A catheter bending measuring ruler and its measuring method

A bending measurement and catheter technology, applied in the field of catheter bending measuring ruler and measurement, can solve the problems of high cost and low efficiency of qualified inspection of catheter bending direction, achieve strong physical support, ensure scientific research and production progress, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

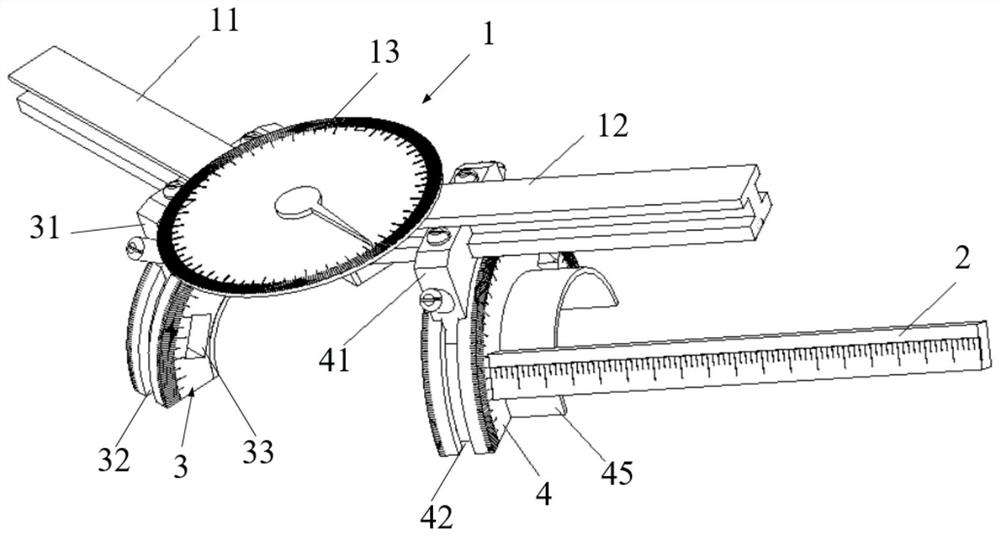

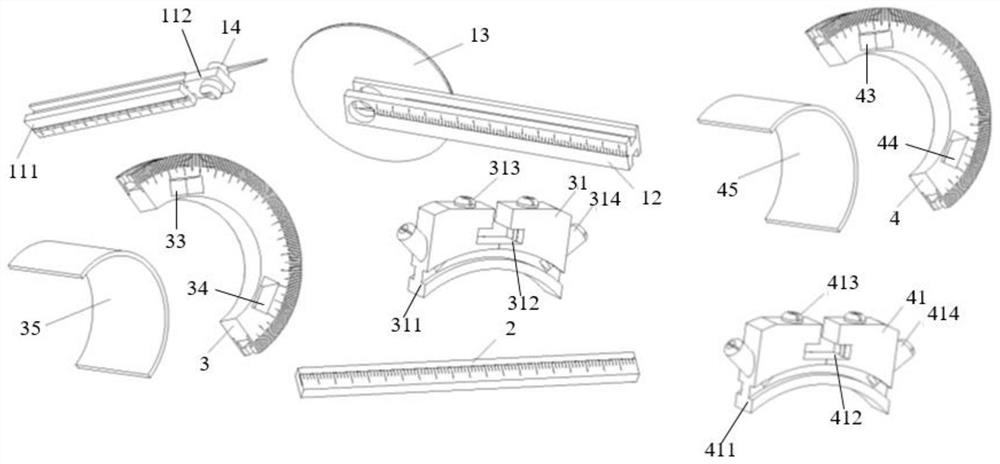

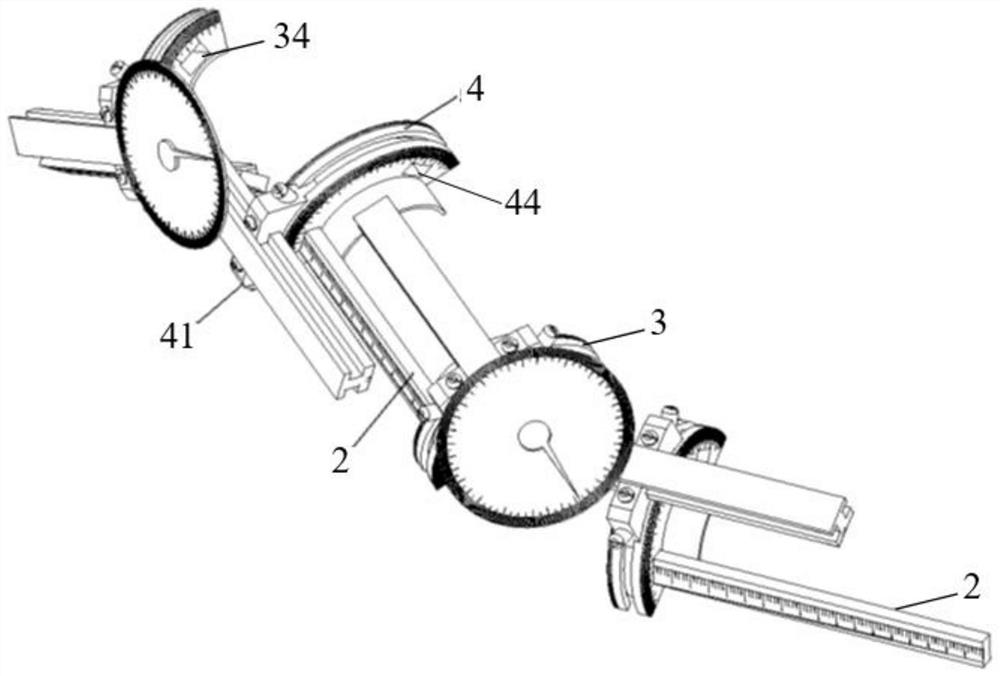

[0056] A specific embodiment of the present invention, such as Figure 1-Figure 4 As shown, a catheter bending measuring ruler is disclosed, including a disc ruler 1, a sliding ruler 2 and a slide rail rotation ruler, the disc ruler 1 is used to measure the angle between adjacent straight sections of the catheter, and the sliding ruler 2 is used to measure the straight line of the catheter The segment length, the slide rail rotation ruler is used to measure the plane rotation space angle of the adjacent curved section of the catheter, and the catheter bending measuring ruler can be used repeatedly.

[0057] During implementation, the catheter bending measuring ruler can be used repeatedly, and the data can be read by simply placing the measuring ruler on the catheter.

[0058] Compared with the prior art, the catheter bending measuring ruler provided in this embodiment, the disc ruler is used to measure the angle between the adjacent straight sections of the catheter, that is,...

Embodiment 2

[0103] Another specific embodiment of the present invention discloses a catheter bending measurement method, using the catheter bending measuring ruler of embodiment 1, the steps include:

[0104] S1: Assemble the catheter bending measuring ruler, and place each catheter bending measuring ruler on the catheter.

[0105] When assembling the catheter bending measuring ruler, the sliding ruler 2 is not installed, and the set screws are not tightened (the first set screw 313, the second set screw 314, the third set screw 413 and the fourth set screw in this embodiment Set screw 414), the first spacer 35 and the second spacer 45 are placed on the part where the straight line section of the conduit is tangent to the arc section.

[0106] It should be noted that when the catheter bending measuring ruler is placed on the catheter, no other means are required to fix it. The catheter bending measuring ruler is placed above the catheter, and the first slider 31 and the first sliding rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com