Patents

Literature

51results about How to "Reduce trial and error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

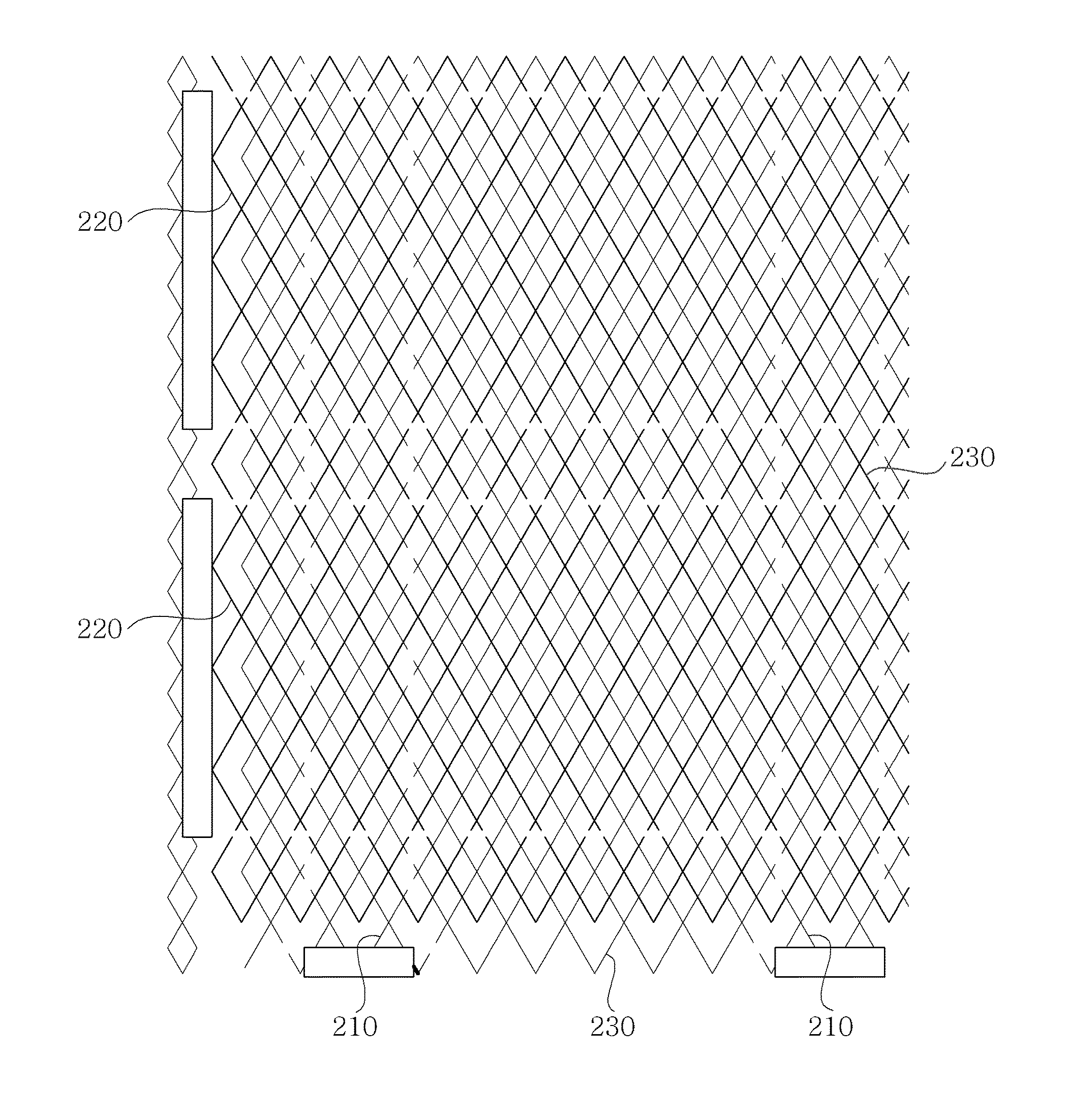

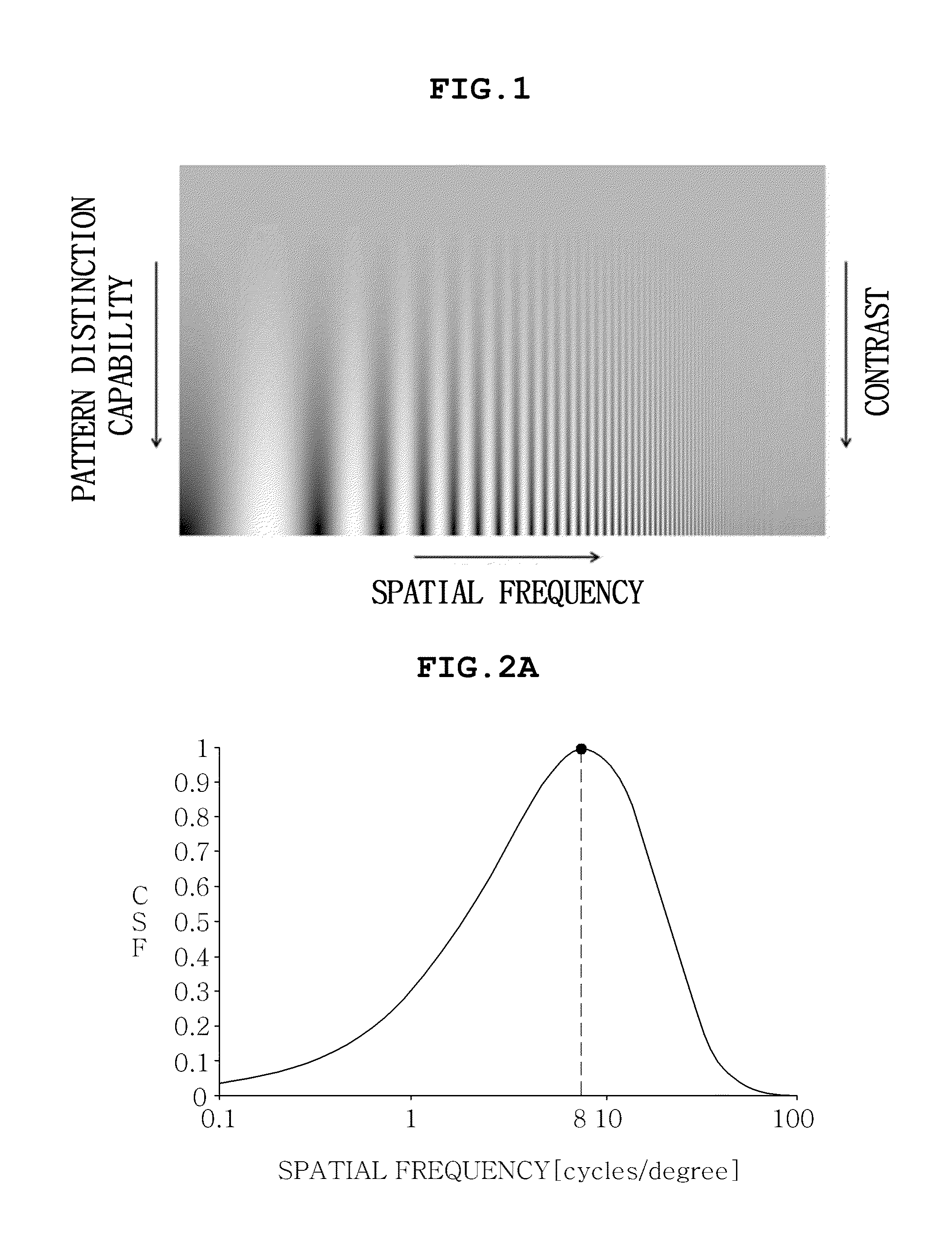

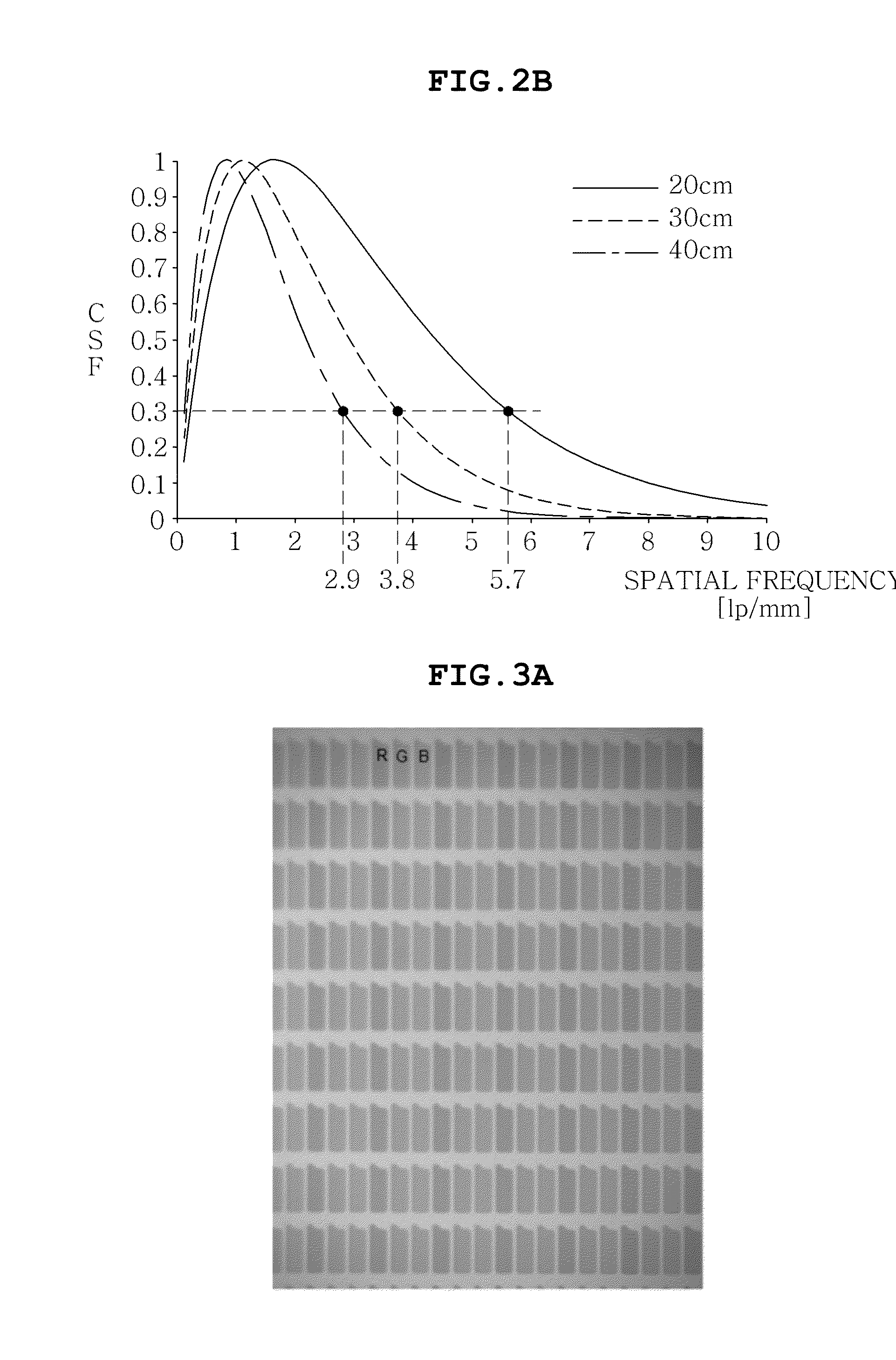

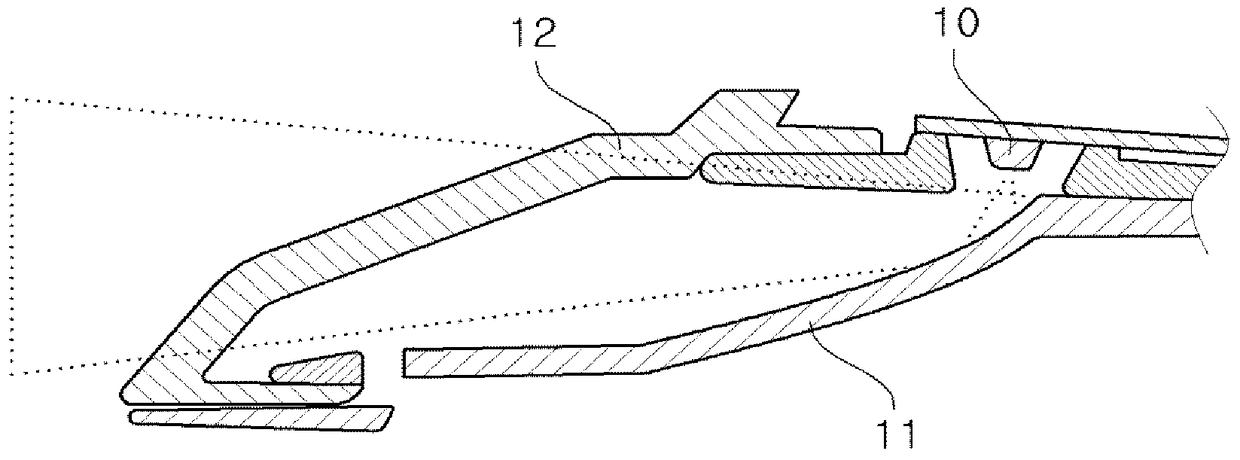

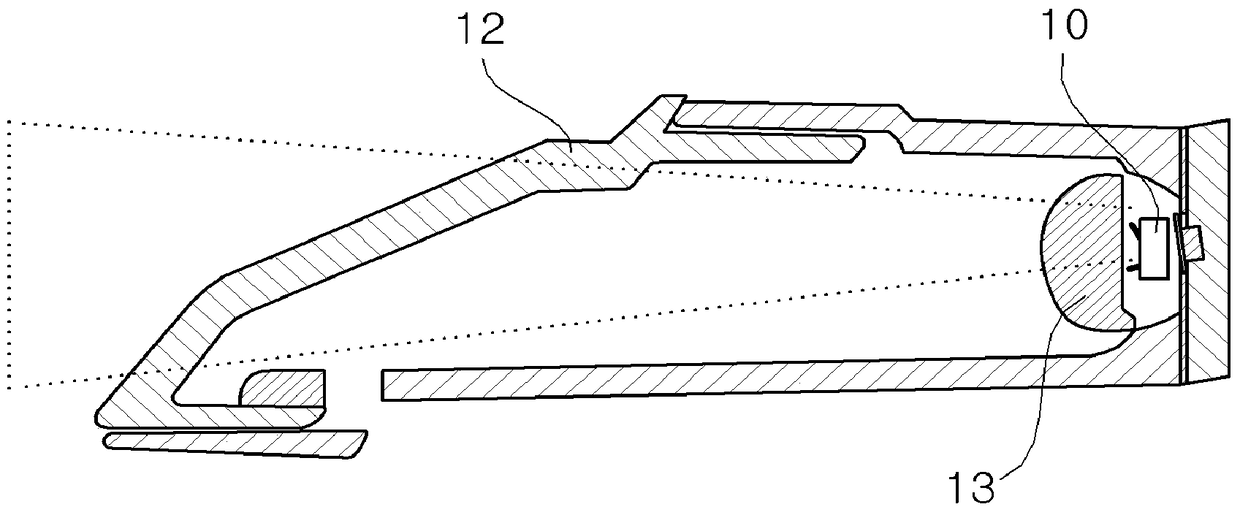

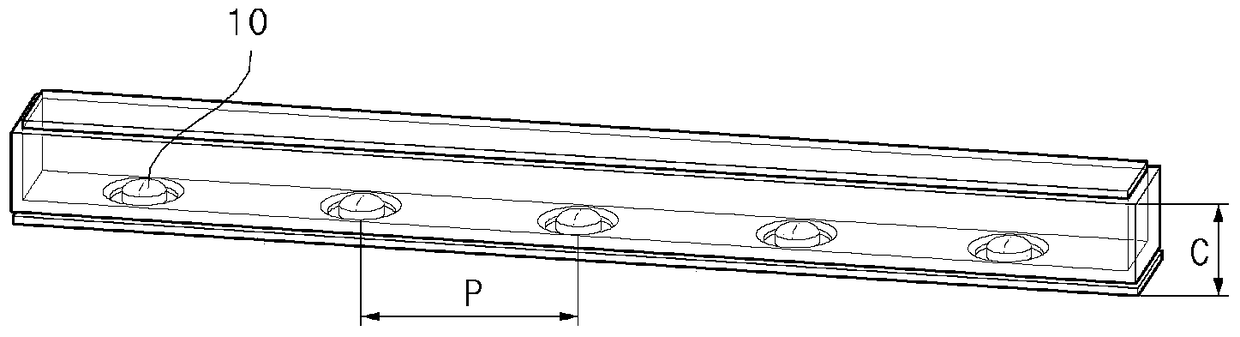

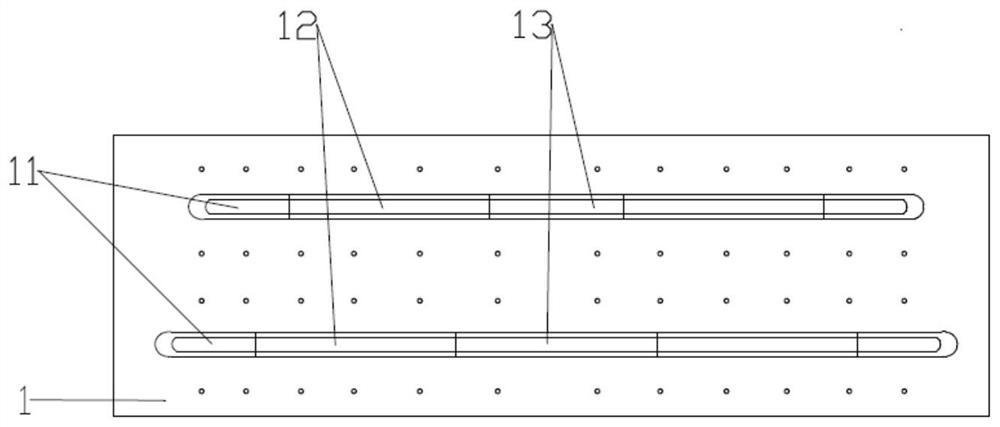

Touch panel

InactiveUS20130341070A1Shorten the overall cycleImprove development efficiencyPrinted circuit aspectsElectrical connection printed elementsEngineeringTouch panel

Disclosed herein is a touch panel, including: mesh conductor lines, wherein a pitch of the mesh conductor line has a value selected from pm=2×pd(fm=fd / 2, pm≦260 μm), wherein pm is a pitch of the mesh conductor line, pd is a pixel pitch of a display, fm is a frequency 1 / pm of the mesh conductor line, and fd is a pixel frequency 1 / pd of the display.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

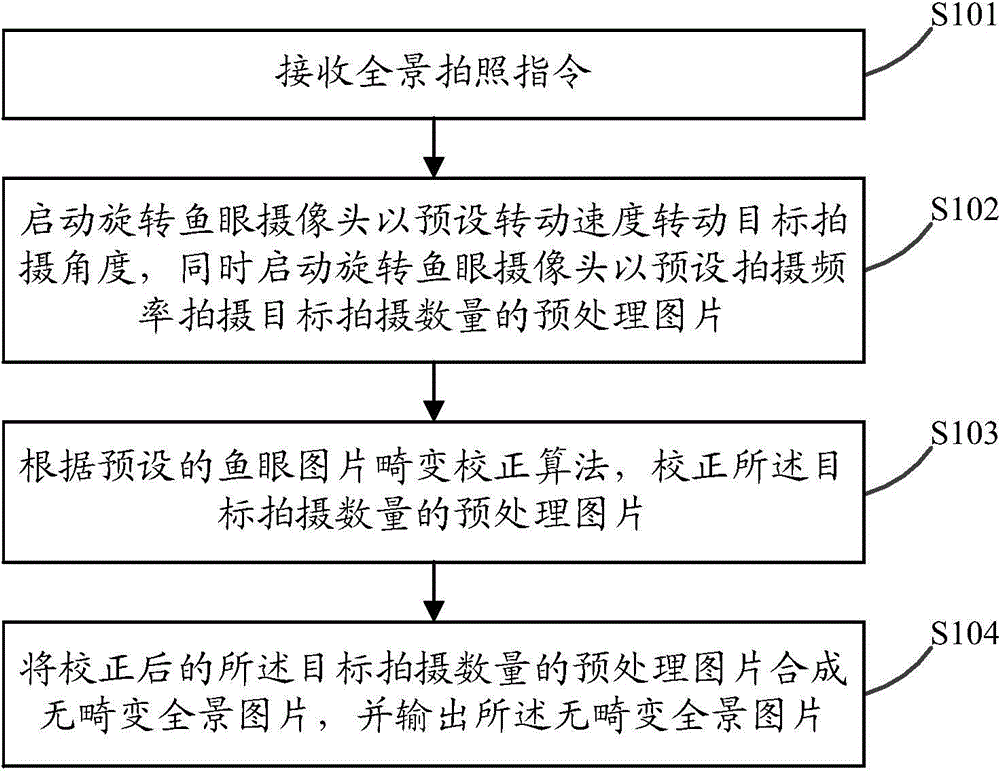

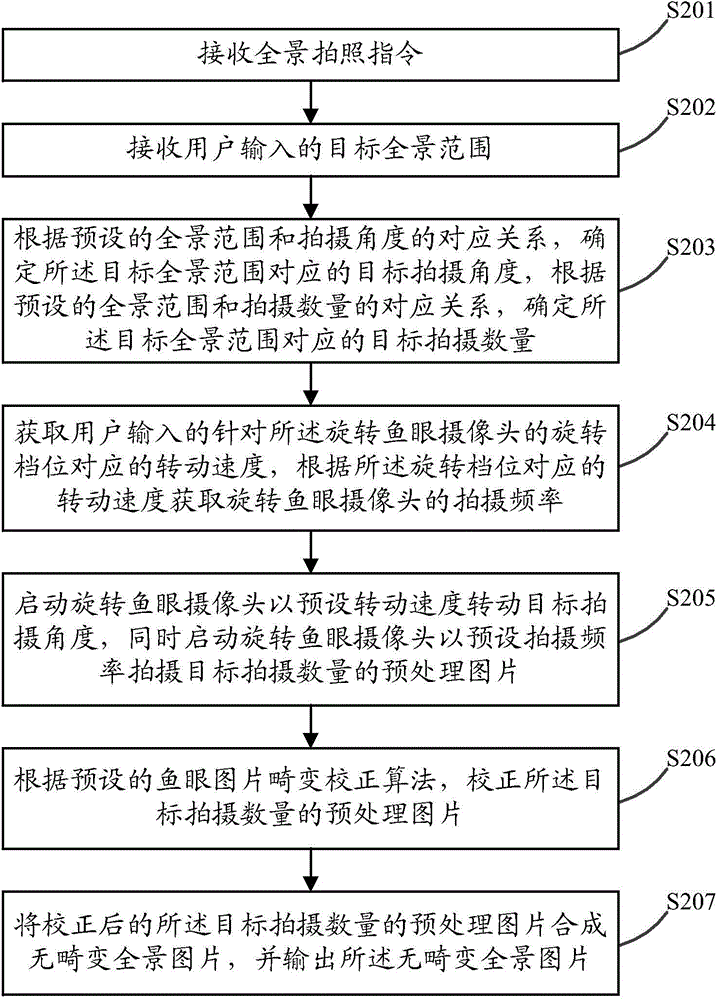

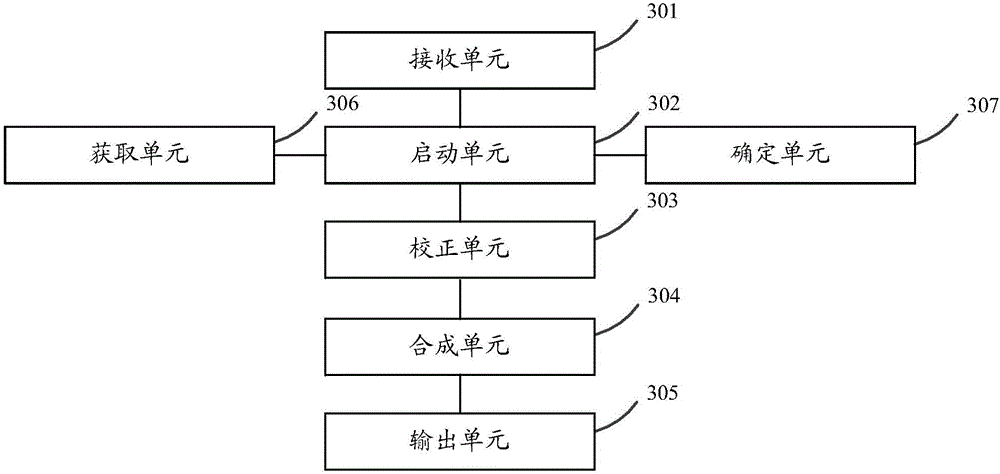

Panoramic photography method and terminal

ActiveCN104639832AImprove the efficiency of panoramic photographySynthesis speedTelevision system detailsColor television detailsPanoramic photographyDistortion correction

The invention provides a panoramic photography method and a terminal. The method comprises the following steps: receiving a photography shooting command; starting a rotary fisheye camera, rotating by a target shooting angle at a preset rotating speed, and simultaneously starting the rotary fisheye camera to shoot a target shooting quantity of preprocessed pictures at a preset shooting frequency; correcting the target shooting quantity of preprocessed pictures according to a preset fisheye picture distortion correction algorithm; synthesizing the corrected target shooting quantity of preprocessed pictures into a distortionless panorama picture, and outputting the distortionless panorama picture. By implementing the panoramic photography method and the terminal, the panoramic photography efficiency of the panoramic photography terminal can be increased.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

