Patents

Literature

100 results about "Good memory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of depositing nanolaminate film for non-volatile floating gate memory devices by atomic layer deposition

Disclosed herein is a method of depositing a nanolaminate film for next-generation non-volatile floating gate memory devices by atomic layer deposition. The method includes the steps of: introducing a substrate into an atomic layer deposition reactor; forming on the substrate a first high-dielectric-constant layer by alternately supplying an oxygen source and a metal source selected from among an aluminum source, a zirconium source and a hafnium source; forming on the first high-dielectric-constant layer a nickel oxide layer by alternately supplying a nickel source and an oxygen source; and forming on the nickel oxide layer a second high-dielectric-constant layer by alternately supplying an oxygen source and a metal source selected from among an aluminum source, a zirconium source and a hafnium source. The nanolaminate film deposited according to the method shows good memory window characteristics compared to those of memory devices fabricated using nanocrystal floating gates according to the prior physical vapor deposition methods, and thus can be applied to non-volatile floating gate memory devices.

Owner:KOREA RES INST OF CHEM TECH

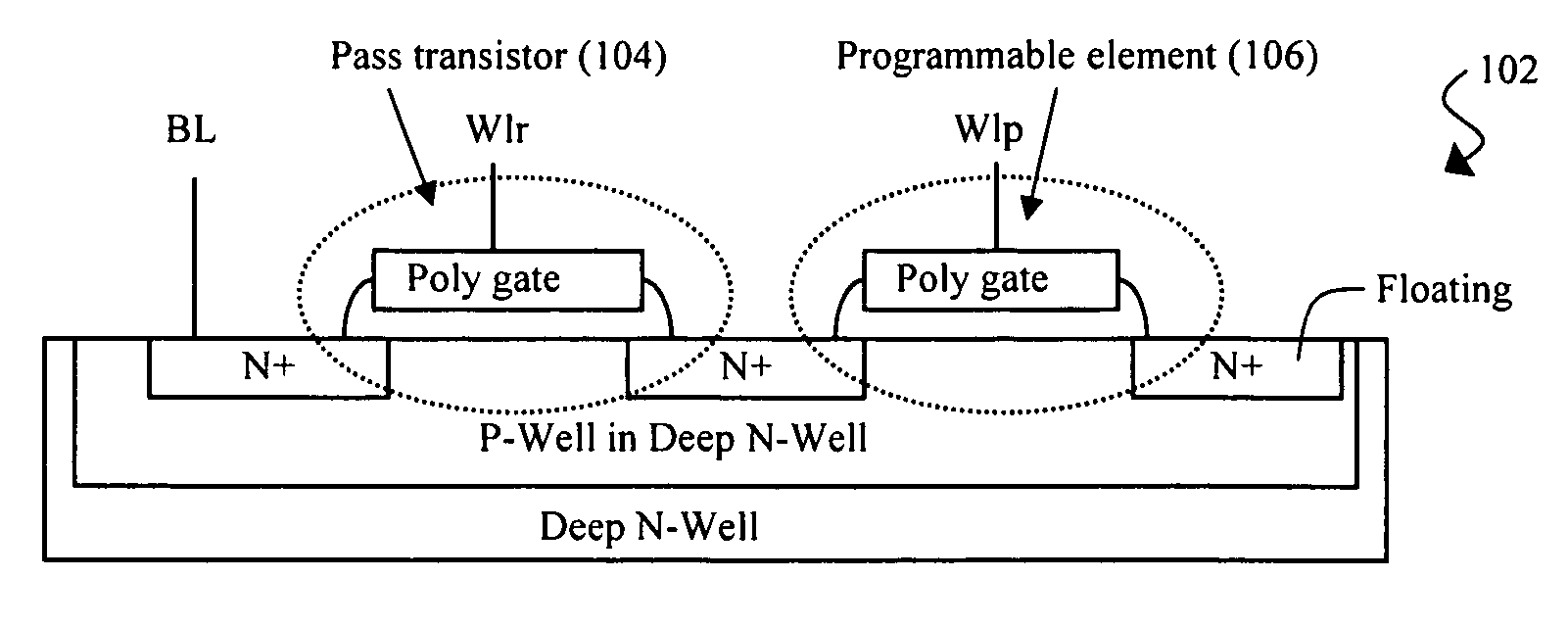

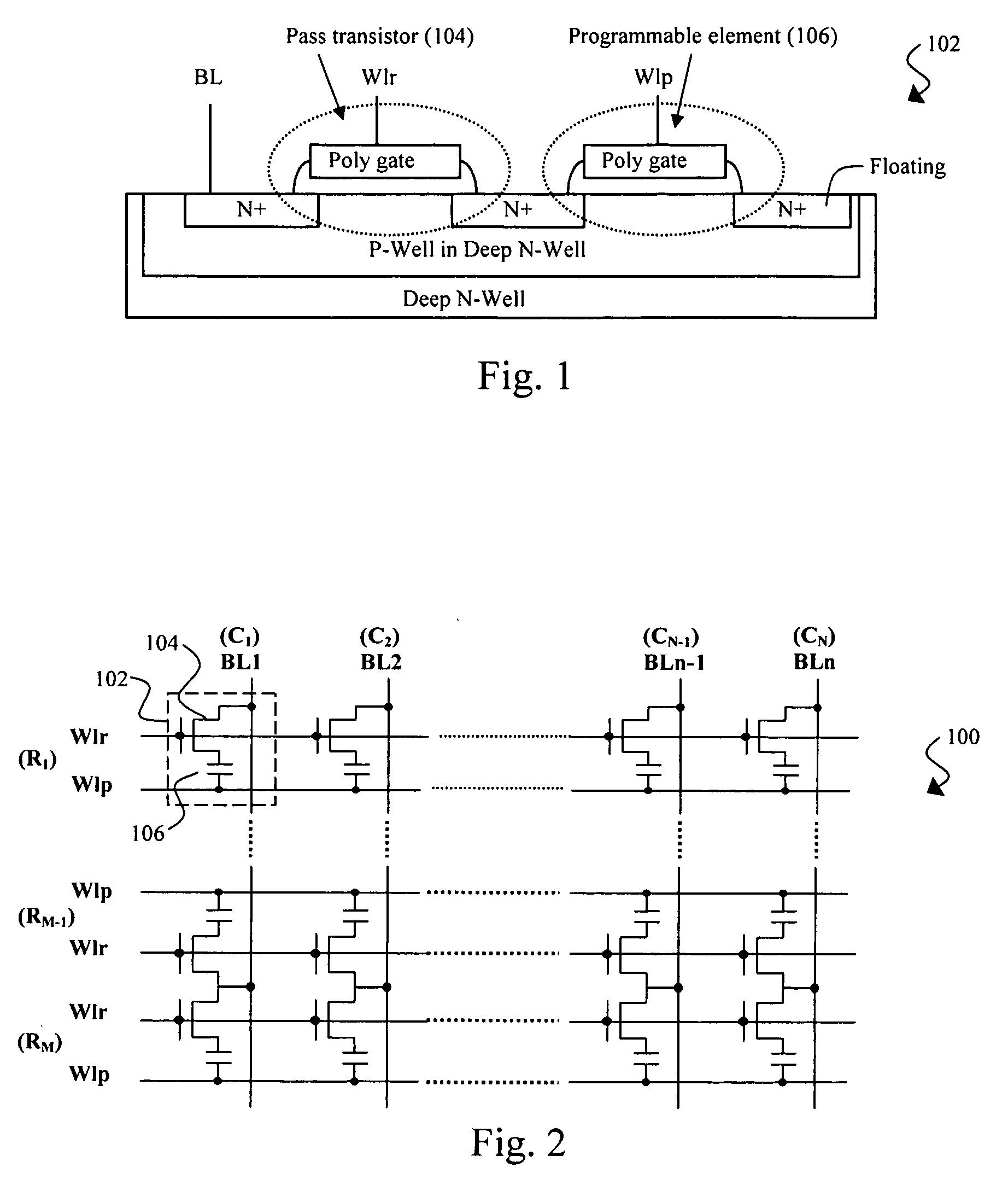

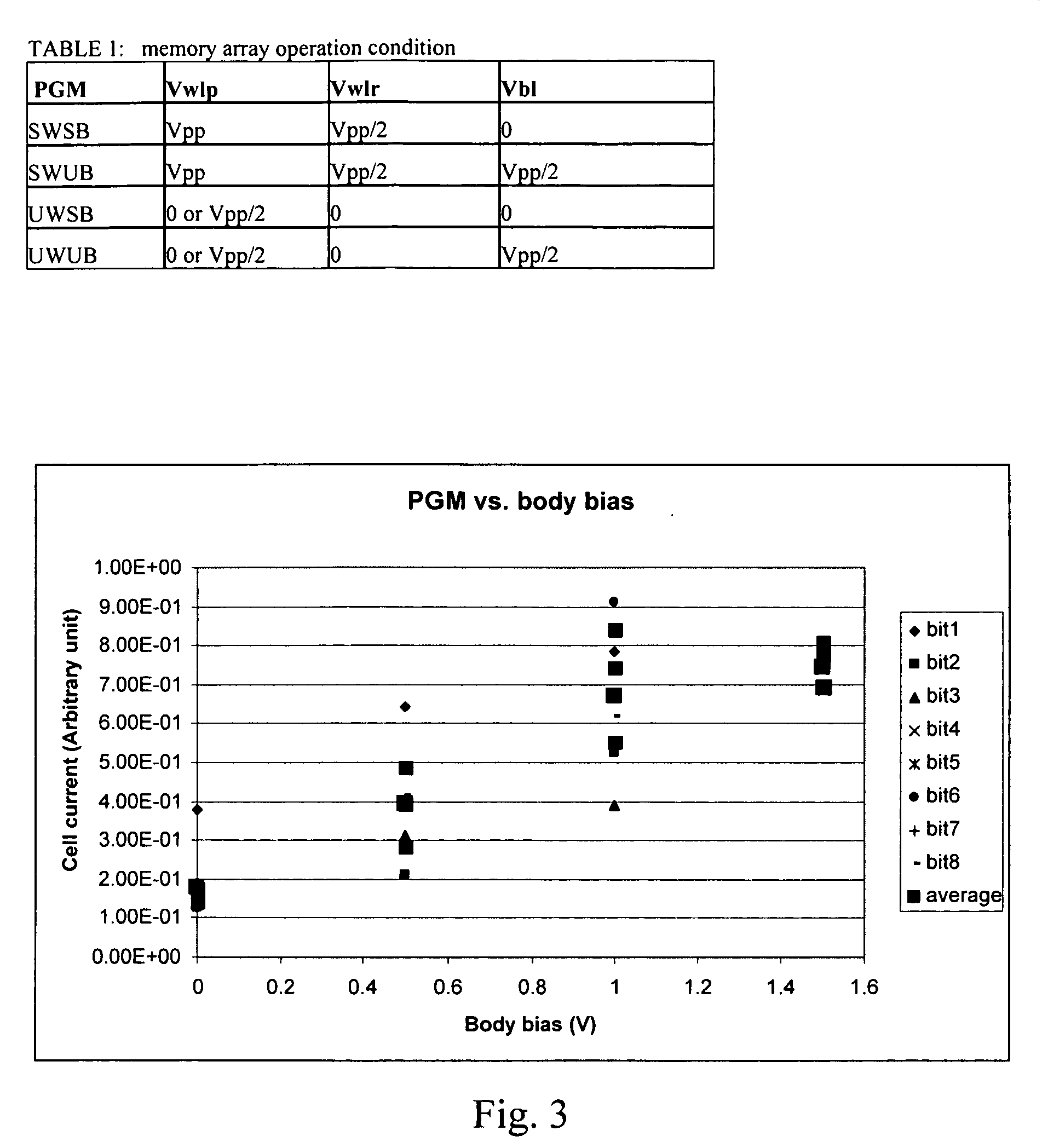

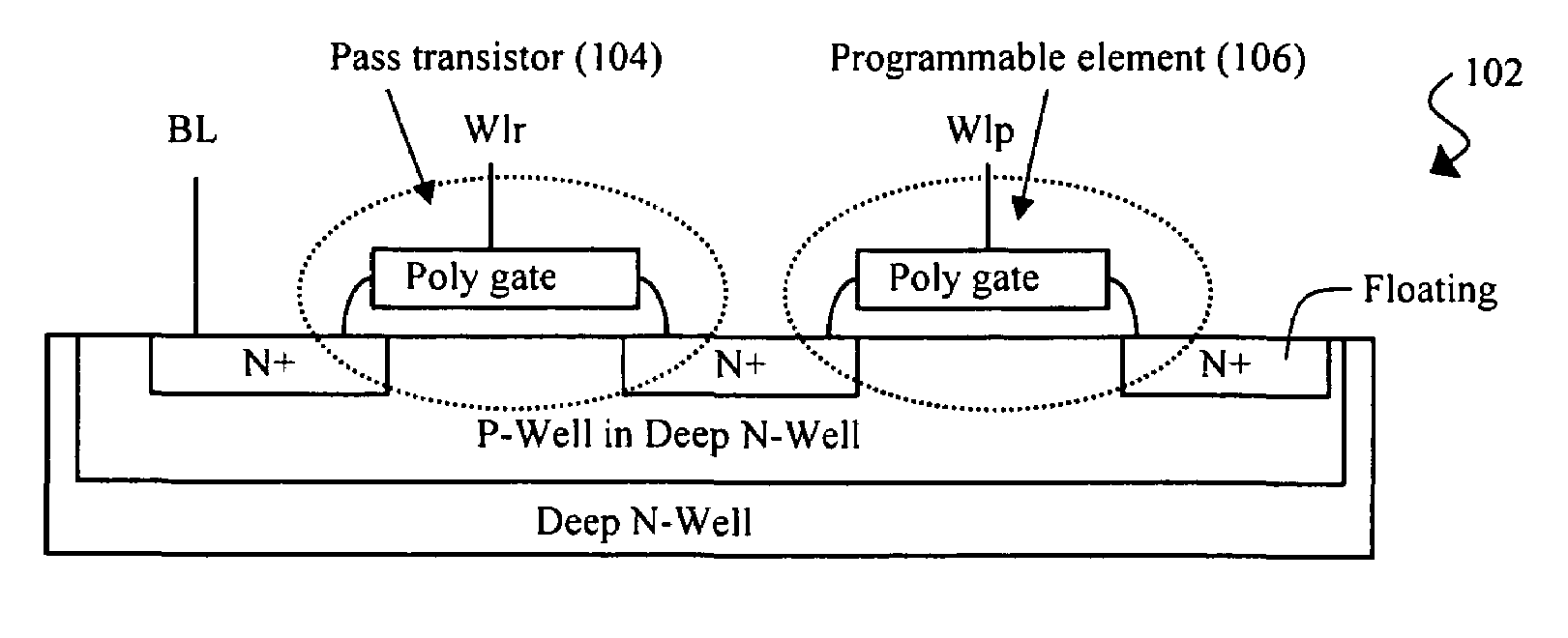

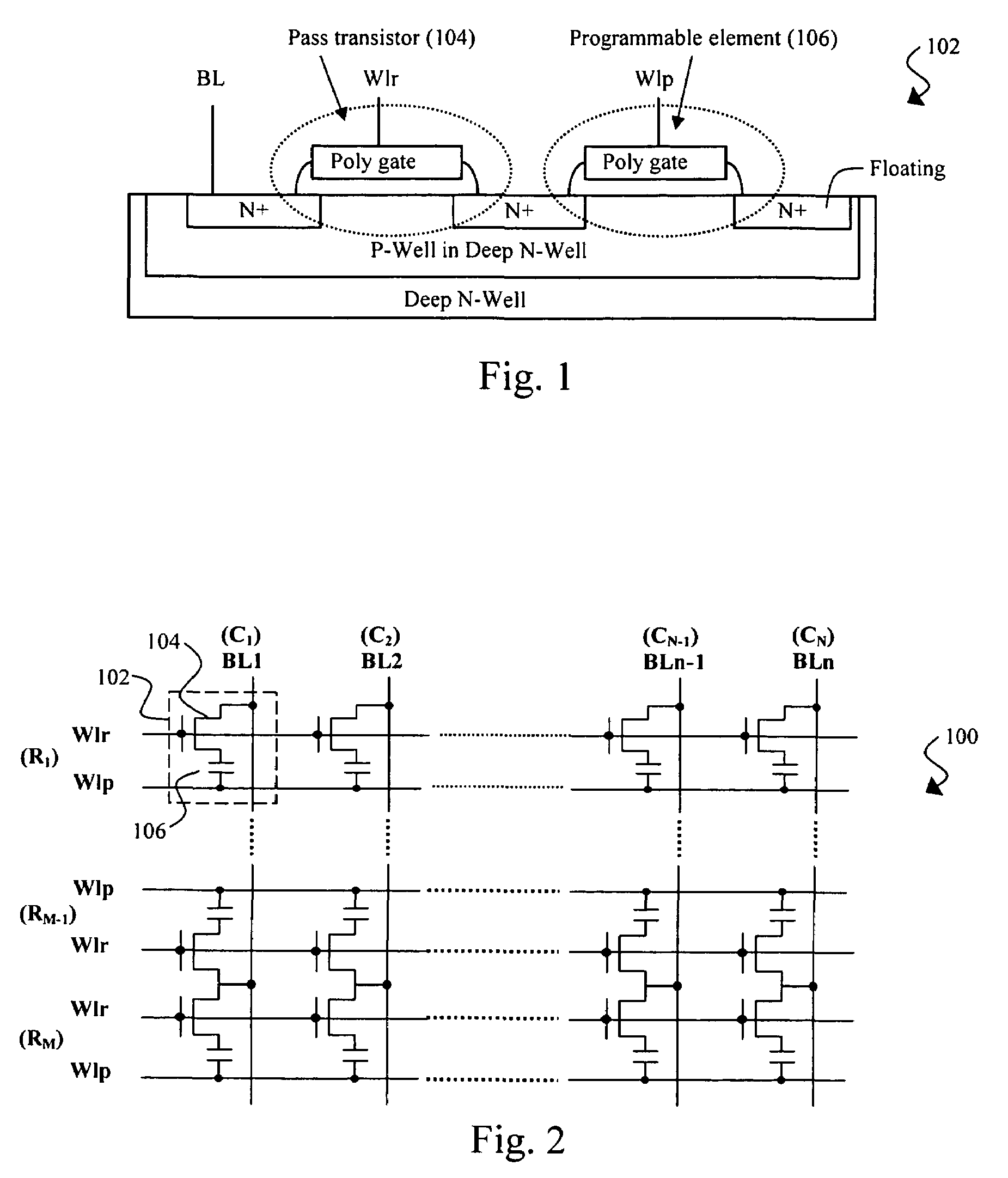

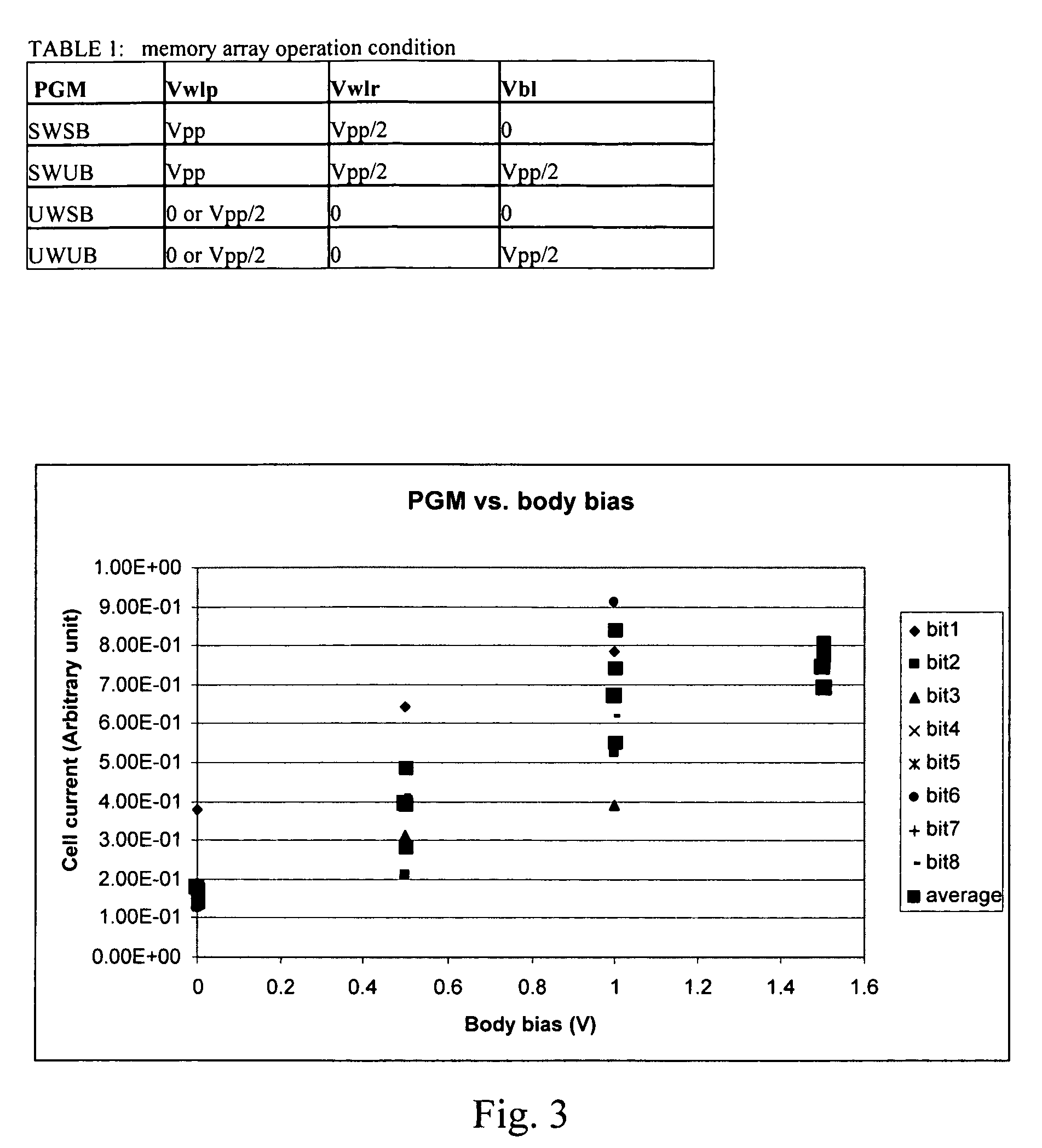

Non-volatile semiconductor memory based on enhanced gate oxide breakdown

A semiconductor memory structure based on gate oxide break down is constructed in a deep N-well. Thus, the electrical field over the programmable element during the transient procedure of gate oxide break down can be controlled to achieve the best memory programming results. The conductivity of the programmed memory cell is increased greatly and conductivity variation between the memory cells is reduced. This is achieved by adding a body bias during the programming process. The body here refers to a P-well formed within the deep N-Well. Furthermore, the read voltage offset is reduced greatly with this new memory configuration. These improved programming results will allow faster read speed and lower read voltage. This new structure also reduces current leakage from a memory array during programming.

