data of the monitoring conversion control system; the conversion system is connected with the equipment event / command processing system and the cache configuration system, and converts an SECS message, an equipment command or an event according to configuration in the cache configuration system; the logic control system is connected with the conversion system and the cache configuration system; and the SECS protocol interface layer is connected with the logic control system.

Owner:SHANGHAI GLORYSOFT CO LTD

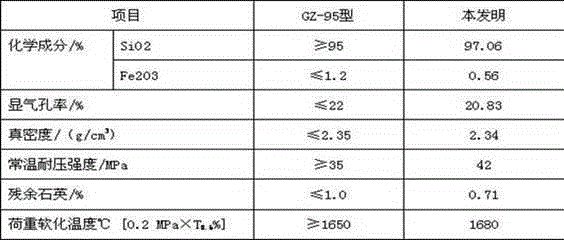

Preparation method of anti-erosion silica brick for carbon calcination furnace

The invention discloses a preparation method of an anti-erosion silica brick for a carbon calcination furnace. Calcined silica materials with different granularities are taken as main raw materials, a combustion aid, a compound additive, an enhancer and a binding agent are added, the raw materials are mulled, pressed, dried, then put into a kiln, and sintered under the thermal insulation condition for 24-30 hours at the temperature of 1,380 DEG C-1,440 DEG C, a finished product is formed and cooled to the normal temperature, and the anti-erosion silica brick is prepared. The high-temperature performance of the product is excellent, the compactness and the yield of finished products are improved, the erosion resistance is improved, and the service life of the carbon calcination furnace is greatly prolonged.

Owner:REFRACTORY MATERIAL OF SINOSTEEL CORP

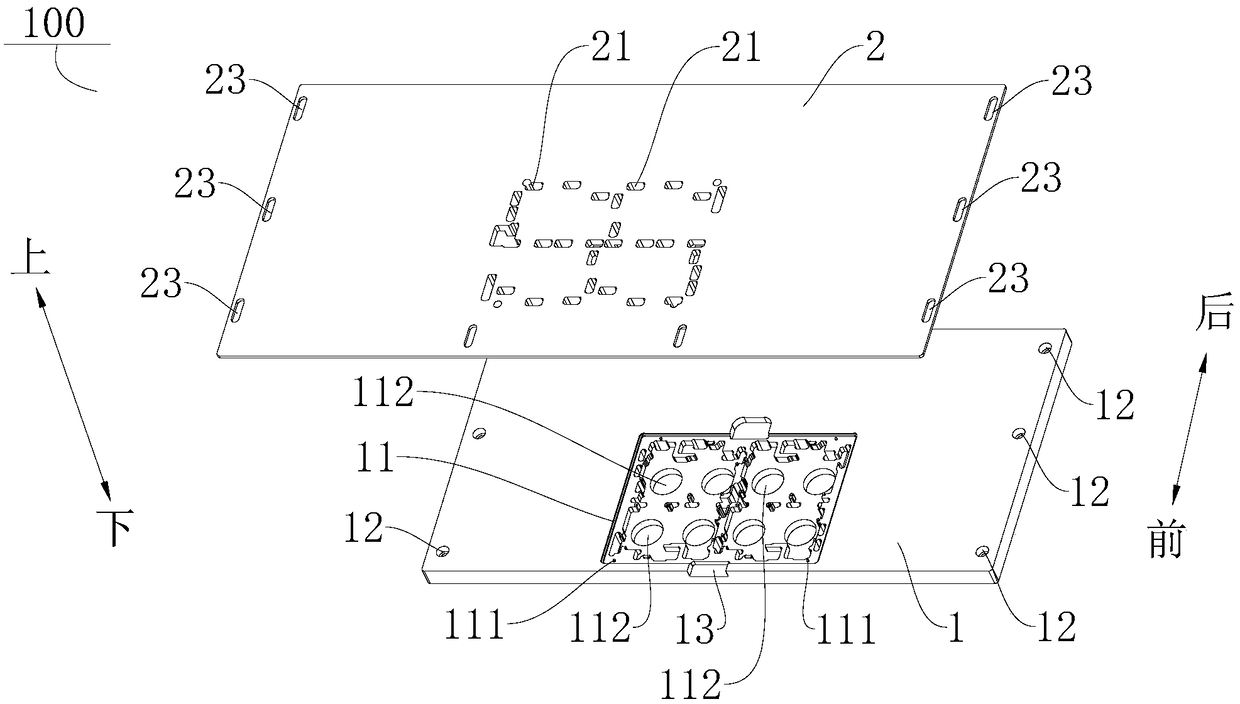

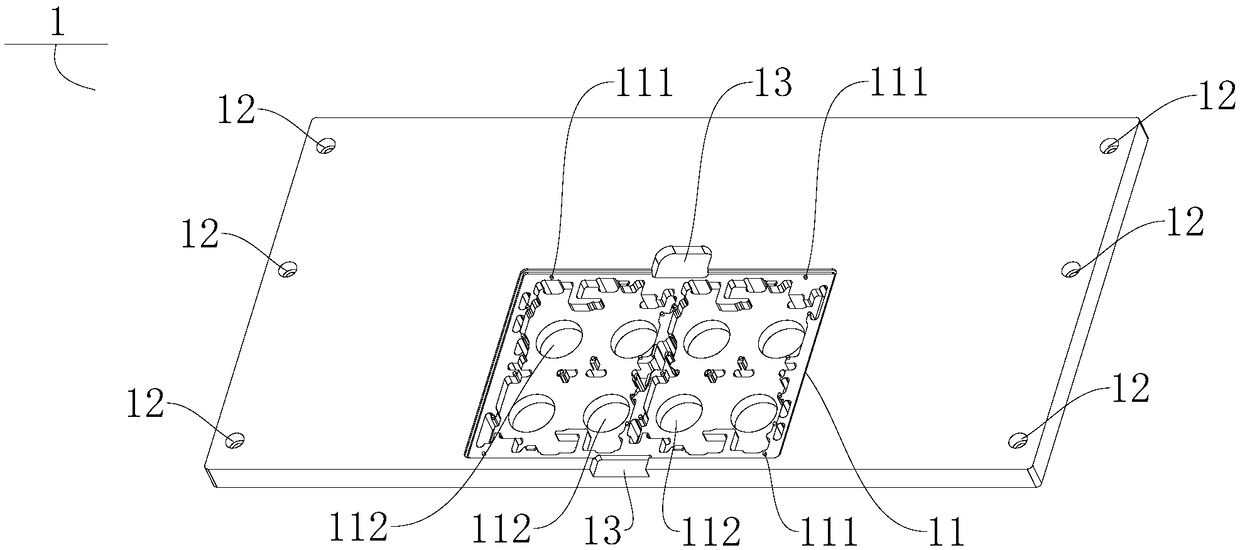

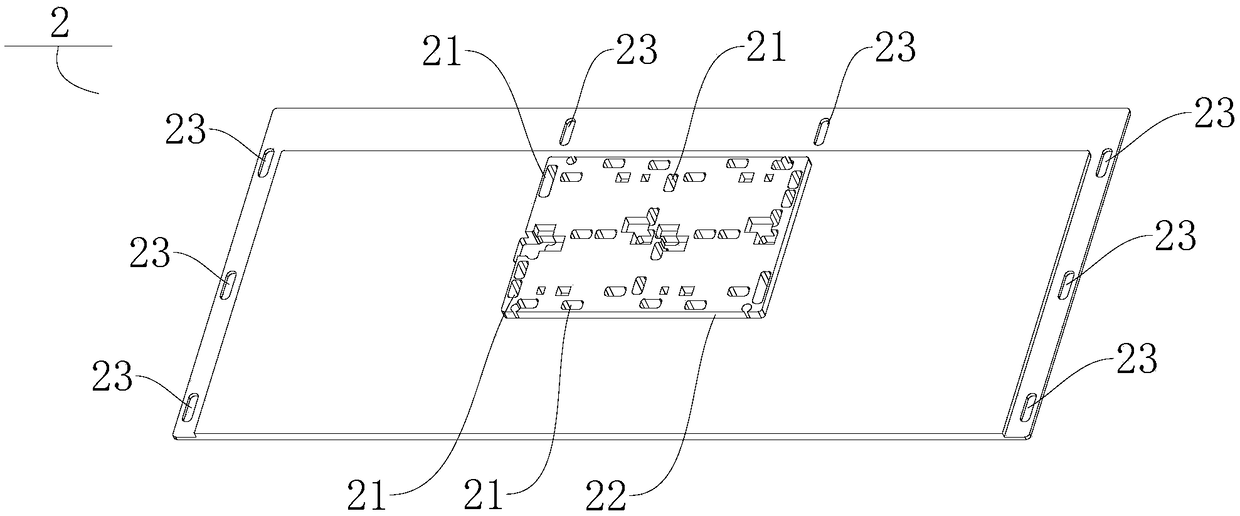

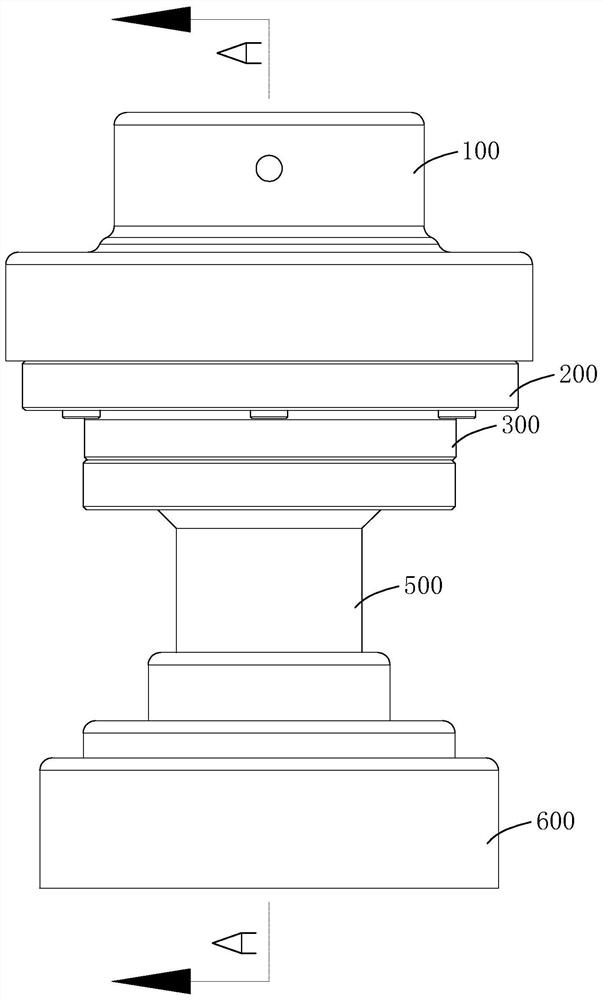

Board segmentation jig, board segmentation equipment and board segmentation method of circuit board

The invention discloses a board segmentation jig, board segmentation equipment and a board segmentation method of a circuit board. The circuit board comprises multiple subsidiary boards. Connecting ribs are connected between every two adjacent subsidiary boards. The board segmentation jig is suitable for segmenting the multiple subsidiary boards of the circuit board. The board segmentation jig comprises a first base plate and a second base plate, wherein the first base plate is provided with a storing groove, the interior of the storing groove is suitable for storing the circuit board, the second base plate and the first base plate are arranged in a stacked manner, the second base plate is provided with a penetration hole, and when the first base plate and the second base plate are stacked, the connecting ribs are opposite to the penetration hole. According to the board segmentation jig, the first base plate and the second base plate have a limiting effect on the circuit board, the cutting technology is adopted, and by means of penetration to the penetration hole of the second base plate, precise cutting of the connecting ribs can be achieved. In addition, in the circuit board cutting process, the circuit board can be produced and cut without manual operation and control, thus, intensity of manual operation is reduced, the production error is reduced, and the production efficiency is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

