Mechanical transmission static gear shifting simulation method based on AMESim

A technology of mechanical transmission and simulation method, which is applied in the direction of design optimization/simulation, instrumentation, geometric CAD, etc., and can solve the problems of inability to accurately calculate the shift force curve, cost increase, and inability to predict the shift force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to illustrate the technical solution of the present invention more clearly, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0055] According to the actual structure, the present invention forms a simulation modeling method, which can predict the shift force curve, and extract the objective evaluation index corresponding to the subjective evaluation index, reduce the cycle process of design-experiment-improvement, and improve static shifting performance.

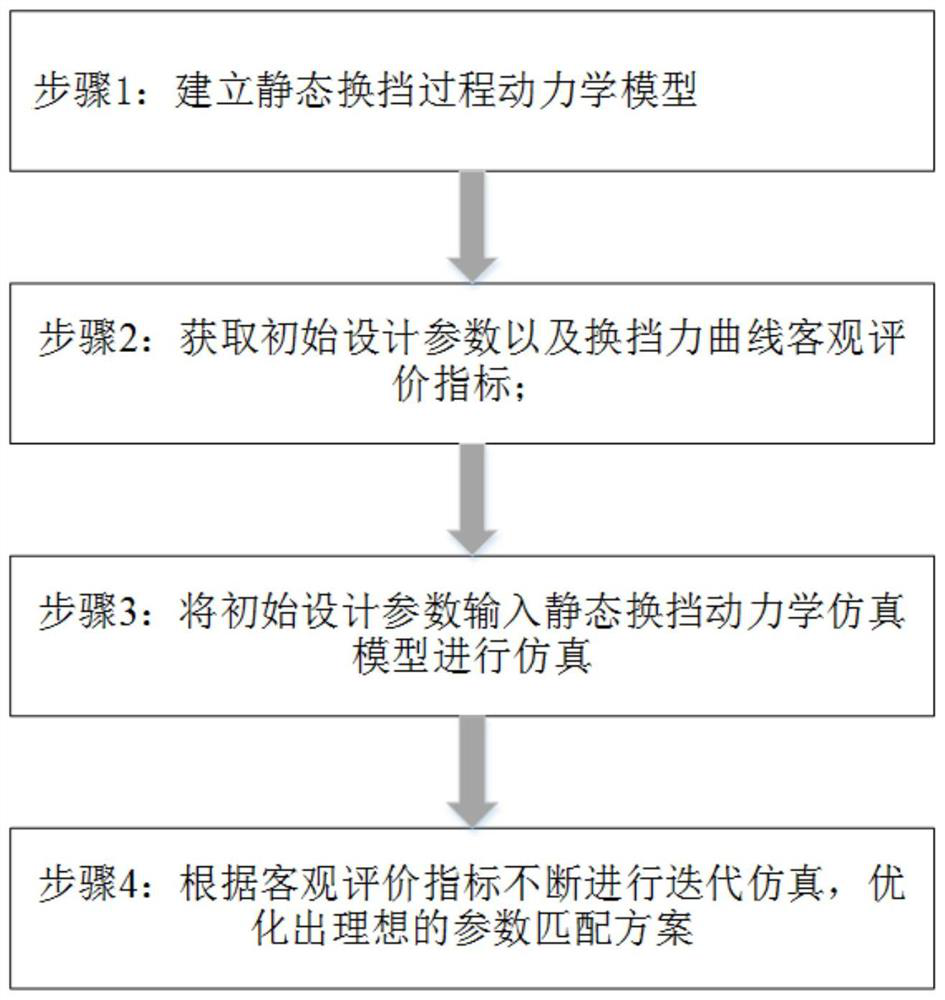

[0056] Such as figure 1 Shown, the present invention discloses a kind of mechanical transmission static shift simulation method based on AMESim, comprises the following steps:

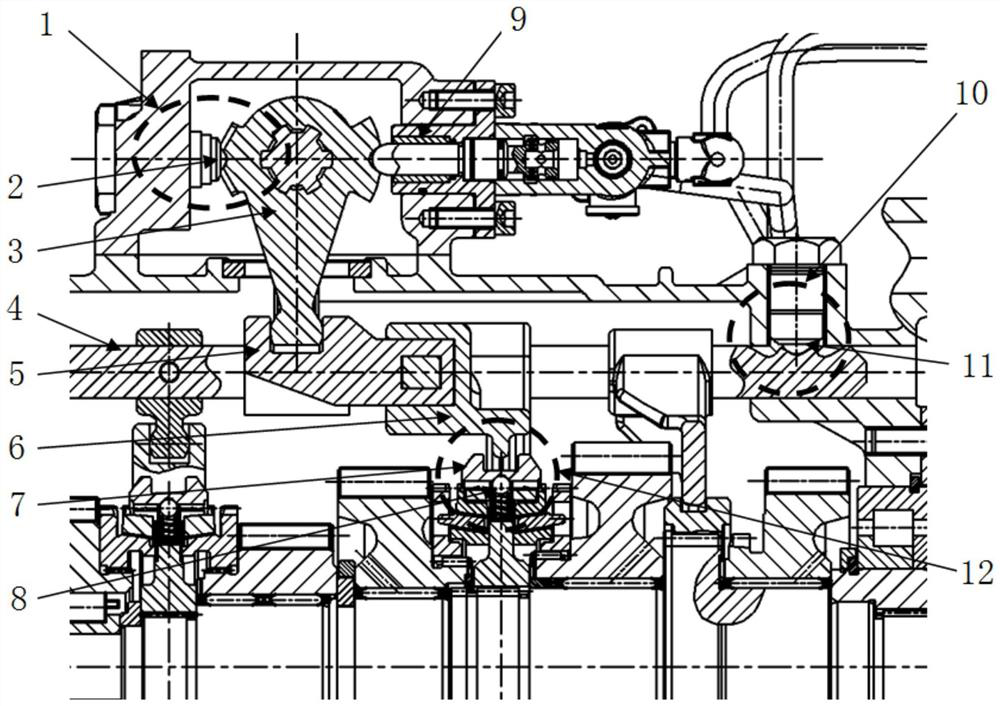

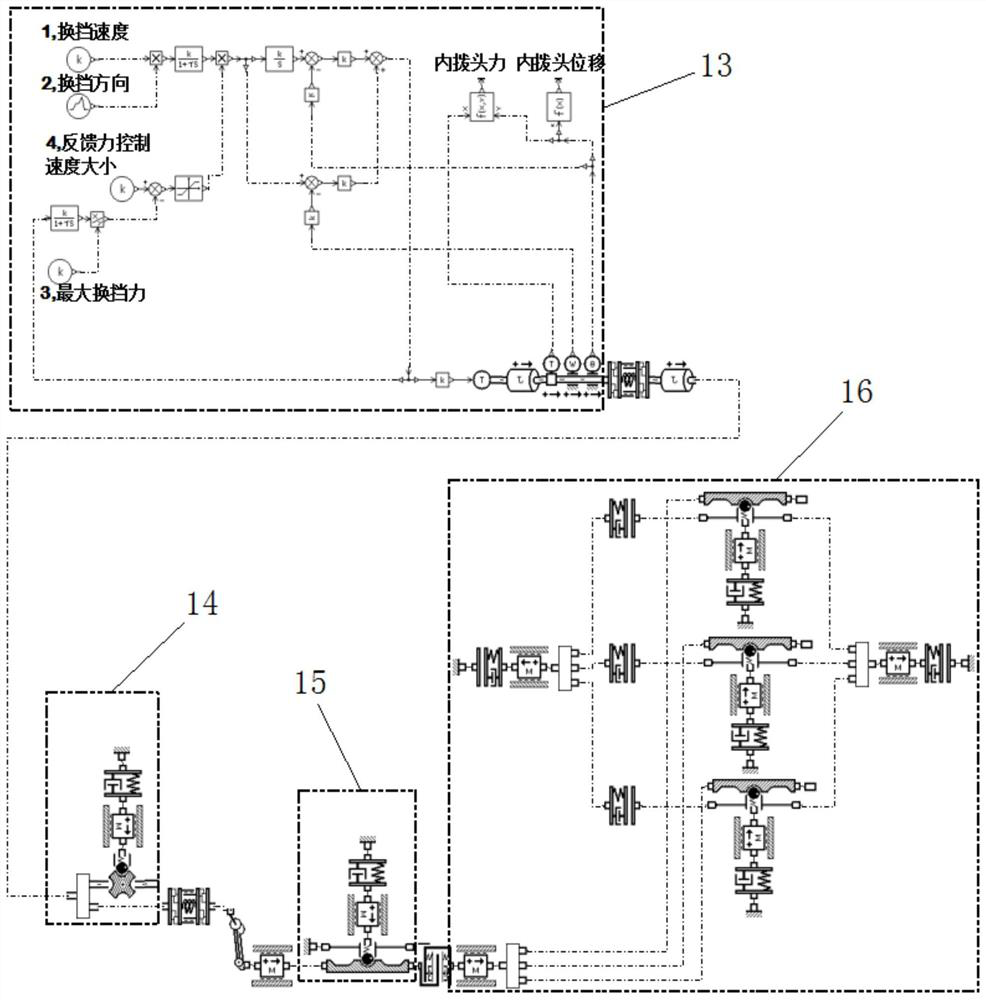

[0057] Step 1: Establish the dynamic model of the static shifting process, including the equivalent model of the shift force, displacement and speed closed-loop feedback control actuator of the test bench 13, the self-locking structure model of the shift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com