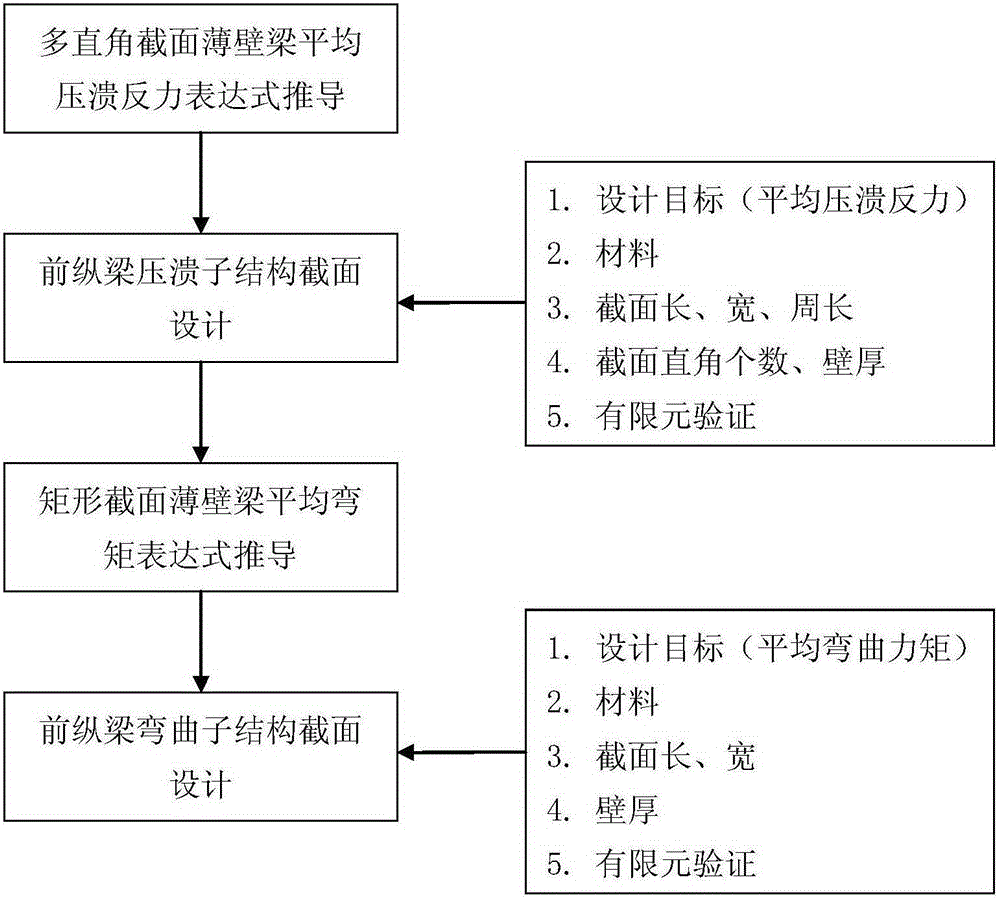

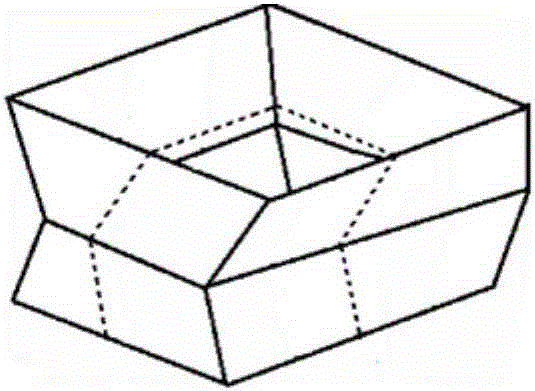

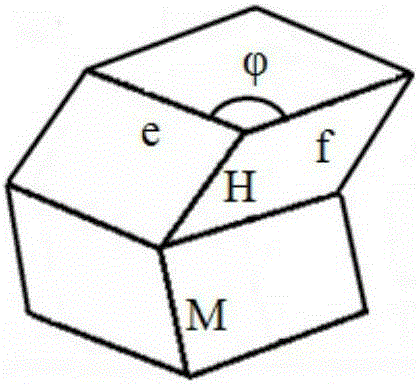

Front longitudinal beam anti-collision performance design method for passenger vehicle

InactiveCN103425848ARapid designShorten the design and development cycleSpecial data processing applicationsEngineeringTrial and error

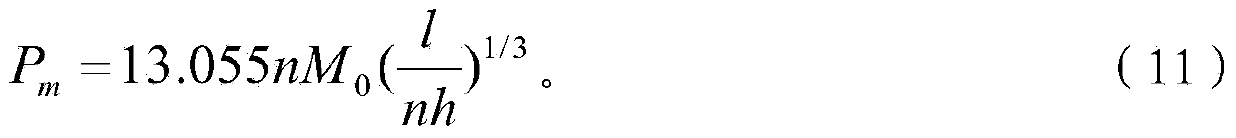

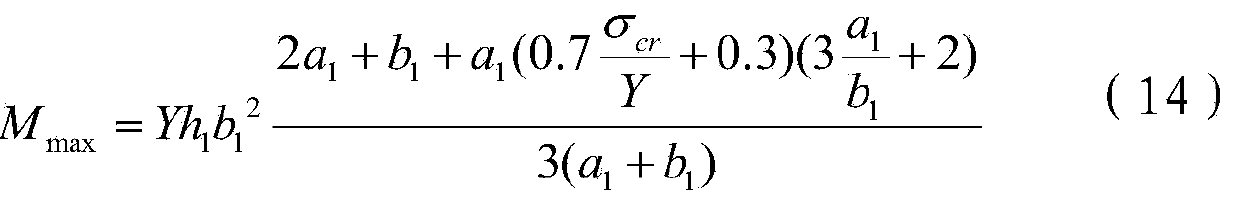

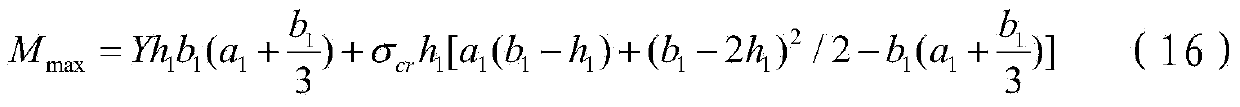

The invention discloses a front longitudinal beam anti-collision performance design method for a passenger vehicle and aims at solving the problems that when the traditional trial-and-error method is used for designing the front longitudinal beam of a car in the prior art, a computer simulation model needs to be repeatedly modified, the testing needs to be repeatedly carried out, and the like. The front longitudinal beam anti-collision performance design method for the passenger vehicle comprises the following steps that 1, the average crushing counter force expression (shown as the accompanying drawing) of a multi-right-angle cross section thin wall beam is deduced, in the expression, Pm is the average crushing counter force, the unit of the Pm is kN, n is the number of the cross section right angles of the multi-right-angle cross section thin wall beam, M0 is the unit length plastic limit bending moment, the unit of M0 is N.mm, l is the cross section circumference of the multi-right-angle cross section thin wall beam, the unit of the l is mm, h is the wall thickness of the multi-right-angle cross section thin wall beam, and the unit of the h is mm; 2, the cross section of the crushing deformation part of the front longitudinal beam is designed; 3, the average bending moment expression (Mm=(0.3-0.5)Mmax) of a rectangular cross section thin wall beam is deduced, in the expression, Mm is the average bending moment of the rectangular cross section thin wall beam, and the unit of the Mm is N.mm; and 4, the cross section of the bending deformation part of the front longitudinal beam is designed.

Owner:JILIN UNIV

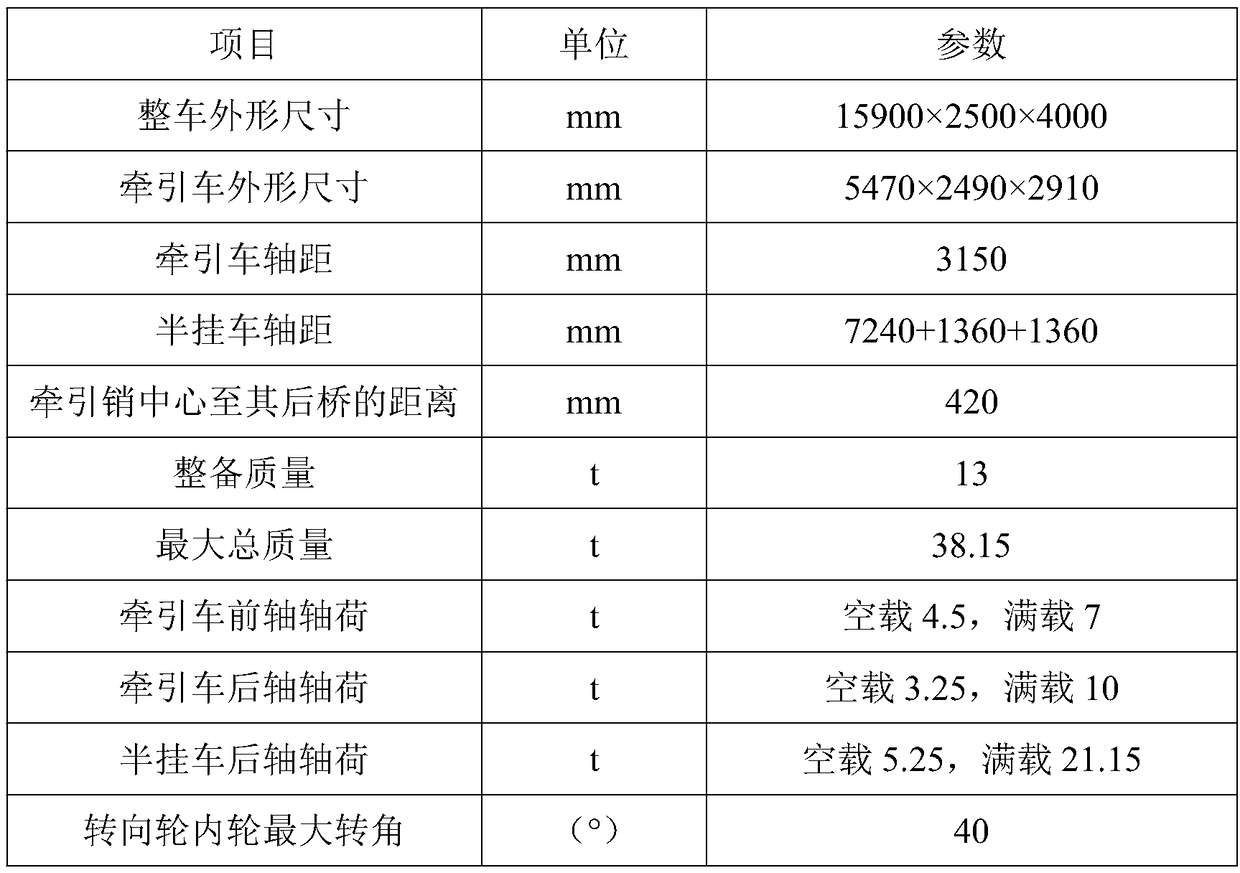

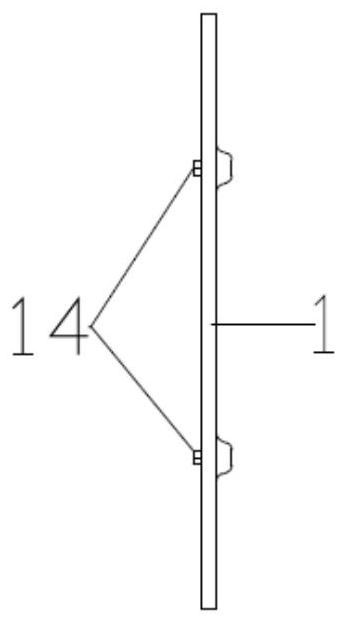

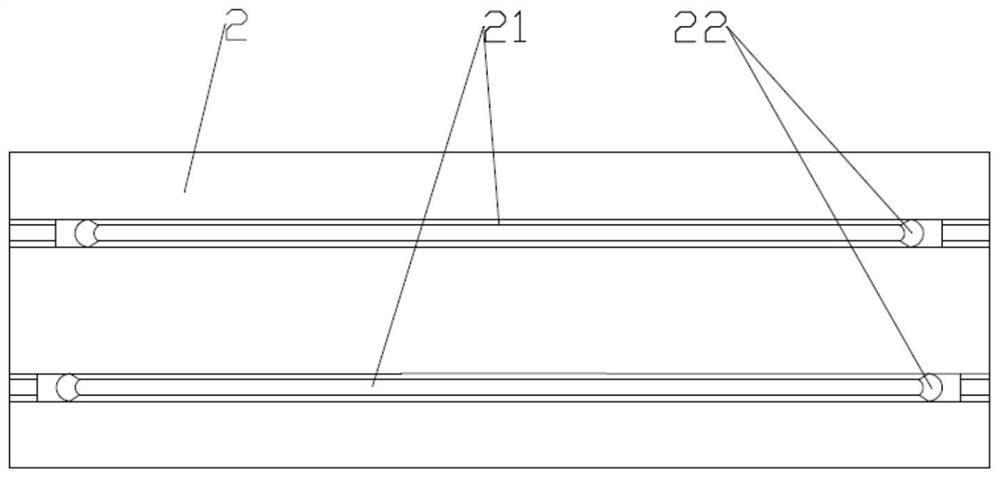

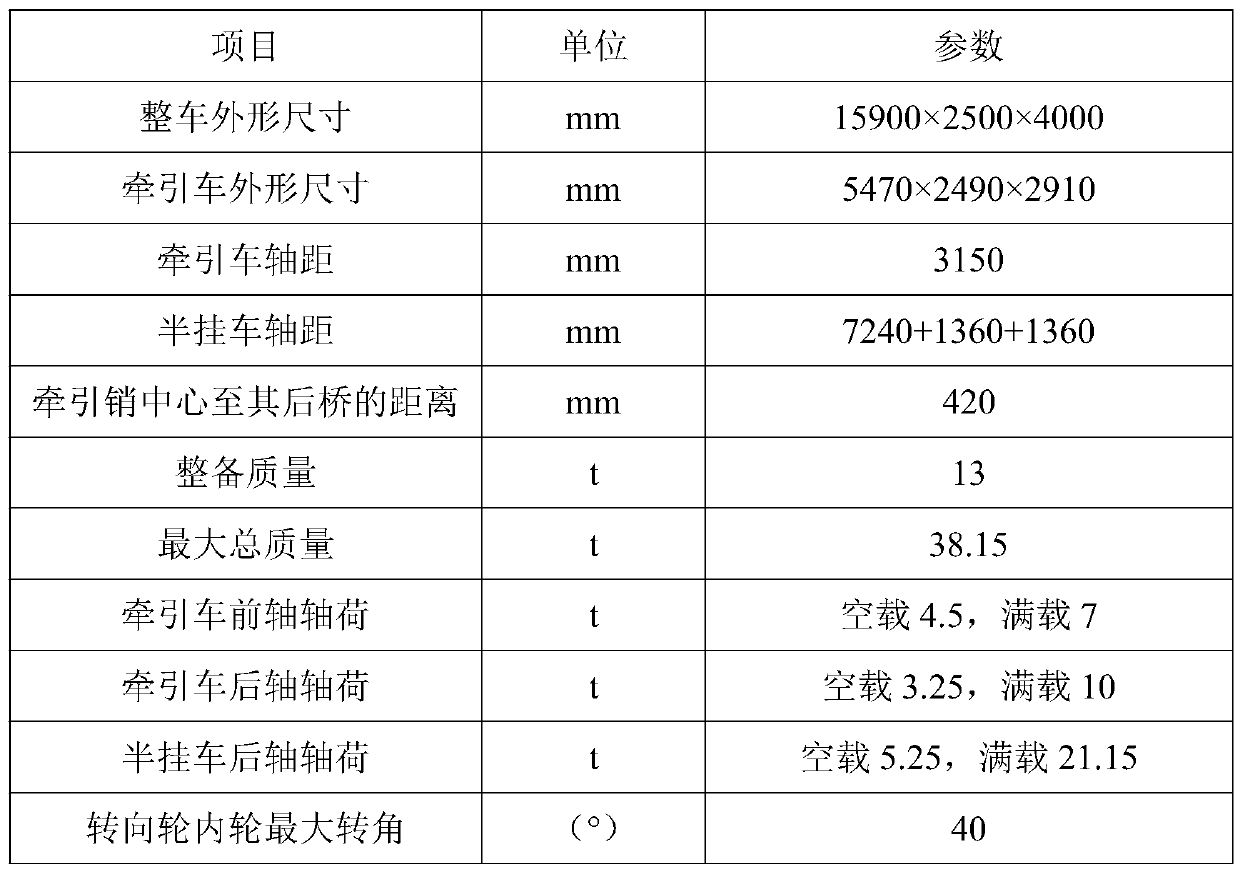

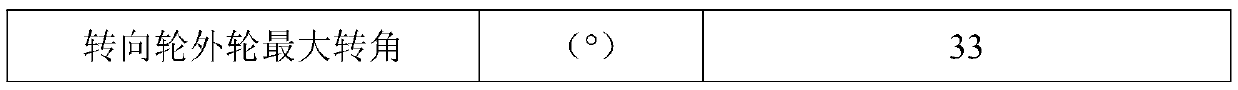

Induction control method for semi-trailer train linear back off

ActiveCN109367620ASolve the situation that it is difficult to achieve straight-line reversingLive bootSteering partsSteering wheelSemi-trailer

The invention discloses an induction control method for semi-trailer train linear back off. According to the linear back-off requirements of a driver, the steering wheel rotation direction and rotation angle prompt is provided for the driver, and accordingly the driver is assisted in linear back-off operation completing. By means of the induction control method, the requirement for the back-off skill of the driver can be lowered, the back-off accidents are reduced, and meanwhile the back-off efficiency is improved.

Owner:HEFEI UNIV OF TECH

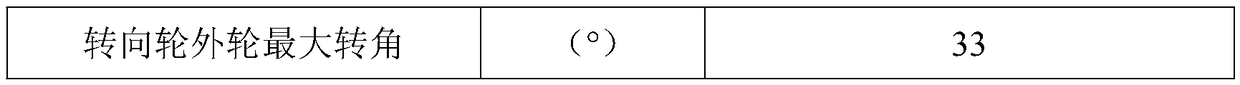

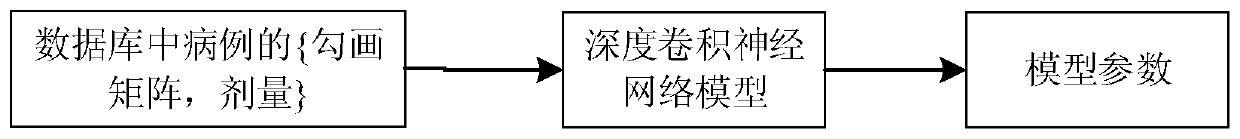

Plan implementation method and device based on predicted dose guidance and Gaussian process optimization

PendingCN110232964AQuality assuranceReduce trial and errorMedical simulationMedical data miningData setMedicine

The invention provides a plan implementation method and apparatus based on predicted dose guidance and Gaussian process optimization, and relates to the field of radiotherapy technology. The method comprises: calculating a predicted dose of a case by using a dose prediction model; calculating a plan score of the predicted dose according to the scoring rule as an optimal plan score; determining a plurality of sets of plan parameters based on the a priori database according to organ anatomy information; calculating corresponding plan scores of the plurality of sets of plan parameters, and constituting a Gaussian data set; and based on the Gaussian data set, calculating new plan parameters by using the Gaussian process, calculating the corresponding plan scores, adding the calculated scores to the Gauss data set, iteratively executing the step, and finally calculating the intensity-modulated optimization results under the plan parameters corresponding to the highest score in the Gauss data set. By the use of the predictive model to predict the dose distribution of the case to optimize the guidance, the quality of the plan is guaranteed, and by the use of the Gaussian process to calculate the posterior distribution based on the a priori data, the number of trial and error is reduced, thereby speeding up the optimization.

Owner:SUZHOU LINATECH INTELLIGENT SCI & TECH CO LTD

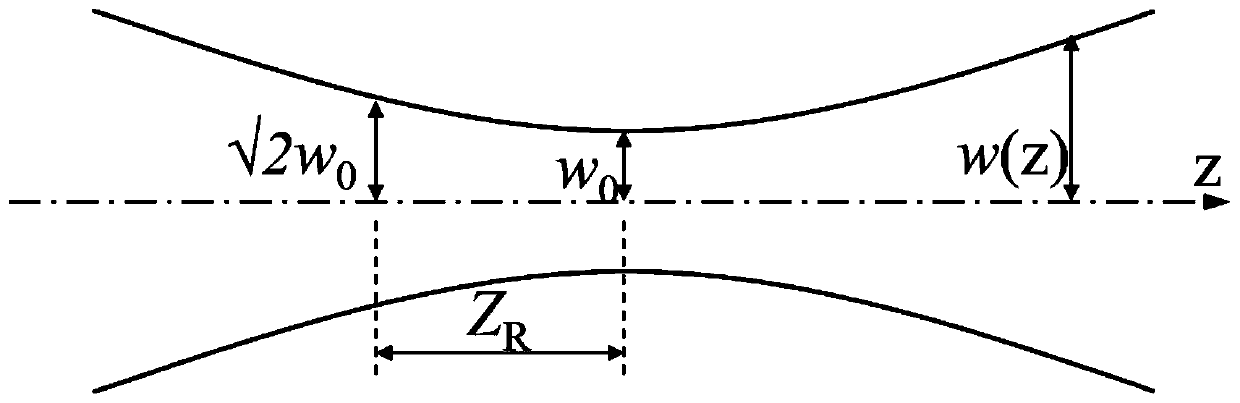

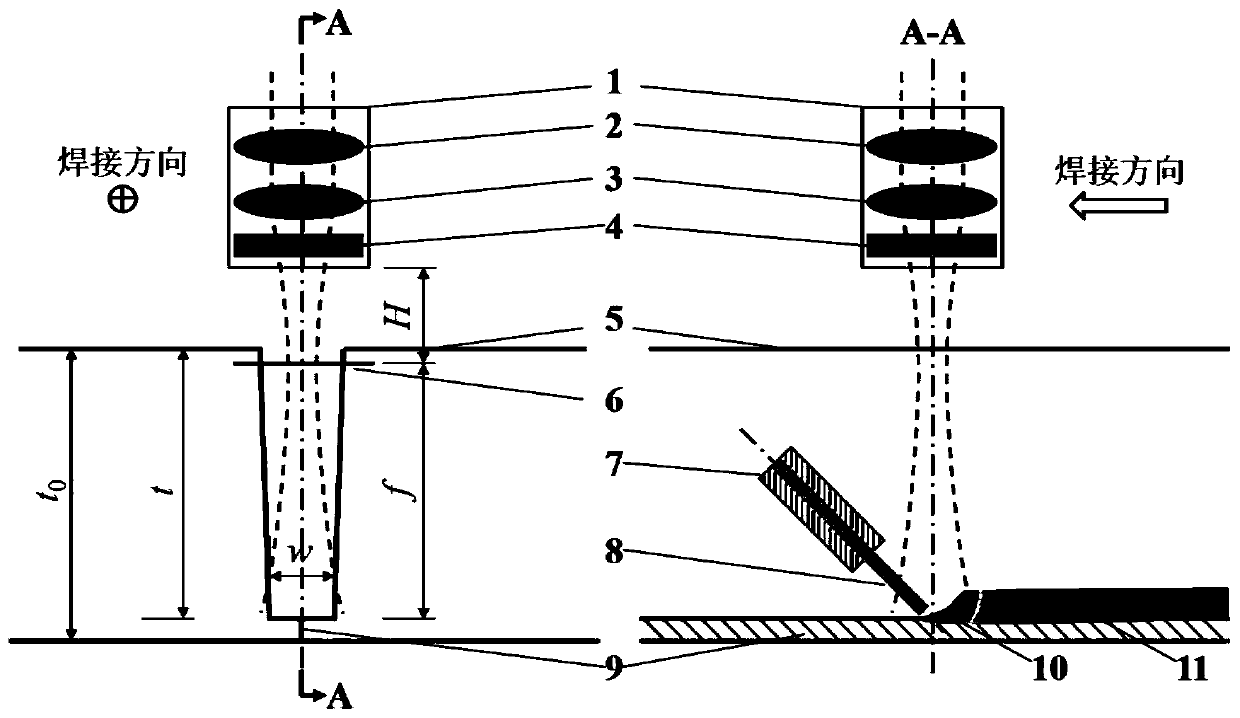

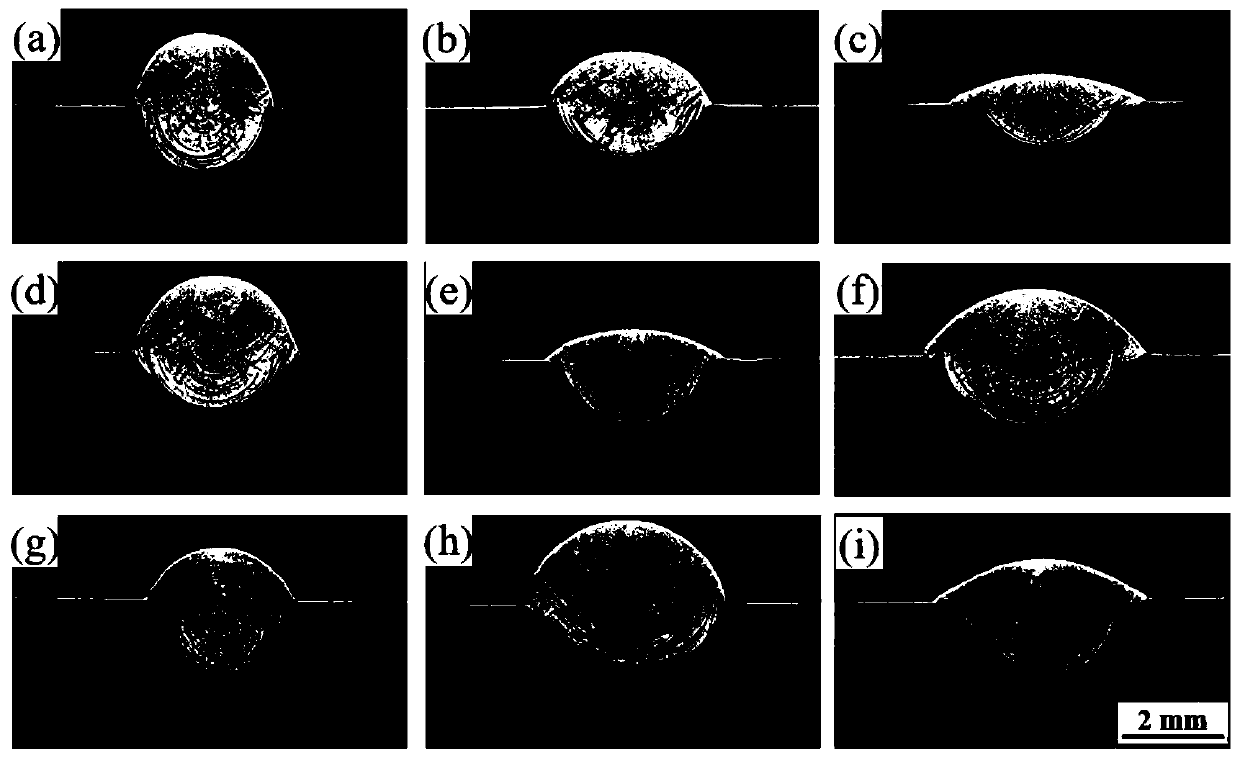

Method for calculating groove width of narrow gap laser filler wire welded plat

ActiveCN110340529AShorten application cycleReduce the number of trialsLaser beam welding apparatusProcess optimizationGroove width

The invention discloses a method for calculating the groove width of a narrow gap laser filler wire welded plate. According to laser beam transmission characteristic parameters, a proper laser defocusamount range for the thickness of a to-be-welded plate can be obtained; according to the defocus amount range, a well-formed laser filler wire single-pass surfacing process parameter window and the welding bead width variation range are obtained on a flat plate of the same material; the expected well-formed groove width is obtained according to the sidewall melting condition and spatial interference analysis; and a groove is machined in a to-be-welded test plate, and narrow gap laser filler wire welding is completed. The well-formed ultra-thick plate narrow gap laser filler wire welding process parameters can be quickly calculated, and the number and cycle of experiments required for process optimization are greatly reduced. According to the specified characteristic parameters of laser filler wire welding equipment, whether narrow gap welding of the corresponding thick plate can be completed or not is judged, the process parameter window is given, and the application period of the narrow gap laser filler wire welding technology is greatly reduced.