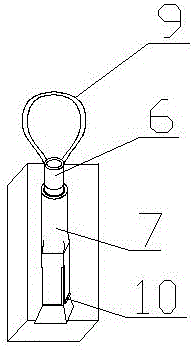

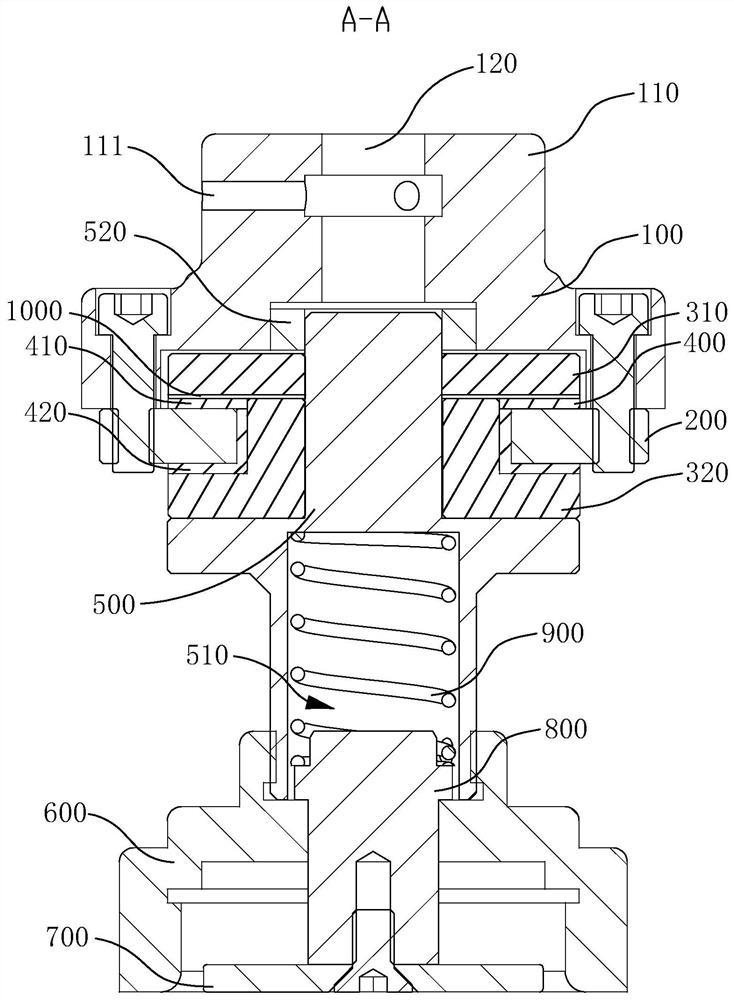

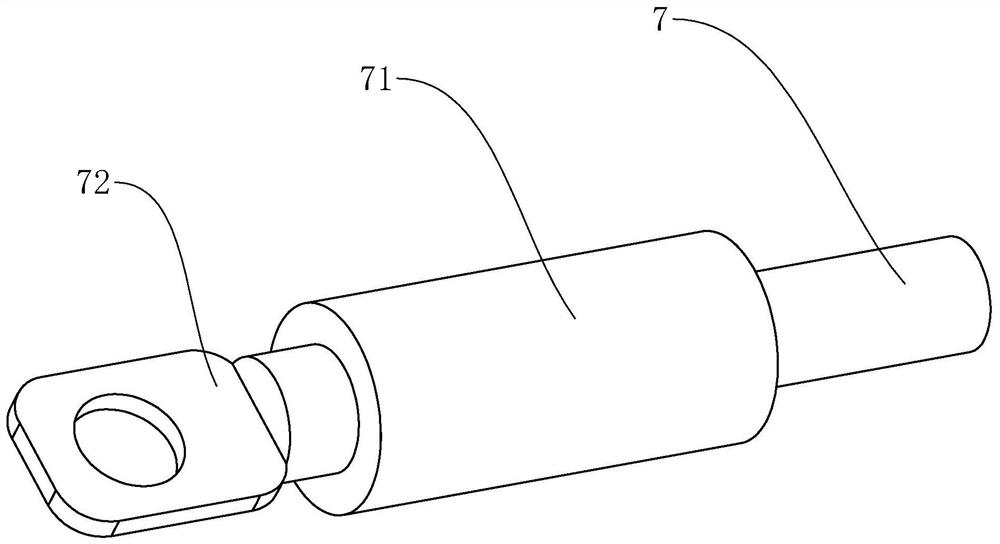

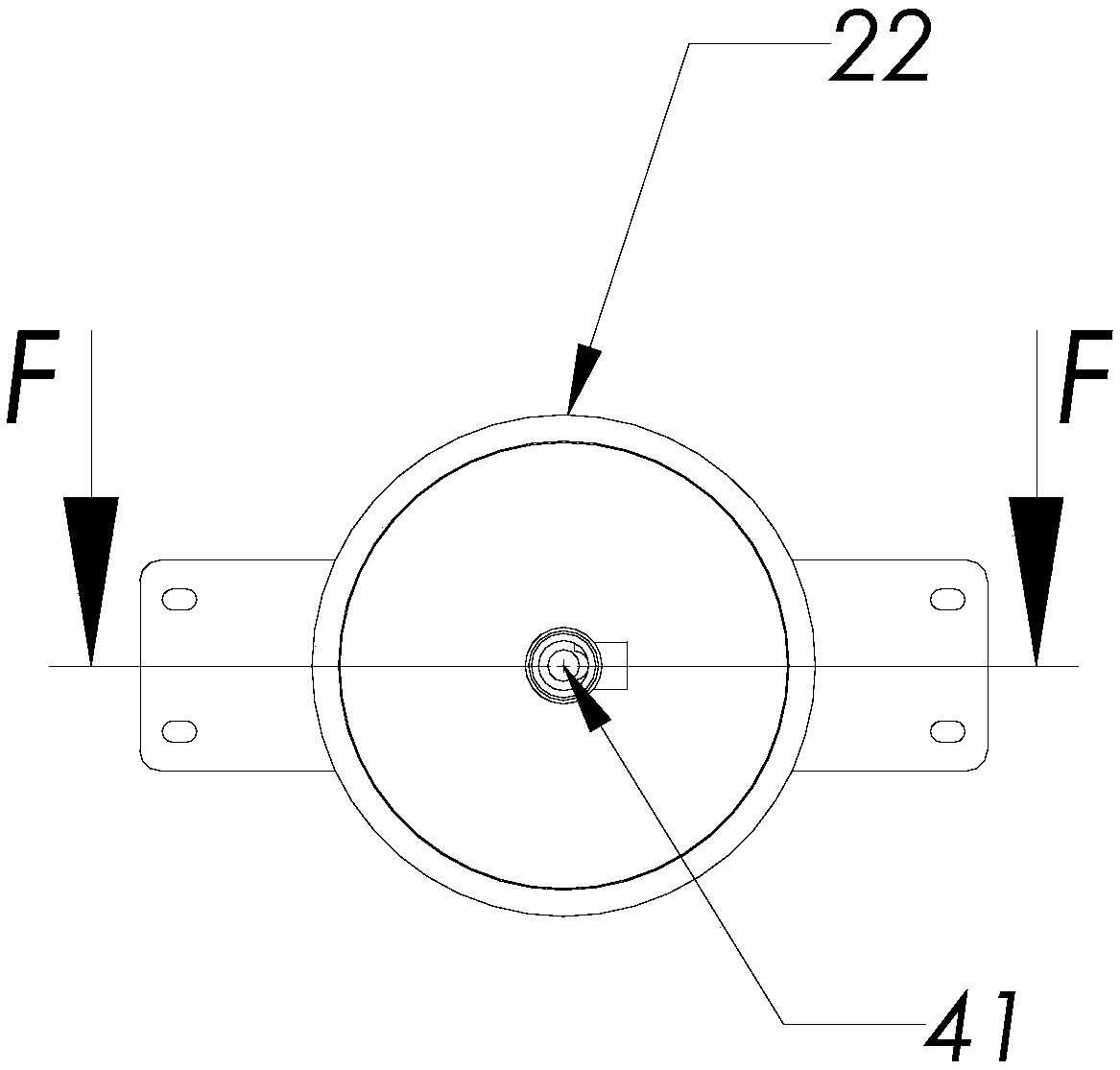

Cap screwing head friction clutch, cap screwing head and cap screwing machine of cap screwing head

PendingCN112758867AHigh precisionReduce production errorsCapsThreaded caps applicationDrive shaftBottle cap

The invention discloses a cap screwing head friction clutch, a cap screwing head and a cap screwing machine. The cap screwing head friction clutch comprises a connecting sleeve, a rotating disc, a fixing block and a connecting piece, wherein the connecting sleeve is used for being connected with a driving shaft of the cap screwing machine, the rotating disc and the connecting sleeve are coaxially arranged, the rotating disc is fixedly connected with the connecting sleeve, the fixing block and the connecting sleeve are coaxially arranged, a first groove is formed in the circumferential surface of the fixing block in a surrounding manner, and the fixing block comprises a first fixing block body and a second fixing block body, a second groove is formed in the circumferential surface of the connecting piece in a surrounding manner, and the rotating disc is connected with the fixing block through the connecting piece. According to the cap screwing head friction clutch, after a bottle cap is screwed, rotation between the cap screwing head and the driving shaft is smooth, the screwing accuracy of the bottle cap can be improved, and production errors are reduced.

Owner:佛山市金科机械设备有限公司

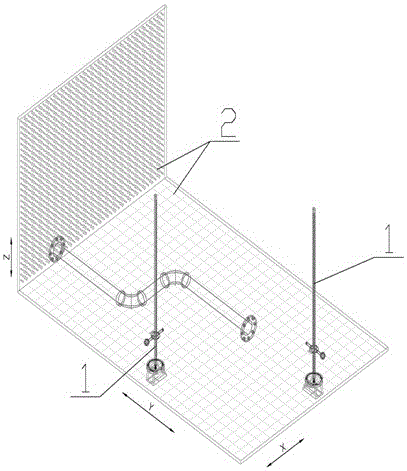

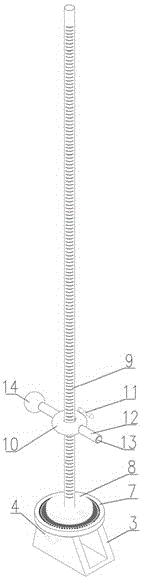

Pipe check platform instrument

ActiveCN105136032AReduce production errorsImprove working environmentUsing optical meansMeasurement deviceEngineering

The invention discloses a pipe check platform instrument, characterized by comprising a fixed mounting platform and a plurality of measurement mechanisms. The fixed mounting platform comprises a horizontal reference plate with an X graduation line and a Y graduation line, and a vertical reference plate perpendicular to the horizontal reference plate; the vertical plate is provided with connection apertures used for fixing installation flanges of a detected pipe. Each measurement mechanism comprises a scale column, and a base capable of being fixed to the horizontal reference plate; the base is provided with a panel; the scale column is provided with an infrared ray projector capable of sliding up and down along the scale column; the lower end of the scale column is fixedly provided with a rotary angle disc; the rotary angle disc is in connection with the panel, and can rotate relative to the panel.