Owner:SYNOPSYS INC

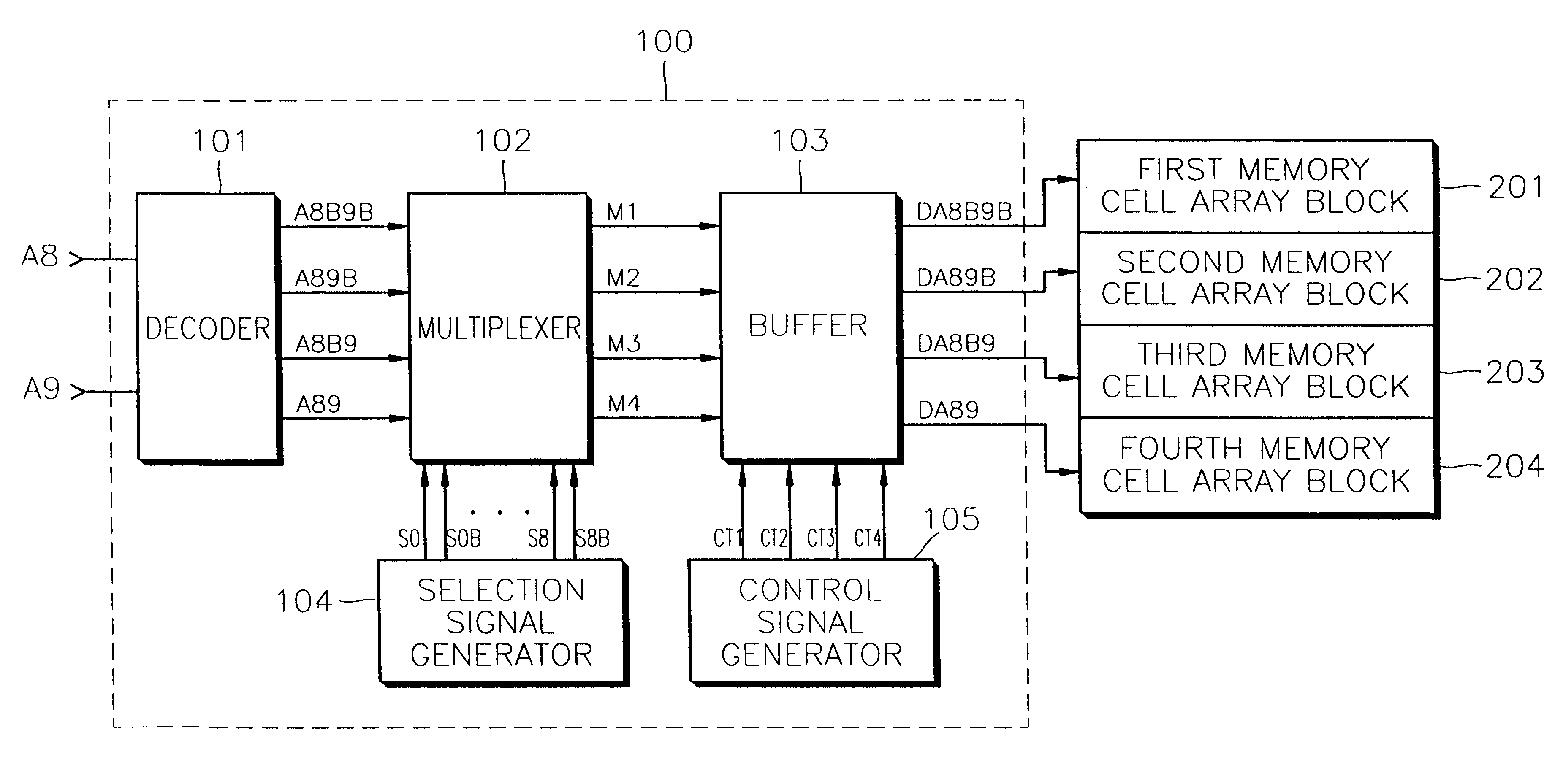

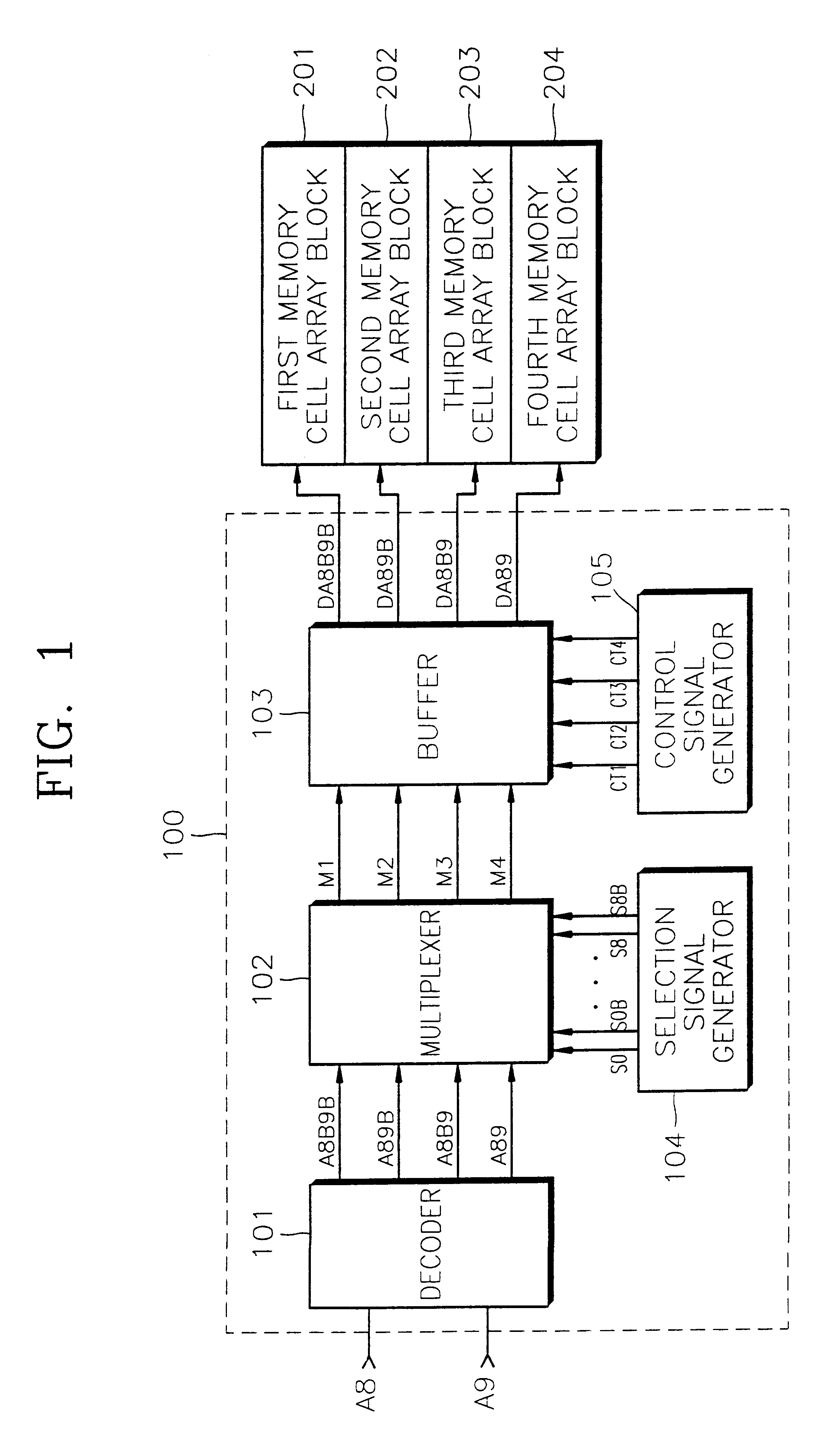

Memory device with address translation for skipping failed memory blocks

A semiconductor memory device capable of operating normally even when a failed memory cell remains after repair. The semiconductor memory device includes a plurality of memory cell array blocks, and address decoding circuitry for receiving an address and for accessing good memory cell array blocks and skipping failed memory cell array blocks.