Owner:XI AN JIAOTONG UNIV

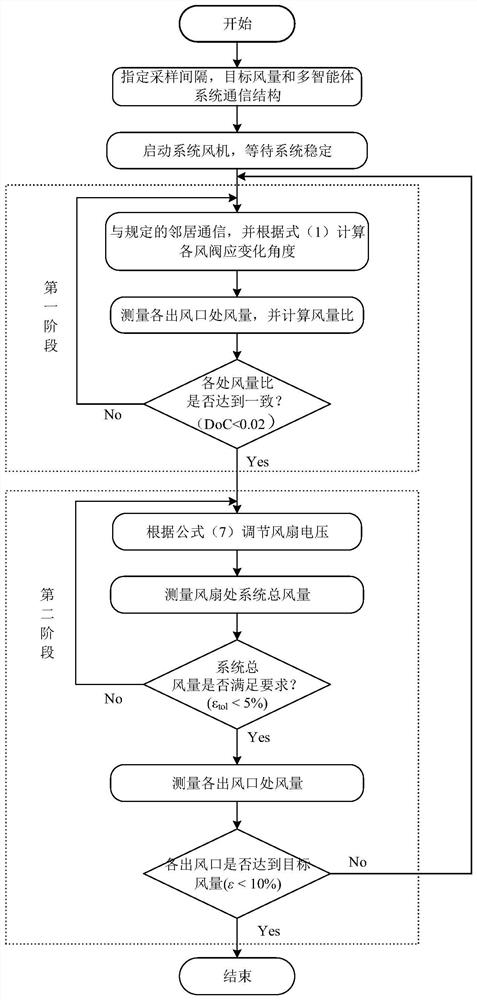

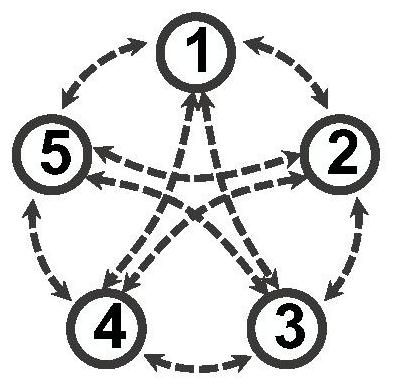

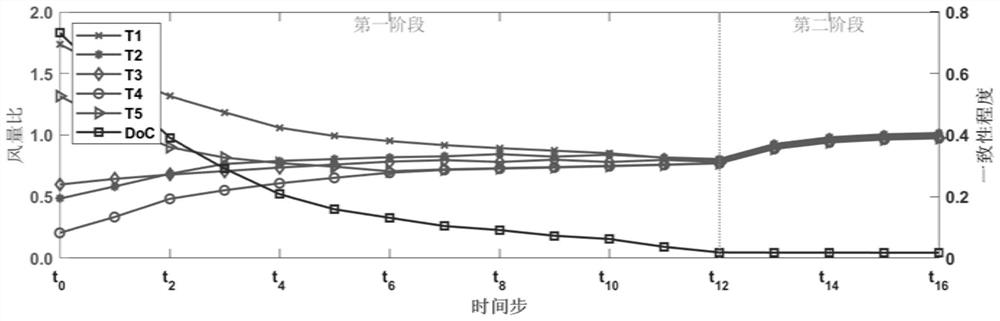

Online wind balance control method and control system for ocean platform ventilation system

ActiveCN114265306AImprove control efficiencyReduce trial and error rateEfficient regulation technologiesAdaptive controlAir volumeEnvironmental geology

The invention provides an online wind balance control method and system for an ocean platform ventilation system. According to the method, the target air outlet volume of each cabin air outlet is set, the real-time air outlet volume of each cabin air outlet is collected, and the ratio rx of the actual air outlet volume of each air outlet to the target air outlet volume is calculated; the ratios are adjusted to be consistent r *; and adjusting the rotating speed of the total fan according to r * so as to balance the air volume of each air outlet. According to the requirement for multi-air-outlet control of the ocean platform ventilation system, multi-agent consistency cooperative control is applied to the air balance problem of the ocean platform ventilation system. Special ventilation system maintenance or debugging time is not needed, online adjustment can be achieved, when the ventilation system operates normally, the air balancing device is used for air balancing, and the influence on a ventilation system user is reduced in practical application.

Owner:OCEAN UNIV OF CHINA

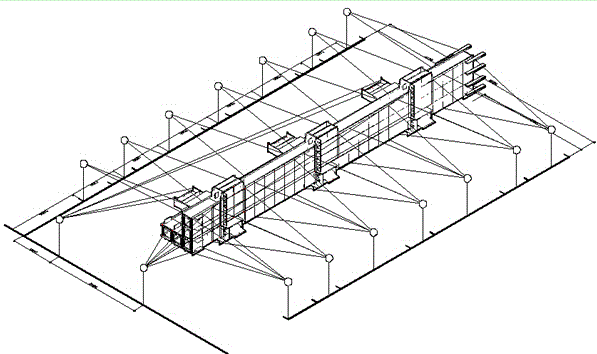

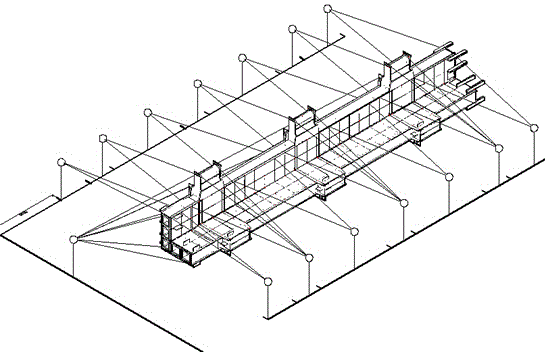

Size detection method of ultra-large combined type steel-box-shaped steel column and steel plate shear wall

InactiveCN105606080AEnsure the quality of appearanceReduce wasteSurveying instrumentsSteel columnsMachining process

The invention belongs to the technical field of constructional engineering and in particular relates to a size detection method of an ultra-large combined type steel-box-shaped steel column and a steel plate shear wall. The size detection method can be used for accurately and rapidly rechecking a node space size of a steel part so as to ensure the output quality of the steel part. A deviation condition of a multi-node complicated steel part of the steel part is intuitively reflected, correction work of factories is guided, groping and probing are reduced and labor hours are saved. Through observation and inspection of steel parts of the same type, an influence rule on a whole deformation tendency of the steel part by manufacturing procedures is obtained; in a subsequent steel part manufacturing process, evidences are provided for the improvement of a machining process, and manufacturing and machining precision is continuously improved, and time and labor are saved and material wastes are reduced. The molding quality of the steel part is continuously improved, the matching of field installation is coordinated, so that the steel part can be machined accurately in one time and reworking does not occur in field. The guarantee degree of a construction progress is improved, the approval of owners and each matched subcontract unit is won and the project is propelled smoothly.

Owner:ZHEJIANG BADA CONSTR GRP

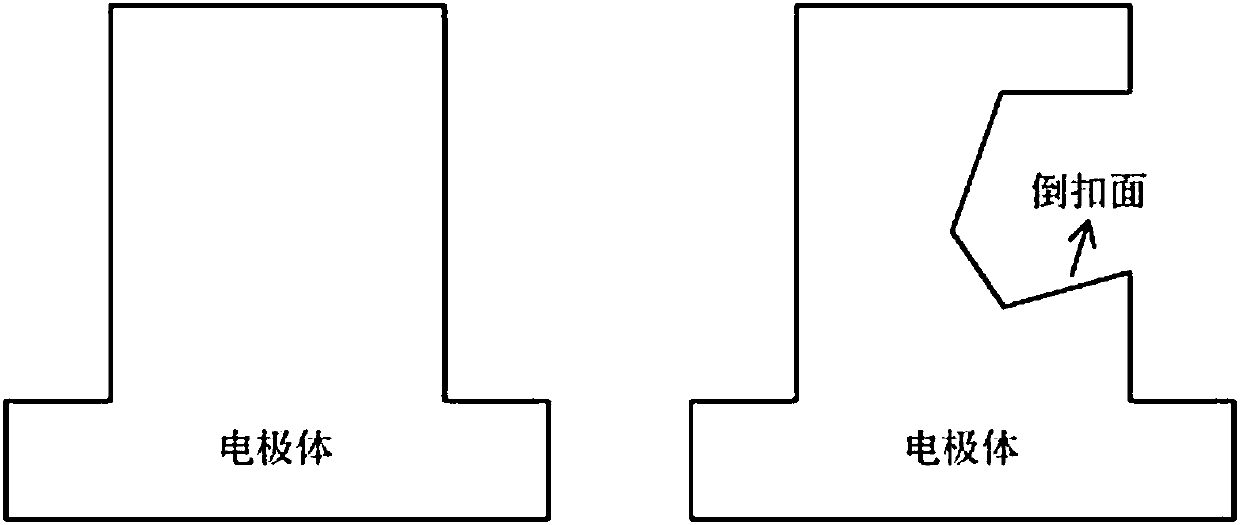

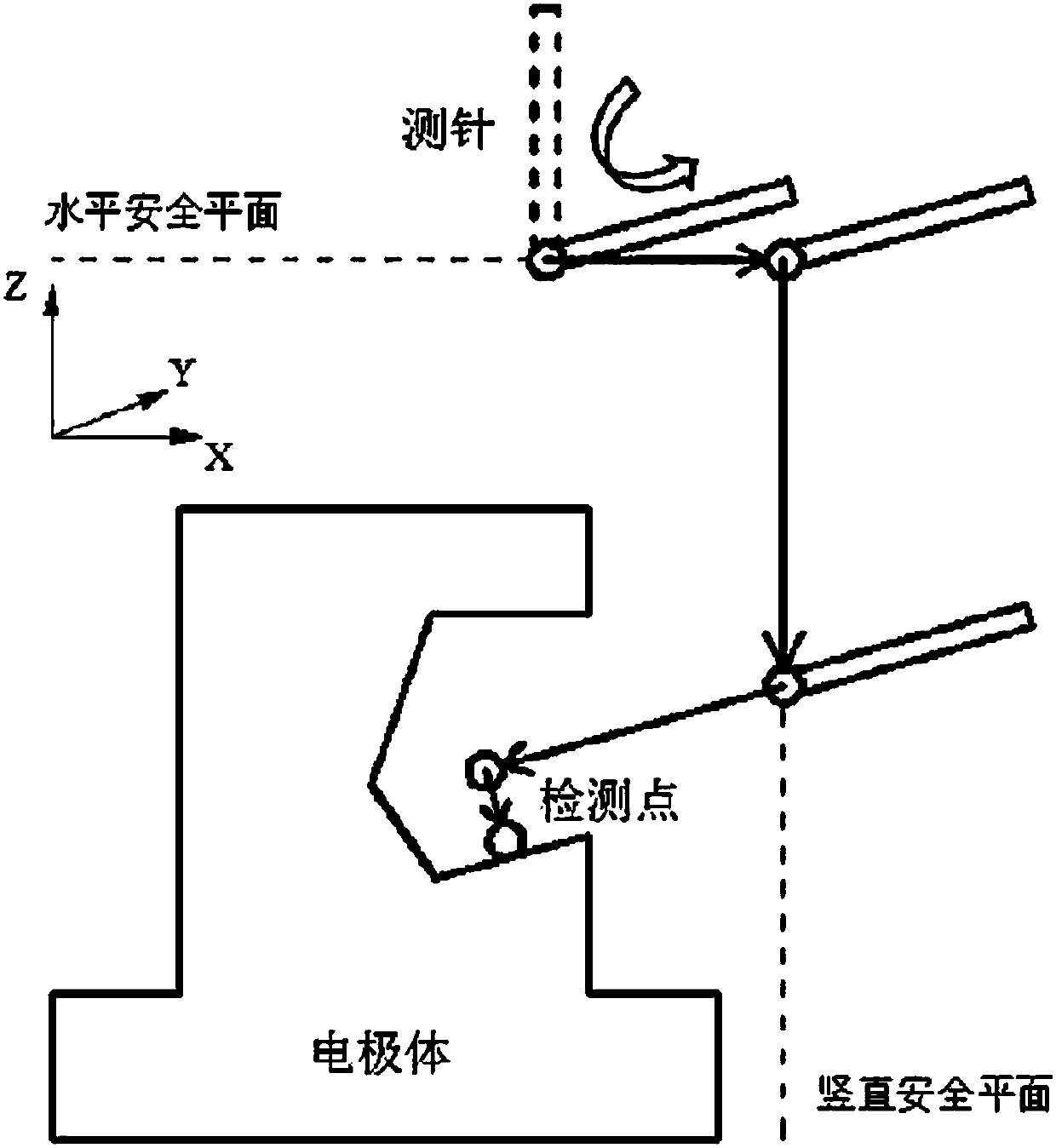

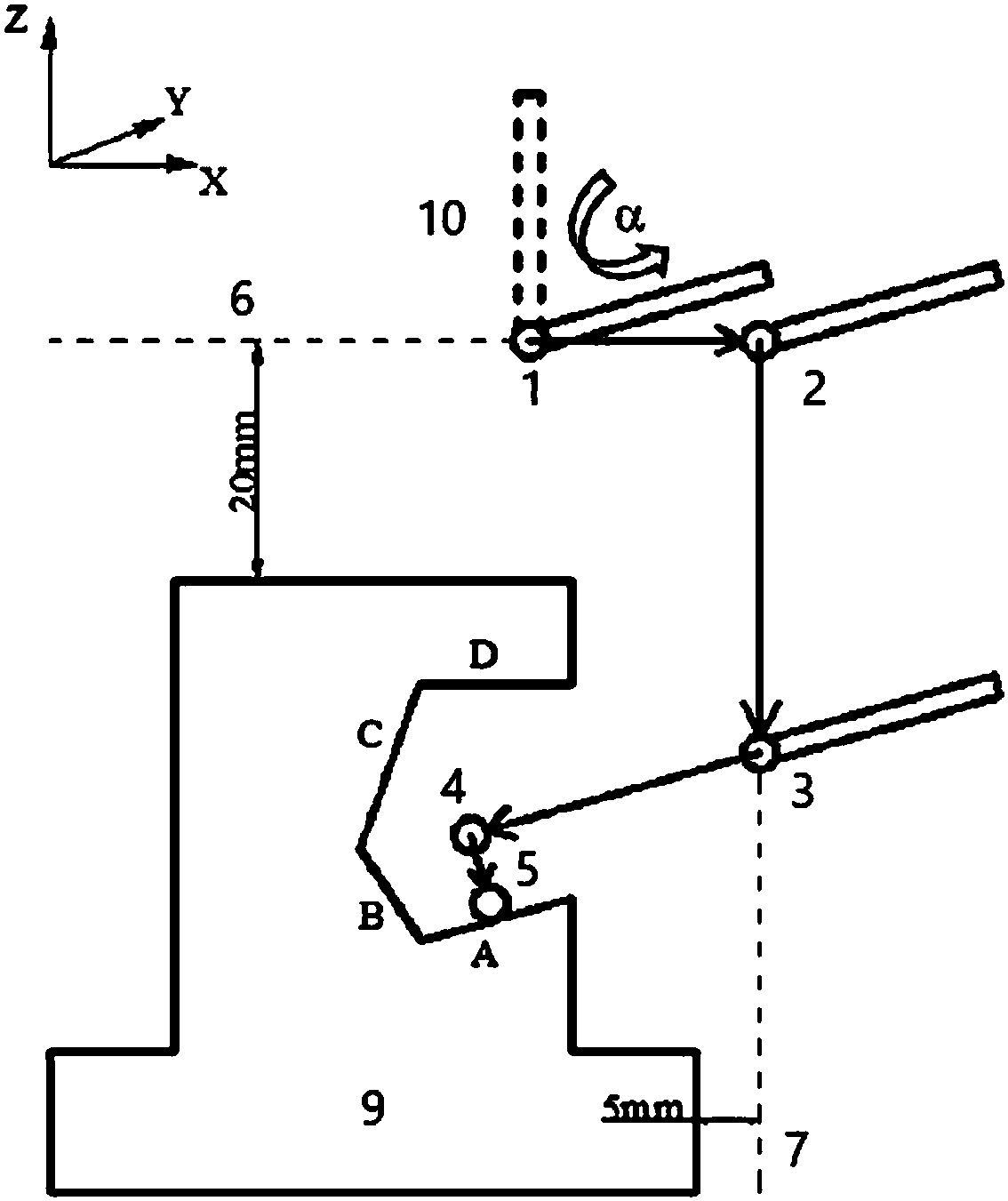

Three-coordinate automatic detection realizing method of belt back-off electrode

InactiveCN107869939AReduce energy consumptionReduce trial and errorMechanical measuring arrangementsPhysicsElectrode

The invention discloses a three-coordinate automatic detection realizing method of a belt back-off electrode and overcomes the defect that existing three-coordinate measuring automatic detection cannot generate interference-free measuring traces of a measuring probe and the belt back-off electrode. Influence of existence of an electrode back-off face on generation of an three-coordinate automaticdetection program is fully taken into consideration, the defect that measuring probe measuring traces automatically generated by existing three-coordinate detection programs interfere with a to-be-detected belt back-off electrode is overcome, and automatic generation of a belt back-off electrode measuring program can be realized by utilizing the method. Actual testing proves that interference-freemeasuring traces of the measuring probe of a three-coordinate detector and the belt back-off electrode can be acquired conveniently and quickly, and needs on accurately measuring shape and size of the belt back-off electrode of the three-coordinate detector are met.

Owner:中数复新智能科技(上海)有限公司

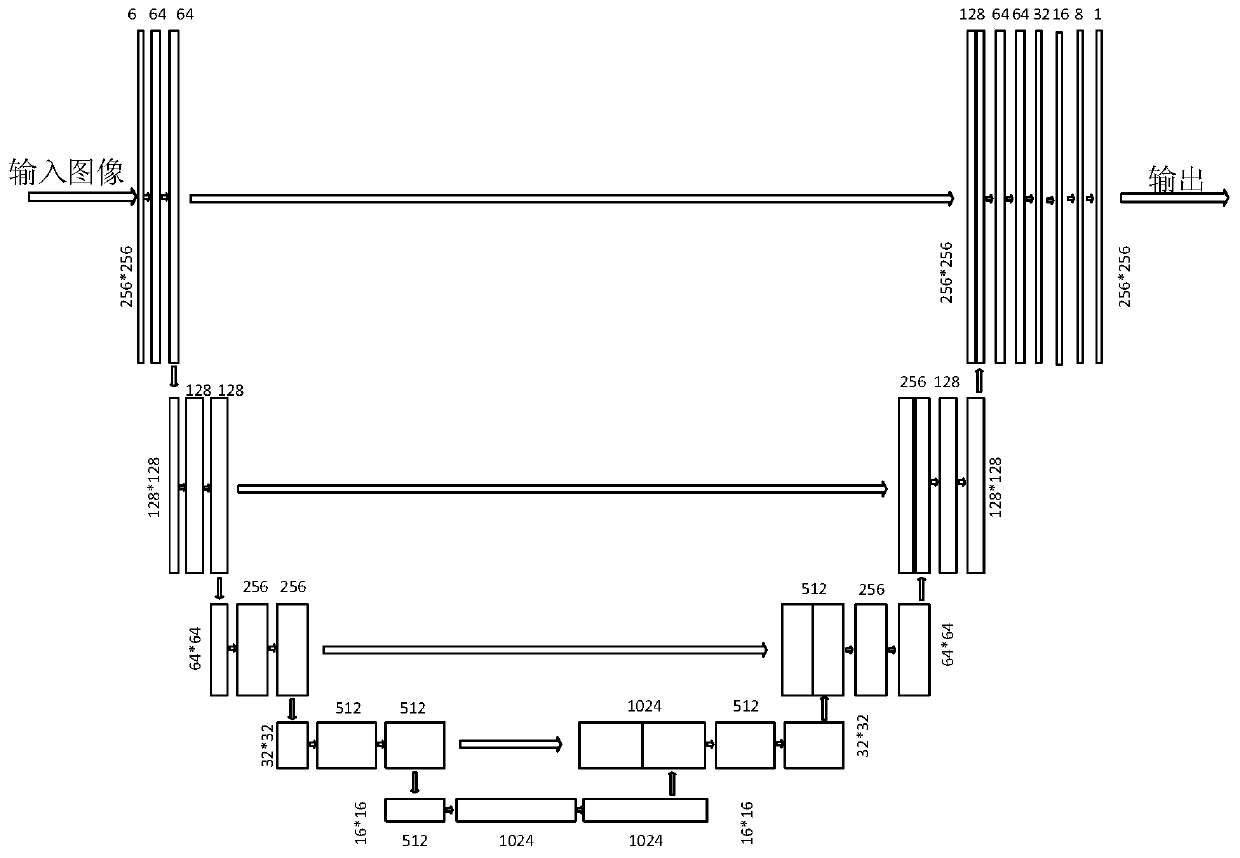

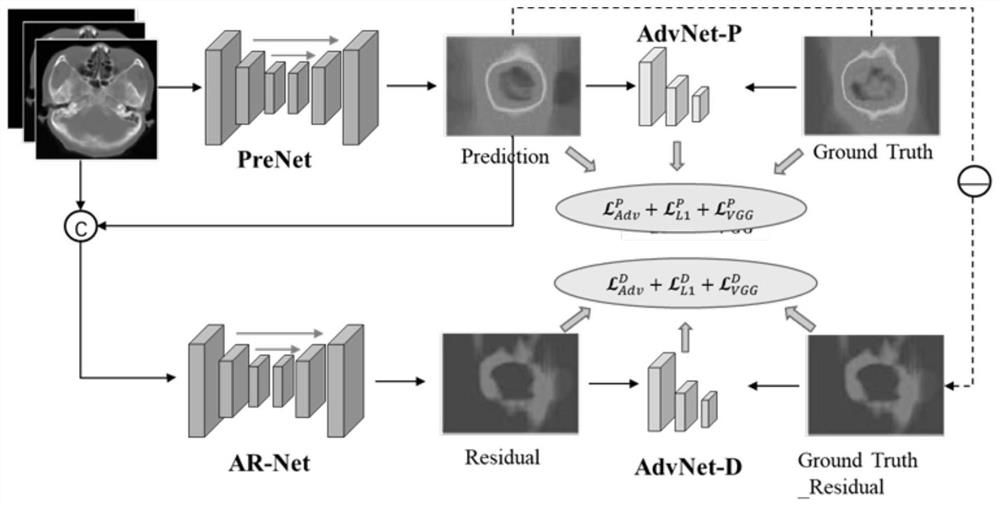

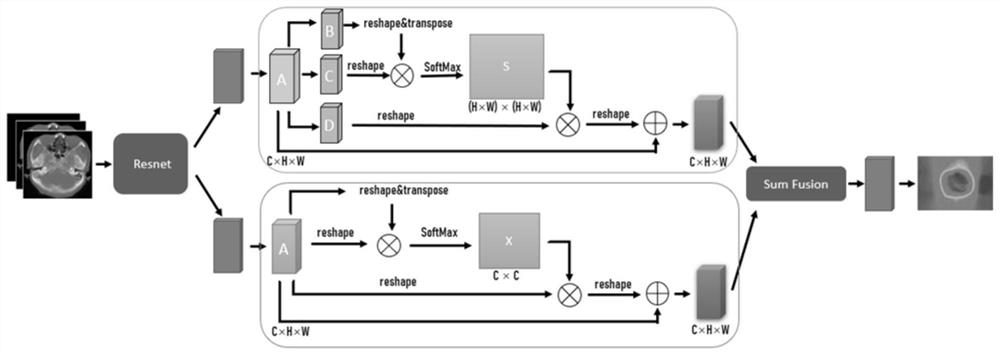

Three-dimensional dose distribution prediction method based on adaptive correction adversarial network