Owner:GUANGXIN SHIPBUILDING & HEAVY IND

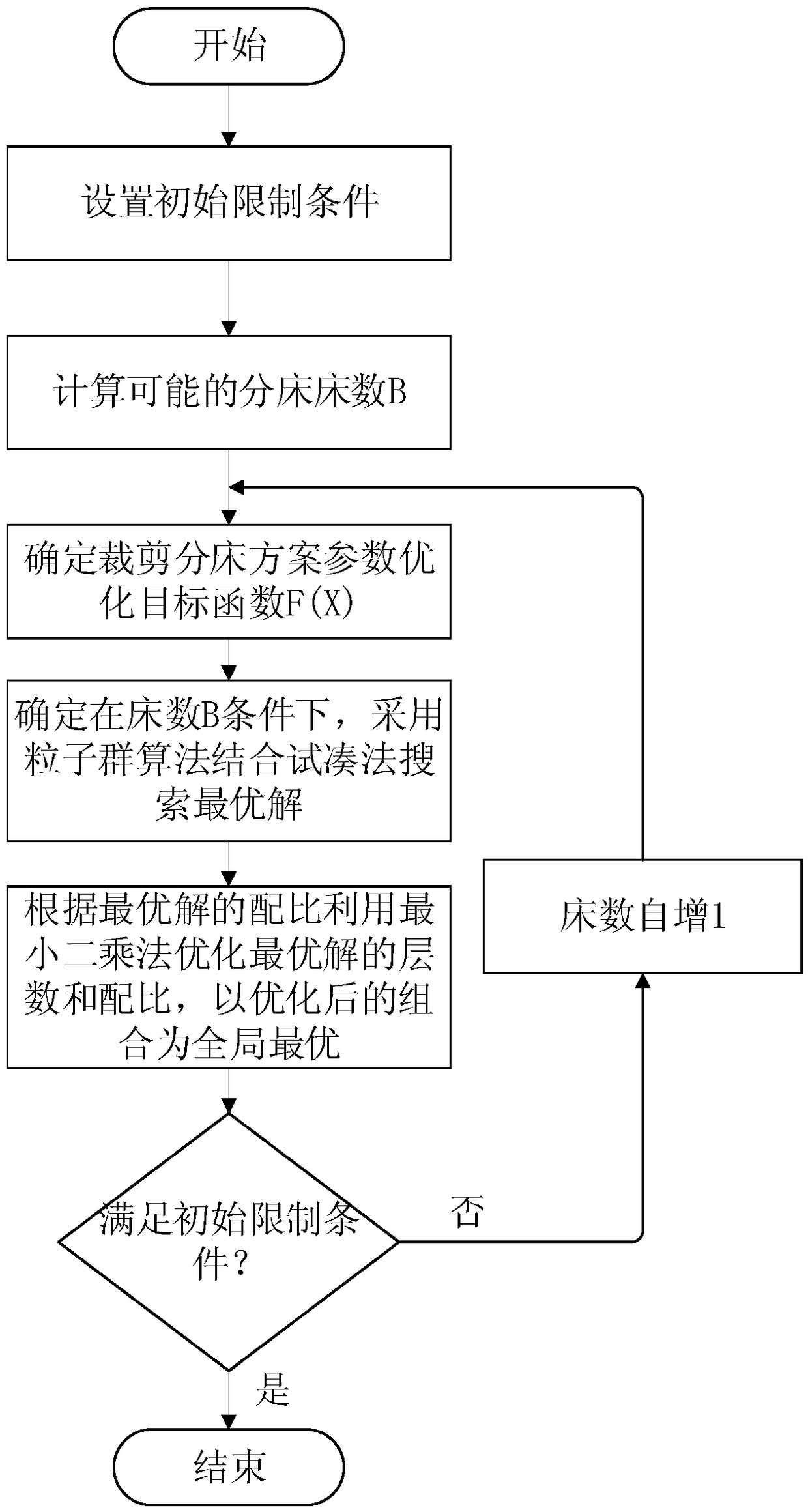

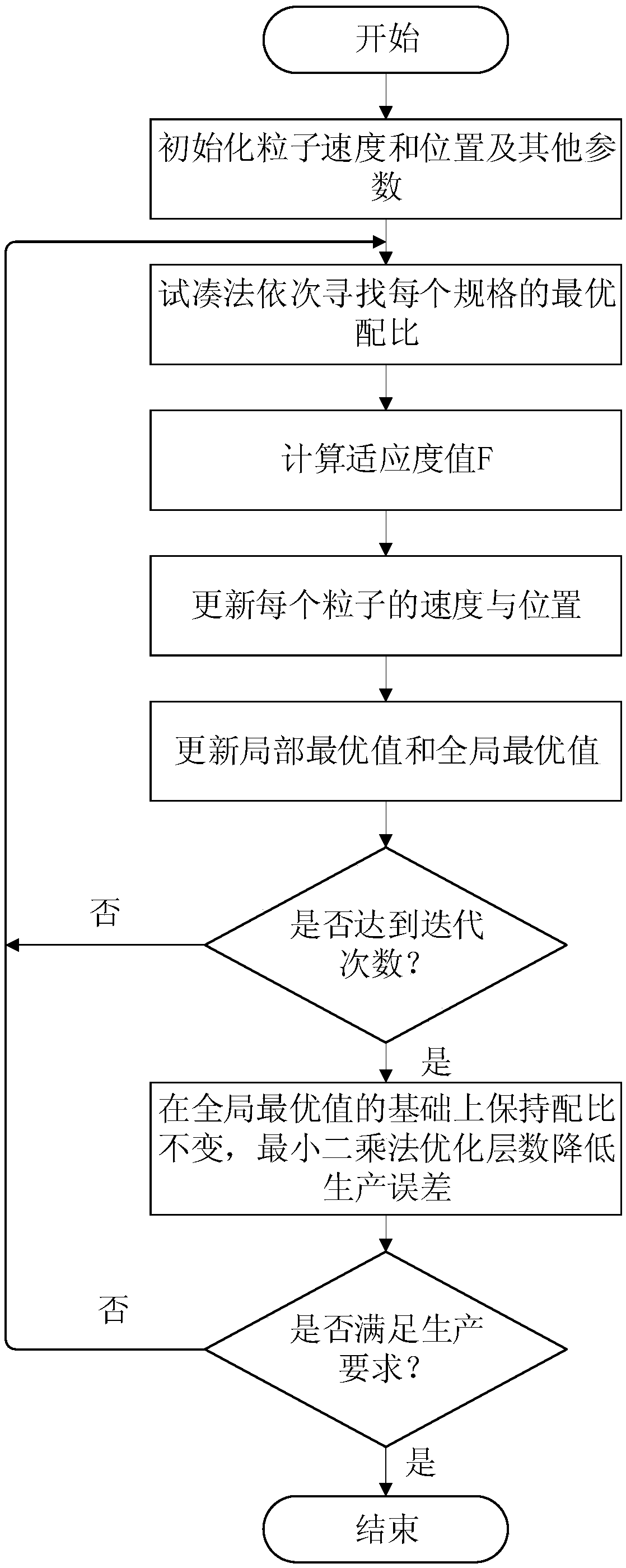

Method of garment cutting bed splitting based on trial-and-error particle swarm optimization

ActiveCN109359313AReduce production errorsFast convergenceComputer aided designSpecial data processing applicationsEngineeringSwarm algorithms

A method of garment cutting bed splitting based on trial-and-error particle swarm optimization is proposed. Based on the relatively fixed short interval integer matching problem, the trial-and-error method is used to quickly select the optimal matching ratio, and then combined with particle swarm optimization algorithm, the ideal combination scheme of cutting layers and nesting ratio can be obtained quickly. The hybrid algorithm makes use of the fast convergence of particle swarm optimization algorithm to enhance the global convergence of the algorithm and converge to the global optimal solution of the standard particle swarm optimization algorithm. Then the least square method is used to optimize the global optimal solution to reduce the experimental error, and then the optimal parametercombination in the garment cutting bed-splitting method can be obtained quickly. The invention provides an intelligent garment cutting bed splitting method capable of realizing quick bed splitting, effectively improving precision and effectively processing different garment orders.

Owner:ZHEJIANG UNIV OF TECH

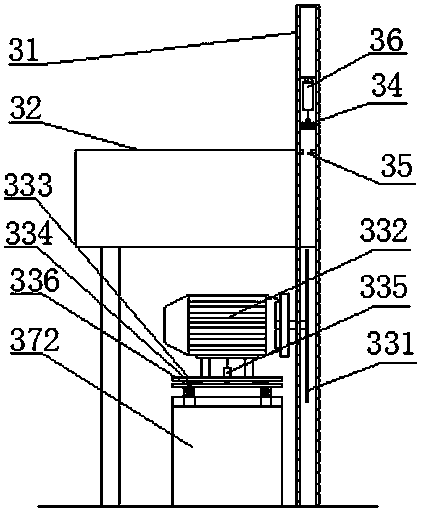

Vacuum low-temperature baking equipment for preparing hawthorn powder

ActiveCN112075465AIncrease the feeding speedHigh precisionBaking ovenSpecial goods bakingMechanical engineeringIndustrial engineering

The invention discloses vacuum low-temperature baking equipment for preparing a hawthorn powder. The vacuum low-temperature baking equipment comprises a baking box, wherein a first sealing plate is arranged on one side of the baking box, a second sealing plate is arranged on the baking box, a rotating frame is arranged in the baking box, the rotating frame comprises rotating wheels distributed ina mirror image manner, rotating plates are arranged between the rotating wheels, a baking tray is arranged on each rotating plate, feeding apparatus is arranged above the baking box, material taking apparatus is further arranged on one side of the baking box, the material taking apparatus comprises a bottom support, and a moving frame is arranged above the bottom support. The vacuum low-temperature baking equipment adopts automatic design, the feeding speed is high, the accuracy is high, the production error is reduced, the working efficiency is improved, the baking box adopts rotary baking, the baking effect is good, the speed is high, the manual operation is not needed for material taking, the material taking apparatus can automatically finish material taking, the damage caused by manualmaterial taking is avoided, and thereby the safety is improved.

Owner:天马(安徽)国药科技股份有限公司

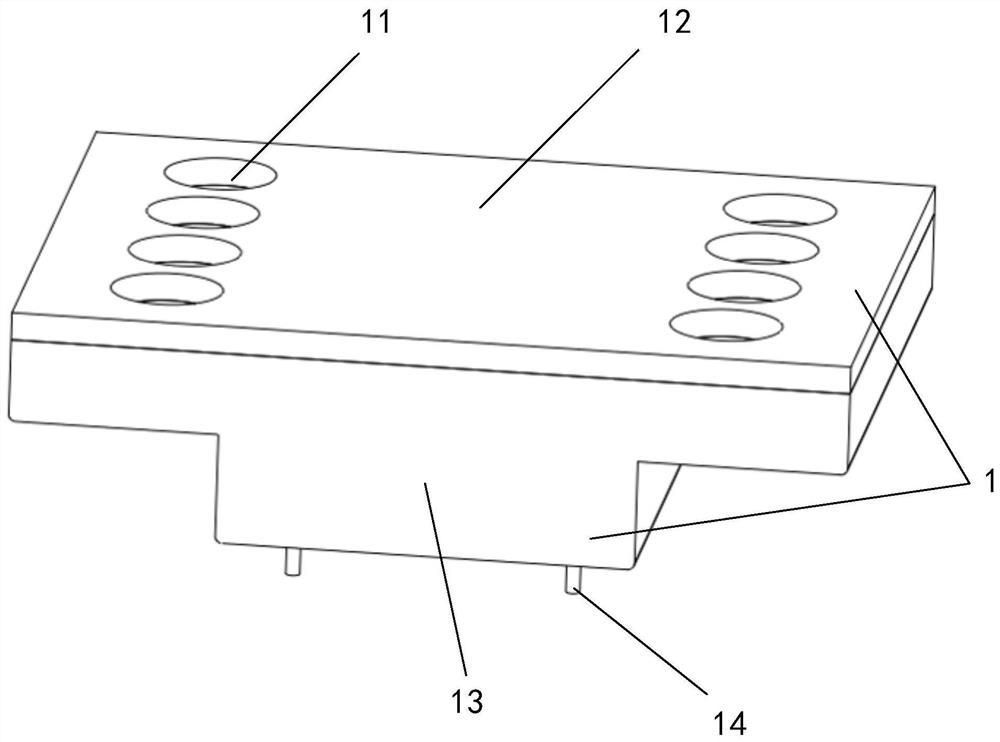

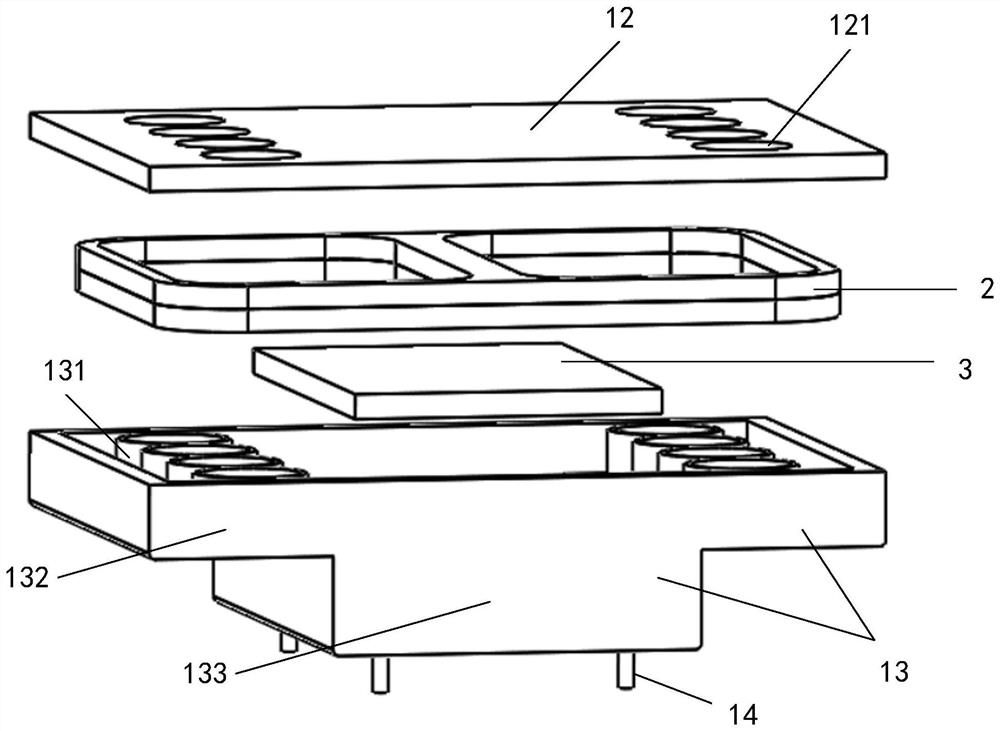

Installation structure of current sampling resistor

InactiveCN106251997AAccurate resistance measurementEasy to manufactureResistor terminals/electrodesBase element modificationsPower flowInsertion depth

The invention provides an installation structure of a current sampling resistor, belongs to the technical field of electronic products, and aims at solving the problem that a current sampling value of an existing current sampling resistor is inaccurate due to an insecure installation mode. The installation structure of the current sampling resistor comprises a current using resistor inserted into a PCB, wherein the current using resistor comprises a sampling end and two wire rods arranged at two sides of the sampling end; each wire rod comprises a first wire segment and a second wire segment; one end of each first wire segment is connected with the sampling end and the other end of each first wire segment is connected with the corresponding second wire segment; the arrangement direction of each first wire segment is parallel to the surface of the PCB; and the arrangement direction of each second wire segment is vertical to the surface of the PCB. By the installation structure, the insertion depths of two ends of the current sampling resistor are consistent, so that the resistance measurement accuracy of the sampling resistor is ensured to ensure the accuracy of the sampling current value.