Owner:SAMSUNG ELECTRONICS CO LTD

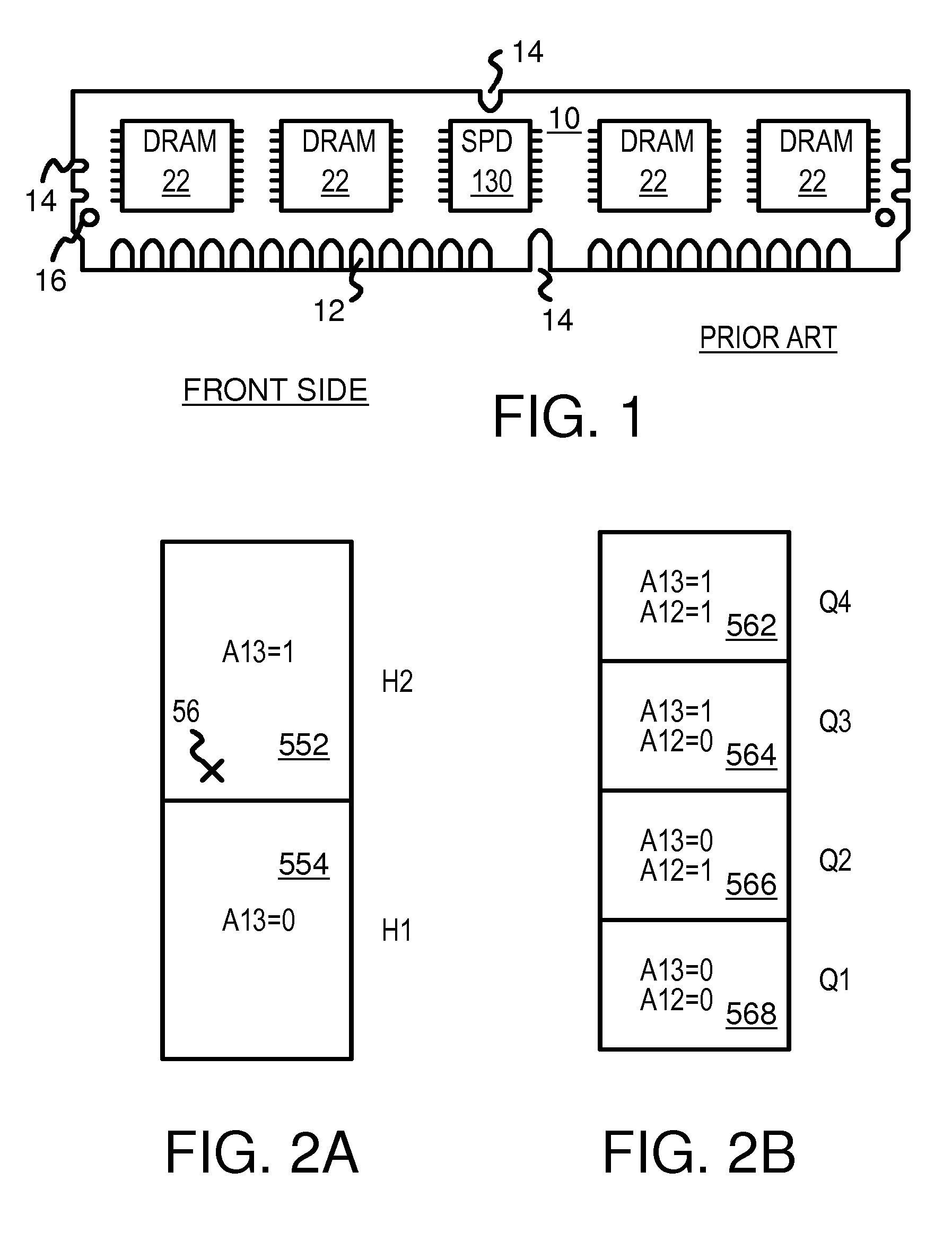

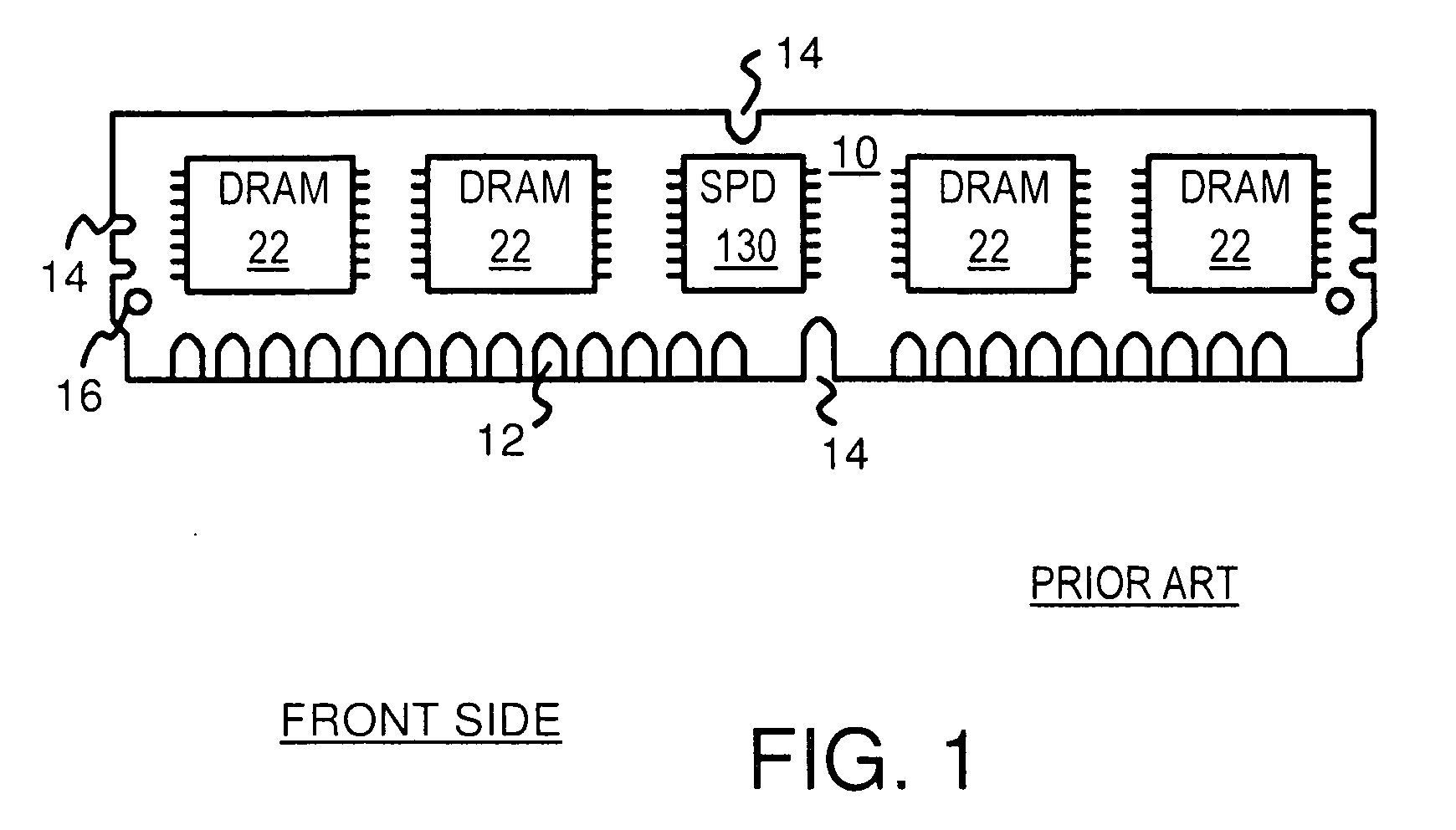

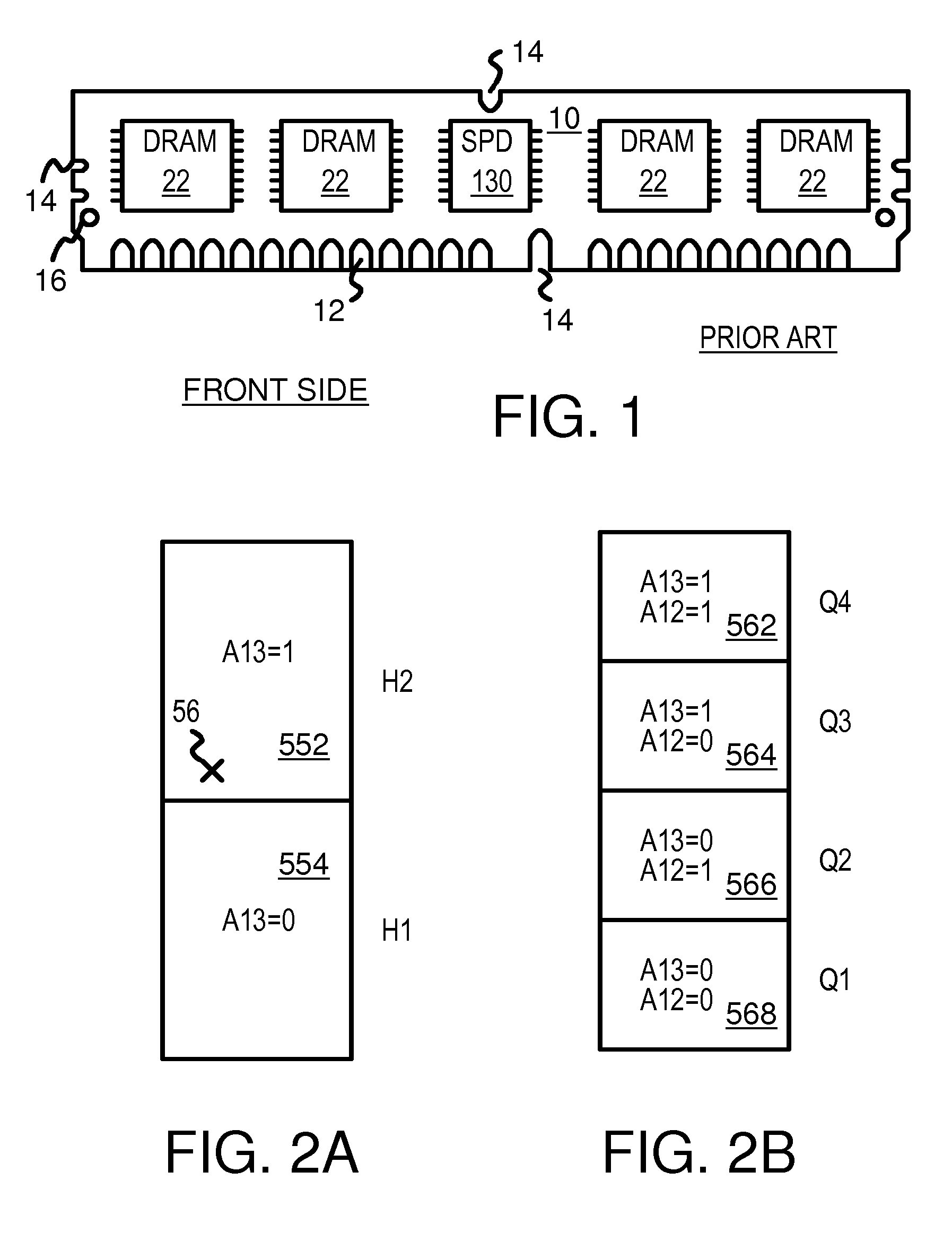

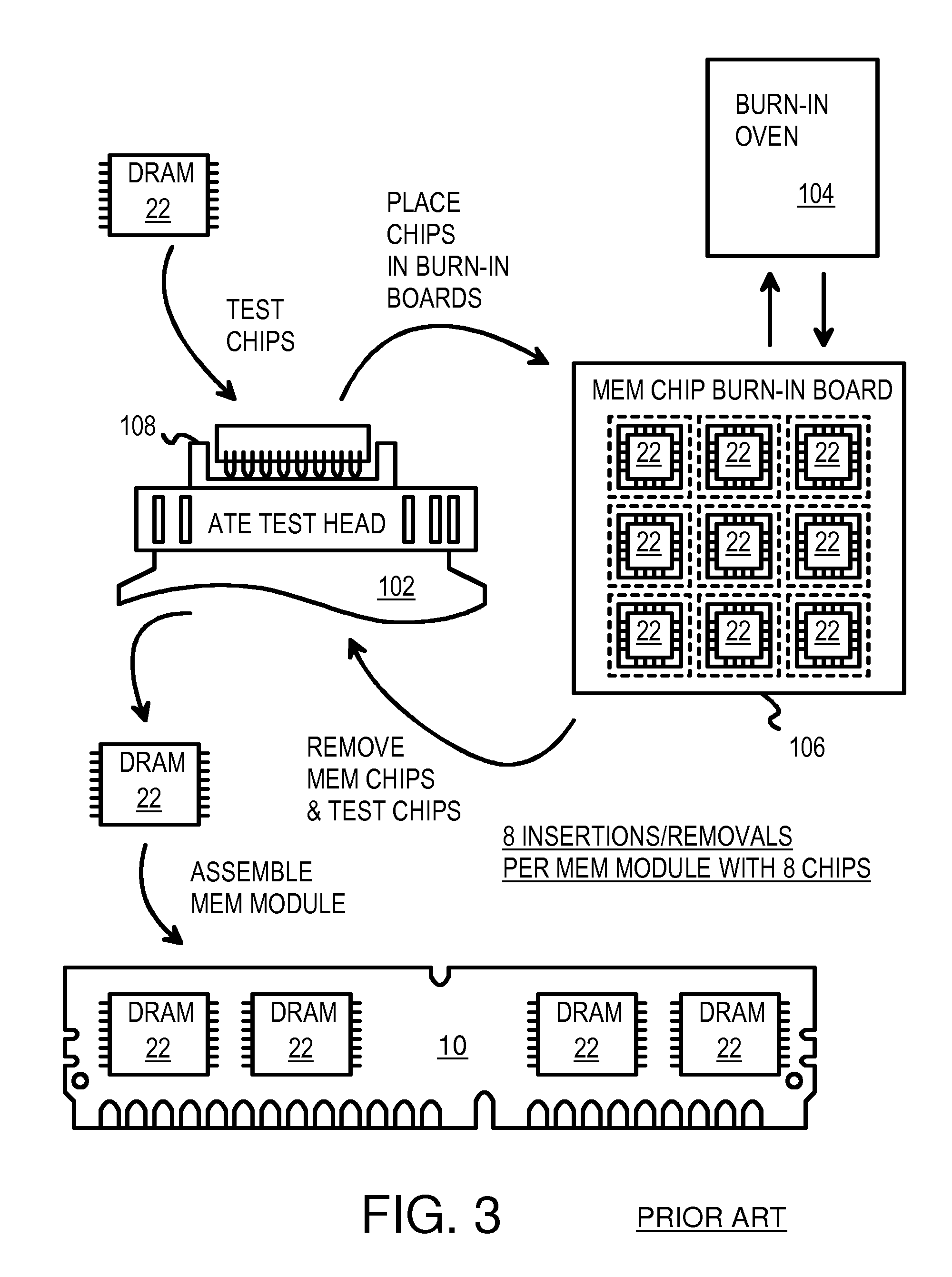

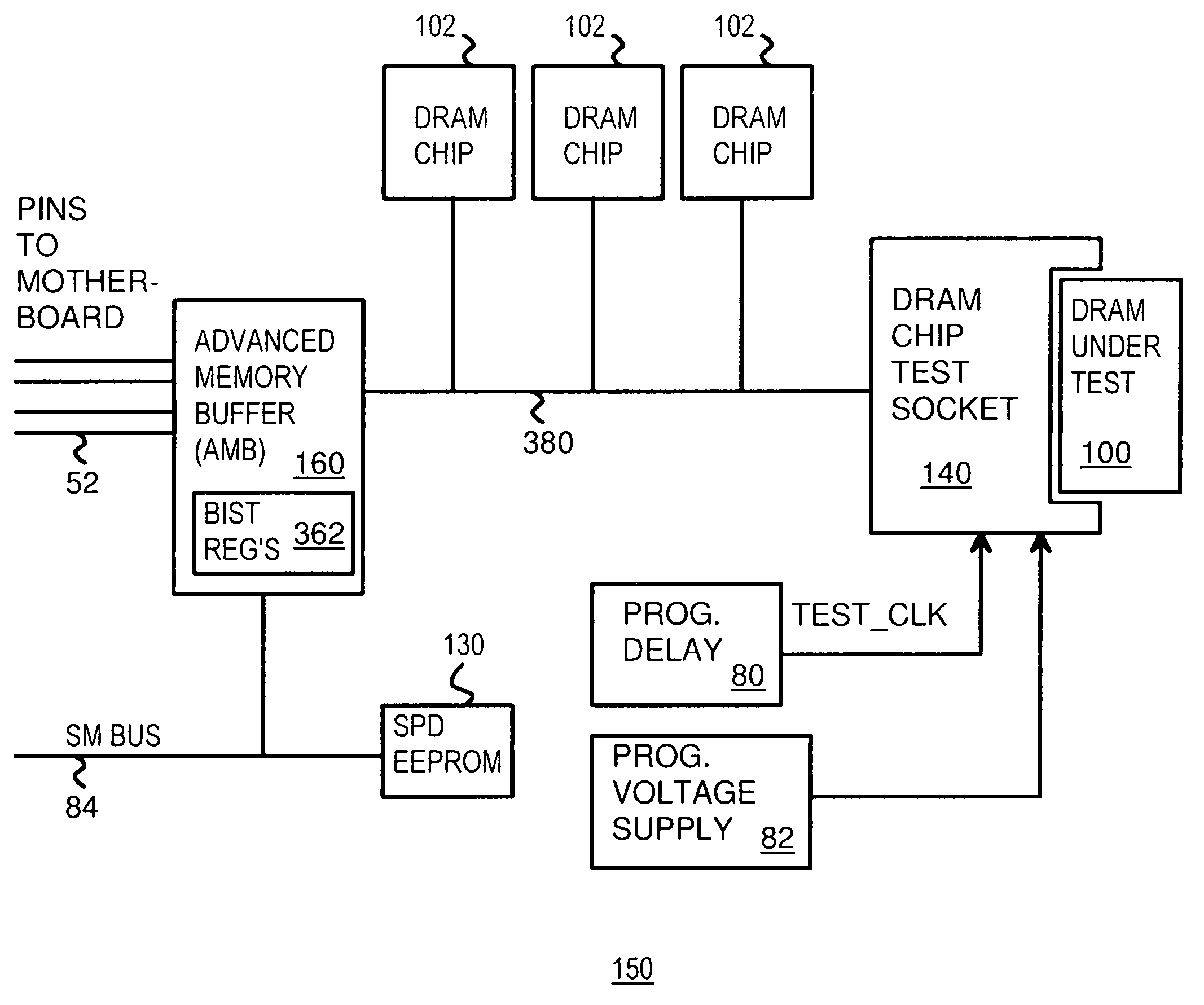

Manufacturing Method for Partially-Good Memory Modules with Defect Table in EEPROM

ActiveUS20090137070A1Semiconductor/solid-state device testing/measurementSolid-state devicesSerial presence detectDram chip

A manufacturing method makes memory modules from partially-good DRAM chips soldered to its substrate. The partially-good DRAM chips have a number of defective memory cells that is below a test threshold, such as 10%. Packaged DRAM chips are optionally pre-screened and considered to pass when the number of defects found is less than the test threshold. A defect table is created during testing and written to a serial-presence-detect electrically-erasable read-only memory (SPD-EEPROM) on the memory module. The memory module is finally tested on a target-system tester that reads the defect table during booting, and redirects memory access to defective memory locations identified by the defect table. The memory modules may be burned in or tested at various temperatures and voltages to increase reliability.

