Monitoring system with photoelectric sensor and monitoring method

A photoelectric sensor and monitoring system technology, applied in the direction of color/spectral characteristic measurement, instruments, measuring devices, etc., can solve the problems that the state value and intermediate quantity are not an intuitive value, affect data statistics, and poor appearance color, etc., to achieve convenience The effect of monitoring statistics, saving labor, and reducing trial and error rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

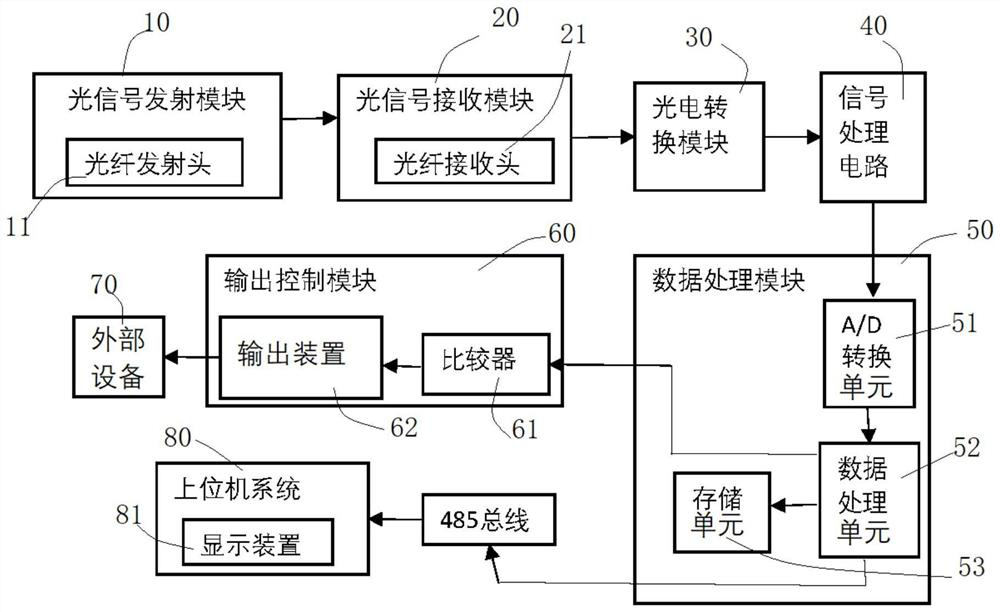

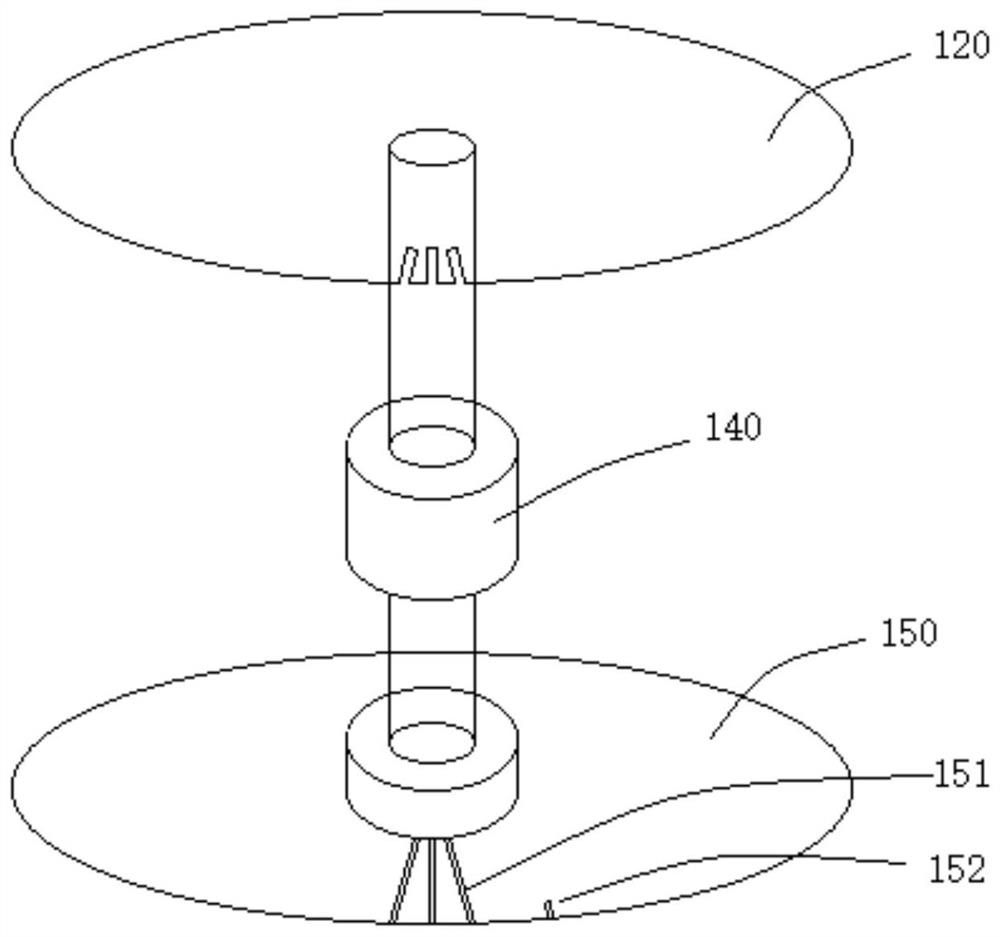

[0041] The present invention mainly provides a monitoring system with a photoelectric sensor. In one embodiment, the monitoring principle of the monitoring system of the present invention can be summarized as follows: the optical fiber transmitting head sends out a constant optical signal of a specific wavelength, which is received by the optical fiber receiving head. After the signal is converted into an electrical signal by the photoelectric conversion module, it is sent to the high-speed AD module of the MCU for sampling, and then the data is processed and stored in the storage unit, and the data can also be uploaded to the host computer system through the data bus. The optical signal received by the optical fiber receiving head is converted into an electrical signal by the photoelectric conversion module, and the switching value control signal is output by comparing with the set threshold.

[0042] In one embodiment, the working state of the monitoring system of the present...

Embodiment 2

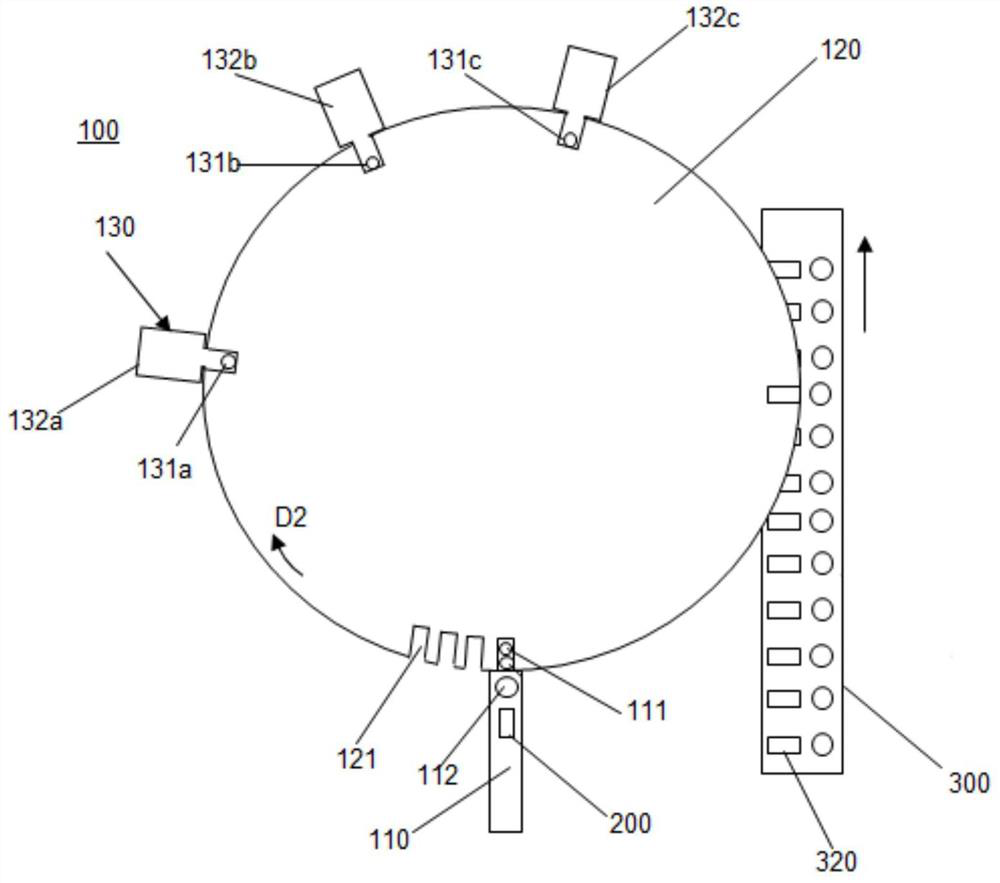

