Distribution method of optical cable chromatography

An optical cable and chromatographic technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of difficult chromatographic distribution of optical fiber belts, difficult to master chromatographic distribution, and company losses, so as to reduce the training time, reduce the degree of mastery, and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

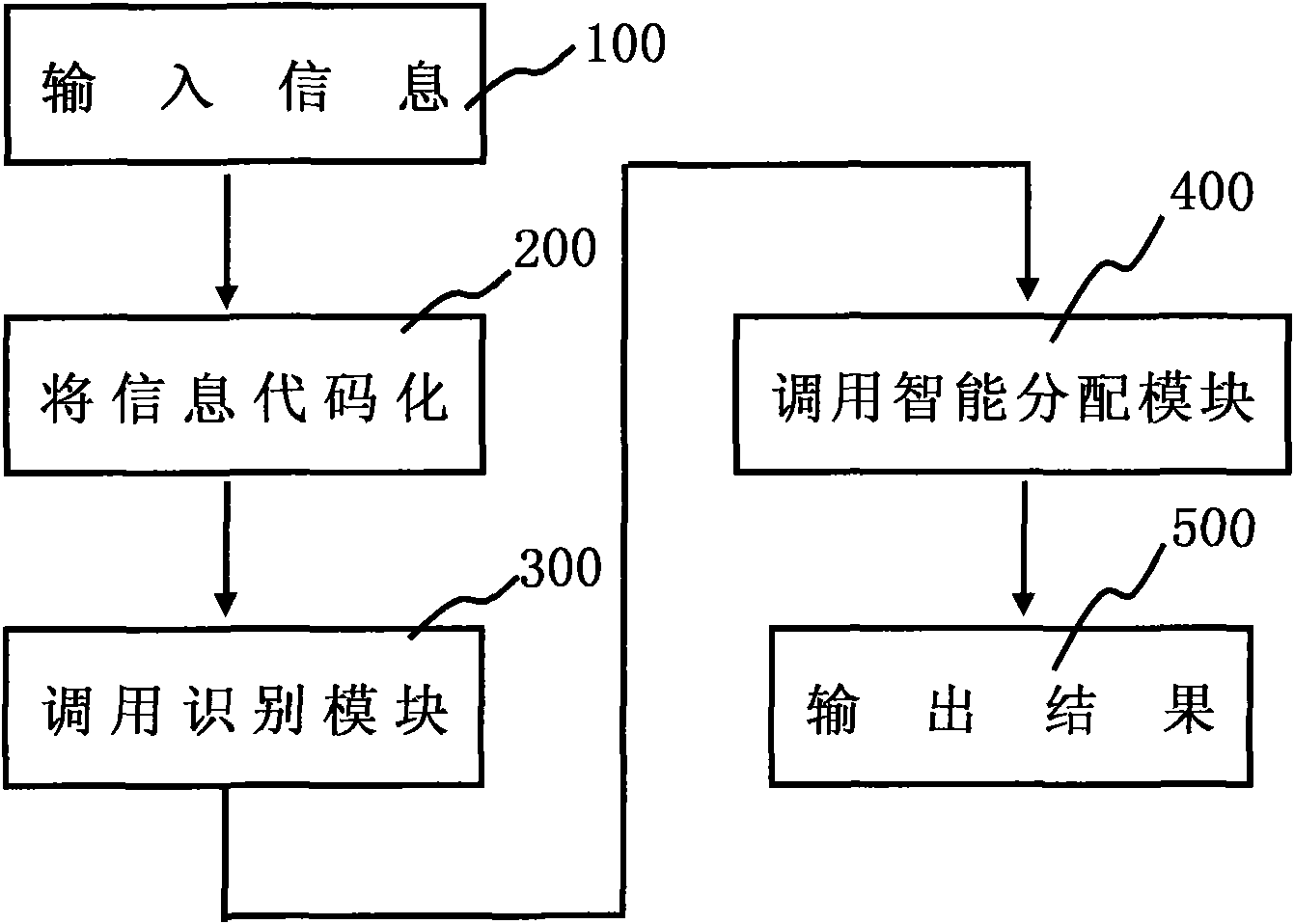

[0014] see figure 1 , the method for optical cable chromatogram distribution of the present invention is characterized in that: it comprises the following steps:

[0015] 100. Input information;

[0016] 200. Code information;

[0017] 300. Call the identification module;

[0018] 400. Call the intelligent allocation module;

[0019] 500. Output the result.

[0020] In step 100, mainly enter the following information:

[0021] Optical cable structure: such as 4 units, 5 units, 6 units, etc.;

[0022] The total number of optical fibers in the cable: 12 cores, 24 cores, 36 cores, 48 cores, etc.;

[0023] Maximum number of fibers in each tube: 4, 6, 8, 10, 12, etc.;

[0024] The maximum number of fibers per tube: 2, 4, 6, 8, 10, etc.;

[0025] Optical cable model: GYTA, GYTS, GYTA53, GYTY53, GYFTY, GYDTA, GYDTS, GYDTY53, GYDTA53, GYXTS, GYXTA, GYXTY, GYTZA, GYFTA, GYFTS, GYXTW, GYDXTW, GYDXTZW, GYTZS, GYFTZ3, GYFTZSY, , GYDTZA, GYFDTY, GYXTZA, GYXTZS, GYXTZY, GYTY, GYT...

Embodiment 2

[0045] Basically the same as Example 1, the difference is:

[0046] In step 200 of encoding information, it is implemented as follows:

[0047] Code part of the information input in the above 100 steps, for example: GYTA53 optical cable, the optical cable structure is 8 units, the total number of optical fibers is 92 cores, the maximum number of cores per tube is 12, and the maximum number of cores per tube is 10. The type is 0 fiber ribbon, the fiber optic chromatogram is the national standard full chromatogram, the loose tube chromatogram is the national standard full chromatogram, the optical fiber is B1.3 type, and the sheath thickness is the nominal value of the national standard; code formation: X20922002608000.

Embodiment 3

[0049] Basically the same as Example 1, the difference is:

[0050] In step 200 of encoding information, it is implemented as follows:

[0051] Code part of the information input in the above 100 steps, for example: GYDTA optical cable, the optical cable structure is 5 units, the total number of optical fibers is 288 cores, the maximum number of cores per tube is 72, and the maximum number of cores per tube is 48. The type is 12 fiber ribbons, the color spectrum of the optical fiber is the full color spectrum of the national standard, the color spectrum of the loose tube is the full color spectrum of the national standard, the color spectrum of the optical fiber ribbon is the full color spectrum of the national standard, the fiber type is B1, and the thickness of the sheath is the nominal value of the national standard; code formation: D02881006505000.

[0052] Beneficial effects of the present invention: ① For information entry personnel, the degree of mastery of optical cabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com