Three-coordinate automatic detection realizing method of belt back-off electrode

An automatic detection and realization method technology, which is applied in the direction of measuring devices, mechanical measuring devices, instruments, etc., can solve the problem of non-interference between the probe and the electrode with an undercut, and achieve the effect of reducing the number of trial and error and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

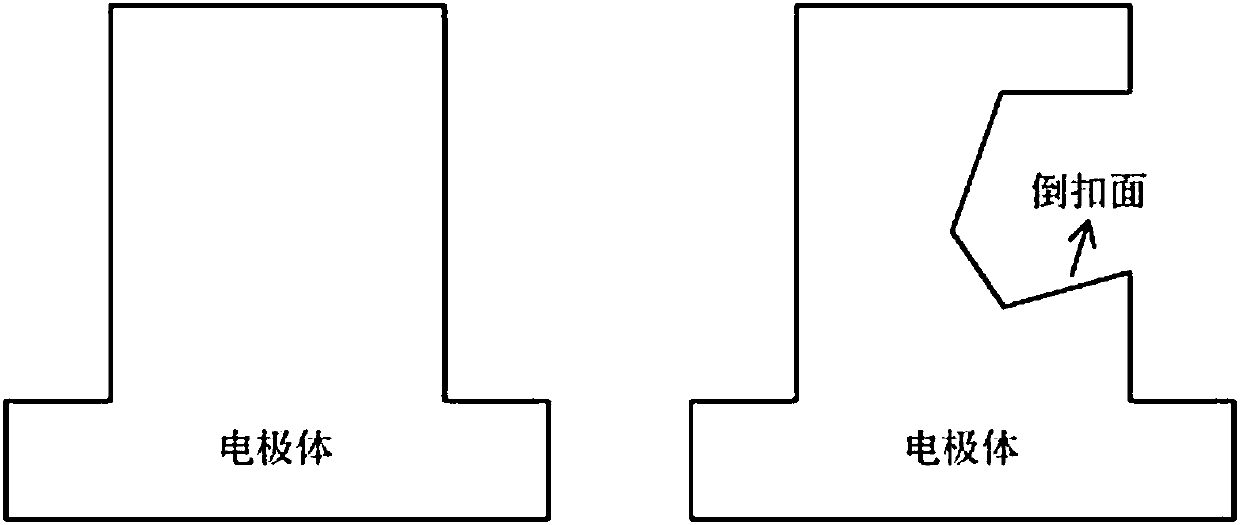

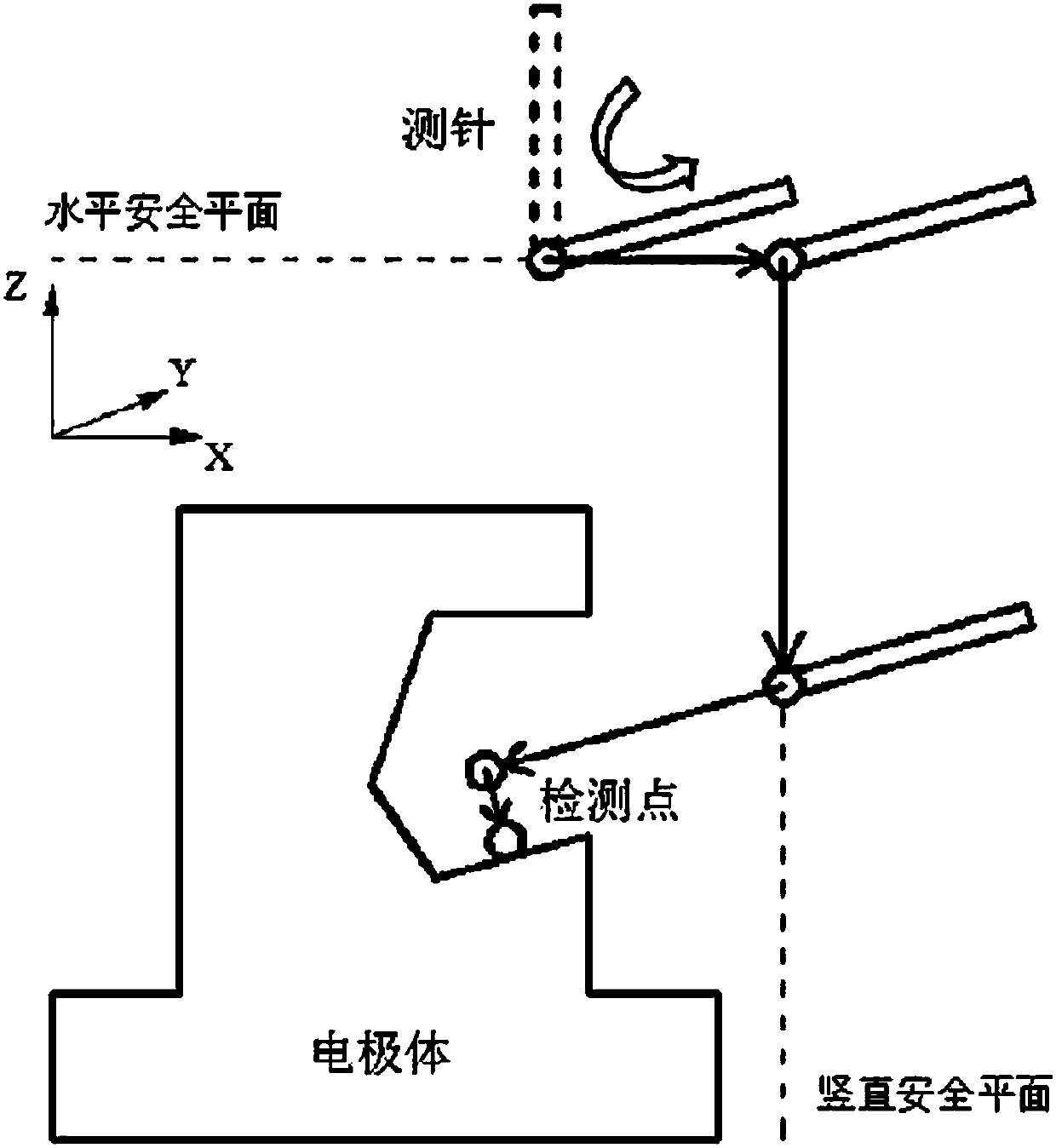

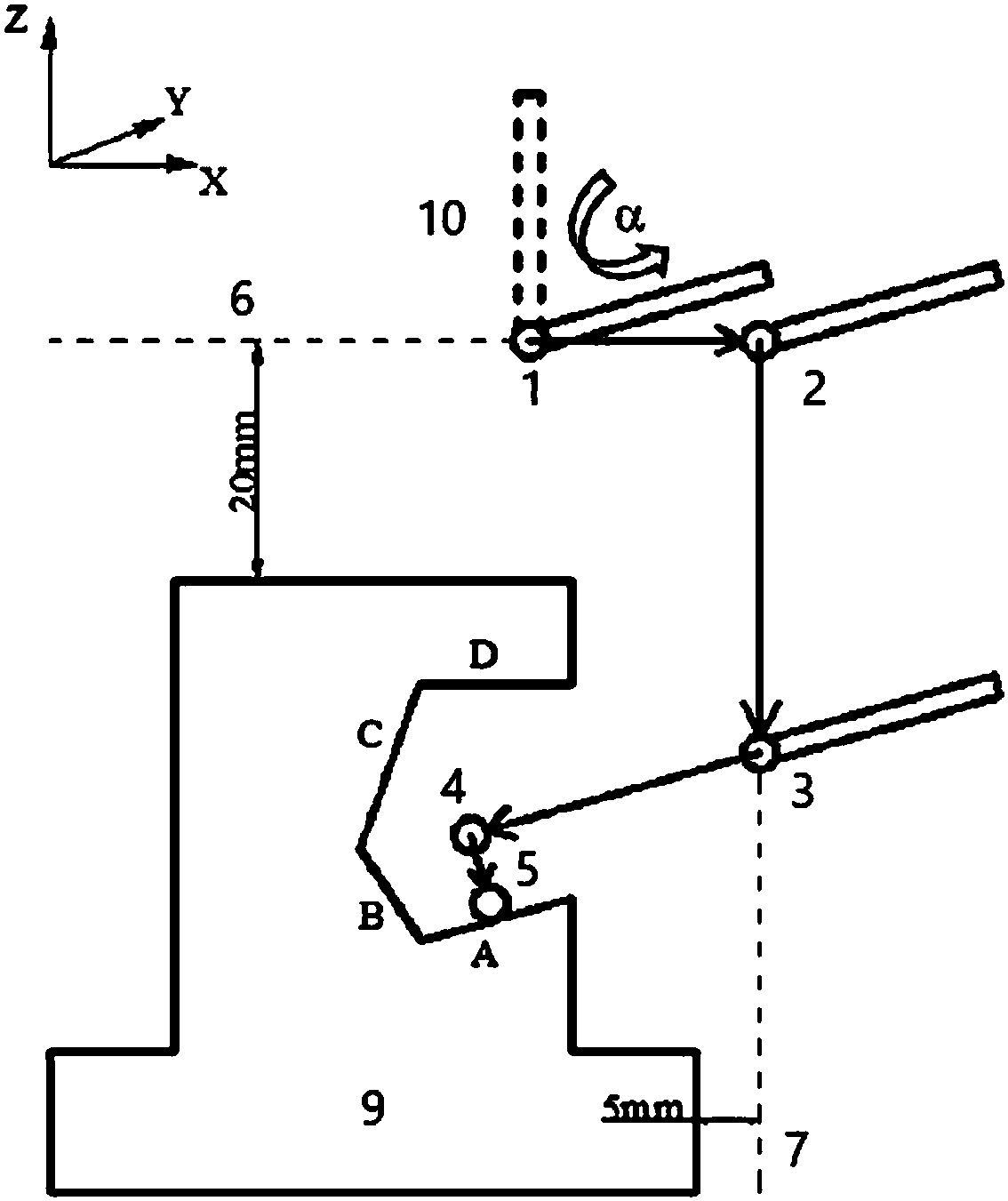

[0036] Such as image 3 As shown, it is a side view of the undercut electrode to be tested in this embodiment, and the electrode has four undercut surfaces A, B, C, and D.

[0037] This embodiment takes a detection point on the undercut surface A as an example to describe in detail the generation of the three-coordinate automatic detection program and the automatic measurement process of the electrode with an undercut.

[0038] In step 1, the coordinates of the detection point, the normal direction of the surface where the point is located, and the retreat distance value set by the three-coordinate measuring instrument are all known quantities. The stylus is first accurately positioned at the detection point, and then retreats to the first intermediate position point 4 near the detection point along the normal direction of the surface where the detection point is located.

[0039] Step 2, using the trial and error method to calculate the minimum clockwise rotation angle α of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com