[0063] On the other hand, the monitoring system of the present invention can also be used to detect the existence of the workpiece on the station, such as whether the front and back of the workpiece are reversed (generally applicable to workpieces with different colors on the front and back), and when the workpiece enters the component processing equipment Before feeding, the workpieces need to be picked out from the material pile, and the workpieces should be arranged in a row facing up, and then the workpieces arranged in a row will enter the feeding station of the component processing equipment.

[0064]In one embodiment, several workpieces can be passed between the optical fiber receiving head 21 and the optical fiber emitting head 11 in sequence (the workpieces that are about to be arranged in a row pass through the optical fiber receiving head 21 and the optical fiber emitting head 11 successively. between inspections), the colors of the several workpieces are different f...

Embodiment 3

[0069] The present invention also provides a monitoring method of a monitoring system with a photoelectric sensor, which includes:

[0070] The optical fiber receiving head 21 receives the optical signal sent from the optical fiber emitting head 11, and transmits the optical signal to the photoelectric conversion module 30, and the photoelectric conversion module 30 converts the optical signal into an electrical signal, and the electrical signal is processed by signal processing. The circuit 40 performs signal processing to obtain an analog signal, the analog signal is converted into a digital signal by the data processing module 50, and the digital signal is compared with the reference signal after being received by the output control module 60, and the output control module 60 according to The comparison result sends out a switching value control signal, and the data processing module 50 monitors the change curve of the digital signal in real time, and displays the change cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com