ActiveCN111888665APrediction of individualized 3D dose distribution informationImprove forecast accuracyX-ray/gamma-ray/particle-irradiation therapyAnatomical structuresAlgorithm

The invention relates to a three-dimensional dose distribution prediction method based on an adaptive correction adversarial network, and provides a three-dimensional dose distribution prediction model based on the adaptive correction adversarial network by taking a generative adversarial network as a basic architecture and utilizing an ensemble learning idea. A dose distribution map as close as possible to target dose distribution is generated by using the idea of mutual game between a generator and a discriminator in the generative adversarial network. At the same time, the adaptive correction network is trained to fit a residual plot between generated and real dose distribution maps. The dose distribution map synthesized by the generator and the residual plot obtained by the adaptive correction network are superposed to obtain more ideal corrected dose distribution conforming to individual differentiation. According to the method, mapping between dosimetry characteristics and a geometric anatomical structure can be effectively learnt, and the network has higher robustness.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV +1

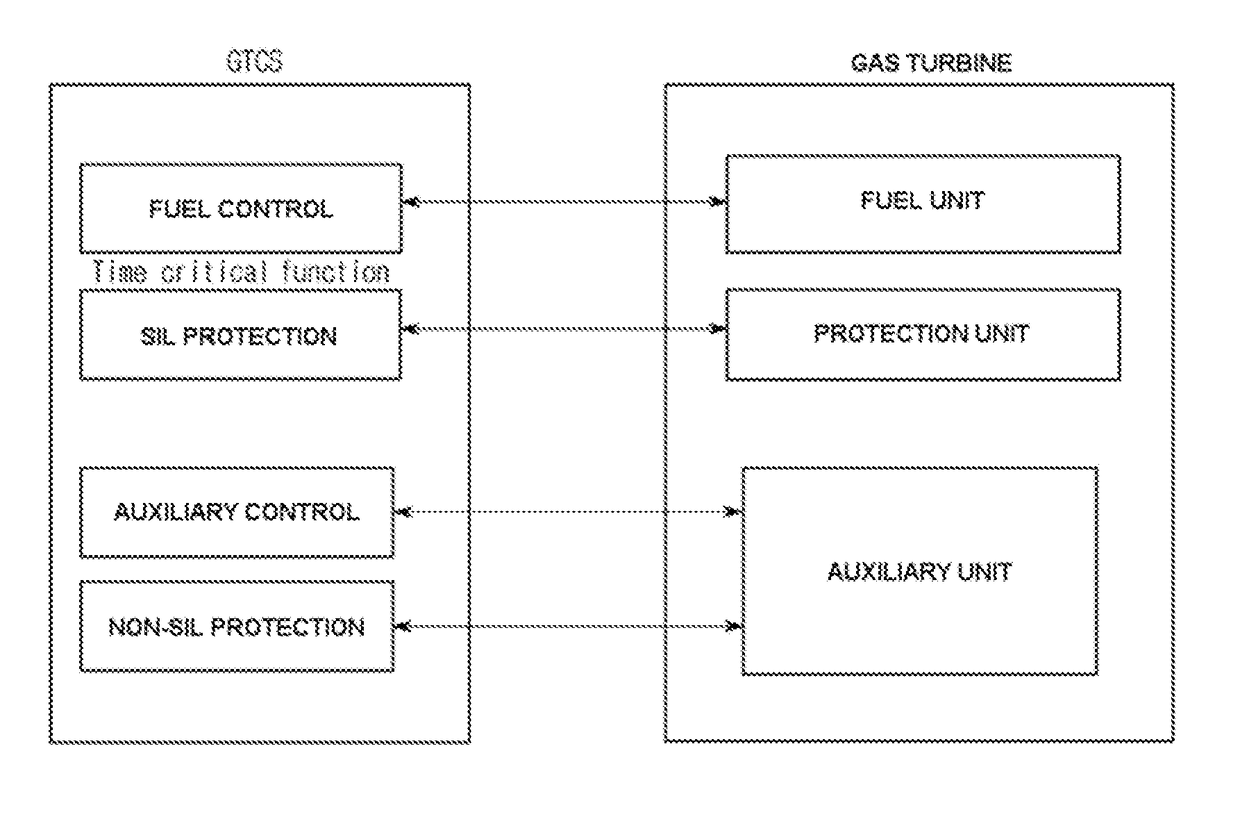

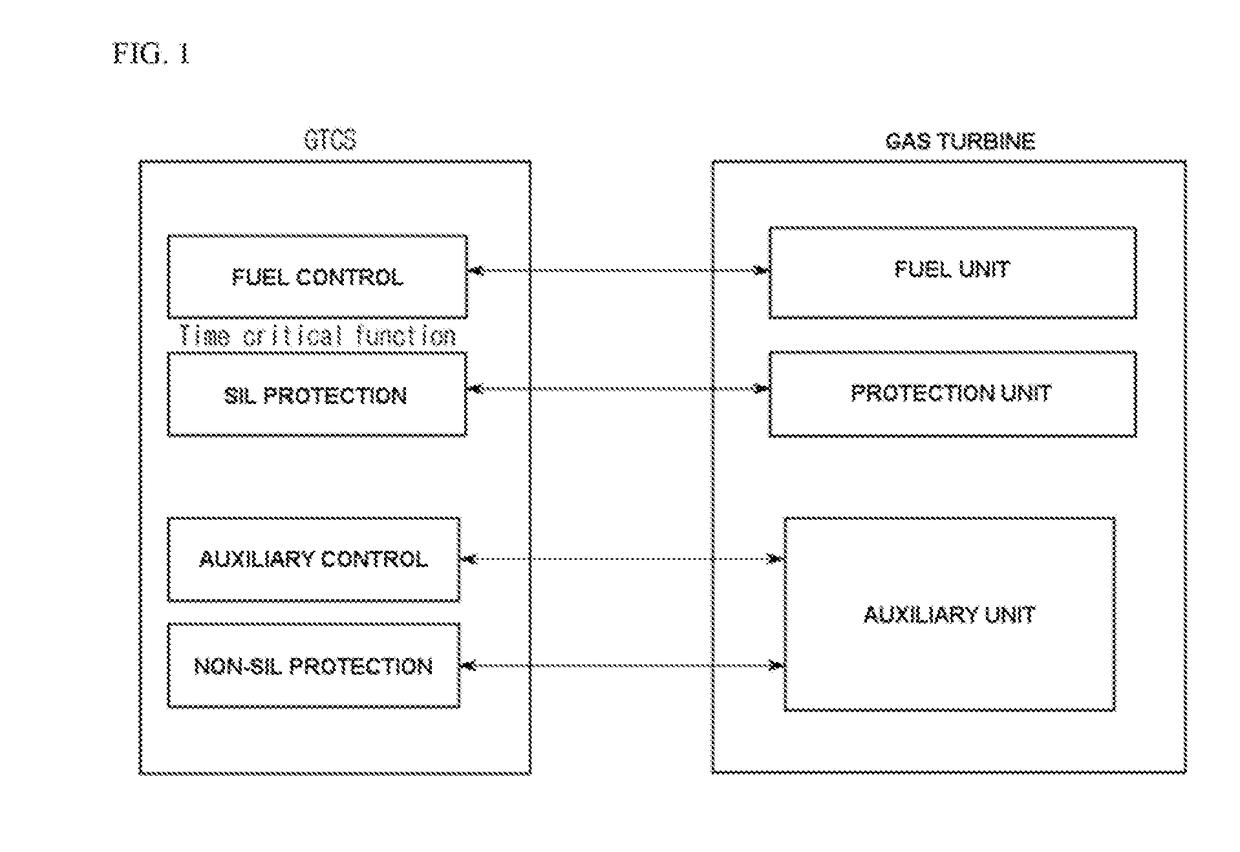

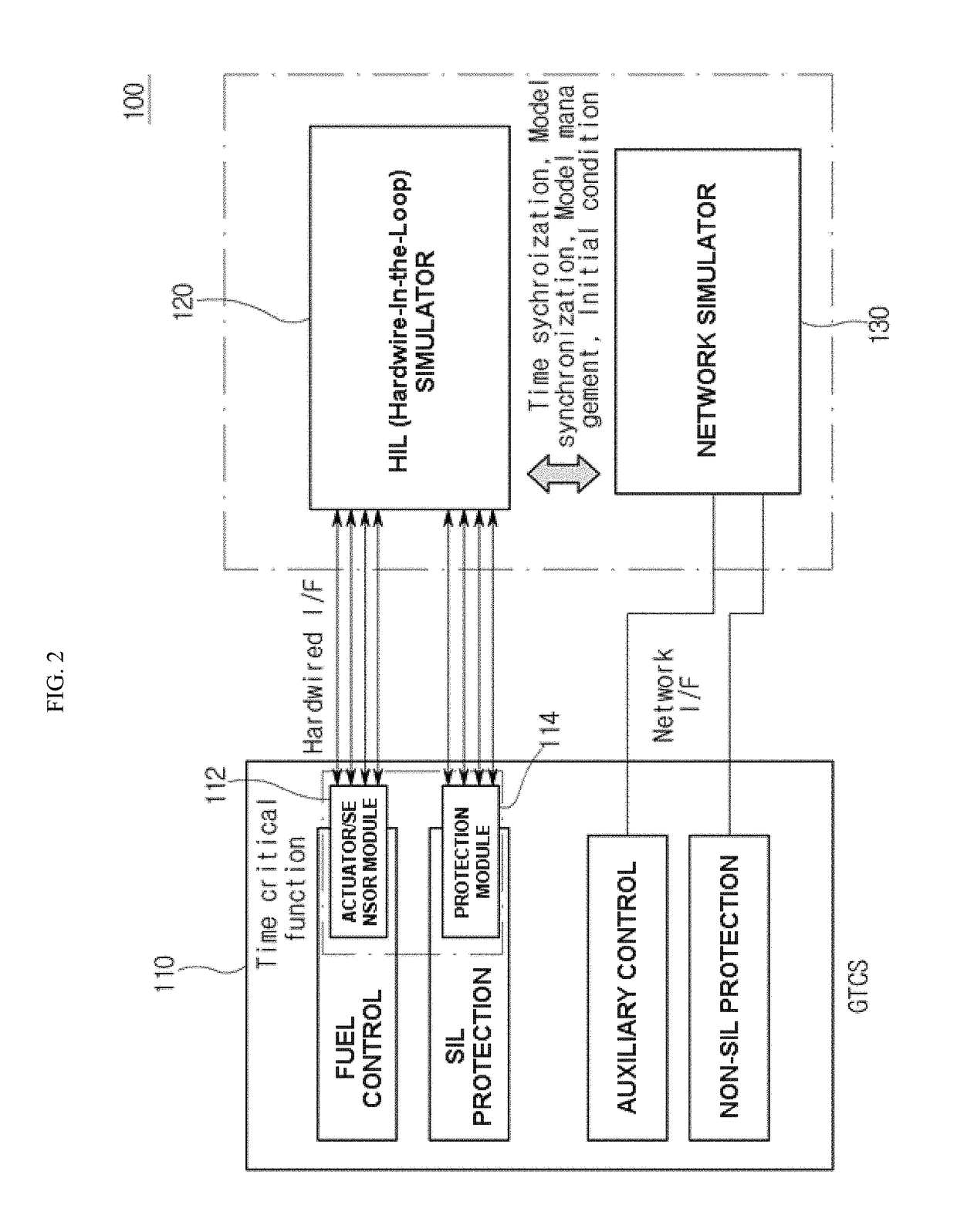

Real-time gas turbine simulation system and execution method thereof

ActiveUS20180284750A1Reduce trialReduce errorsGas-turbine engine testingEngine fuctionsSafety Integrity LevelControl system

Disclosed herein are a real-time gas turbine simulation system and an execution method thereof, capable of verifying input and output signals of an actual gas turbine control system (GTCS) by simulating a gas turbine in real time to reduce trial and error in power plant operation in a gas turbine power generation system. The real-time gas turbine simulation system simulates a gas turbine to verify a GTCS for controlling a gas fuel through an actuator / sensor module and a safety integrity level (SIL) protection function through a protection module for the gas turbine, and includes a hardwire-in-the-loop (HIL) simulator connected to the actuator / sensor module and the protection module through one or more hardwires to simulate a time critical portion of the gas turbine in real time, and a network simulator connected to the GTCS through a network to simulate a non-time critical portion of the gas turbine in real time.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

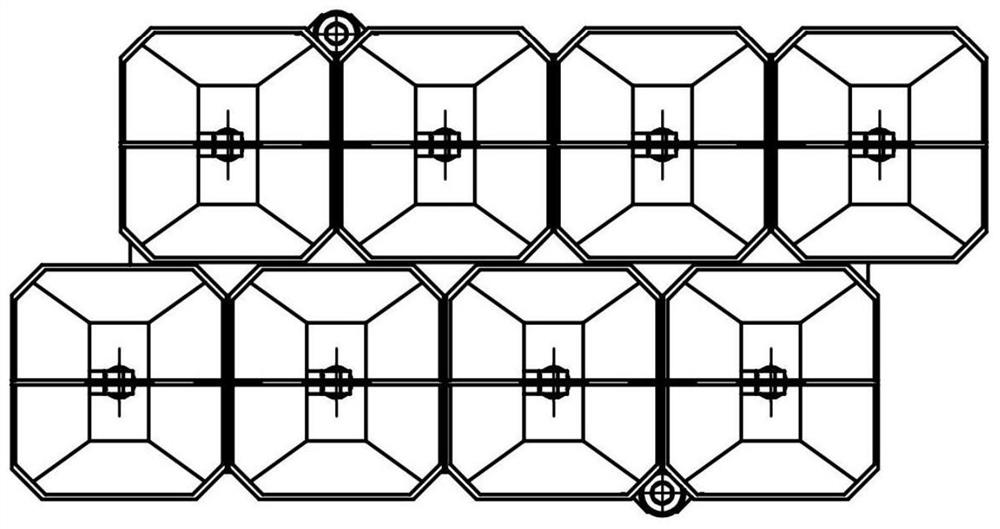

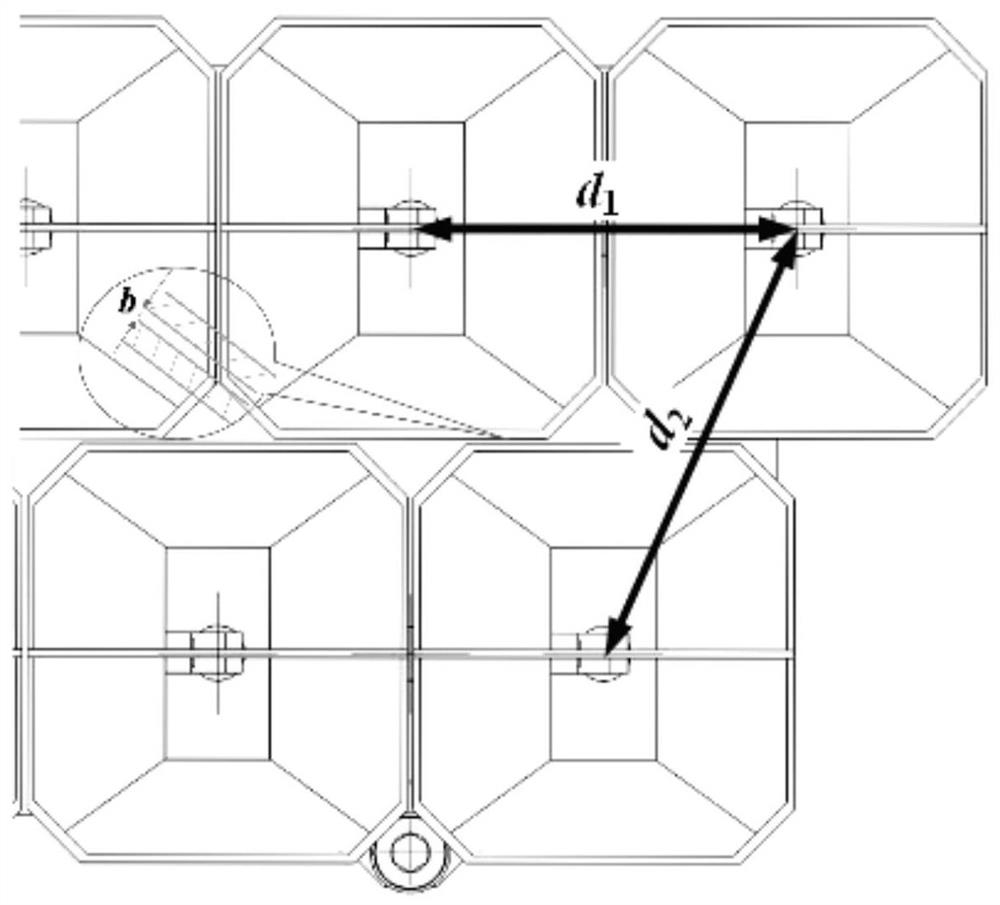

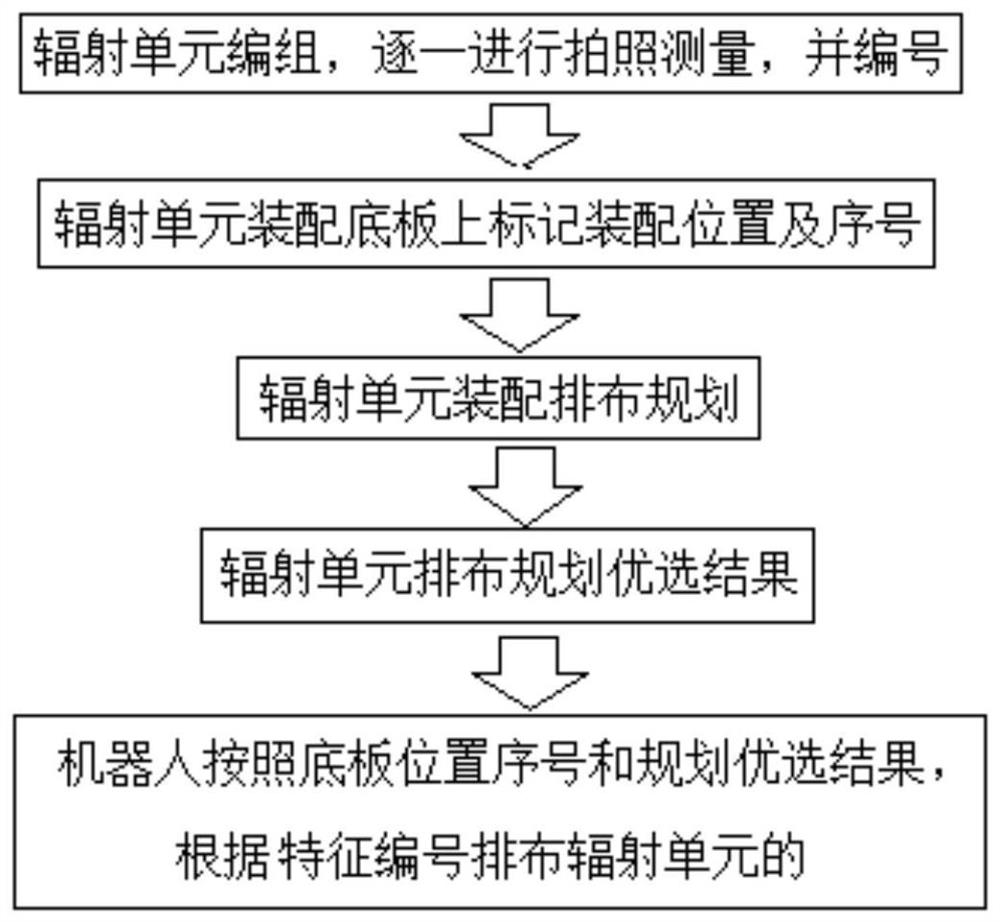

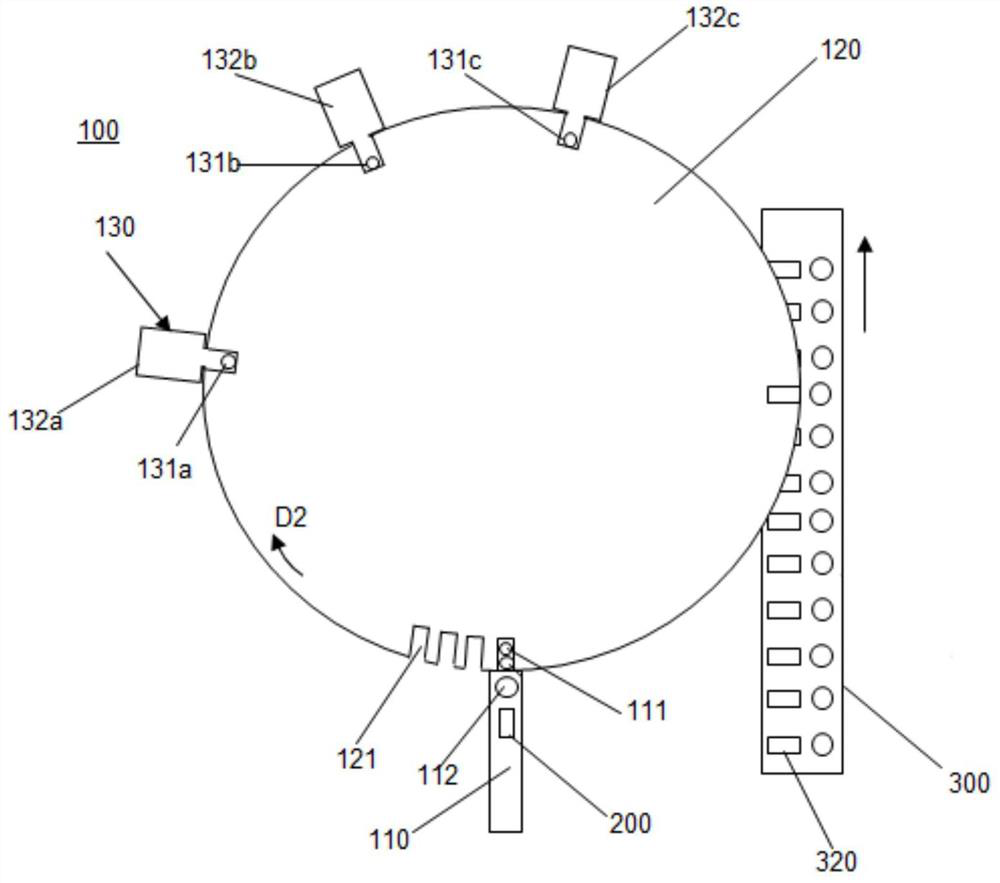

Intelligent arrangement and assembly method of feature numbers based on radiation units

PendingCN112018508AReduce the probability of interferenceHigh precisionRadiating elements structural formsIndividually energised antenna arraysSoftware engineeringMechanical engineering

An intelligent arrangement and assembly method of the feature numbers based on radiation units comprises the following steps: A) grouping the radiation units to be assembled, photographing and measuring the radiation units one by one, numbering the radiation units one by one, and calculating a required mouth edge center distance and a mouth edge margin; B) sequencing, numbering and marking serialnumbers of to-be-assembled arrangement positions on a radiation unit array assembly bottom plate; C) enabling an upper computer to carry out radiation unit assembling arrangement planning; D) enablingthe upper computer to determine a radiation unit arrangement planning optimization result; and E) enabling a robot to automatically and intelligently arrange the radiation units according to the position serial number of the bottom plate, the arrangement planning optimization result and the feature numbers and assemble the radiation units into an array according to the output data of the upper computer. The one-time assembly success rate and the efficiency of the whole assembly process are improved, the assembly preparation period is greatly shortened, and the assembly precision and consistency of the radiation unit are greatly improved; and completely efficient and automatic operation can be achieved for large-scale radiation unit array arrangement and assembly which are difficult to achieve by manpower.

