Size detection method of ultra-large combined type steel-box-shaped steel column and steel plate shear wall

A steel plate shear wall and dimension detection technology, which is applied in measuring devices, measuring instruments, surveying and mapping, and navigation, etc., can solve the problems such as the shortage of external dimension inspection methods, and achieve the effect of reducing exploration and testing, reducing material waste and saving man-hours.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

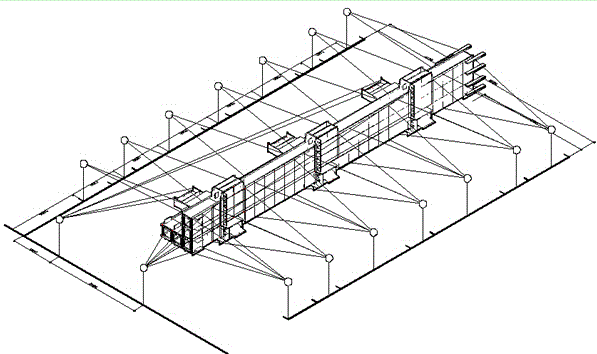

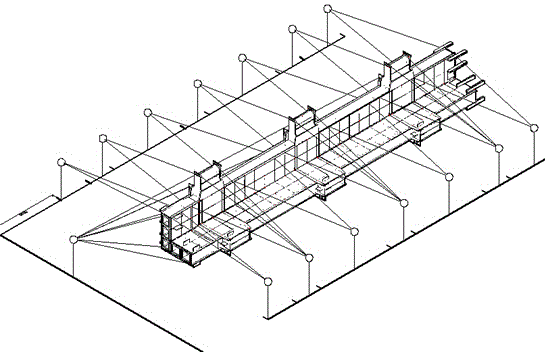

[0023] see figure 1 As shown, a method for detecting the size of a super large combined steel box-shaped steel column and a steel plate shear wall described in this embodiment includes the following steps:

[0024] 1. First of all, choose a solid and flat site as the 3D observation site, and there should be no vibration operations around the site. In order to facilitate the turning and shifting of components, the site should be within the working range of lifting equipment. In this example, the storage warehouse on one side of the large-scale component painting workshop is selected, and there is a hoisting crane on the upper part to assist in lifting and placing.

[0025] 2. After the hoisting and placement are stable, select key control points at the steel member corbels, beam-column connections, and vertical member connection points, and set reflective stickers on the control points. The reflective stickers are simple self-adhesive prisms. Since the total station used on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com