Pipe check platform instrument

A technology for platform instruments and pipes, applied in the field of calibrating instruments, can solve problems such as difficulty in accurately inspecting the correctness of pipes, low inspection accuracy of pipes, and increased modification costs, so as to improve the working environment of workers, shorten the shipbuilding cycle, and reduce The effect of shipbuilding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

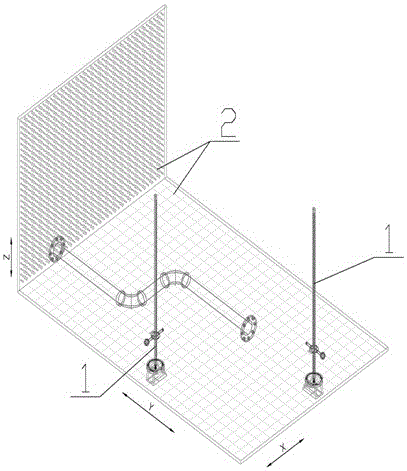

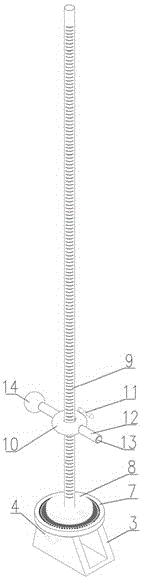

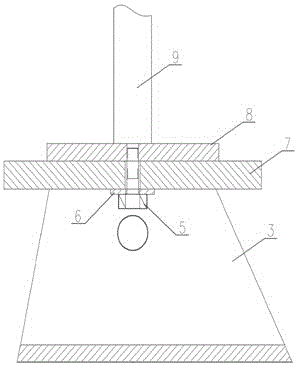

[0021] refer to Figure 1 to Figure 4 , the invention discloses a pipe calibration platform instrument, which includes a fixed installation platform 2 and a plurality of measuring devices 1. The fixed installation platform 2 is relatively simple, and it is composed of a vertical reference plate and a horizontal reference plate. The vertical reference plate is wide The diameter is 2 meters and the height is 1.5 meters. There are two kinds of connecting holes drilled on the horizontal reference plate, the hole diameters are φ11mm and φ21mm, which can cover pipe diameters below DN150 and quickly install. The installation method is: use the installation flange hole of the pipe as the standard to find the matching hole on the horizontal reference plate, and directly use two bolts or more than two bolts to connect. The horizontal platform is 3 meters long and 2 meters wide, and the surface is engraved with vertical and horizontal lines at equal distances of 10mm as scale lines for q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com