Front longitudinal beam anti-collision performance design method for passenger vehicle

A design method and front longitudinal beam technology, applied in calculation, special data processing applications, instruments, etc., can solve problems such as repeated revisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0159] The process of designing a front longitudinal beam using the crashworthiness design method of the passenger car front longitudinal beam:

[0160] 1. Derivation of the average crush reaction force expression of thin-walled beams with multiple right-angled sections

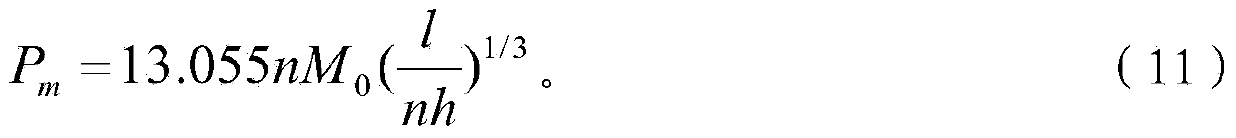

[0161] According to the derivation process in the specific implementation, the expression of the average crushing reaction force of thin-walled beams with n right-angled sections is obtained as:

[0162] P m = 13.055 nM 0 ( l nh ) 1 / 3 - - - ( 11 )

[0163] In the formula: P m is the average crushing reaction force, the unit is kN; n is the number of right angles of thin-walled be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com