Vehicle lamp design method

A design method and technology for vehicle lights, applied to headlights, road vehicles, vehicle parts, etc., can solve the problems of manpower and time, and achieve the effect of improving uniformity and reducing the number of LEDs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The existing design method capable of improving the light uniformity of the FDT surface light source is performed through countless trial and error, and thus requires a lot of manpower and time. The present invention provides a formulaic optimal design method for vehicle lamps that can solve this technical problem.

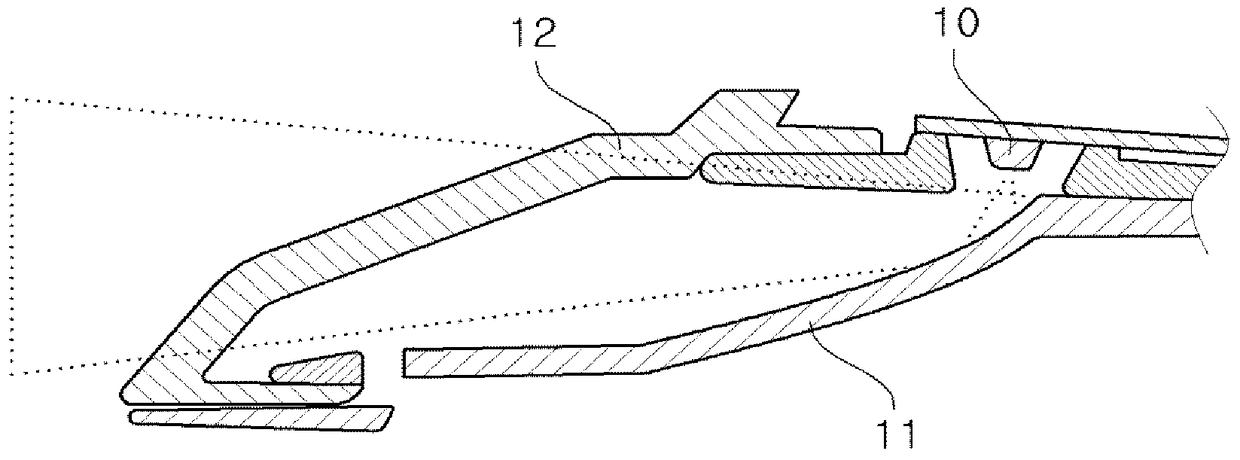

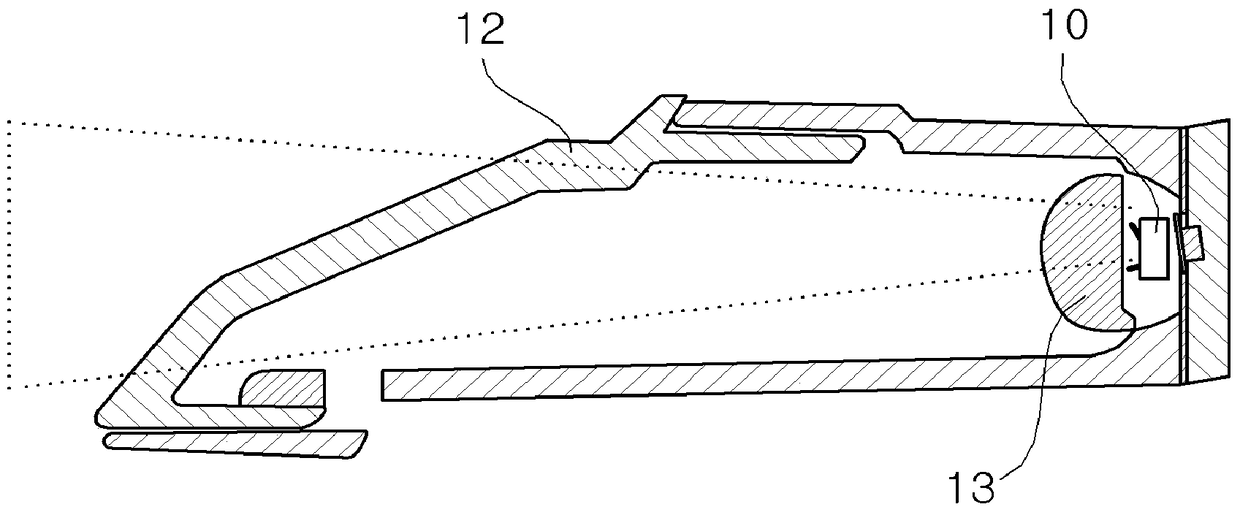

[0026] A method of designing a lamp for a vehicle according to the present invention will be described below with reference to the drawings.

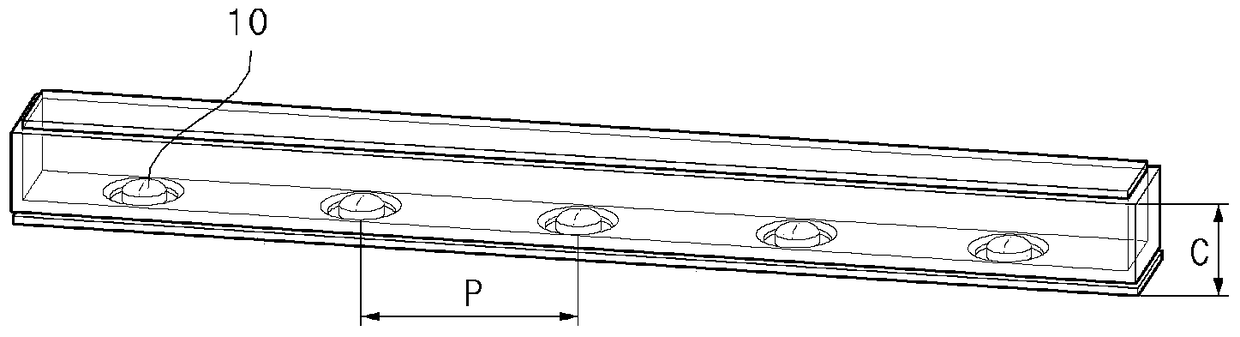

[0027] image 3 is a schematic diagram showing spaces and gaps between light sources according to a preferred embodiment. refer to image 3 , the light uniformity of FDT is a function of the spacing (PITCH) and gap (AIR GAP) between LEDs. To improve specific light uniformity, a proper combination of the two variables, spacing P and gap C, is required. Through this correlation, light uniformity can be improved, and the number of light sources 10 such as LEDs can be reduced. The present invention actually verifies...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com