Owner:浙江朗科智能电气有限公司

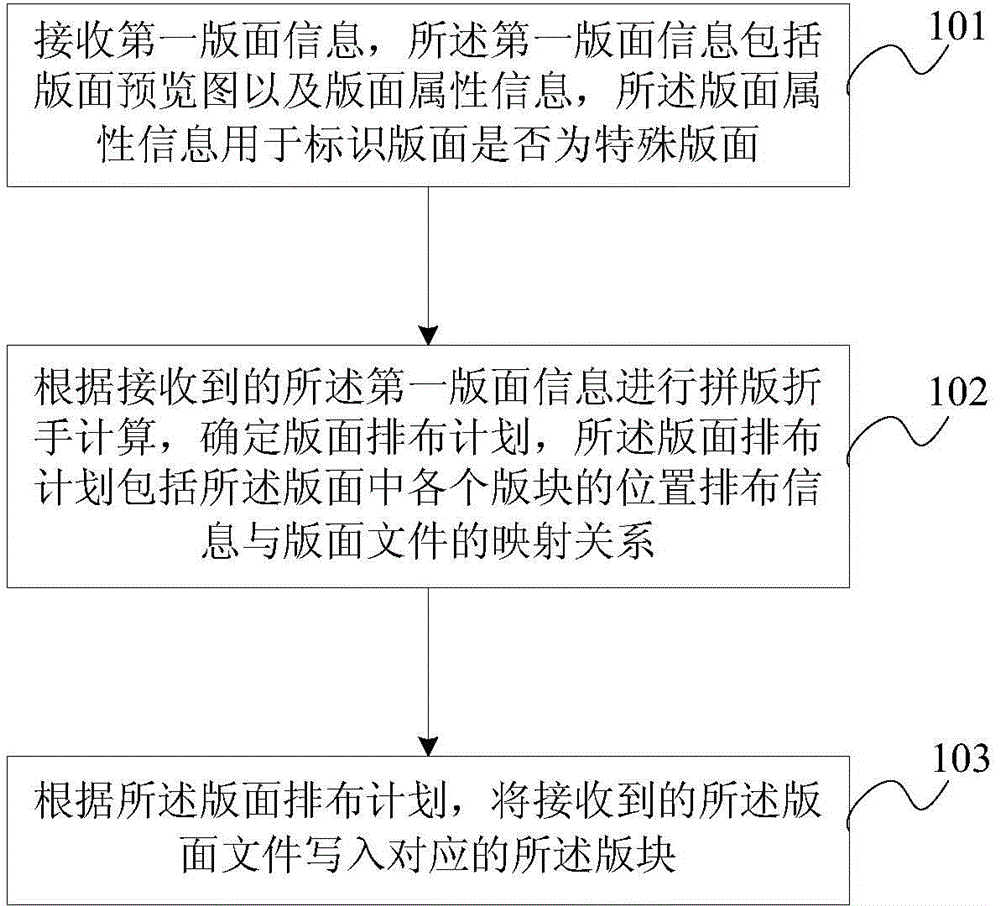

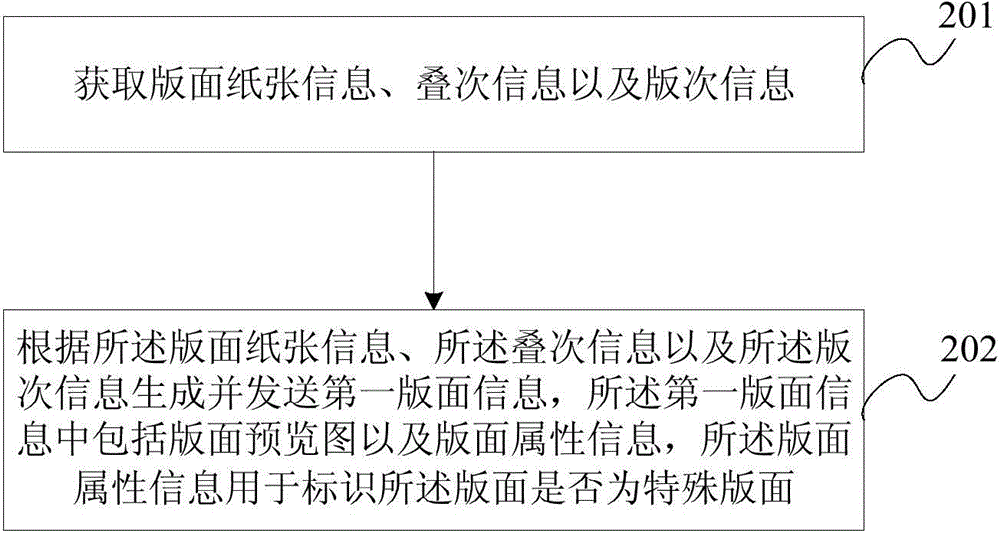

Page layout method, device and system

InactiveCN105573974AImplement upside-down orchestrationReduce production errorsNatural language data processingSpecial data processing applicationsProgram planningInverted order

The invention provides a page layout method, device and system. The method comprises the steps of receiving first page information, wherein the first page information comprises a page preview and page attribute information which is used for identifying whether the page is a special page or not; carrying out page imposing calculation according to the received first page information, determining a page layout plan, arranging the special page in an inverted order and overturning at the degree of 180; and writing the received page file to a corresponding section according to the page layout plan. Therefore, the inverted layout of the pages is realized and the production mistake is reduced.

Owner:NEW FOUNDER HLDG DEV LLC +1

Stainless steel sloping plate forming equipment

PendingCN108326098AIncrease productivityReduce labor costsMetal-working feeding devicesShearing machinesWave shapeMaterials science

Owner:ZHEJIANG LIANCHI WATER EQUIP

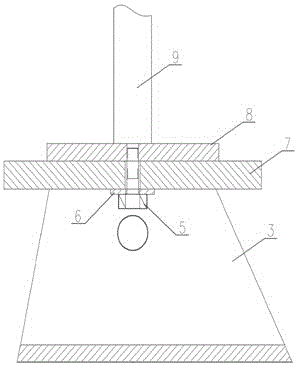

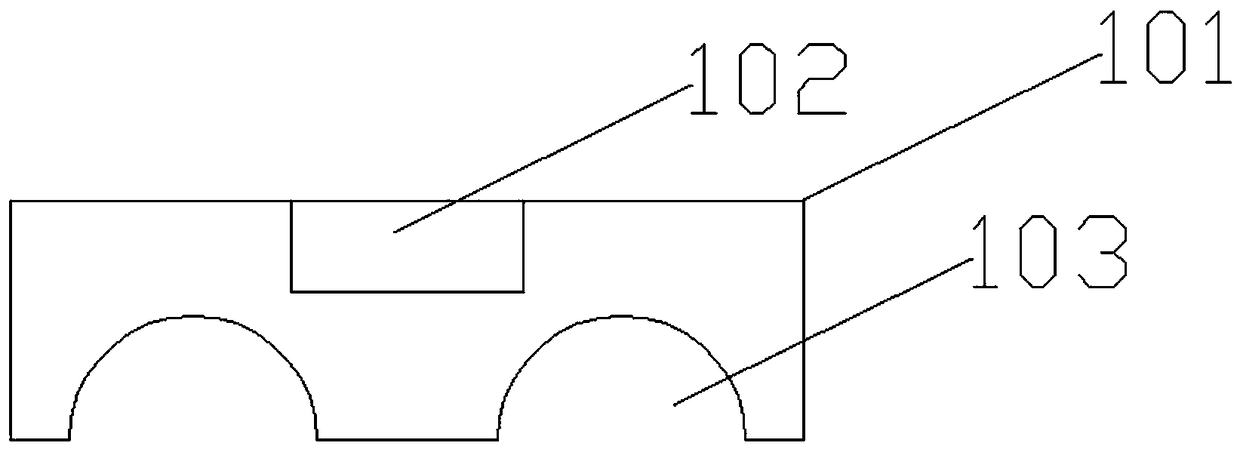

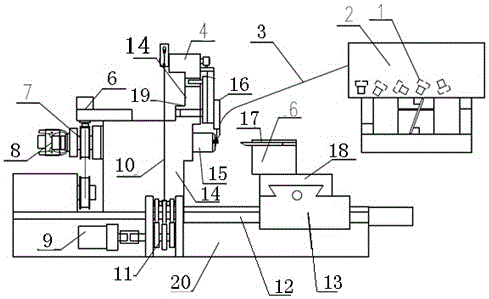

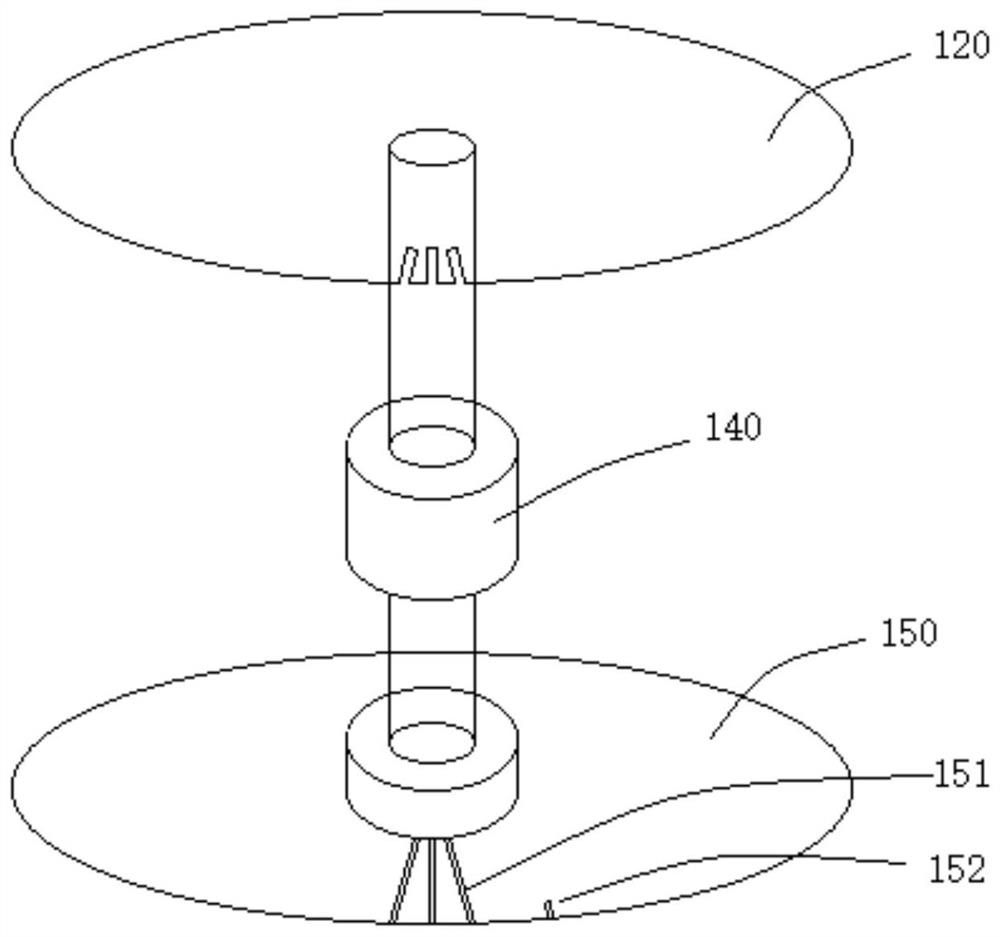

A forming device for aluminum parts of automobile brakes

ActiveCN107520412BReduce handlingAvoid damageFoundry mouldsMoulding machinesEngineeringVehicle brake

The invention discloses a vehicle brake aluminum part molding device. The device comprises a base; the base is provided with a support rod and a bracket; the support rod is provided with a bearing 1; a separation plate sleeves the bearing 1; a limiting plate 1 is arranged at the front end of the separation plate; an upper model is arranged at the upper end of the separation plate, and is provided with a pouring pipe; a lower model is arranged at the lower end of the separation plate; a limiting plate 2 is arranged on the side surface of the bracket; a two-way lead screw is arranged in the bracket; a fixed base is arranged at the bottom of the two-way lead screw; a stepper motor is arranged at the upper end of the bracket; a main shaft of the stepper motor is connected with the two-way lead screw; nut bases are respectively arranged at two ends of the two-way lead screw; an upper sand box and an upper support base are respectively arranged at two ends of the nut base at the upper end; a pressing column is arranged at the bottom of the upper support base; a lower sand box and a lower support base are respectively arranged at two ends of the nut base at the lower end; a seepage plate is arranged at the bottom of the lower sand box; and a molding core box is arranged at the upper end of the lower support base. The device is high in machining efficiency, low in production error, simple in operation and excellent in economic benefit.

Owner:芜湖市云峰铸造有限责任公司

Flexible shearing device

ActiveCN104511642ASolve technical problems with excessive gapsQuality improvementShearing machinesMetal working apparatusEngineeringMechanical engineering

