Rotor coil shaping machine of wind driven generator

A technology of wind power generators and rotor coils, applied in wind power generation, manufacturing of motor generators, electrical components, etc., can solve problems such as large manufacturing errors of coils, and achieve the effect of reducing production errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

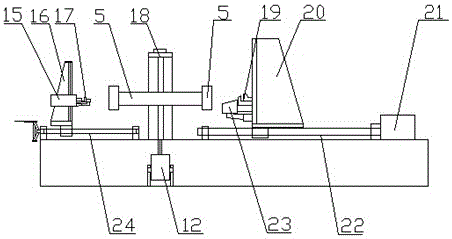

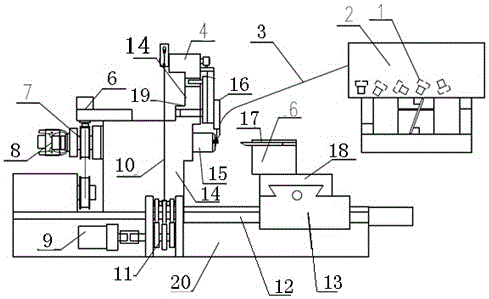

[0009] Depend on figure 1 , figure 2 Known: A rotor coil shaping machine is composed of a front side pulling mechanism, a rear side pulling mechanism, a left horizontal pulling mechanism, a right horizontal pulling mechanism, and a hydraulic power mechanism. The front pulling mechanism is composed of a servo motor 1 and a fixed rod 2 , Clamping cylinder 3, front jaw 4, lifting slider 14, rotating crank 13, transmission screw rod 18, described rear side pulling mechanism is made up of clamping cylinder 5, fixed rod 6, servo motor 7, lifting slider 8. Rear jaws 9, rotating crank, and transmission screw 18 are formed. The grasping mechanism of the left transverse pull mechanism is composed of lifting seat 15, left transverse movement seat 16, left jaw 17, and moving screw mandrel 24. The right horizontal pull mechanism is composed of jaws 19, right traverse seat 20, bending jerk 23, servo motor 21, and transmission screw rod 22. The hydraulic power mechanism is composed of oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com