Owner:KINGSTON DIGITAL CO LTD

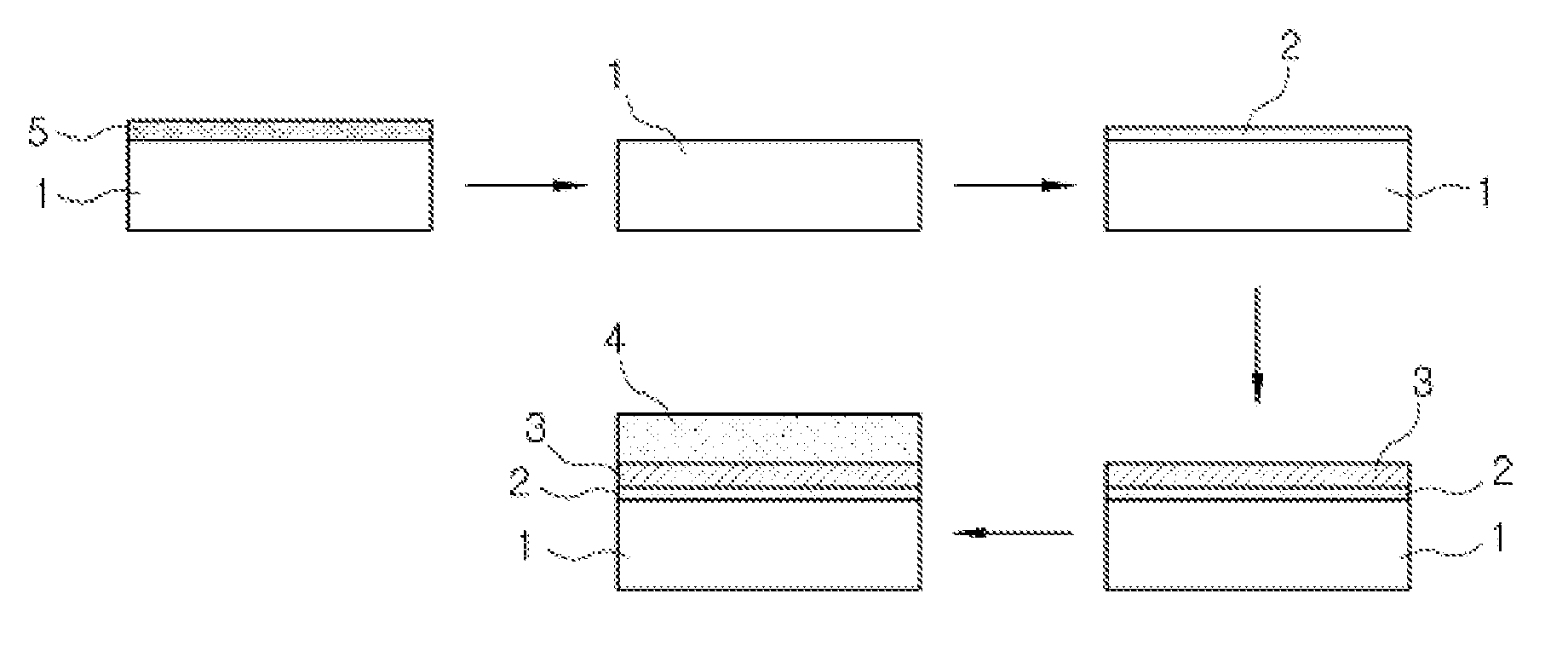

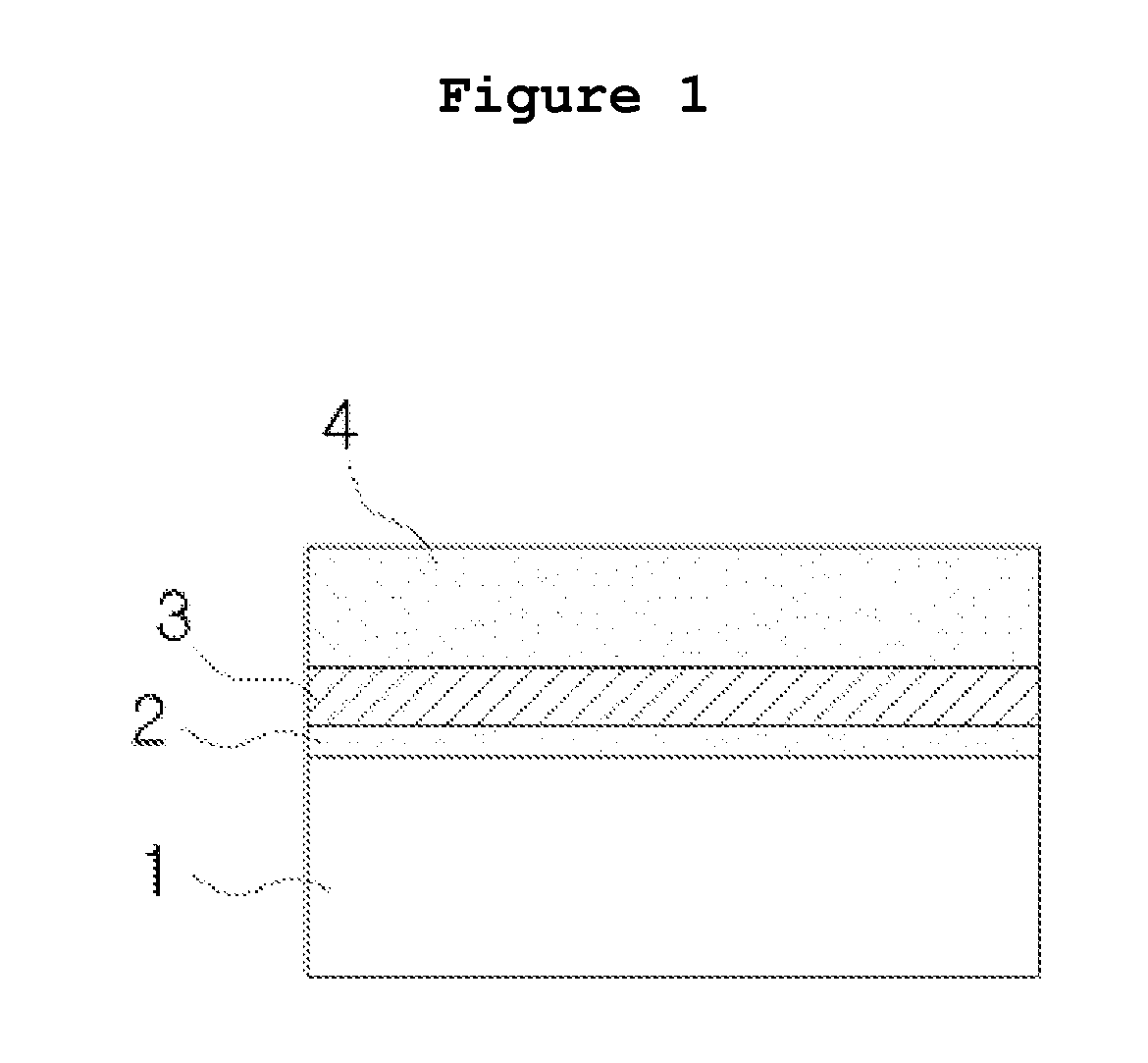

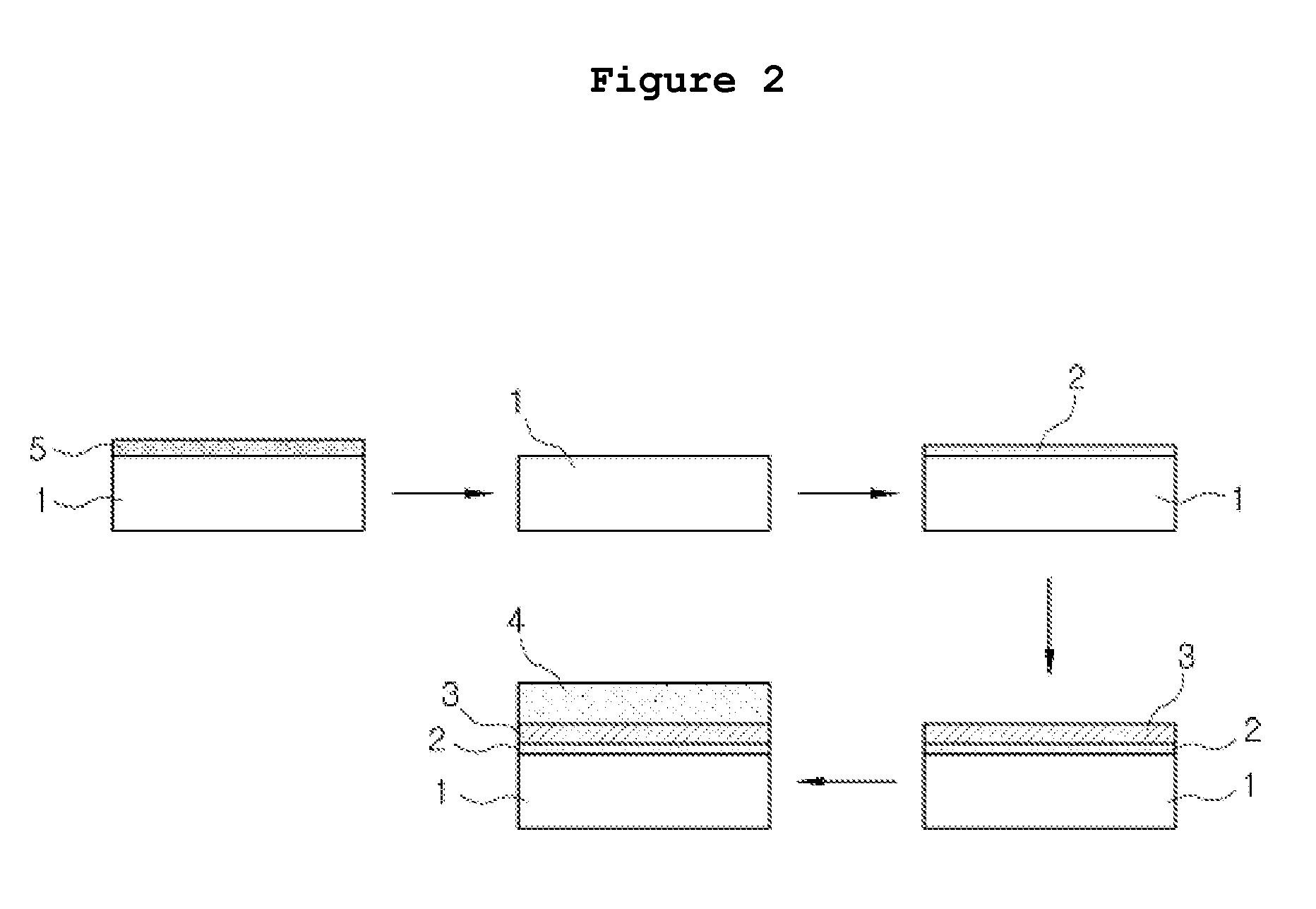

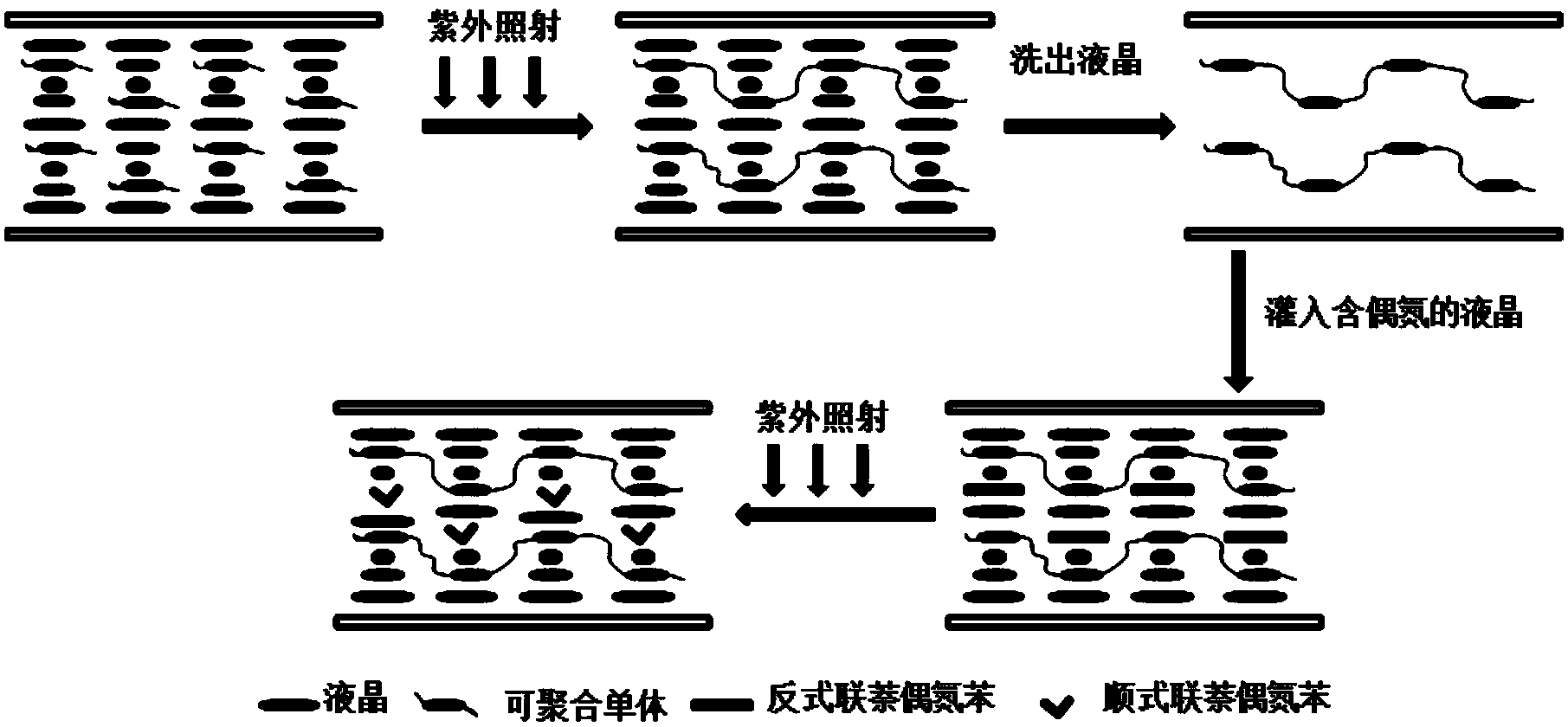

Dual-reflection zone cholesteric liquid crystal film with reversible light response characteristic and preparation method for dual-reflection zone cholesteric liquid crystal film

ActiveCN104142587AReversible regulationGood memory effectNon-linear opticsUltraviolet lightsPolymer thin films

The invention discloses a dual-reflection zone cholesteric liquid crystal film with a reversible light response characteristic and a preparation method for the dual-reflection zone cholesteric liquid crystal film. The method comprises the following steps of 1) mixing a chiral compound, a polymerizable monomer, nematic phase liquid crystals and a photoinitiator, pouring