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

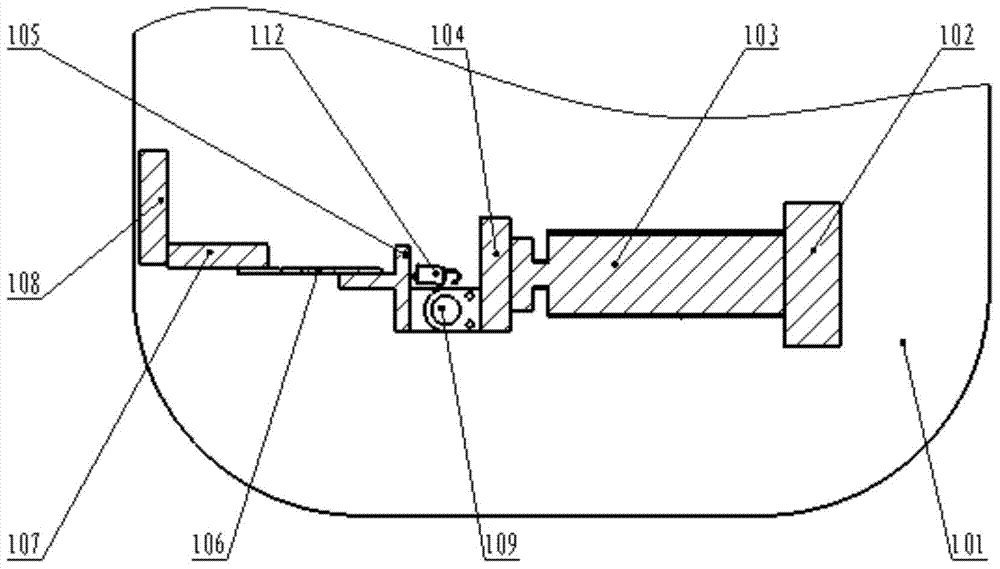

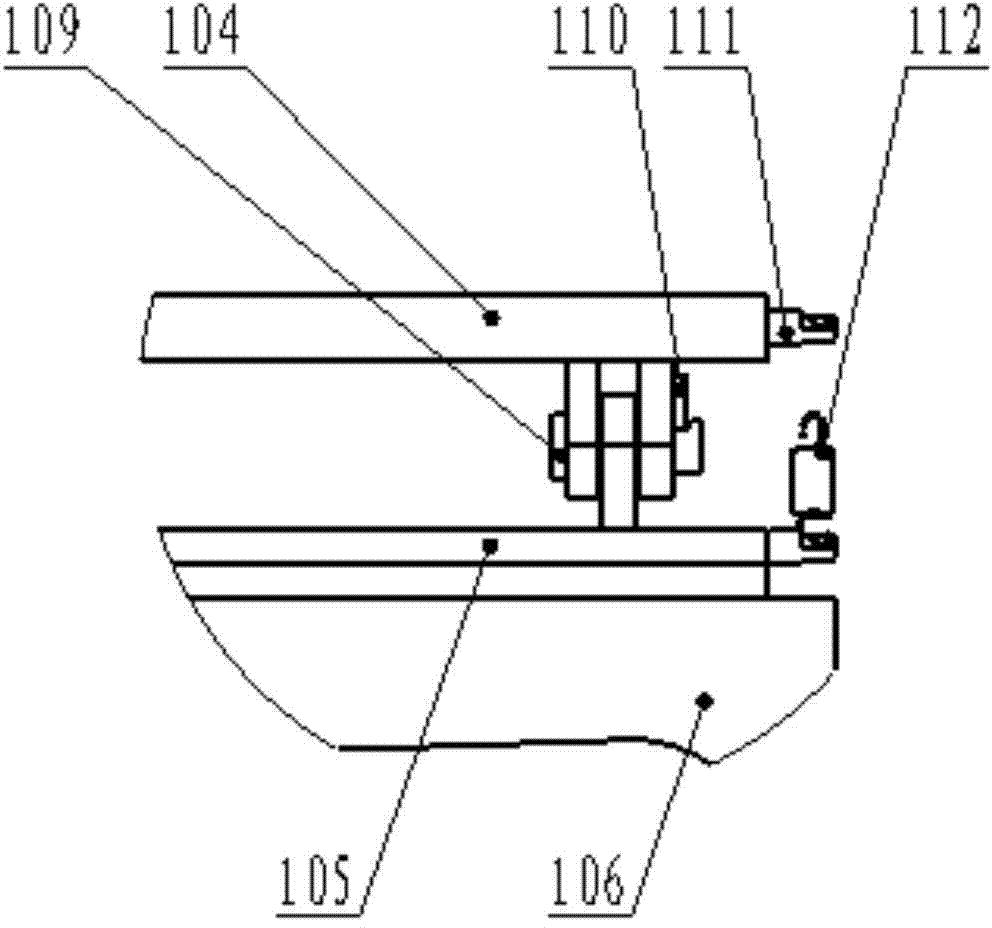

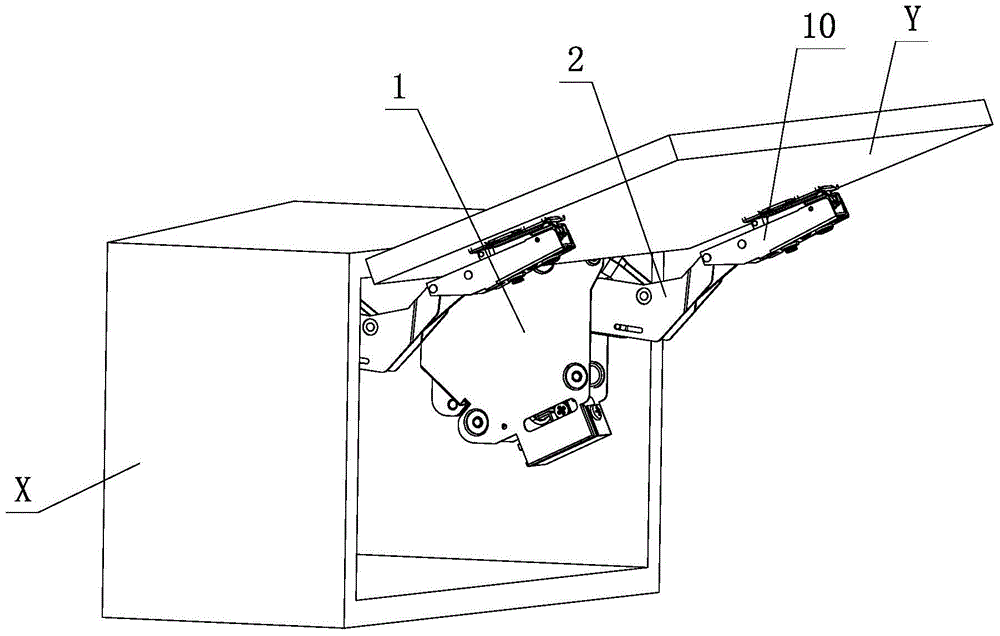

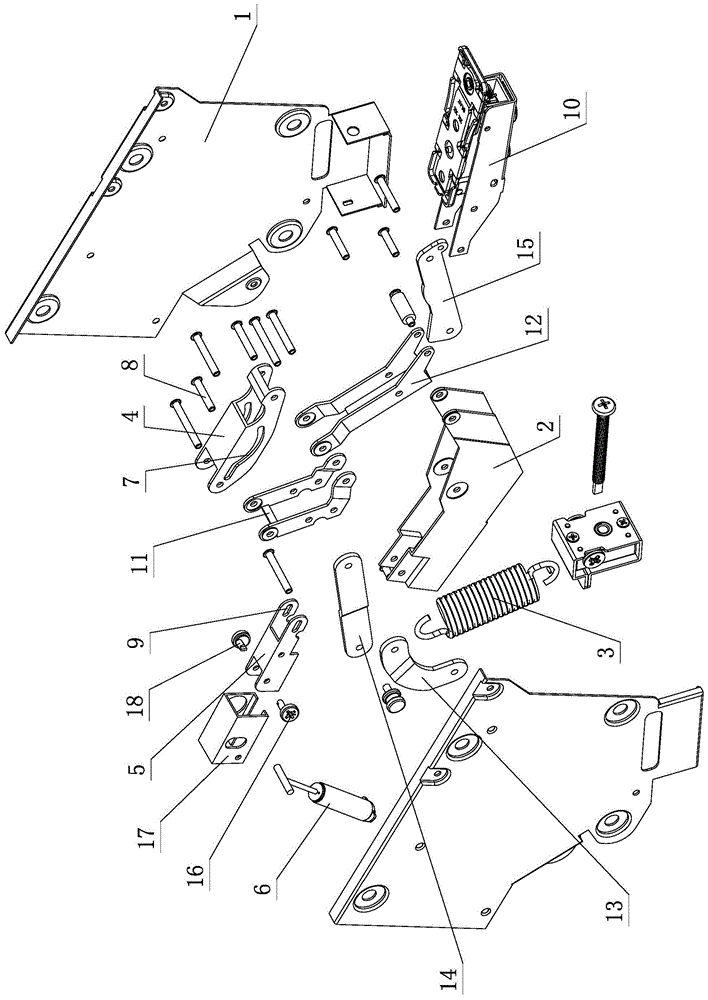

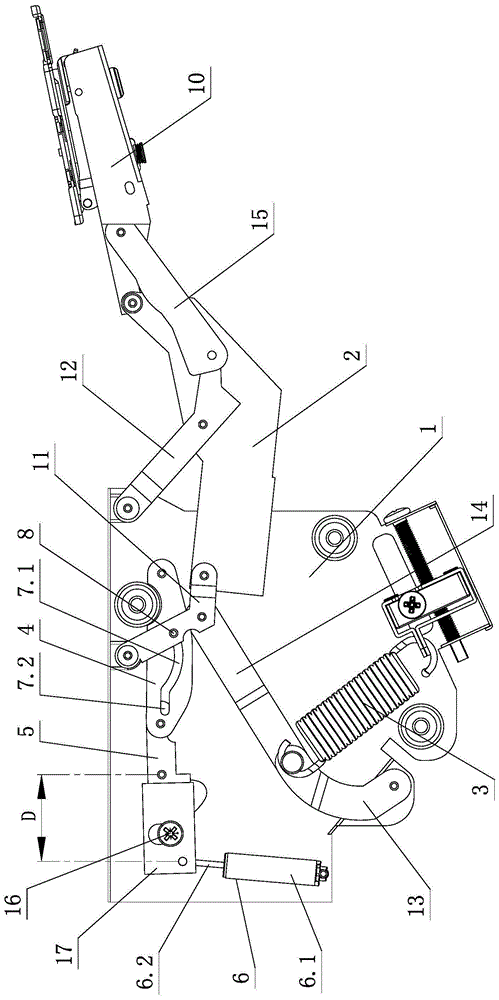

Adjustable furniture damping control structure

ActiveCN105041091BOpen smoothlyAccurate openingBuilding braking devicesPin hingesEngineeringControl theory

An adjustable furniture damping operation structure comprises a fixing seat, a hinge arm, a spring, a connecting arm assembly and a stop element. The connecting arm assembly at least comprises a first connecting arm and a second connecting arm. One end of the first connecting arm and one end of the second connecting arm are hinged to the fixing seat and the other end of the first connecting arm and the other end of the second connecting arm are hinged to the hinge arm. The stop element is hinged to the hinge arm and turned over, opened and closed to the fixing seat through the spring. A damping device in transmission fit with a lever is arranged on the fixing seat. The damping device comprises a swing rod element, a lever element and a damper. The first connecting arm at least drives the swing rod element when the stop element is closed, the swing rod element drives the lever element to act on the damper, and the damper is compressed so as to achieve the buffer effect. An adjusting assembly is arranged on the damping device and used for adjusting the position of the swing rod element or the lever element or the damper relative to the fixing seat, so that force acting on the damper by the swing rod element and / or the lever element is increased or decreased, and finally the buffer force is adjusted when the stop element is closed.

Owner:伍志勇

Cloud monitoring building material mould

PendingCN109986682AReduce manufacturing costGuaranteed accuracyMould auxillary partsTransmissionEngineeringMachining

The invention provides a cloud monitoring building material mould, and mainly relates to the field of building material forming equipment. The mould comprises a base, wherein the top surface of the base is provided with a plurality of supporting beams; the tops of the supporting beams are provided with a plurality of baffles in sliding connection with the supporting beams; the bottoms of the baffles are provided with opening and closing devices, and power systems are arranged on the opening and closing devices; positioning strips are detachably and fixedly arranged at the corresponding position of each baffle; mould heads are slidably arranged on the positioning strips, and the mould heads separates two adjacent baffles into mould forming cavities. The device has the advantages that the machining error can be reduced through horizontally adjusting the device; products with different specifications can be produced by using the same mould through adjusting the positioning strips; and theproduction cost of the mould is saved.

Owner:SHENZHEN MYX PC BLOCKS CO LTD

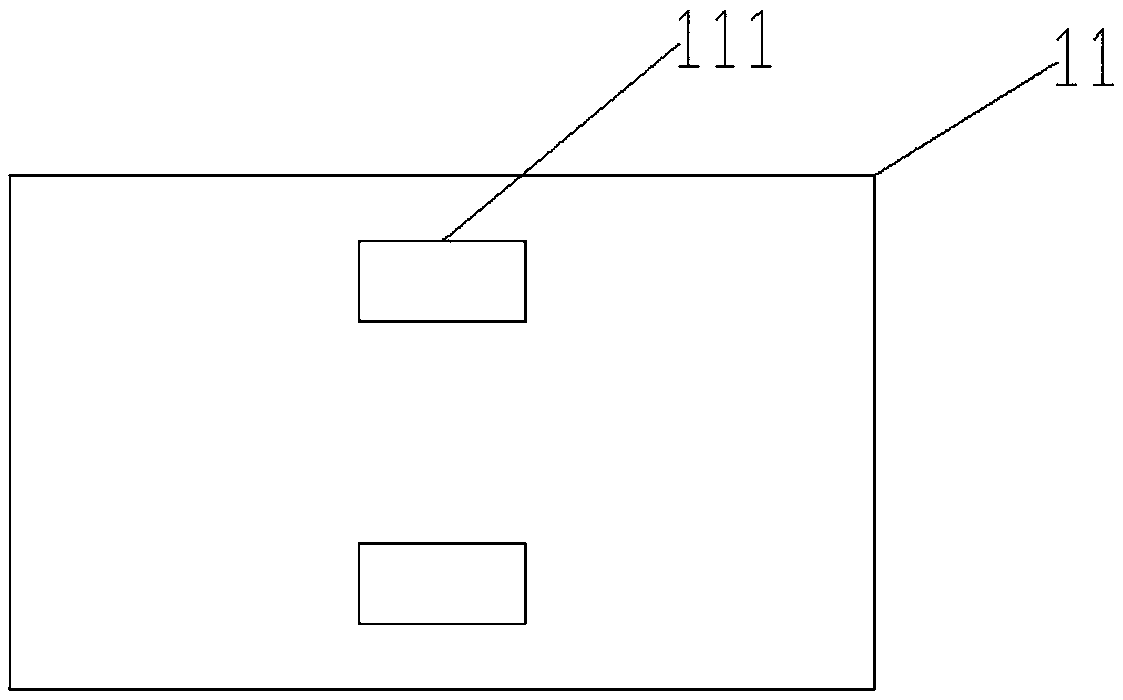

Semi-automatic electrical cabinet auxiliary wiring and pairing integrated system and use method thereof

PendingCN113097830AReduce production errorsImprove efficiencyCoupling device engaging/disengagingConnection formation by deformationInformation controlComputer printing

The invention relates to a semi-automatic electrical cabinet auxiliary wiring and pairing integrated system and a use method thereof, and relates to the field of electrical control cabinet wiring equipment. The semi-automatic electrical cabinet auxiliary wiring and pairing integrated system comprises a wiring control device and a wiring execution device, and the wiring control device comprises an input mechanism, a control mechanism and a display mechanism; information input by the input mechanism comprises the length of a wire, the wiring sequence of the wire, the connection relation between the wire and a wire marking pipe and the connection relation between the wire and a component, the control mechanism processes the information input by the input mechanism and displays the input information through the display mechanism, and the control mechanism is electrically connected with the input mechanism and the display mechanism; and the wiring execution device comprises a cutting machine, a printer and a terminal crimping machine, the cutting machine and the printer are electrically connected with the control mechanism, and the control mechanism controls the cutting machine and the printer to work according to information input by the input mechanism. The system has the advantages that the possibility of lead manufacturing errors caused by negligence of workers is reduced, and meanwhile the lead manufacturing efficiency and the electric control cabinet wiring efficiency are improved.