Owner:SHANGHAI CAMA OPTOELECTRONICS EQUIP

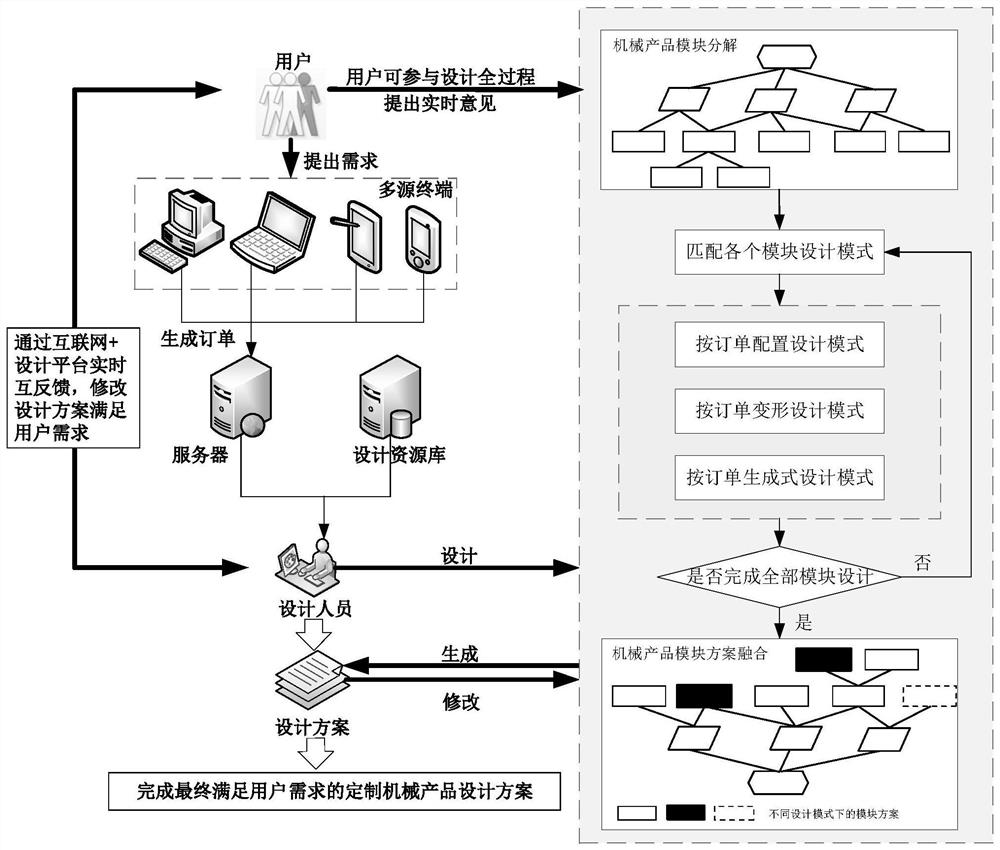

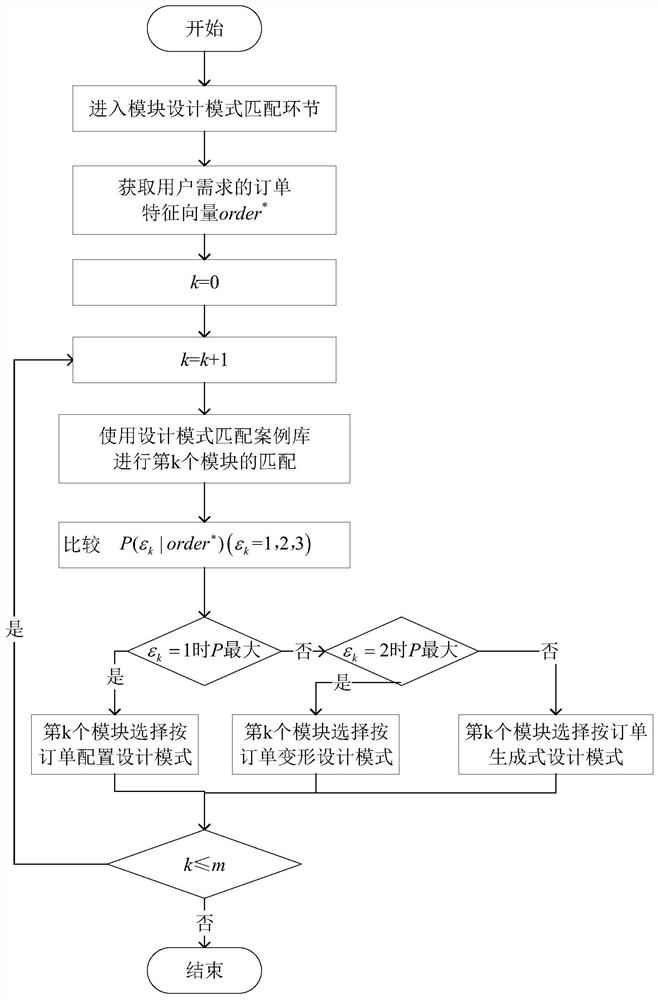

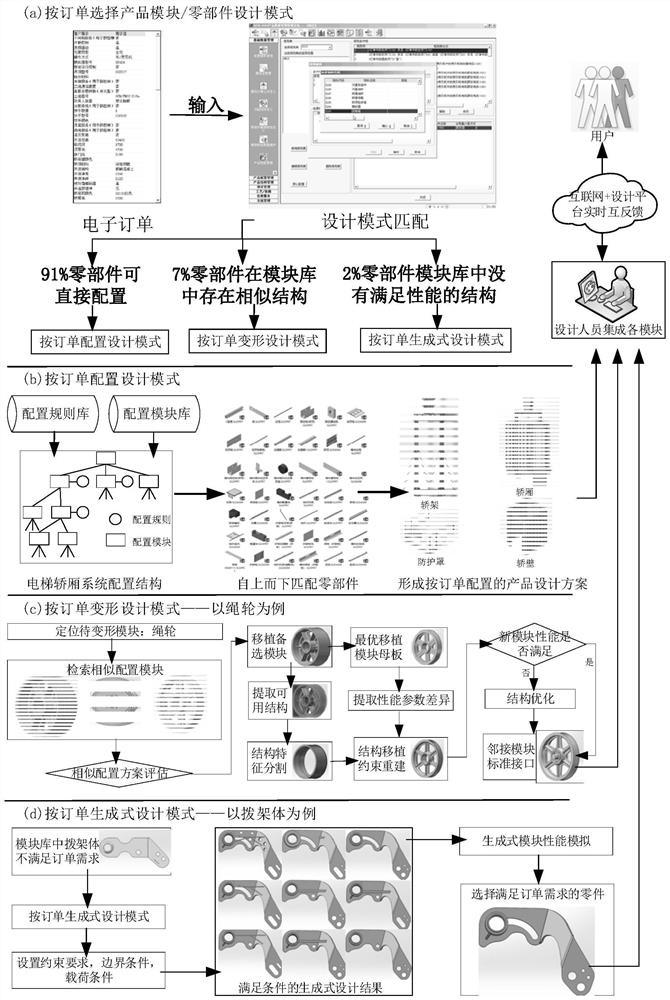

Mechanical product personalized design mode matching method oriented to 'Internet +' environment

ActiveCN111815409AReduce trial and errorImprove design efficiencyBuying/selling/leasing transactionsManufacturing computing systemsPersonalizationThe Internet

The invention discloses a mechanical product personalized design mode matching method oriented to the Internet + environment. According to the method, a user order is quantified into a feature vector,a mechanical product is decomposed into modules, a historical case library is constructed, and a design mode scheme matched according to the user order is obtained according to the probability that auser is satisfied when different design modes are adopted by all the modules of the mechanical product. From the perspective of probabilistic, a personalized design mode matching method of each design module in product customization design is researched according to the Bayesian theorem; the user satisfaction probability values of different design modes adopted by different design modules are calculated, the design mode corresponding to each design module is matched, the trial and error situation when a designer selects the design mode according to design experience is reduced, and the designefficiency is improved; and the intelligence and operability in the personalized design mode matching process are improved.

Owner:ZHEJIANG UNIV

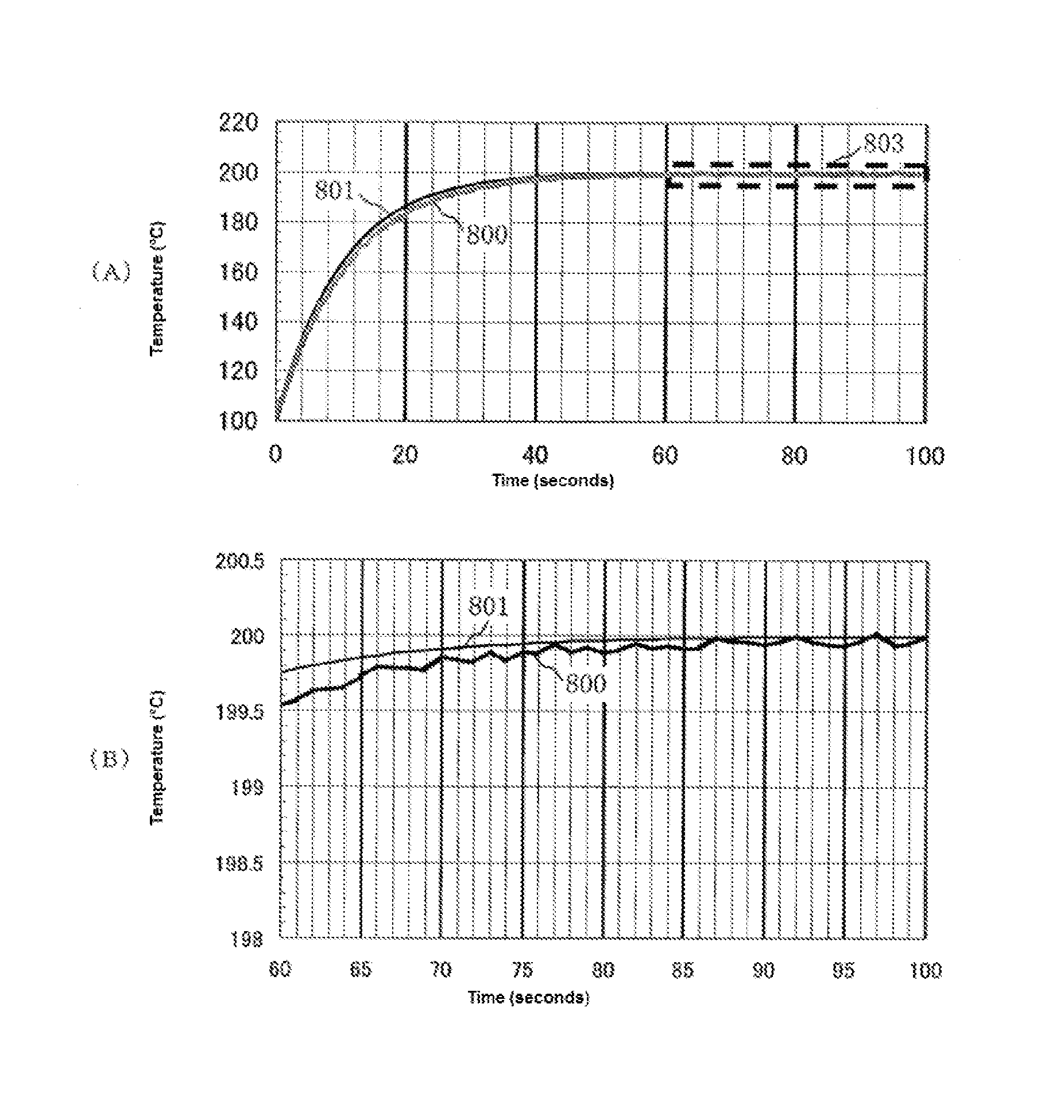

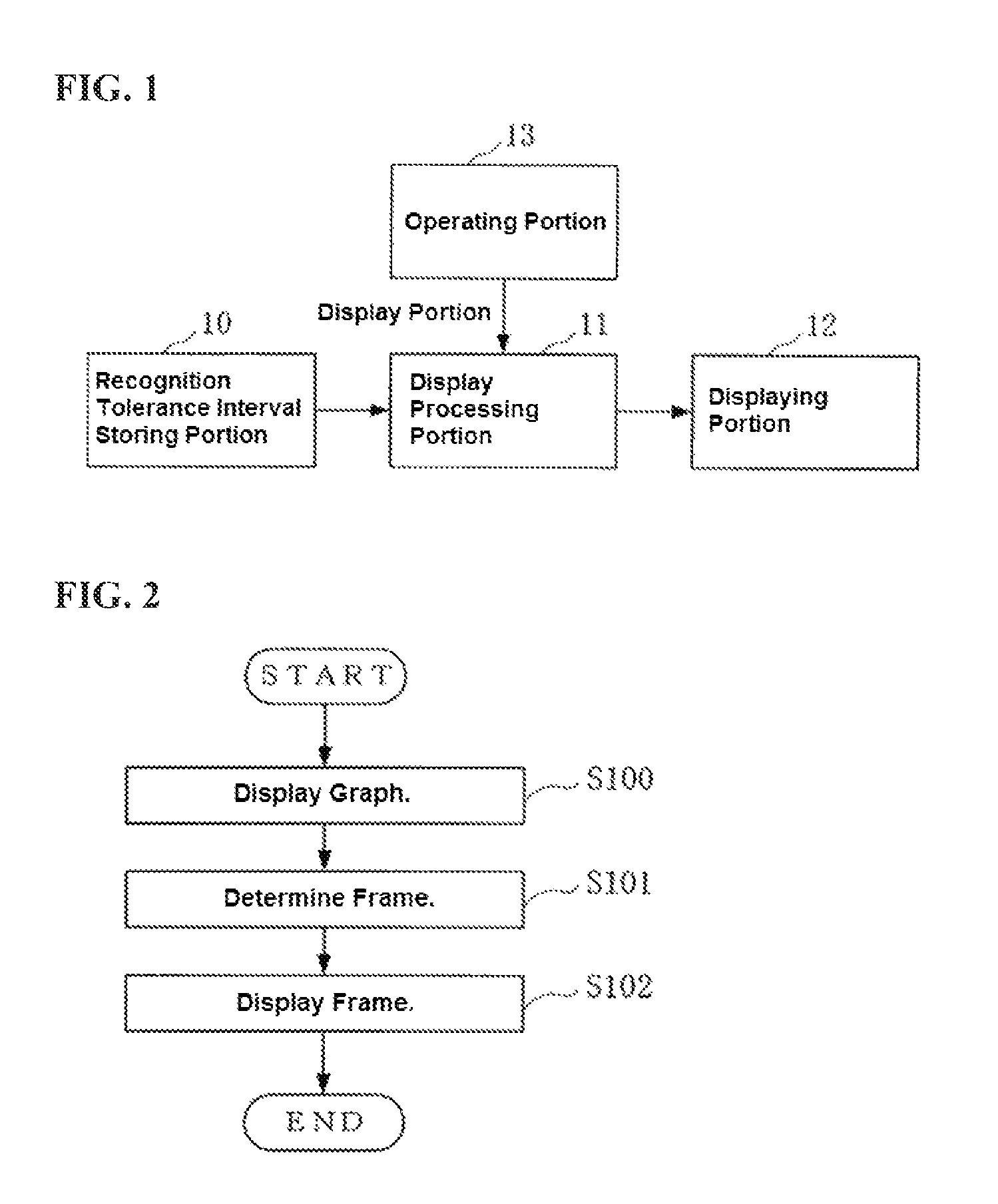

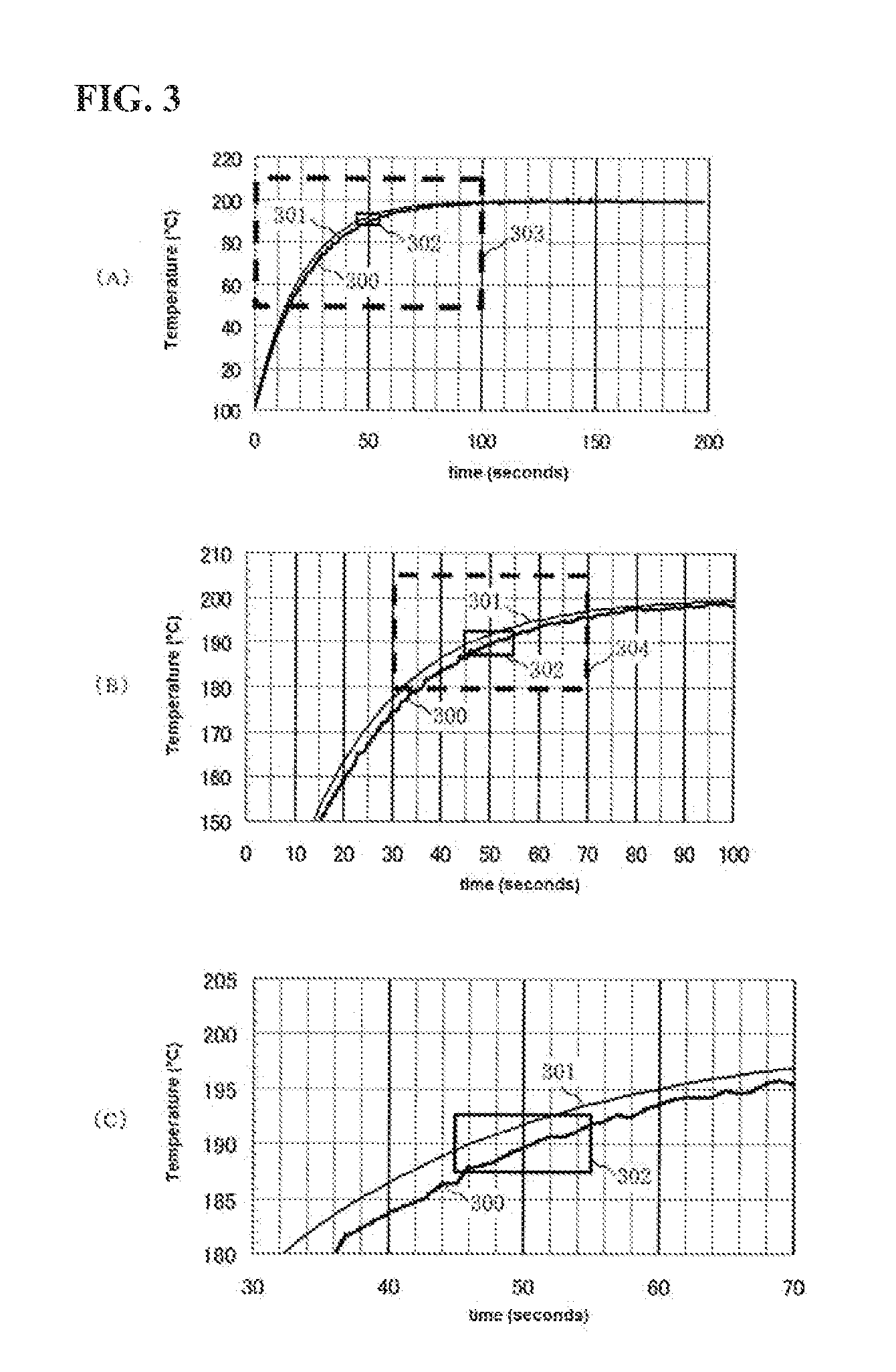

PID adjustment support device and method

InactiveUS8666708B2Reduce the trial-and-error by the userReduce trial and errorComputation using non-denominational number representationAdaptive controlEngineeringTolerance interval

A PID adjustment support device has: a recognition tolerance interval storing portion for storing, in advance, a recognition tolerance interval understood by a user regarding target quantity data of a model to be controlled; and a display processing portion for graphing and displaying, on a displaying portion, the target quantity data and, as a modeling result, a model-response waveform that is a control-response waveform calculated based on the model to be controlled, and for overlaying with the modeling result and displaying the recognition tolerance interval stored in the recognition tolerance interval storing means.

Owner:YAMATAKE HONEYWELL CO LTD

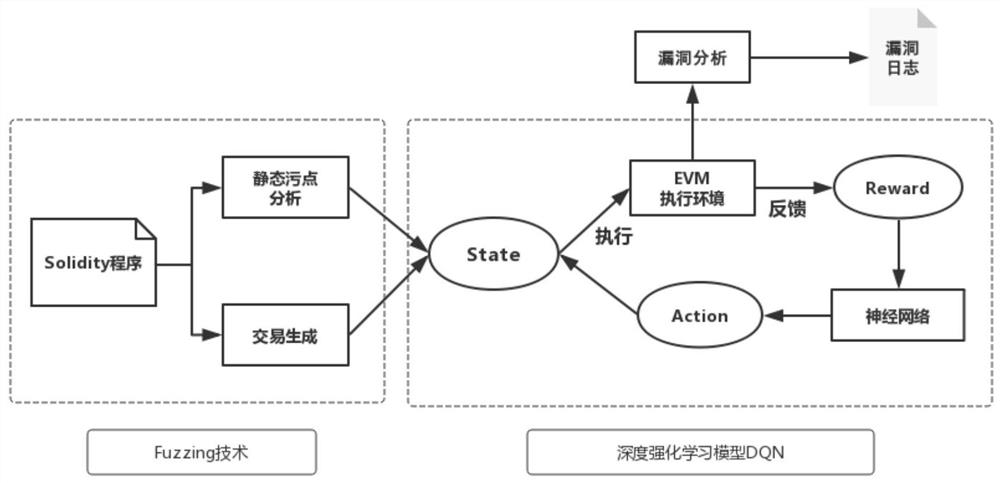

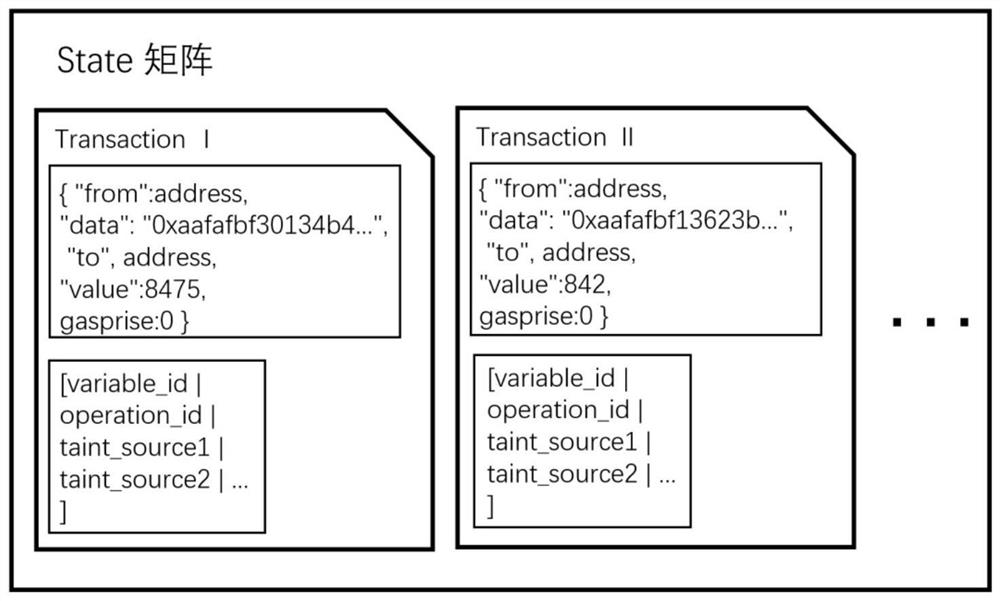

Method, system and medium for checking smart contract vulnerabilities

ActiveCN110399730BEasy to detectReduce false alarm ratePlatform integrity maintainanceSmart contractSolidity