Owner:常州瓦良格电气有限公司

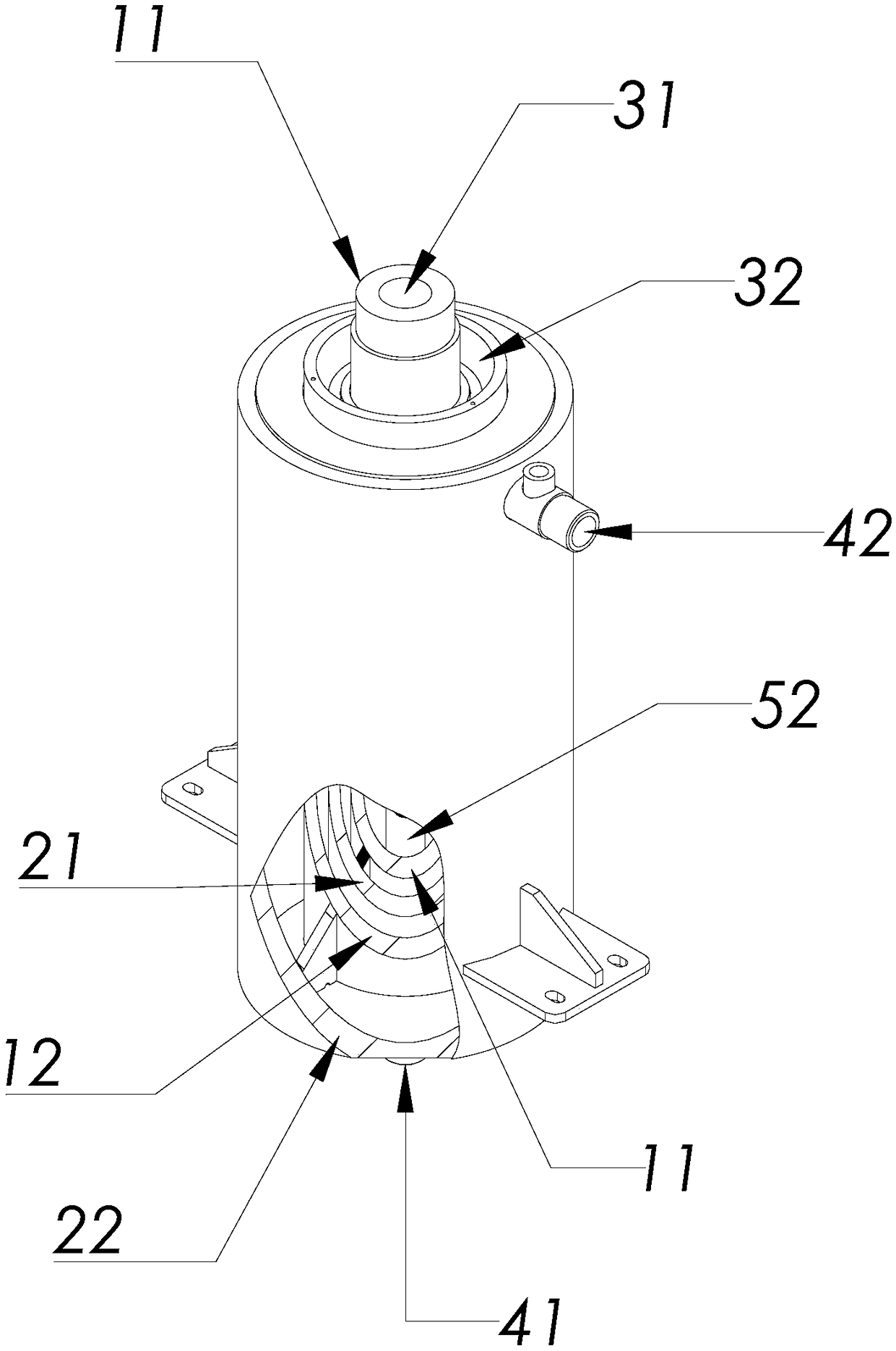

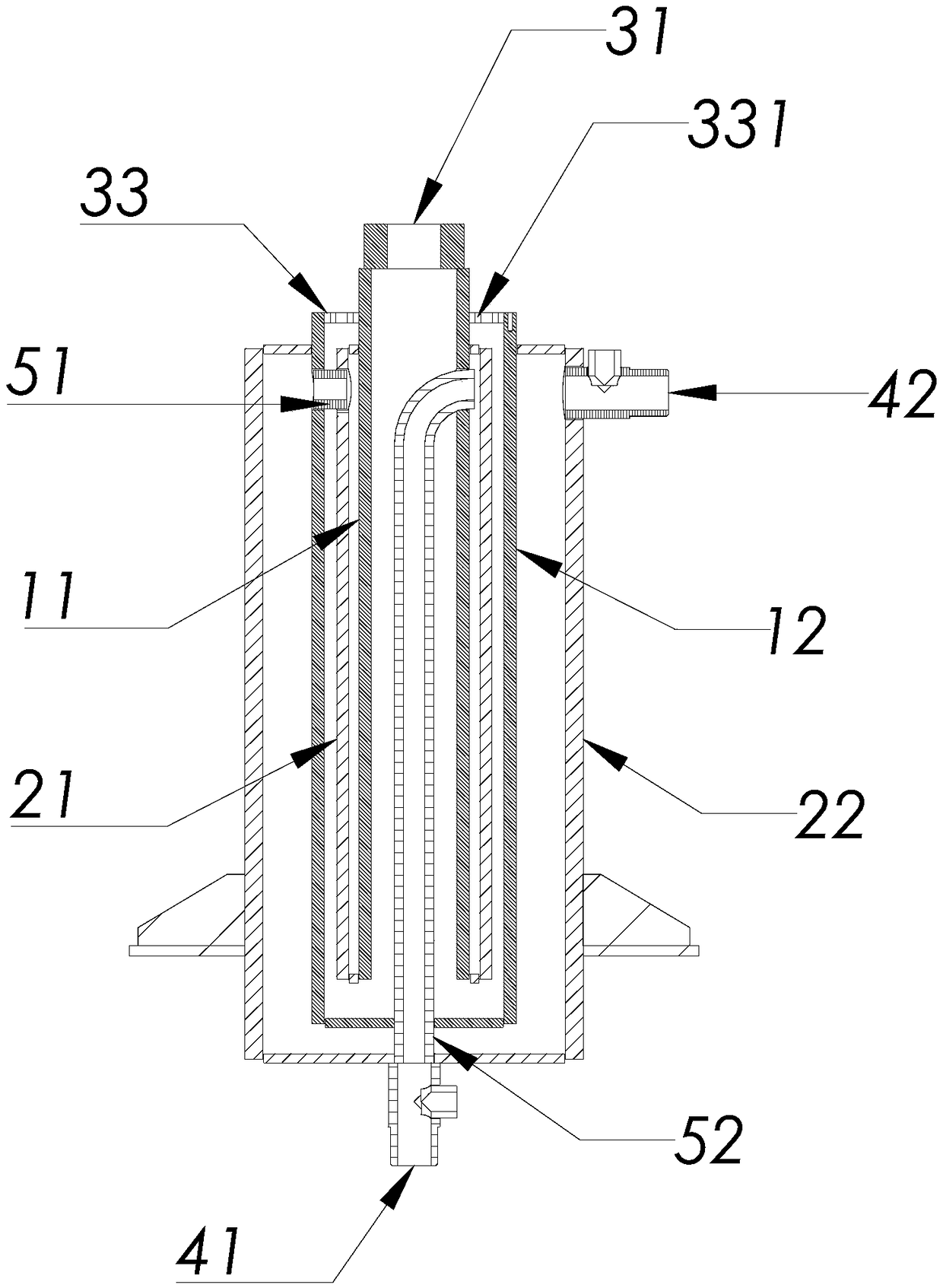

Tank type heater

PendingCN109489281AReduce difficultyLess consumablesLighting and heating apparatusExothermal chemical reactions for heatingEngineeringMachining

The invention provides a tank type heater, and relates to the technical field of heaters. The technical problems that an existing heating reaction device is complex in structure and large in manufacturing technology difficulty are solved. The tank type heater comprises a heat generating tank body and a heat conducting medium tank body separated from each other by a cavity, the heat generating tankbody comprises an inner layer heating tank and an outer layer heating tank which communicate with each other, and the heat conducting medium tank body comprises a medium inner layer tank and a mediumouter layer tank which communicate with each other, and the inner layer heating tank, the medium inner layer tank, the outer layer heating tank and the medium outer layer tank are laminated and sleeved together from inside to outside. A heat conducting medium inlet and a heating conducting medium outlet which allow heat conducting media to flow in and flow out of the heat conducting medium tank body are formed in the heat conducting medium tank body, heat released by materials which are oxidized in the heat generating tank body is absorbed by the heat conducting media in the heat conducting medium tank body. The tank type heater is used for reducing the machining and manufacturing difficulty and machining cost of the existing oxidative heating reaction devices.

Owner:佛山市无火发热新能源科技有限公司

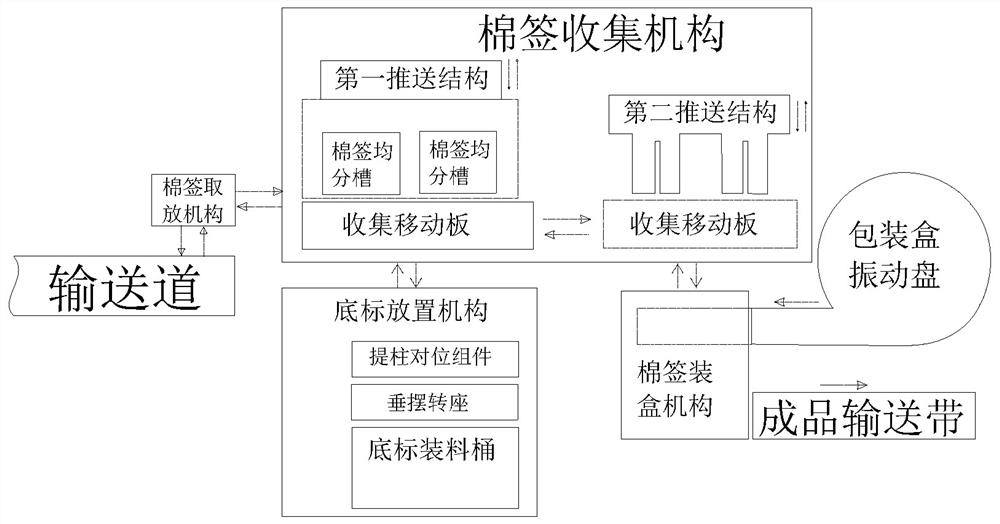

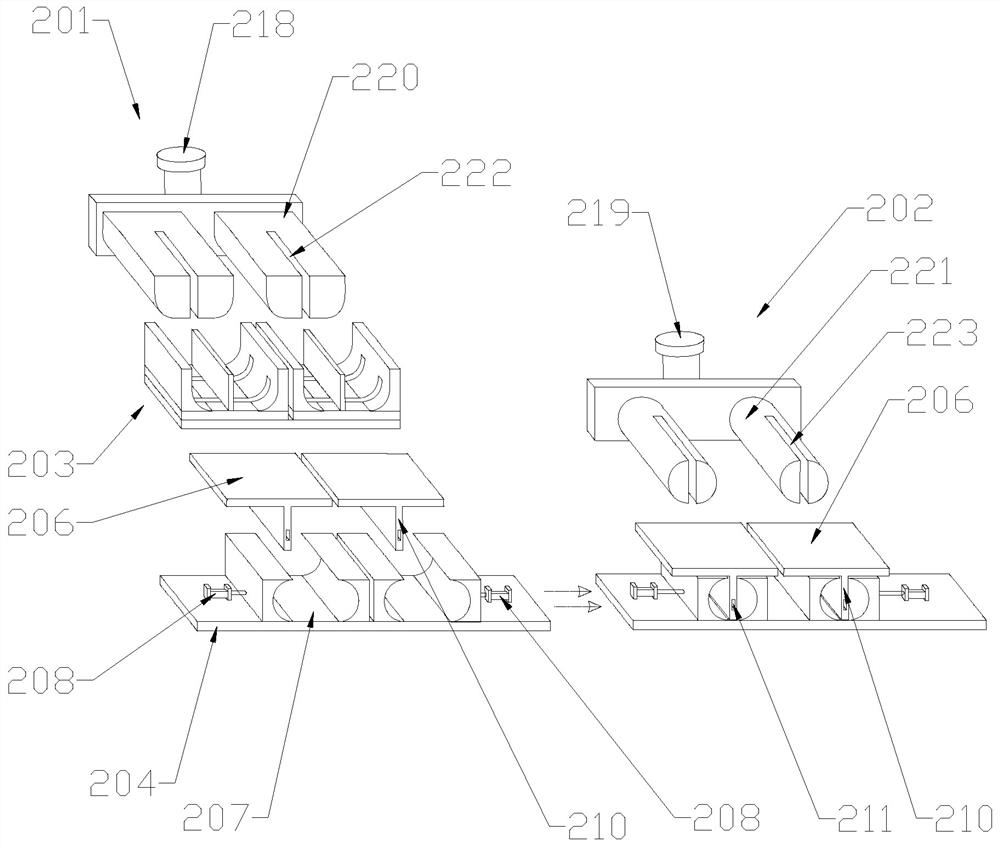

Automatic cotton swab packaging machine

InactiveCN112298673AIncrease productivityReduce production errorsIndividual articlesPaperboardEngineering

The invention discloses an automatic cotton swab packaging machine which comprises a cotton swab taking and placing mechanism, a cotton swab collecting mechanism, a bottom label placing mechanism anda cotton swab boxing mechanism. The cotton swab collecting mechanism comprises a first pushing structure, a second pushing structure, a cotton swab equipartition groove, a collecting moving plate, a lifting bottom baffle and a T-shaped partition plate; the bottom label placing mechanism comprises a bottom label charging barrel, a label placing lifting cylinder, a vertical swing rotating seat, a mounting seat and a lifting column alignment assembly; and the cotton swab boxing mechanism comprises a packaging taking and placing frame, a packaging lifting motor, a packaging overturning motor, a packaging swing motor, a vertical moving frame and a packaging gripper. According to the automatic cotton swab packaging machine, cotton swabs are grabbed and placed into the equipartition groove so asto be aligned through a pushing mechanism, then bottom label paperboards are accurately added, boxing treatment is carried out, the whole process is automatically carried out, manual participation isnot needed, and the bottom label paperboards and the cotton swabs are stably combined and placed into packaging boxes so as to be collected, so that the production efficiency is improved, and production errors are reduced.

Owner:DONGGUAN DAWEI HEALTH PROD

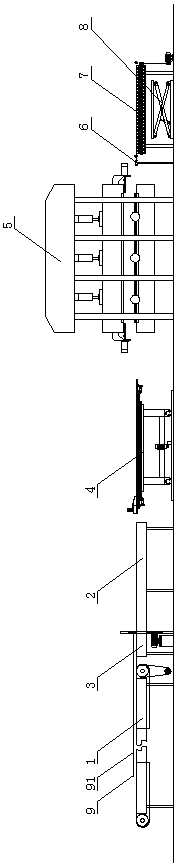

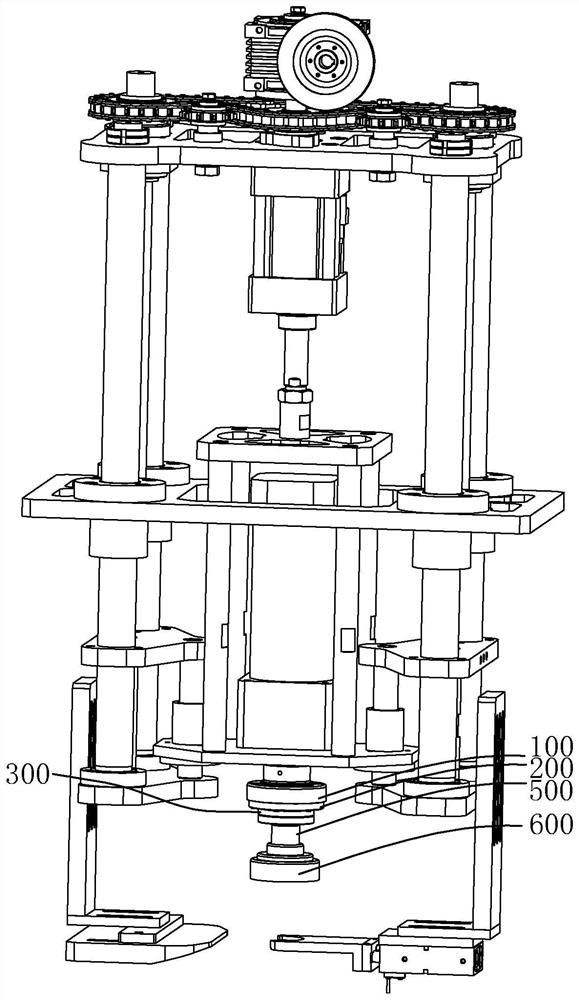

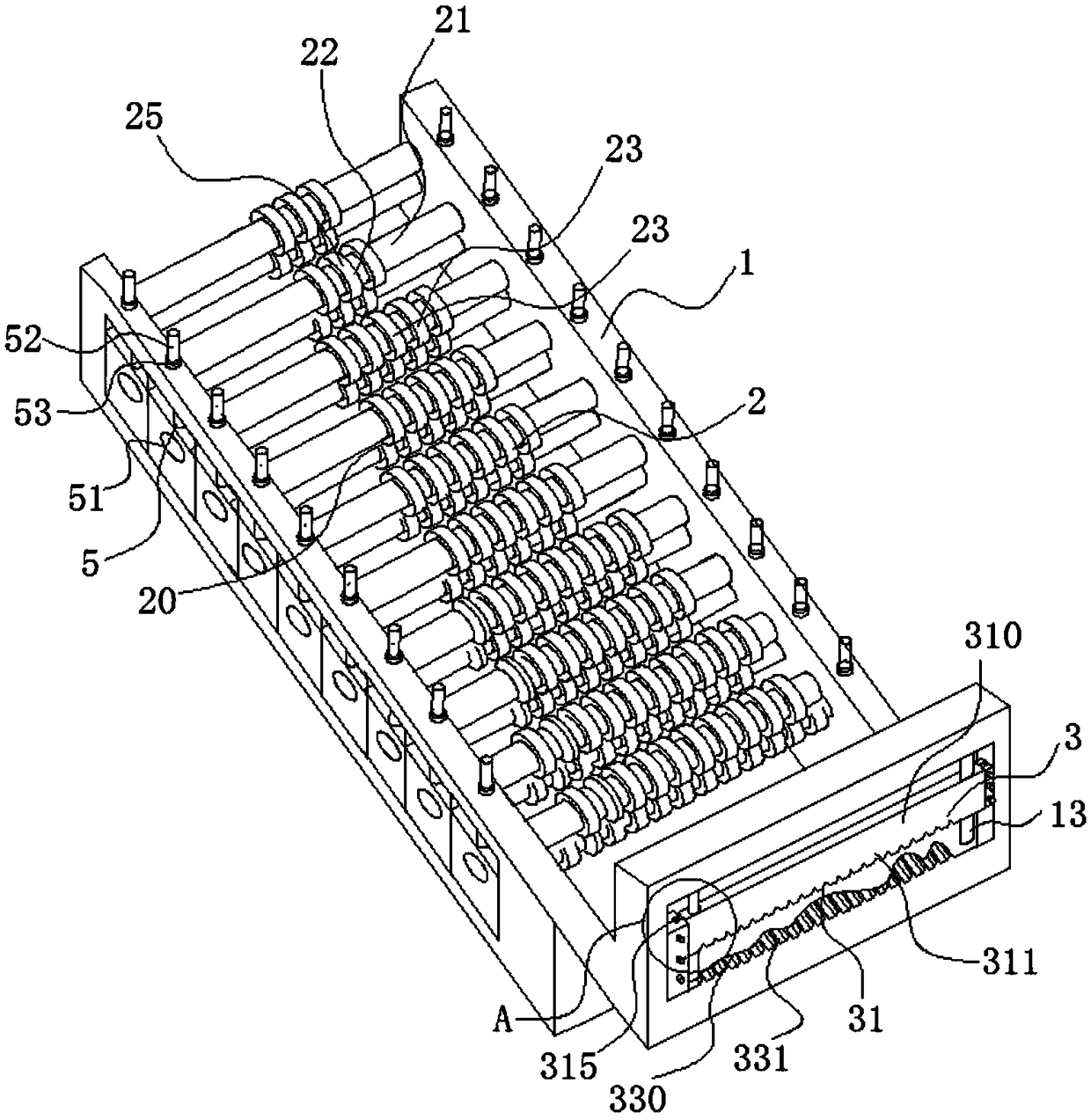

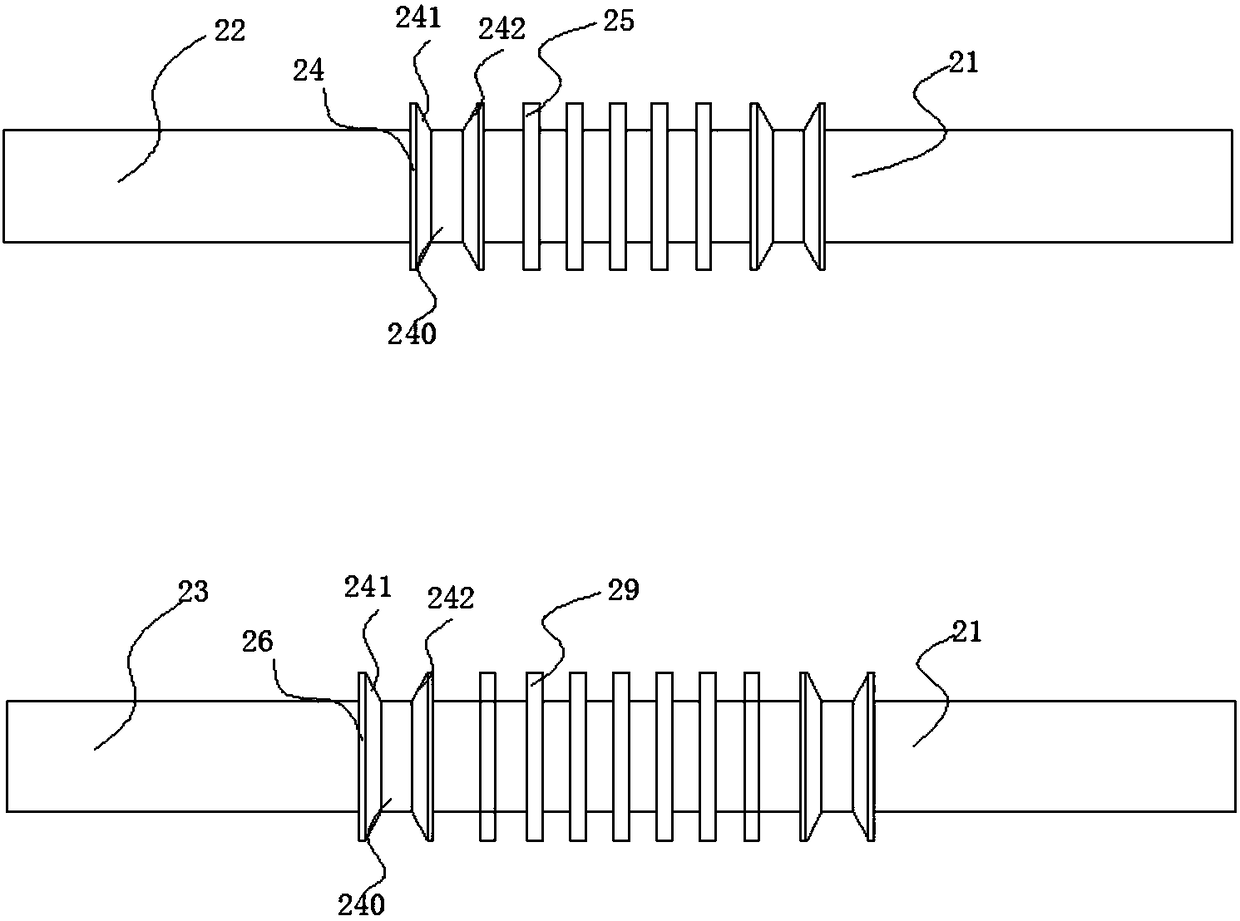

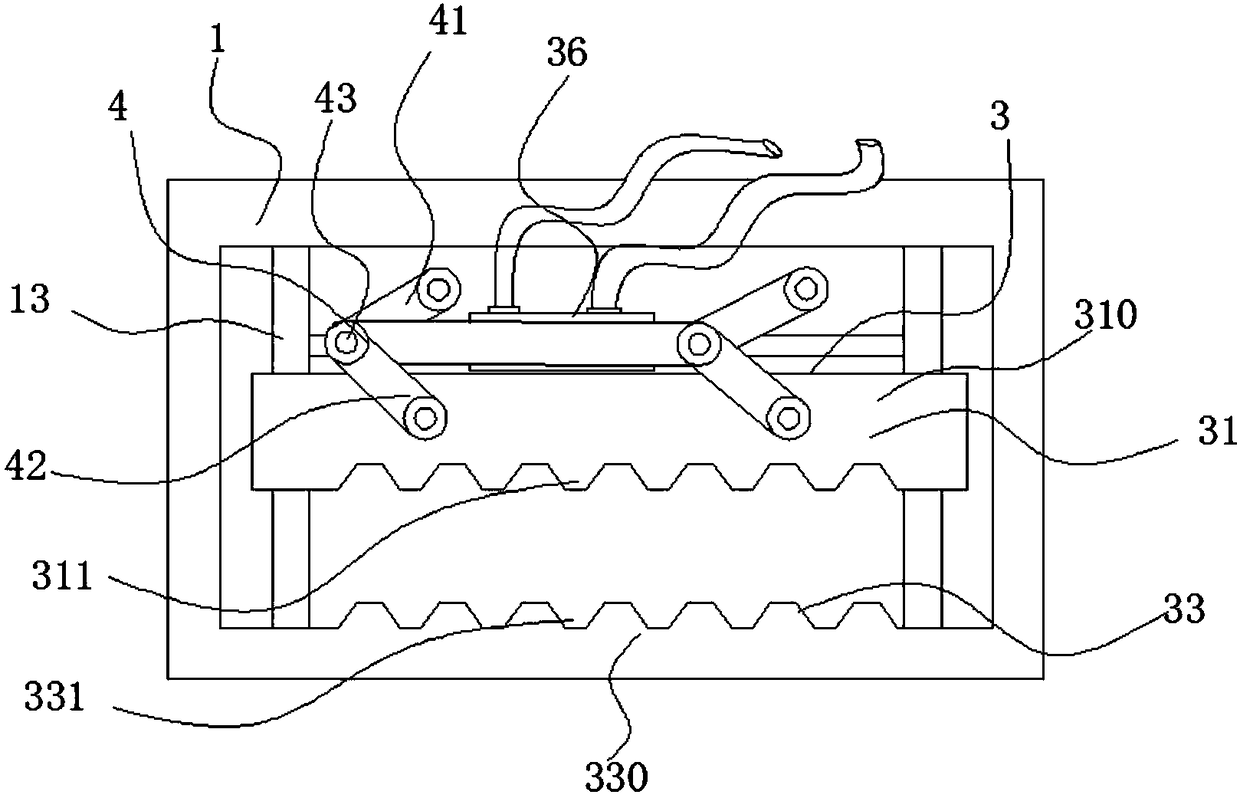

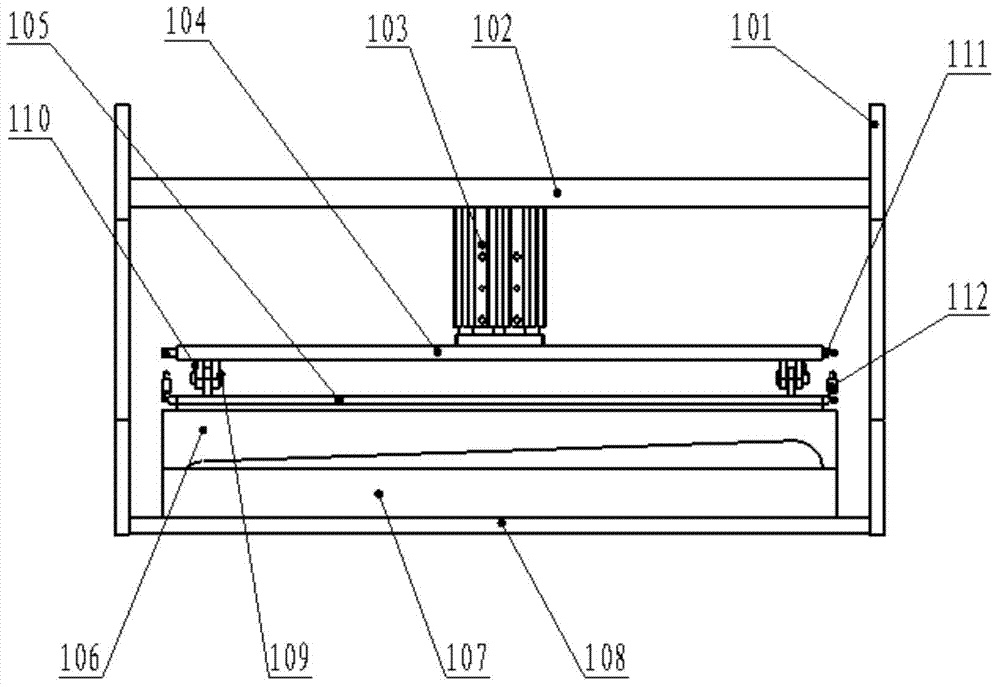

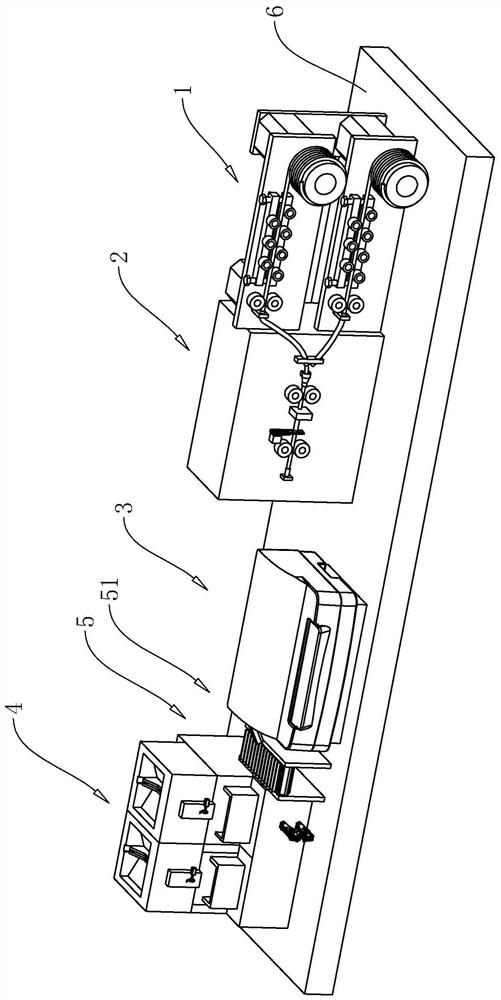

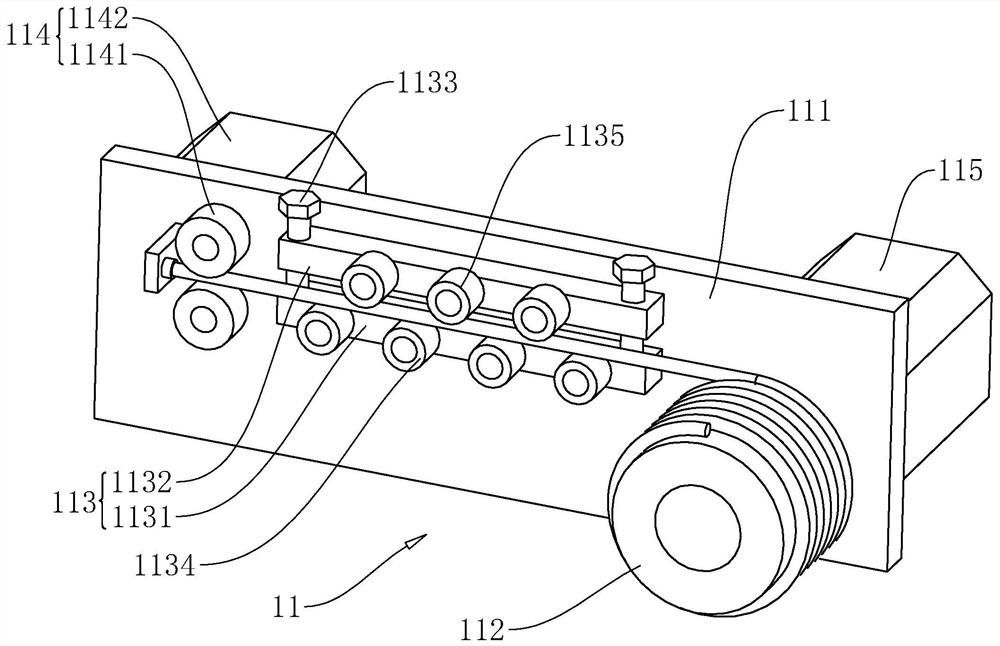

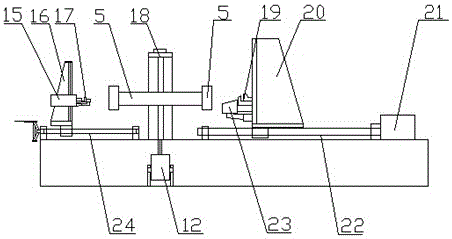

Rotor coil shaping machine of wind driven generator

InactiveCN106712396AReduce production errorsManufacturing dynamo-electric machinesWind energy generationWind drivenWind force

The invention provides a rotor coil shaping machine of a wind driven generator. The rotor coil shaping machine is composed of a front side pull mechanism, a rear side pull mechanism, a left transverse pull mechanism, a right transverse pull mechanism and a hydraulic power mechanism. The rotor coil shaping machine is characterized in that a fixing rod (2) is installed on a rotating crank (13), a front clamping claw (4) is installed on an elevating slide block (14), a clamping cylinder (3) is installed on the front clamping claw (4), a servo motor (7) and an elevating slide block (8) are installed on the fixing rod (6), the fixing rod (6) is installed on the rotating crank, and a rear clamping claw (9) is installed on the elevating slide block (8). According to the rotor coil shaping machine of the wind driven generator, the clamping claws clamp a coil and then the framework of the shape of the coil is formed by pulling of the side pull mechanisms and the left and right rotating transverse pull mechanisms, and the curved surface of the coil is formed by a bending stiffener through torsion. Therefore, formation of the shape of the rotor coil can be completely processed by one machine tool so that production error caused by the production machine tool can be reduced.