Owner:SHANGHAI JIAOTONG UNIV

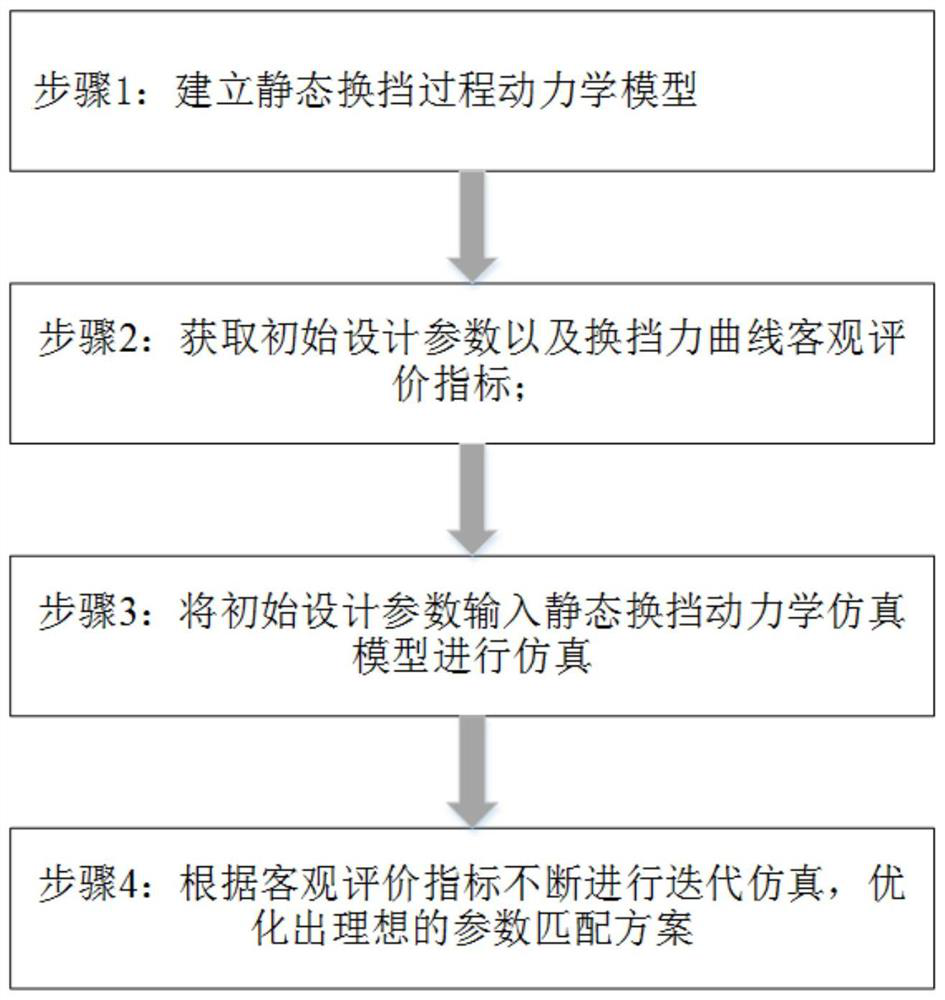

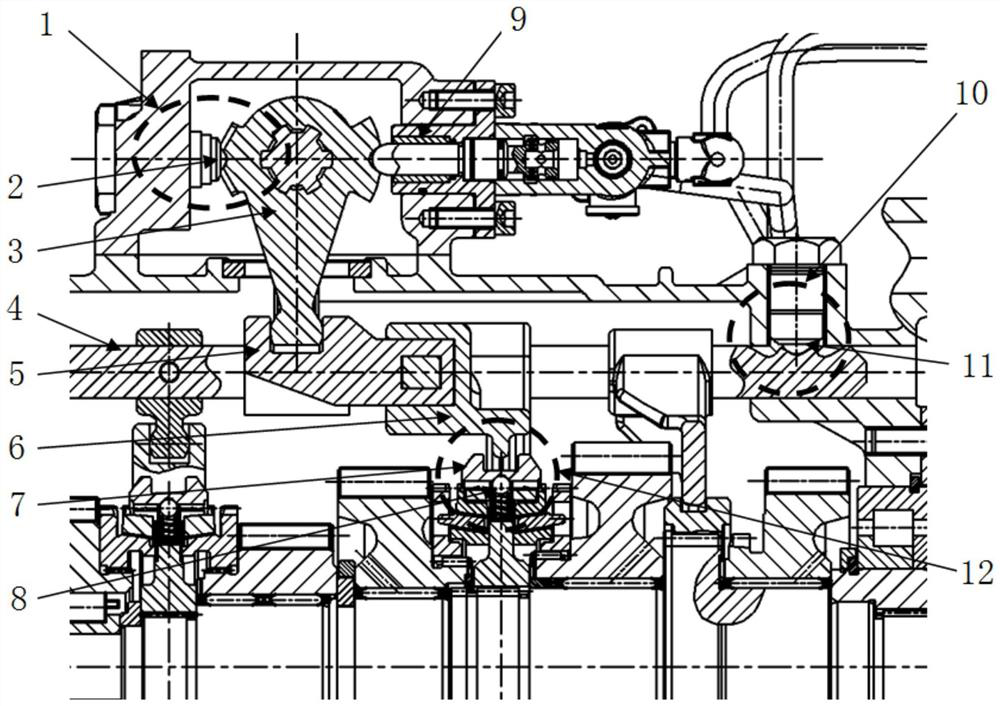

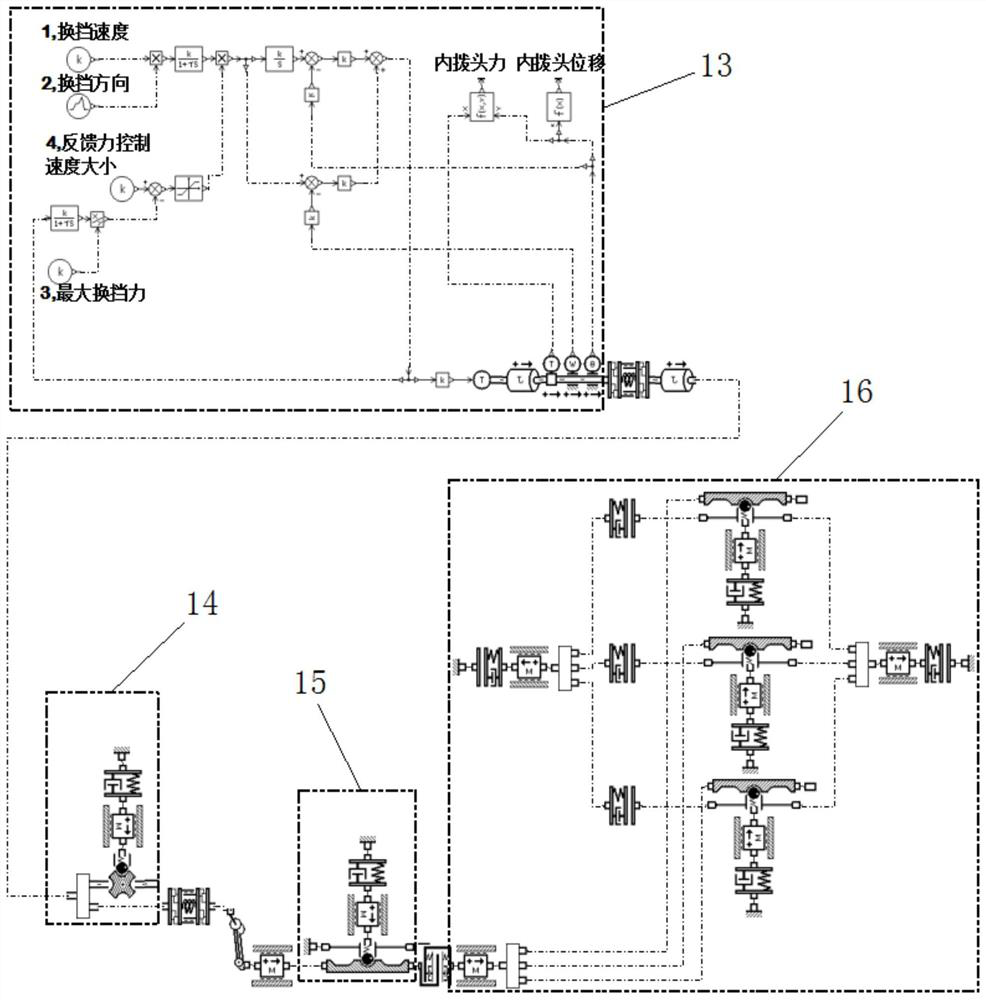

Mechanical transmission static gear shifting simulation method based on AMESim

PendingCN113111449AReduce trial and errorReduced cycle design processGeometric CADDesign optimisation/simulationClassical mechanicsEngineering

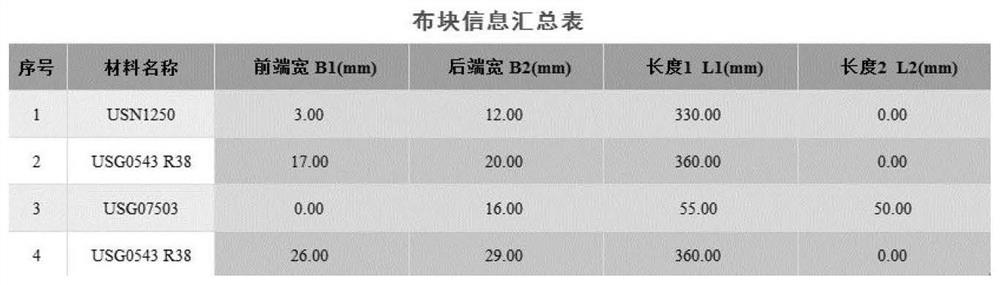

The invention relates to a gear shifting simulation method of a transmission, in particular to a mechanical transmission static gear shifting simulation method based on AMESim, and aims to solve the problems that in the design process of an existing mechanical transmission, gear shifting force of all positions in the whole gear shifting process cannot be accurately predicted, a whole gear shifting force curve cannot be accurately calculated, and the gear shifting force cannot be accurately predicted. The design period of gear shifting related parts of the transmission is long, and the cost is increased. The method comprises the steps that a mechanical transmission static gear shifting process dynamic simulation model based on AMESim is established; initial design parameters of three grooves of the mechanical transmission and objective evaluation indexes of a gear shifting force curve are obtained; inputting the initial design parameters into a dynamic simulation model for simulation; iterative simulation is continuously carried out according to the objective evaluation indexes of the gear shifting force curve, and an optimized matching scheme of the groove size and the spring parameters is obtained.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

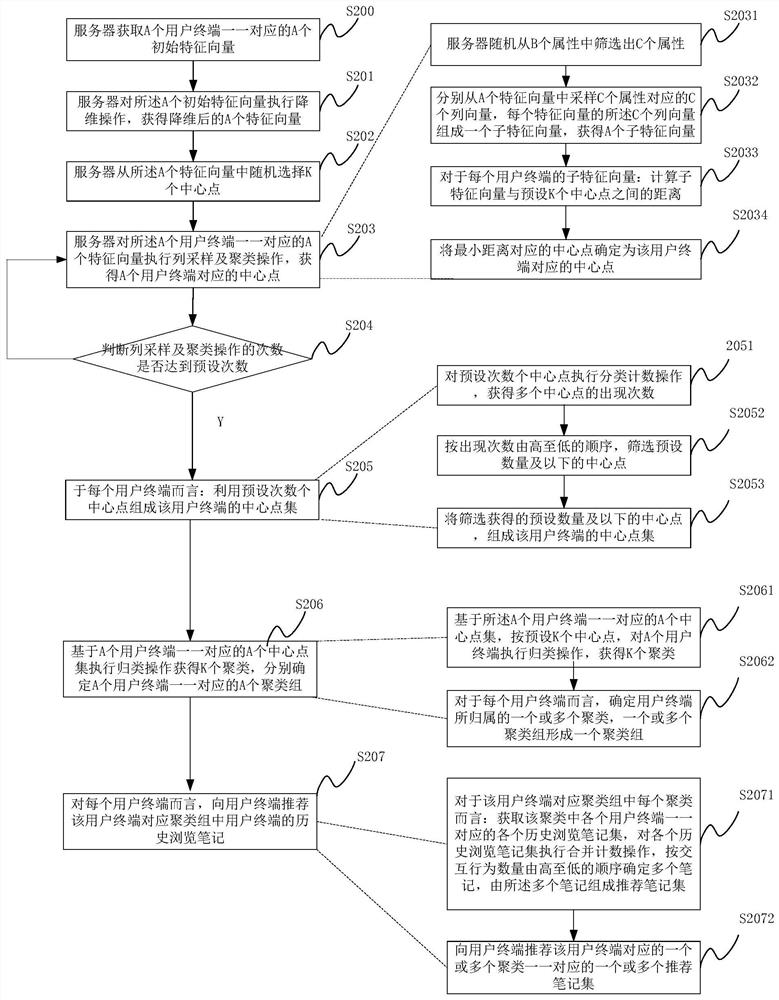

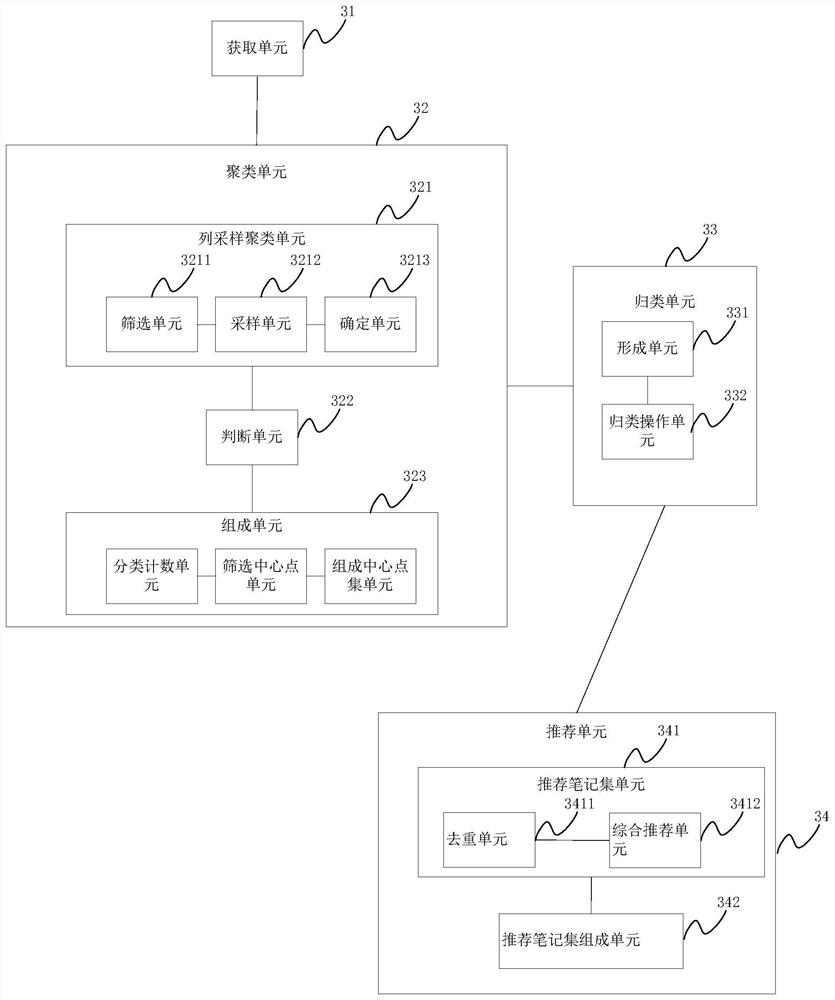

Note recommendation method, device and system

PendingCN111639263AReduce trial and errorCharacter and pattern recognitionWebsite content managementEngineeringCluster group

The invention provides a note recommendation method, device and system. The method comprises the steps of acquiring A feature vectors corresponding to A user terminals in a one-to-one mode; performingcolumn sampling and clustering operations for a preset number of times on the A feature vectors corresponding to the A user terminals one by one, and respectively obtaining A central point sets whichcorrespond to the A user terminals one by one and consist of central points obtained by the clustering operations for the preset number of times; based on the A central point sets in one-to-one correspondence with the A user terminals, executing classification operation to obtain K clusters, and respectively determining A cluster groups in one-to-one correspondence with the A user terminals, wherein each clustering group comprises one or more clusters to which the user terminal belongs; and for each user terminal, recommending historical browsing notes of the user terminal in the clustering group corresponding to the user terminal to the user terminal. The trial and error rate in the note recommendation process can be reduced.

Owner:小红书科技有限公司

Crash resistance design method of front side member of passenger car

InactiveCN103425848BRapid designShorten the design and development cycleSpecial data processing applicationsTrial and errorPlastic property

The invention discloses a front longitudinal beam anti-collision performance design method for a passenger vehicle and aims at solving the problems that when the traditional trial-and-error method is used for designing the front longitudinal beam of a car in the prior art, a computer simulation model needs to be repeatedly modified, the testing needs to be repeatedly carried out, and the like. The front longitudinal beam anti-collision performance design method for the passenger vehicle comprises the following steps that 1, the average crushing counter force expression (shown as the accompanying drawing) of a multi-right-angle cross section thin wall beam is deduced, in the expression, Pm is the average crushing counter force, the unit of the Pm is kN, n is the number of the cross section right angles of the multi-right-angle cross section thin wall beam, M0 is the unit length plastic limit bending moment, the unit of M0 is N.mm, l is the cross section circumference of the multi-right-angle cross section thin wall beam, the unit of the l is mm, h is the wall thickness of the multi-right-angle cross section thin wall beam, and the unit of the h is mm; 2, the cross section of the crushing deformation part of the front longitudinal beam is designed; 3, the average bending moment expression (Mm=(0.3-0.5)Mmax) of a rectangular cross section thin wall beam is deduced, in the expression, Mm is the average bending moment of the rectangular cross section thin wall beam, and the unit of the Mm is N.mm; and 4, the cross section of the bending deformation part of the front longitudinal beam is designed.

Owner:JILIN UNIV

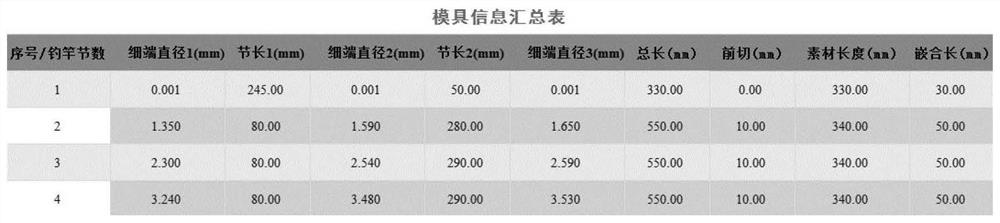

Simulation method and system suitable for fishing rod tonality curve calculation

PendingCN113868908ALower requirementLow professional advanced skill requirementsDesign optimisation/simulationComplex mathematical operationsComputational simulationZoology

The invention discloses a simulation method and system suitable for fishing rod tonality curve calculation, and the method comprises the steps: obtaining input information which at least comprises one of material information, mold information, laying layer information and load information of a target fishing rod; performing equivalence according to the input information, wherein the variable cross-section structure of the target fishing rod is equivalent to multiple sections of constant cross-section structures arranged in sequence, and meanwhile the geometric dimension and rigidity information of each section of constant cross-section structure are obtained; obtaining deformation displacement of different parts of the target fishing rod through calculation, and obtaining a tonality curve simulation result of the target fishing rod. According to the scheme, calculation and simulation are simple and efficient, the tonality curve of the fishing rod can be effectively, rapidly and efficiently simulated, and thus the accuracy and the efficiency of performance verification of the fishing rod are improved.

Owner:WEIHAI GUANGWEI COMPOSITES

Task scheduling method and device, equipment and storage medium

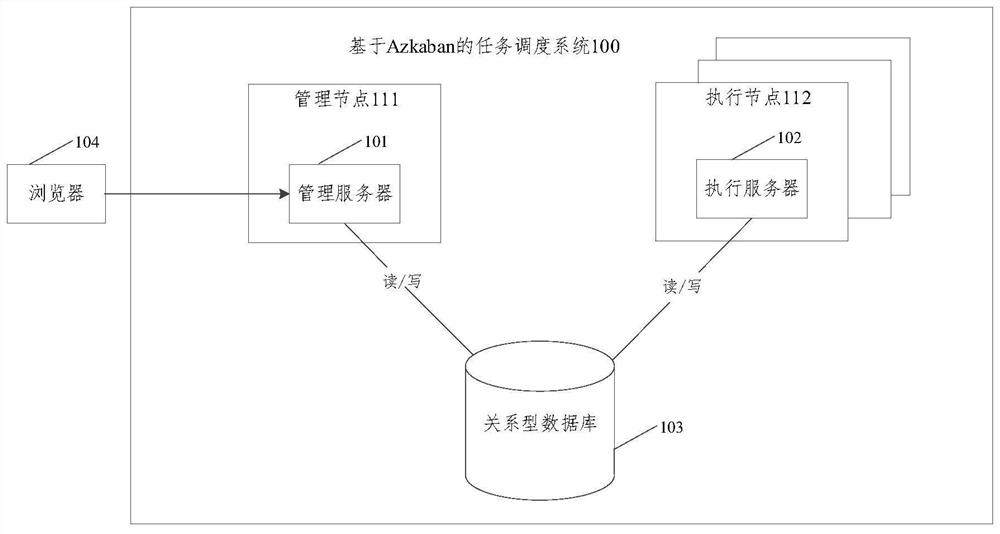

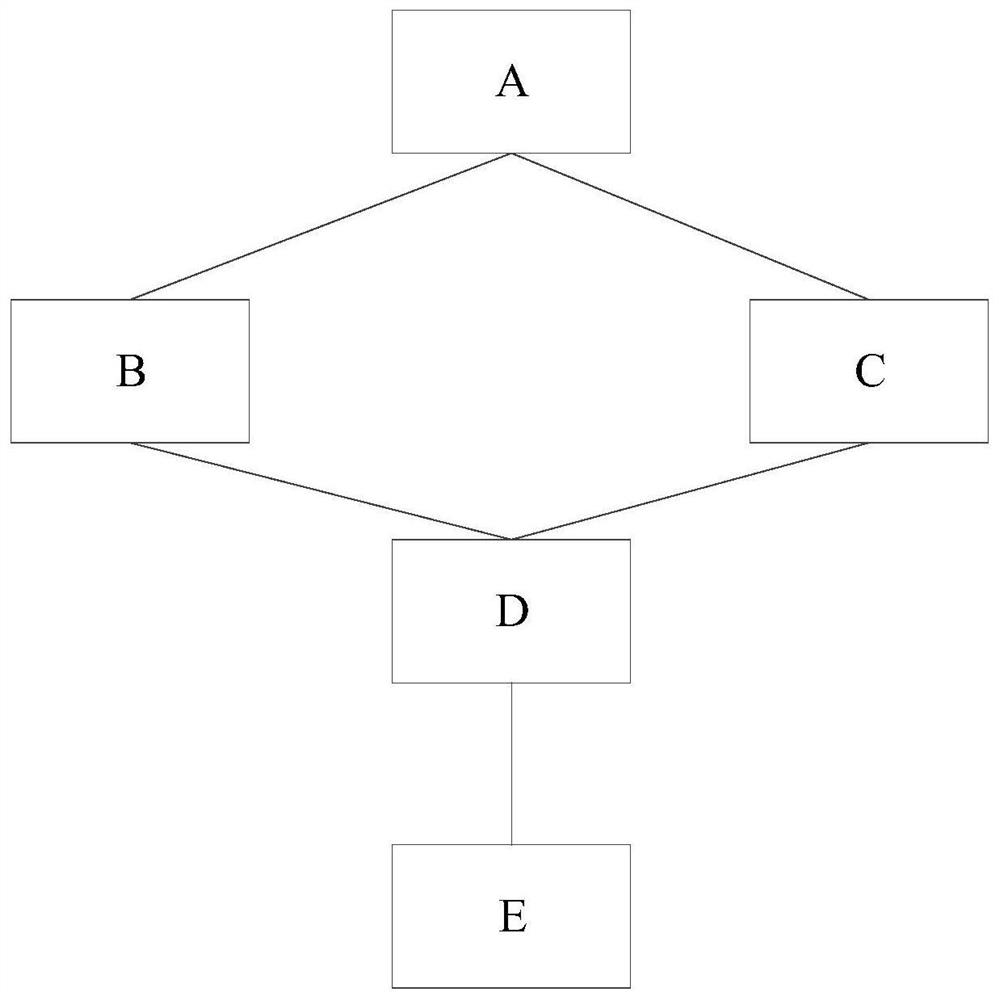

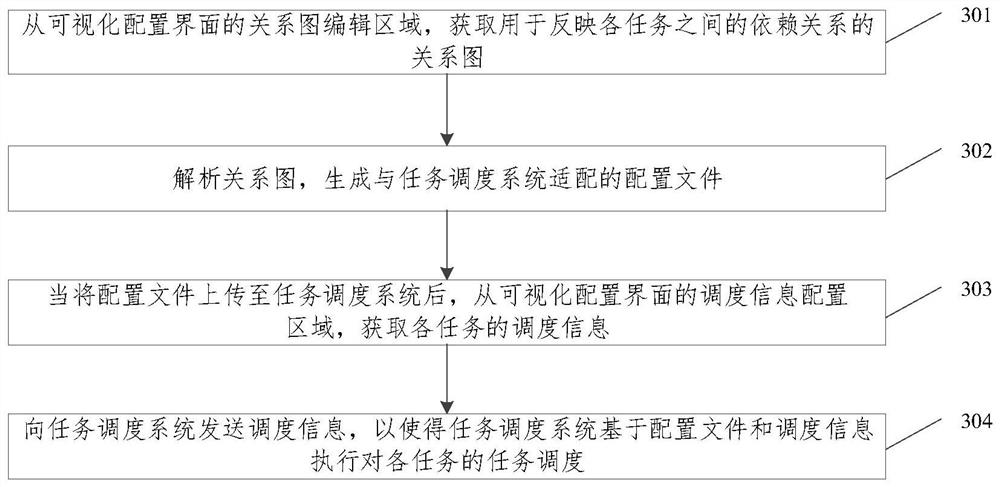

PendingCN113407174AImprove the efficiency of publishing scheduling tasksReduce developmentProgram initiation/switchingVersion controlRelation graphOperating system

The invention relates to a task scheduling method and device, equipment and a storage medium, and the method comprises the steps: obtaining a relation graph used for reflecting the dependency relationship between tasks from a relation graph editing region of a visual configuration interface; analyzing the relation graph, and generating a configuration file matched with the task scheduling system; after the configuration file is uploaded to a task scheduling system, obtaining scheduling information of each task from a scheduling information configuration area of the visual configuration interface; and sending the scheduling information to a task scheduling system, so that the task scheduling system executes task scheduling on each task based on the configuration file and the scheduling information. According to the relation graph editing area and the scheduling information configuration area of the visual configuration interface, configuration of scheduling information and the dependency relation used for analyzing the configuration file in the one-time configuration process is achieved, and therefore the configuration process is simple.

Owner:微民保险代理有限公司

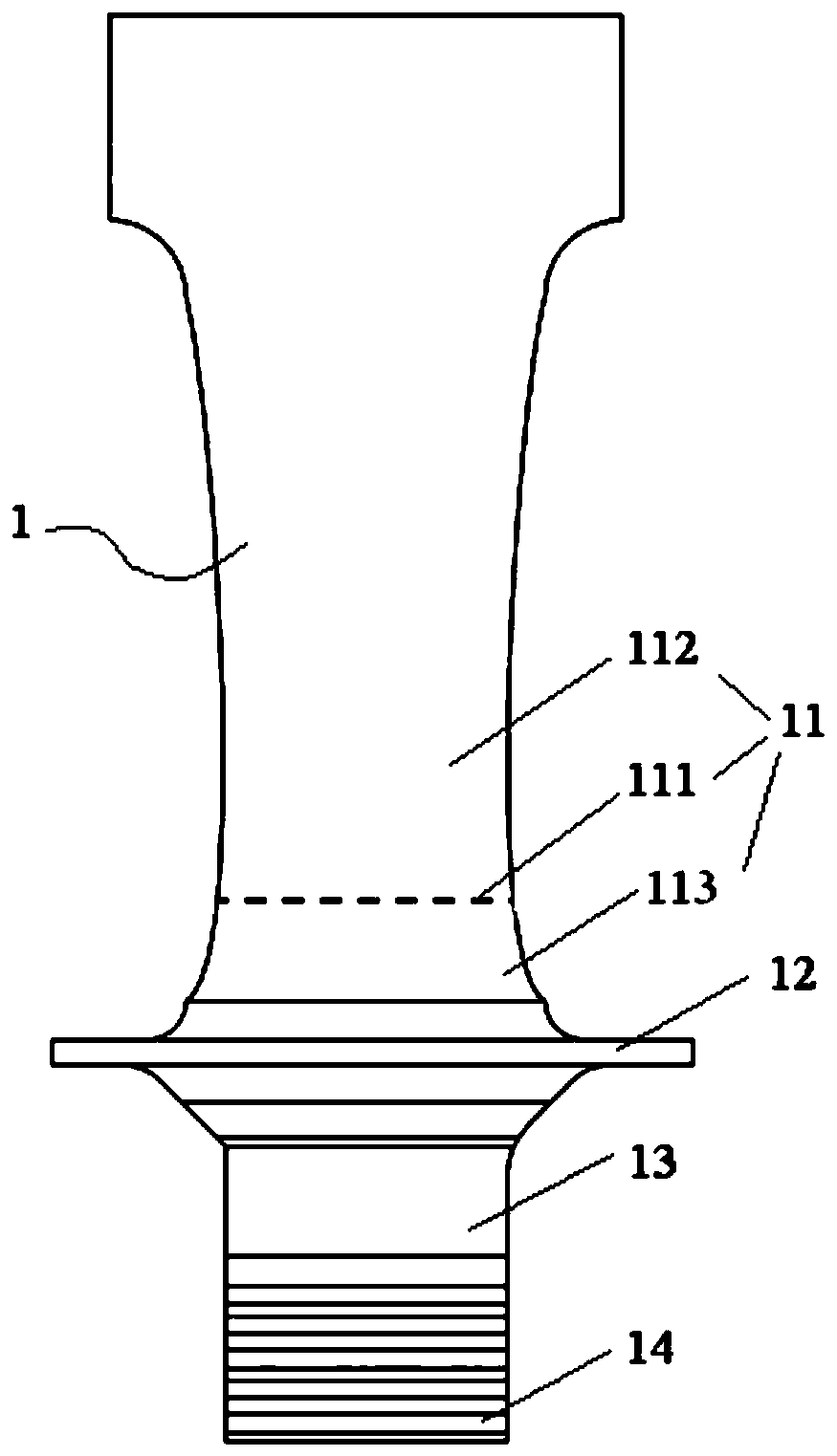

Wheel disc burst prevention blade and design method of weak structure of wheel disc burst prevention blade

ActiveCN110185498AReduce weightReduce kinetic energyBlade accessoriesMachines/enginesDesign methodsKinetic energy

The invention discloses a wheel disc burst prevention blade and a design method of a weak structure of the wheel disc burst prevention blade. The wheel disc burst prevention blade is used for matchinga wheel disc; the blade comprises a tenon, a stretching root, a rim plate and a blade body, wherein a blade body on the blade is provided with the weak structure for ensuring the blade to break before the wheel disc and fly off. According to the wheel disc burst prevention blade, the weak structure is arranged at the blade body on the blade, the breaking flying-off critical rotating speed of theblade is reduced to be lower than the critical breaking rotating speed of the wheel disc, so that the blade breaks before the wheel disc and flies off; moreover, the weak structure is arranged on theblade body of the blade, so that the weight of the broken and flying-off blade is reduced, the kinetic energy of the flying-off blade is effectively reduced, and the consequence that the wheel disc bursts to harm an engine is avoided; and meanwhile, the weight of a case is reduced, the thrust / work weight ratio of the engine is improved, and the fuel consumption rate is reduced.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

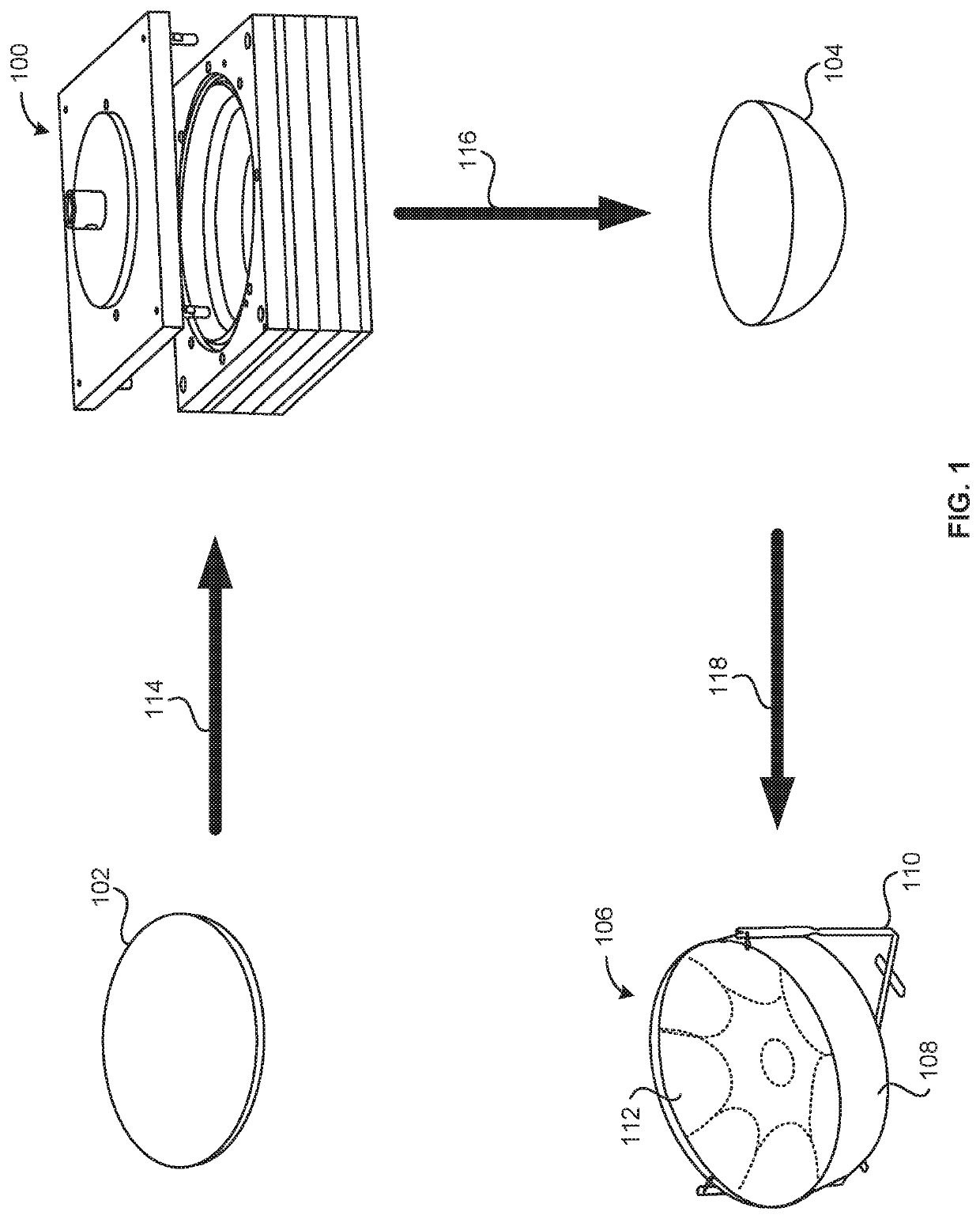

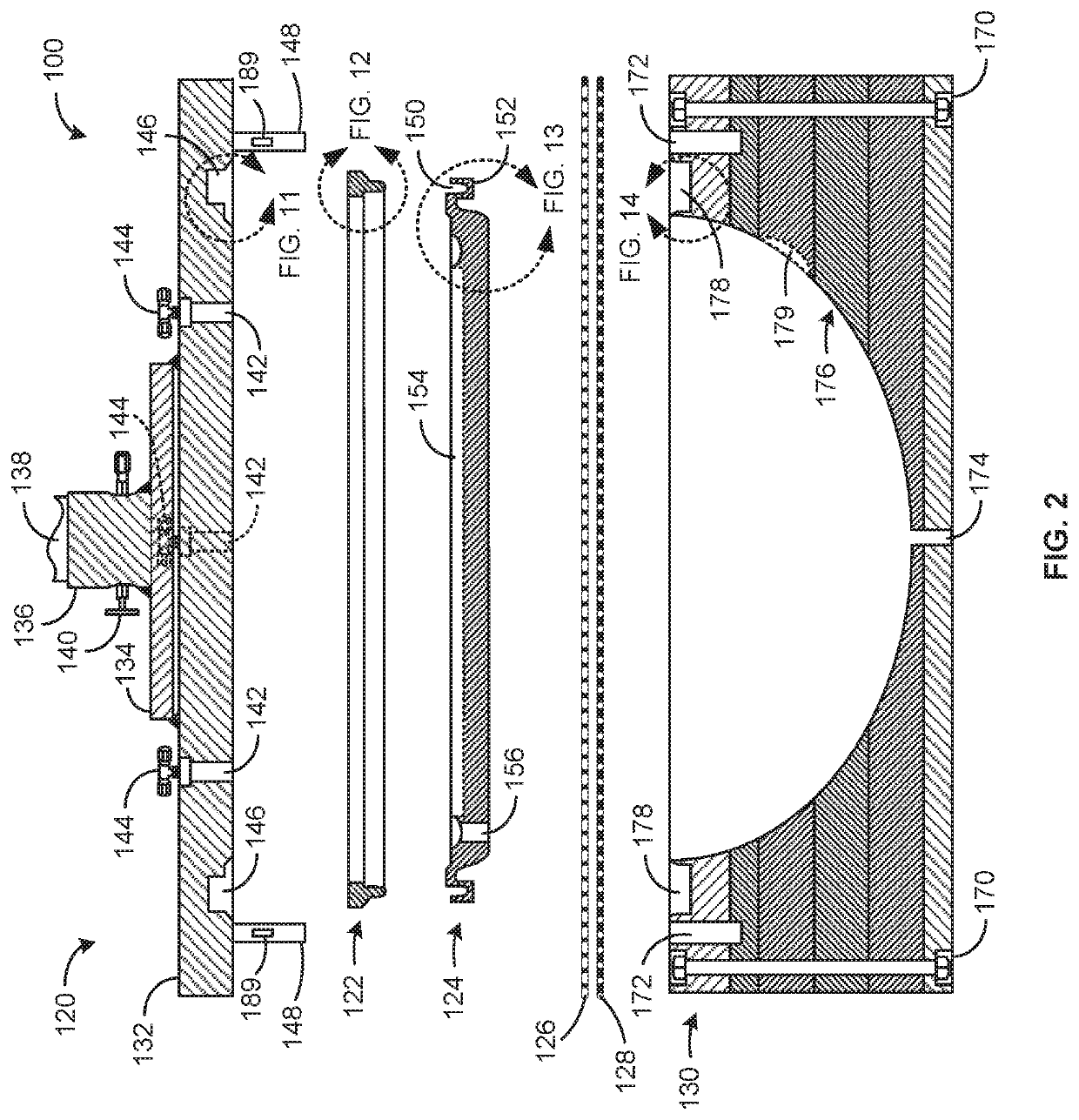

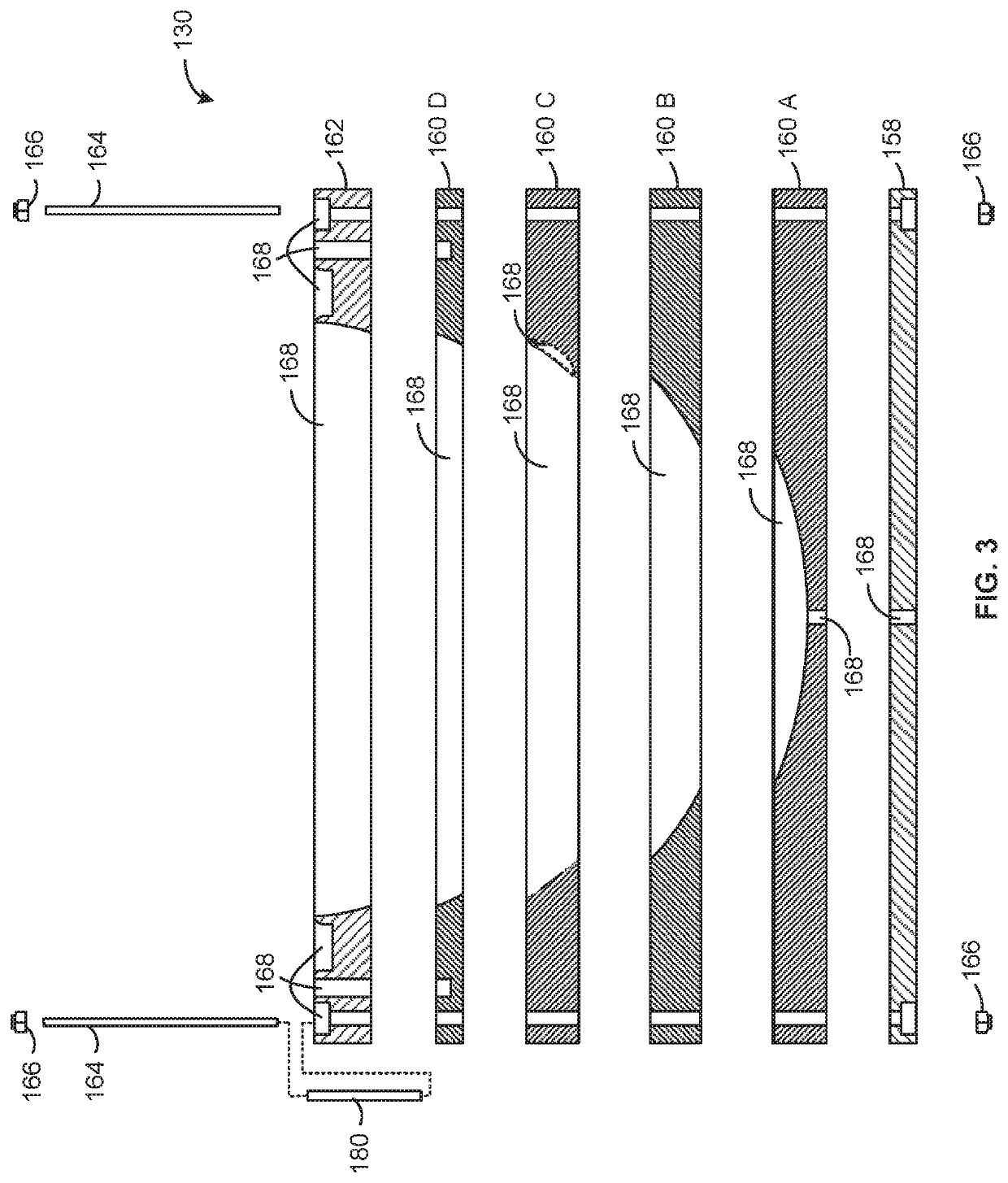

Steelpan musical instrument hydroforming press

ActiveUS20200001343A1Improve predictabilityReduce trial and errorPercussion musical instrumentsMetal-working apparatusMolding machineHydraulic ram

A machine can form a work piece into a bowl subcomponent of a steel pan musical instrument. The machine includes a pressure lid and a die mold. The die mold may be formed of non-metal layers stacked between metal layers. In example operation, a blank or work piece is inserted between the lid and die mold. The lid is pressed down (e.g., by a hydraulic ram), forcing a portion of the blank into a face groove of the die mold for sealing. Pressurized water or other fluid introduced between the lid and the blank exerts pressure on the sealed portion of the blank and stretches the blank to conform to a bowl shape of the die mold. Note regions can be introduced by this machine-performed shaping and / or by subsequent manual operations to further prepare the work piece for incorporation into a steel pan musical instrument.

Owner:WAHTUSE JOMO

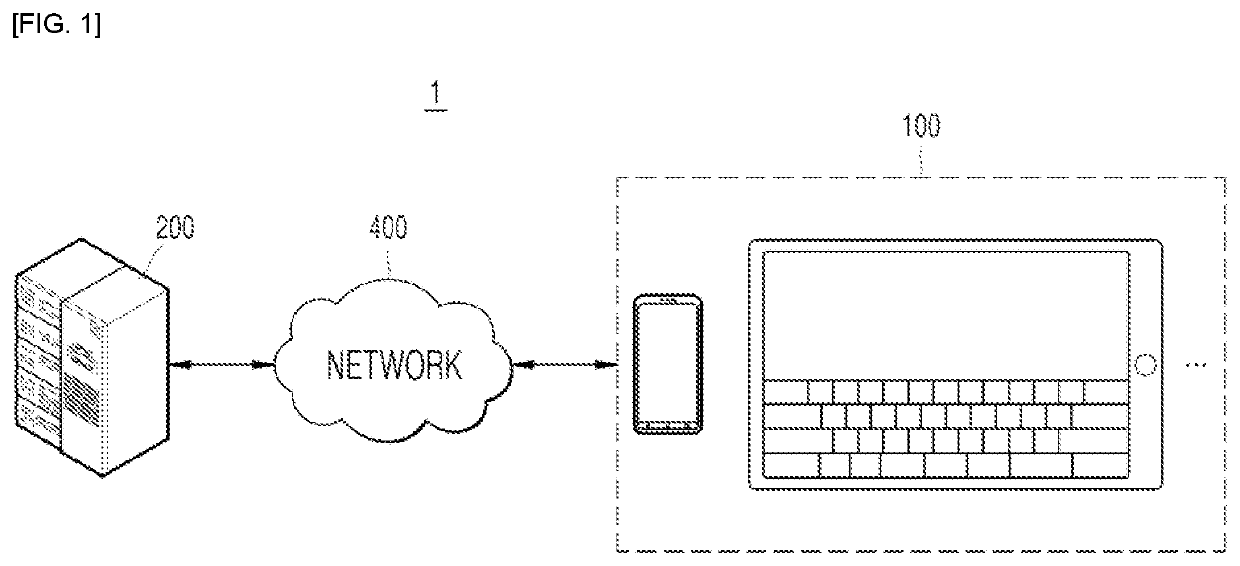

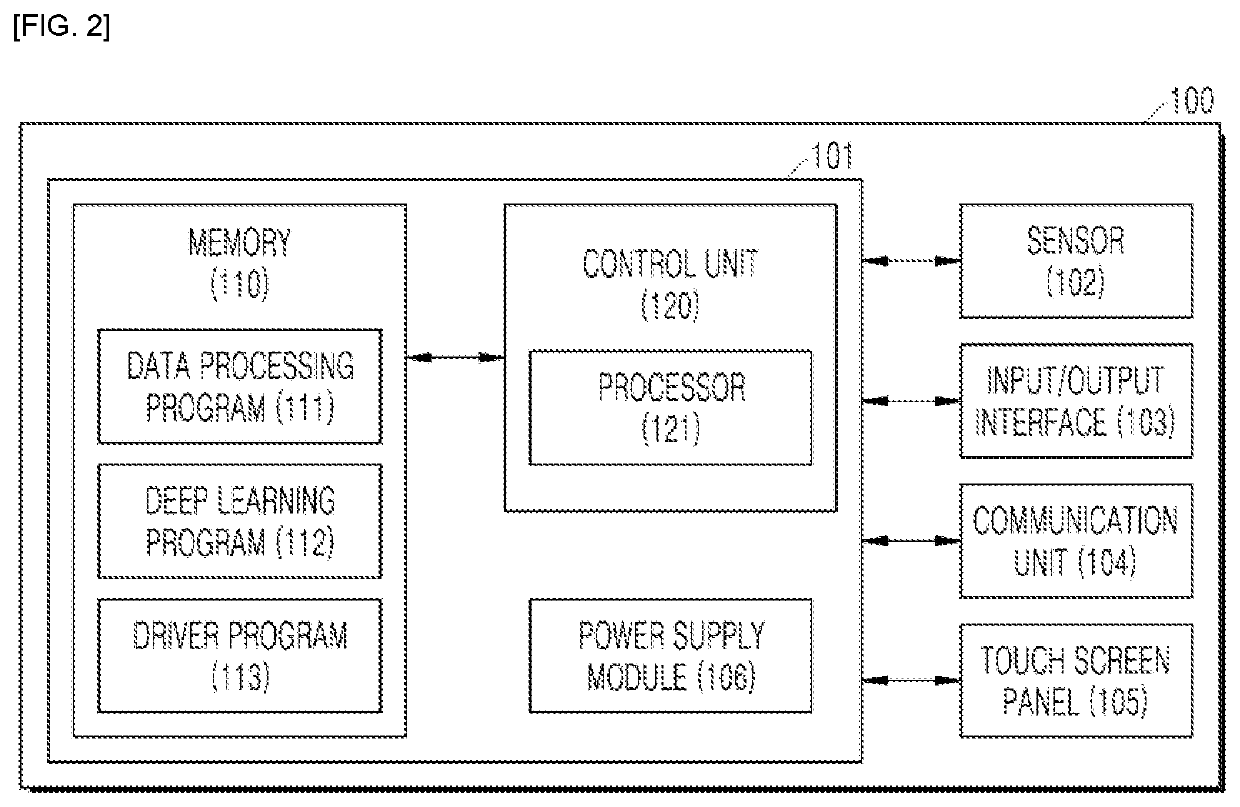

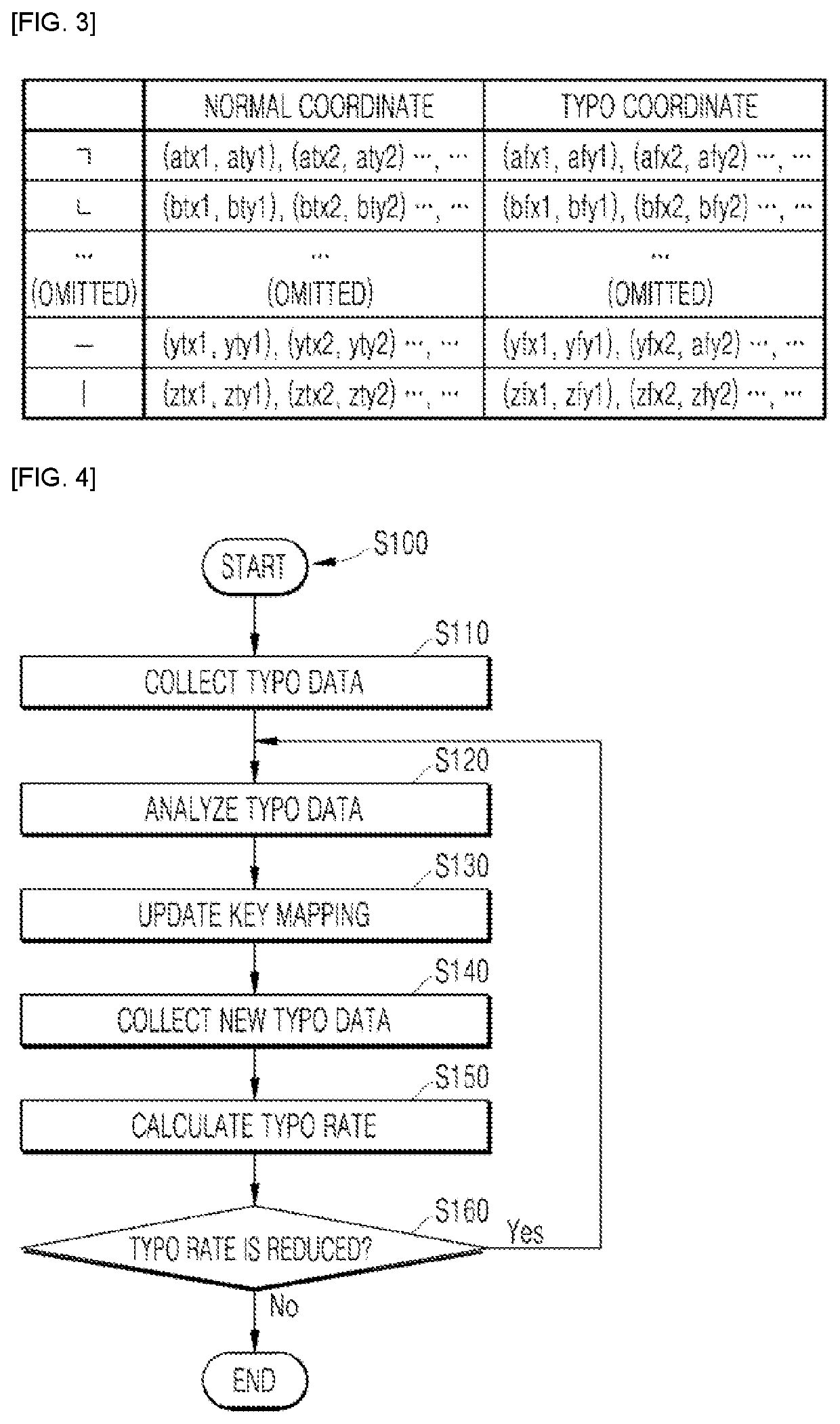

Method and apparatus for controlling virtual keyboard

ActiveUS20200004418A1Reduce rateReduce trial and errorInput/output for user-computer interactionMathematical modelsVirtual keyboardDeep learning

A virtual keyboard control apparatus and control method are disclosed. The virtual keyboard control method includes collecting typo data including a desired input key and an erroneously input key, analyzing the typo data, and updating the key mapping of at least one virtual key of the desired input key and the erroneously input key by using the analyzed result. According to the present disclosure, it is possible to implement the optimum key mapping in which a typo is less generated for each user through Reinforcement Learning of Deep Learning by using the reward called a reduction in a typo rate.