Owner:李炳林

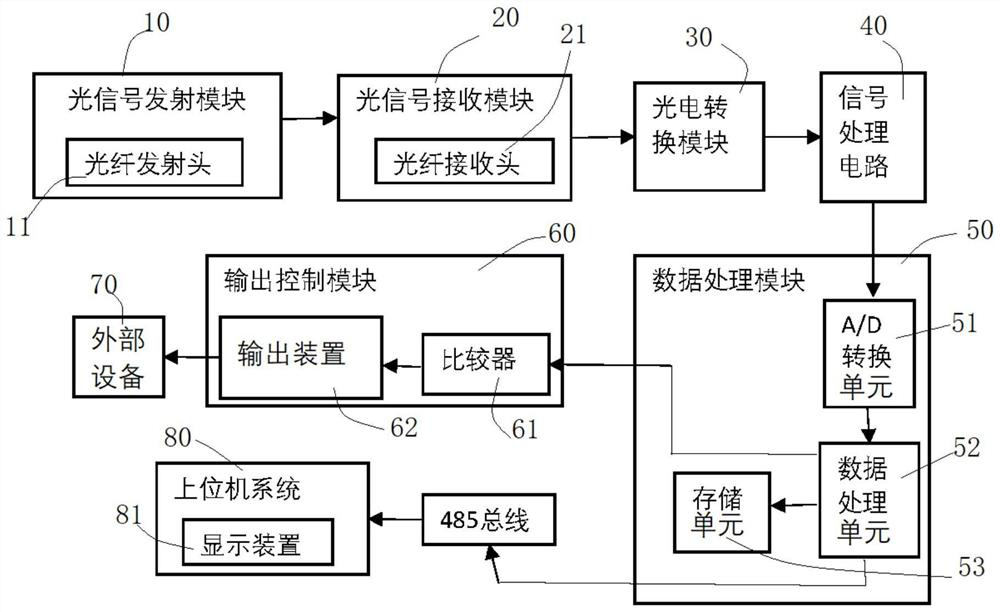

Monitoring system with photoelectric sensor and monitoring method

PendingCN114322781AEasy accessEffective information outputUsing optical meansColor/spectral properties measurementsSoftware engineeringDisplay device

The invention discloses a monitoring system with a photoelectric sensor and a monitoring method thereof.The monitoring system comprises an optical signal receiving module, a photoelectric conversion module, a data processing module and an output control module, and the optical signal receiving module transmits received optical signals to the photoelectric conversion module; the photoelectric conversion module converts the optical signal into an electric signal, the electric signal is transmitted to the data processing module after being processed, the electric signal is converted into a digital signal through the data processing module, and the optical signal received by the optical signal receiving module changes along with the change of a measured physical quantity. The optical signal is converted into a digital signal, the digital signal is processed by the data processing module, the change rule of the measured physical quantity is displayed through a state change curve by the display device, and the monitoring system can be suitable for distance monitoring of high-precision equipment; and whether the appearance color of the product is qualified can be detected.

Owner:苏州优斯登物联网科技有限公司

A fluxgate current sensor and current measurement method

ActiveCN113341201BReduce production errorsReduce the influence of higher harmonicsCurrent measurements onlyVoltage/current isolationElectrical conductorCurrent sensor

The invention provides a fluxgate current sensor and a current measurement method. The fluxgate current sensor includes: an auxiliary magnetic core and at least two closed-loop magnetic circuits; the closed-loop magnetic circuits are symmetrically coupled; the auxiliary magnetic core is arranged in the closed-loop magnetic circuit. Magnetic circuit coupling connection. The fluxgate current sensor of the present invention has a symmetrically coupled closed-loop magnetic circuit, which can provide a magnetic field environment for symmetrical measurement, reduce the influence of high-order harmonics caused by the position of the eccentric conductor, reduce the production error between different sensors, and improve the measurement accuracy. .

Owner:HEFEI ECRIEE TAMURA ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com