Owner:LG ELECTRONICS INC

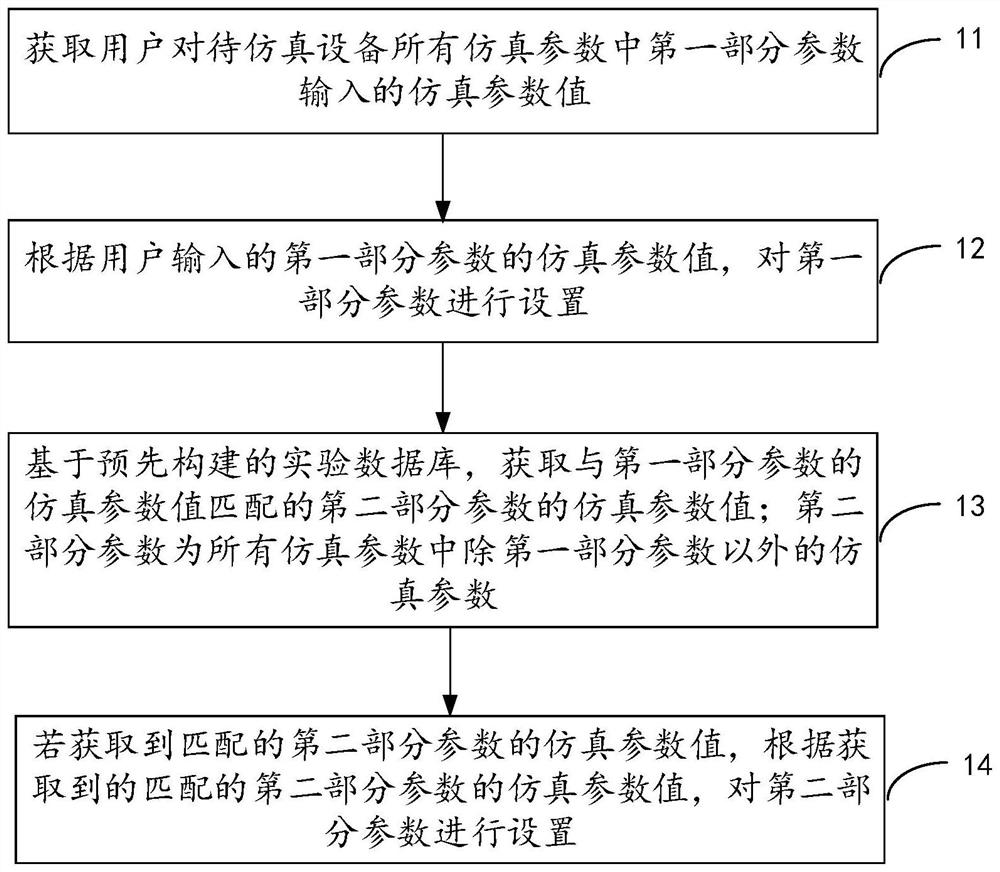

Simulation experiment parameter setting method, device, equipment and storage medium

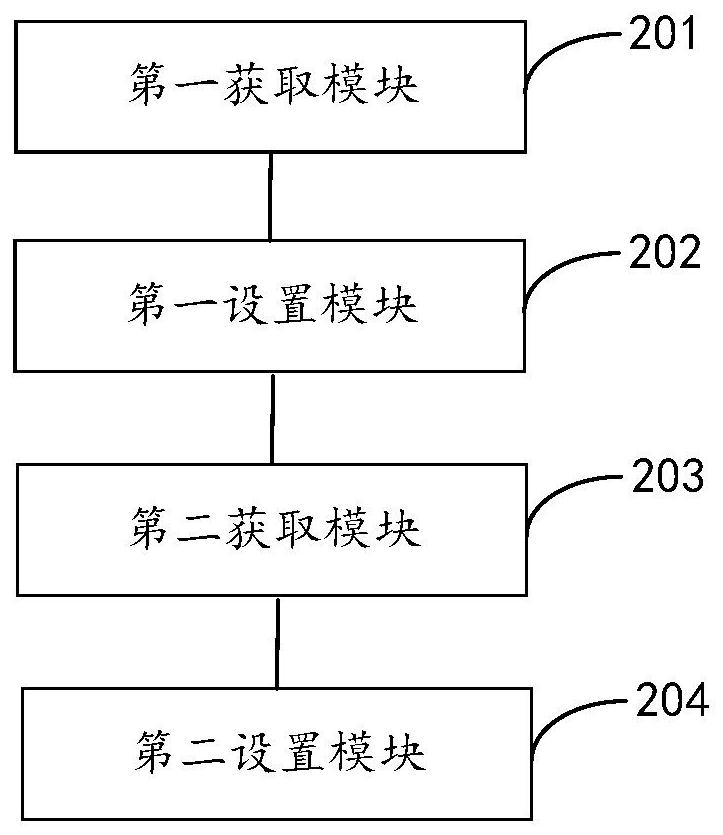

ActiveCN110619152BLow technical requirementsReduce trial and errorGeometric CADDesign optimisation/simulationAlgorithmSimulation

The present application discloses a simulation experiment parameter setting method, device, device and storage medium. The method includes: obtaining a simulation parameter value input by a user for a first part of all simulation parameters of a device to be simulated; setting the first part of the parameter according to the simulation parameter value of the first part of the parameter input by the user; based on a pre-built experiment database, to obtain the simulation parameter values of the second part of the parameters that match the simulation parameter values of the first part of the parameters; the second part of the parameters are all the simulation parameters except the first part of the parameters of the simulation parameters; According to the simulation parameter value of the second part of the matched parameter, the second part of the parameter is set according to the obtained simulation parameter value of the second part of the parameter of the match, which solves the problem of low speed, low speed caused by a large number of simulation experiment parameter settings. effectiveness issue.

Owner:GREE ELECTRIC APPLIANCES INC

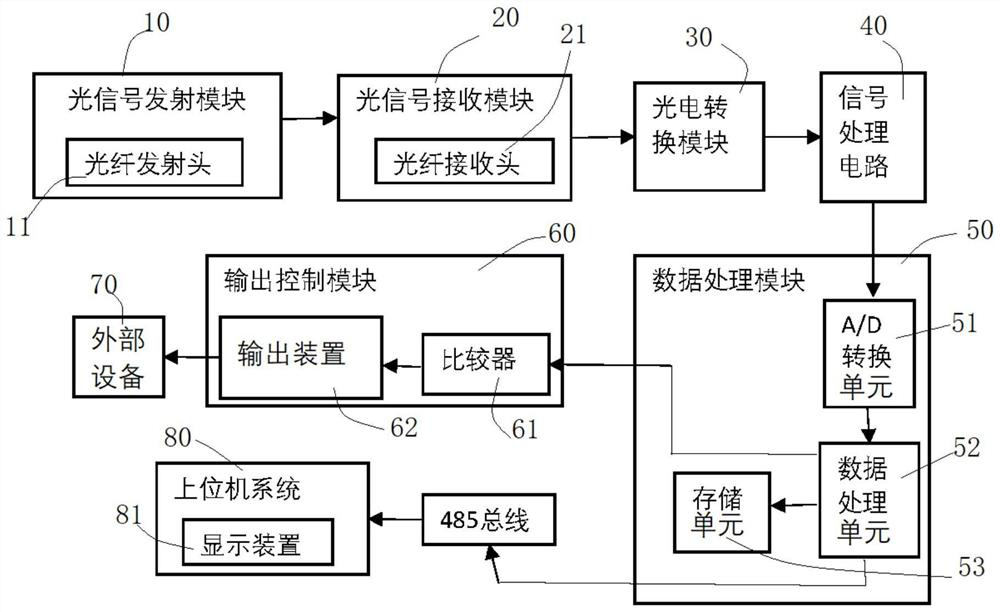

Monitoring system with photoelectric sensor and monitoring method

PendingCN114322781AEasy accessEffective information outputUsing optical meansColor/spectral properties measurementsSoftware engineeringDisplay device

The invention discloses a monitoring system with a photoelectric sensor and a monitoring method thereof.The monitoring system comprises an optical signal receiving module, a photoelectric conversion module, a data processing module and an output control module, and the optical signal receiving module transmits received optical signals to the photoelectric conversion module; the photoelectric conversion module converts the optical signal into an electric signal, the electric signal is transmitted to the data processing module after being processed, the electric signal is converted into a digital signal through the data processing module, and the optical signal received by the optical signal receiving module changes along with the change of a measured physical quantity. The optical signal is converted into a digital signal, the digital signal is processed by the data processing module, the change rule of the measured physical quantity is displayed through a state change curve by the display device, and the monitoring system can be suitable for distance monitoring of high-precision equipment; and whether the appearance color of the product is qualified can be detected.

Owner:苏州优斯登物联网科技有限公司

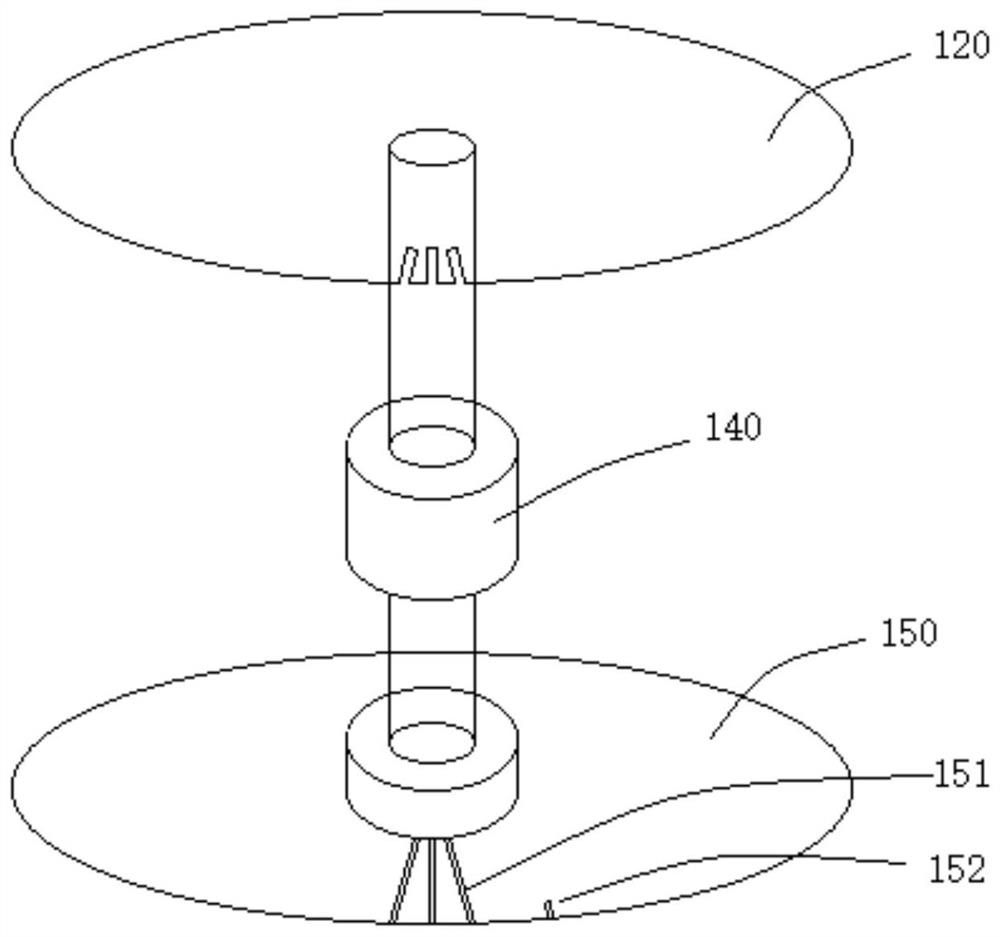

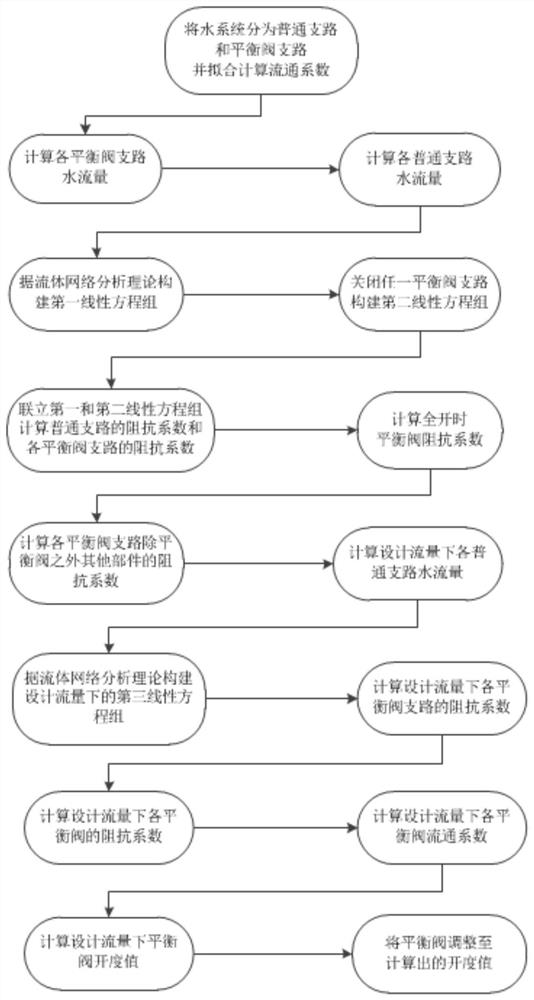

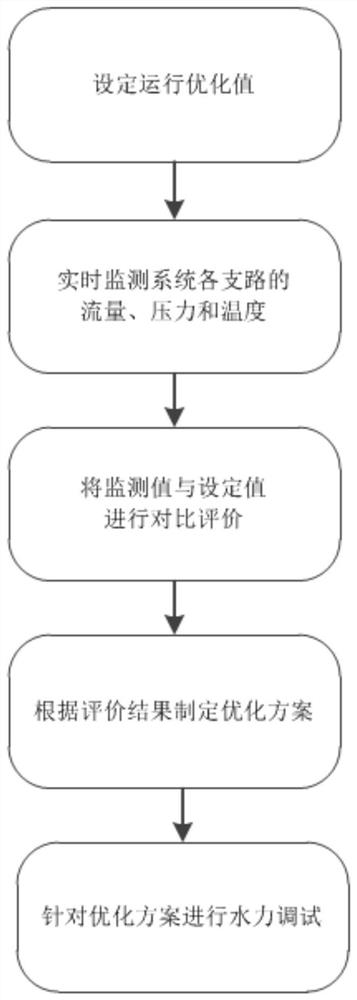

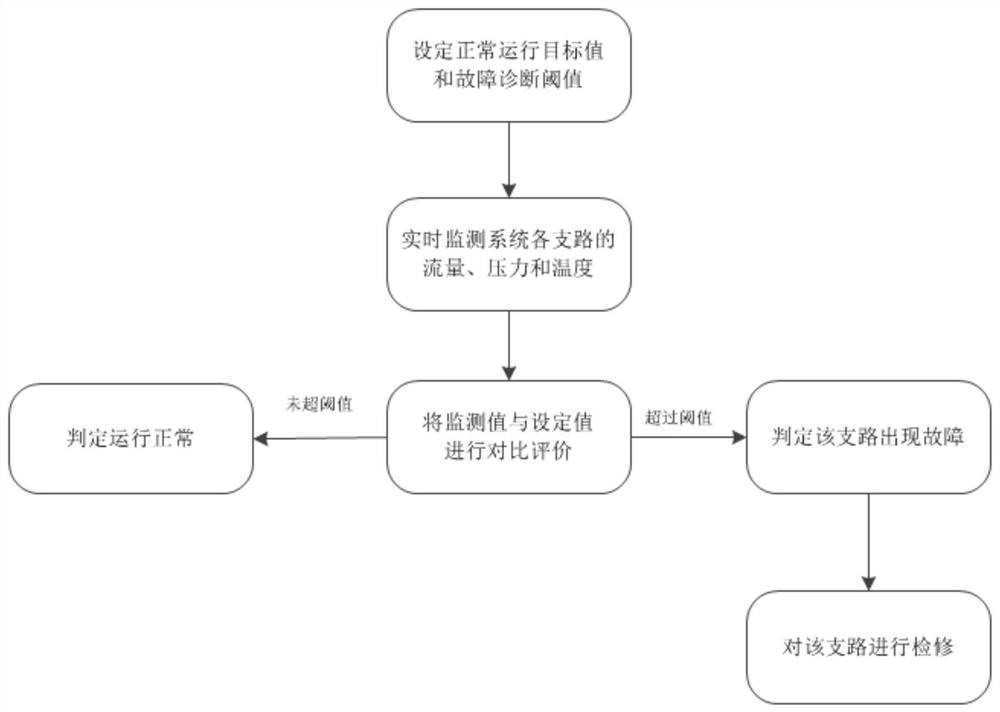

Central air-conditioning water system debugging method, fault diagnosis method, operation optimization method

ActiveCN109163415BReduce trial and errorImprove accuracyMechanical apparatusSpace heating and ventilation safety systemsControl engineeringWater flow

The invention discloses a central air conditioning water system debugging method, a fault diagnosis method and an operation optimization method. A calculation method for constructing an association matrix and a basic loop matrix is adopted according to a fluid network analysis theory, water flow is designed through a balance valve branch of the central air conditioning water system, and an openingdegree value of the balance valve branch of the central air conditioning water system is calculated; and hydraulic balance debugging is carried out according to the calculated opening degree value, and meanwhile, the fault diagnosis and operation optimization are realized according to the contrastive analysis of data value monitored by a monitoring platform in real time and a set normal operationtarget value. The method has the advantages that a scientific basis is provided to the debugging of the central air conditioning water system, the hydraulic debugging efficiency is improved, meanwhile the fault diagnosis and the operation optimization of the water system are achieved, and safe and efficient operation of the system is guaranteed.

Owner:成都慧云阵信息技术有限公司

Vehicle lamp design method

ActiveCN105299556BImprove uniformityReduce the number of LEDsLight source combinationsVehicle headlampsEngineeringDesign methods

The invention relates to a design method for a vehicle lamp. The feature of the invention is to functionalize the interval and gap between the light sources and apply it to the design, so as to improve the uniformity of light. The invention can provide the optimal design scheme of the FDT surface light source lamp. According to the invention, the uniformity can be improved and the number of LEDs can be reduced; the trial and error for improving the light uniformity of the FDT surface light source can be greatly reduced.

Owner:HYUNDAI MOBIS CO LTD

A non-through-diameter beaded panel forming die and a beaded curved panel processing method

ActiveCN111112467BAvoid production design effortImprove processing efficiencyShaping toolsEngineeringStructural engineering

The invention provides a non-through-diameter beaded plate forming die, which includes a die base for a die and a die base for a punch. At least two bead grooves are arranged on the die base, and the shape of the inner wall of the bead groove is the same as The shape of the outer wall of the processed bead matches; a punch is provided on the punch base, and the shape of the outer wall of the punch matches the shape of the inner wall of the bead to be processed; the punch is spliced by several punch segments, and The punch segment is detachably fixed on the punch base; the two ends of the bead groove are provided with die end segments, and the position of the die end segment in the bead groove is adjustable. The non-through beaded plate forming mold of the present invention can adjust the length of the convex and concave dies by splicing the punch segments and adjusting the distance between the end segments of the die at both ends of the bead groove to meet the requirements of multiple strips of different sizes. The demand for one-time molding of the beading greatly expands the scope of use of the mold and avoids a large amount of investment in mold production design.

Owner:JIANGNAN SHIPYARD GRP CO LTD +1

A method for inductive control of semi-trailer trains moving in a straight line

ActiveCN109367620BSolve the situation that it is difficult to achieve straight-line reversingReal-time correctionSteering partsSteering wheelDriver/operator

The invention discloses an induction control method for semi-trailer train linear back off. According to the linear back-off requirements of a driver, the steering wheel rotation direction and rotation angle prompt is provided for the driver, and accordingly the driver is assisted in linear back-off operation completing. By means of the induction control method, the requirement for the back-off skill of the driver can be lowered, the back-off accidents are reduced, and meanwhile the back-off efficiency is improved.

Owner:HEFEI UNIV OF TECH

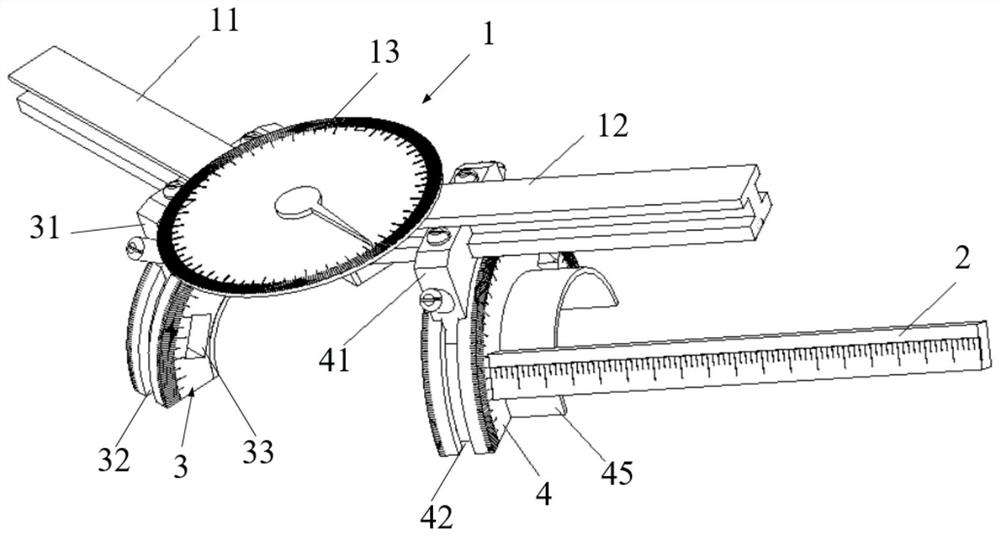

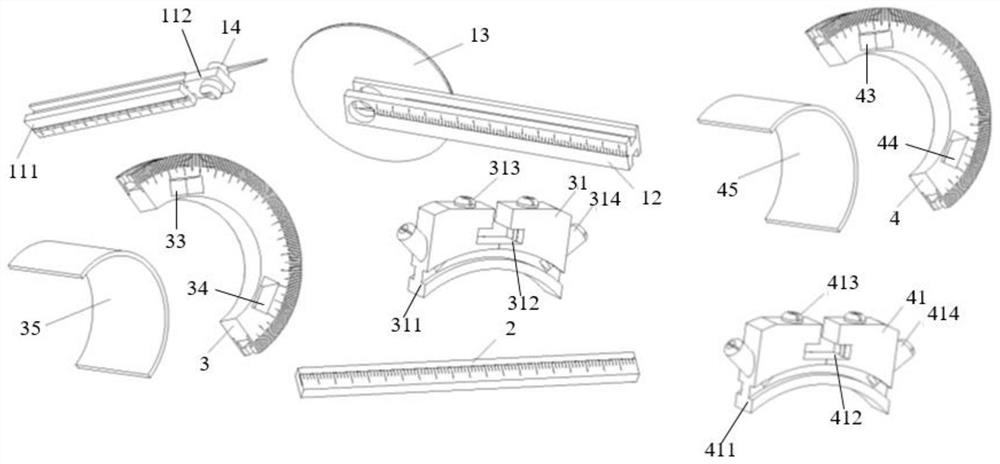

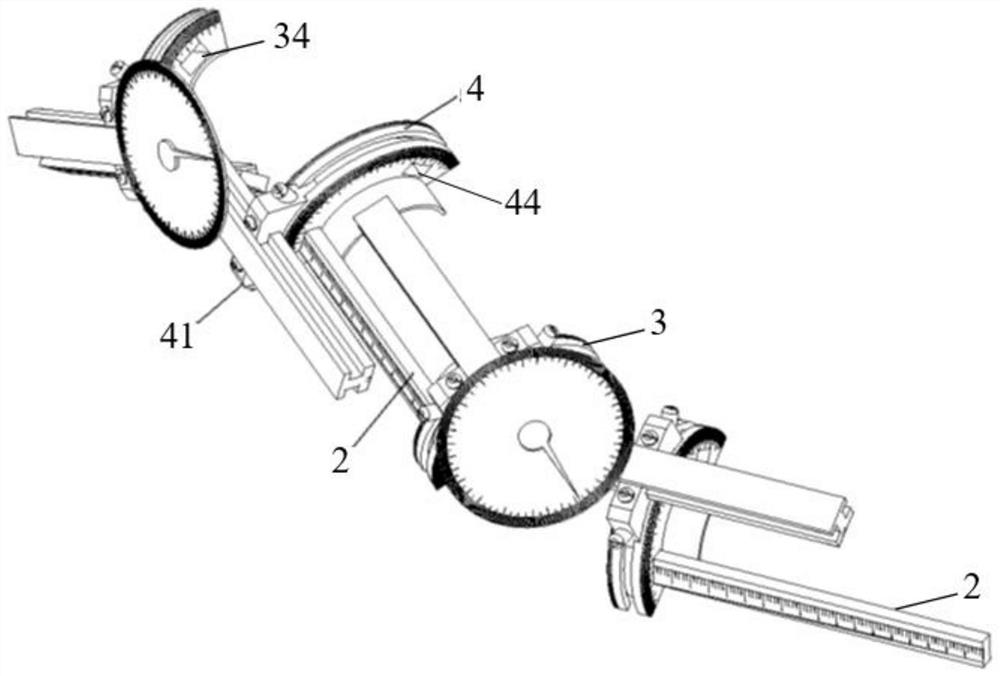

A catheter bending measuring ruler and its measuring method

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com