the mixture into a liquid crystal box, and irradiating by using ultraviolet light to form a cholesteric phase polymer film; 2) soaking the cholesteric phase polymer film in a nonpolar solvent to remove unreacted micromolecular liquid crystals, and pouring a mixture of binaphthylyl azobenzene compounds and the nematic phase liquid crystals to obtain the dual-reflection zone cholesteric liquid crystal film with the reversible light response characteristic. The film prepared by the method can reflect light in two wave bands and can cover a wavelength range of 500-2,000nm. The film has a good memory effect and has high potential application value in the fields such as adjustable optical filters, adjustable multi-mode laser protection, anti-counterfeiting and liquid crystal display.

Owner:PEKING UNIV

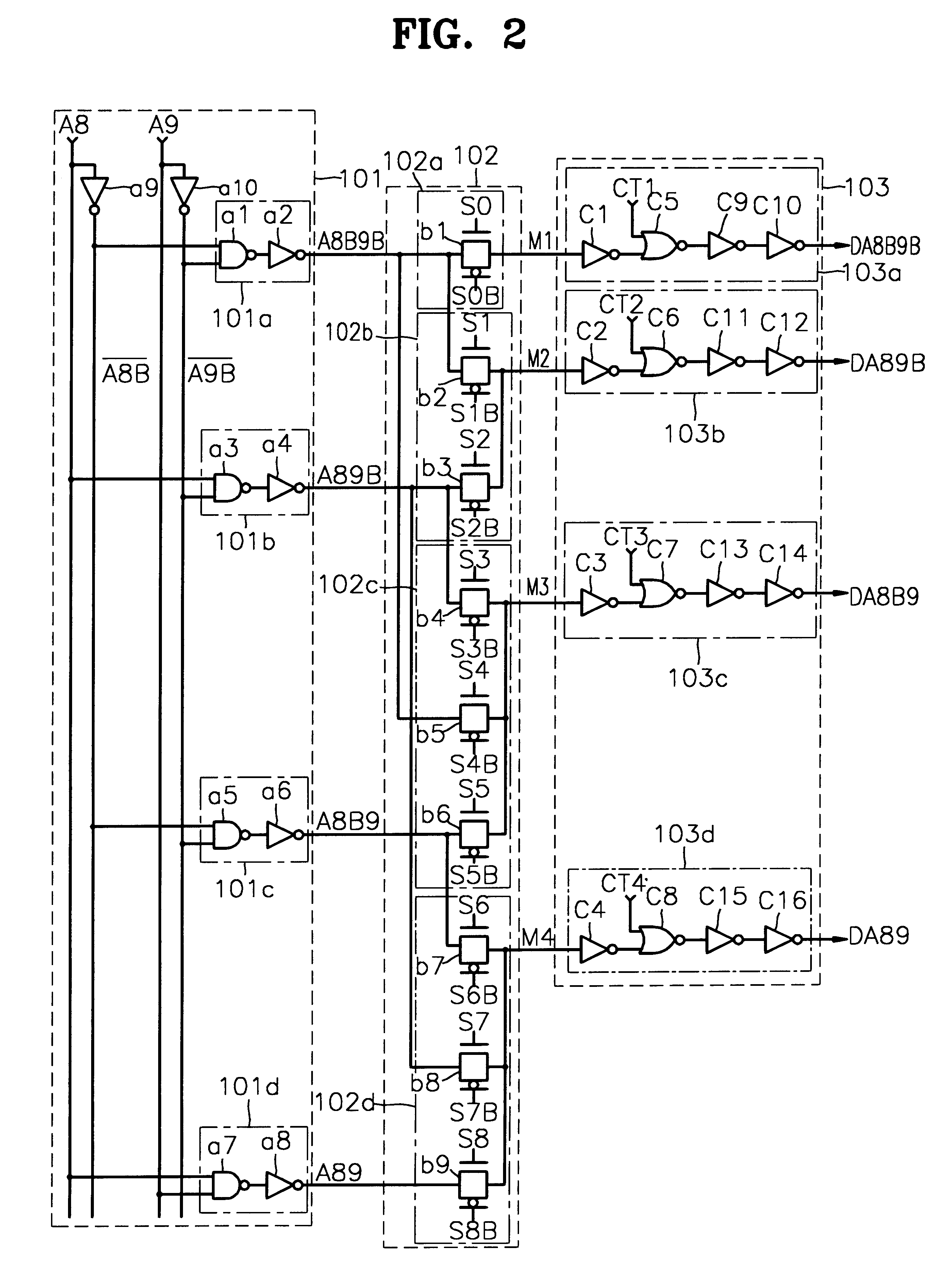

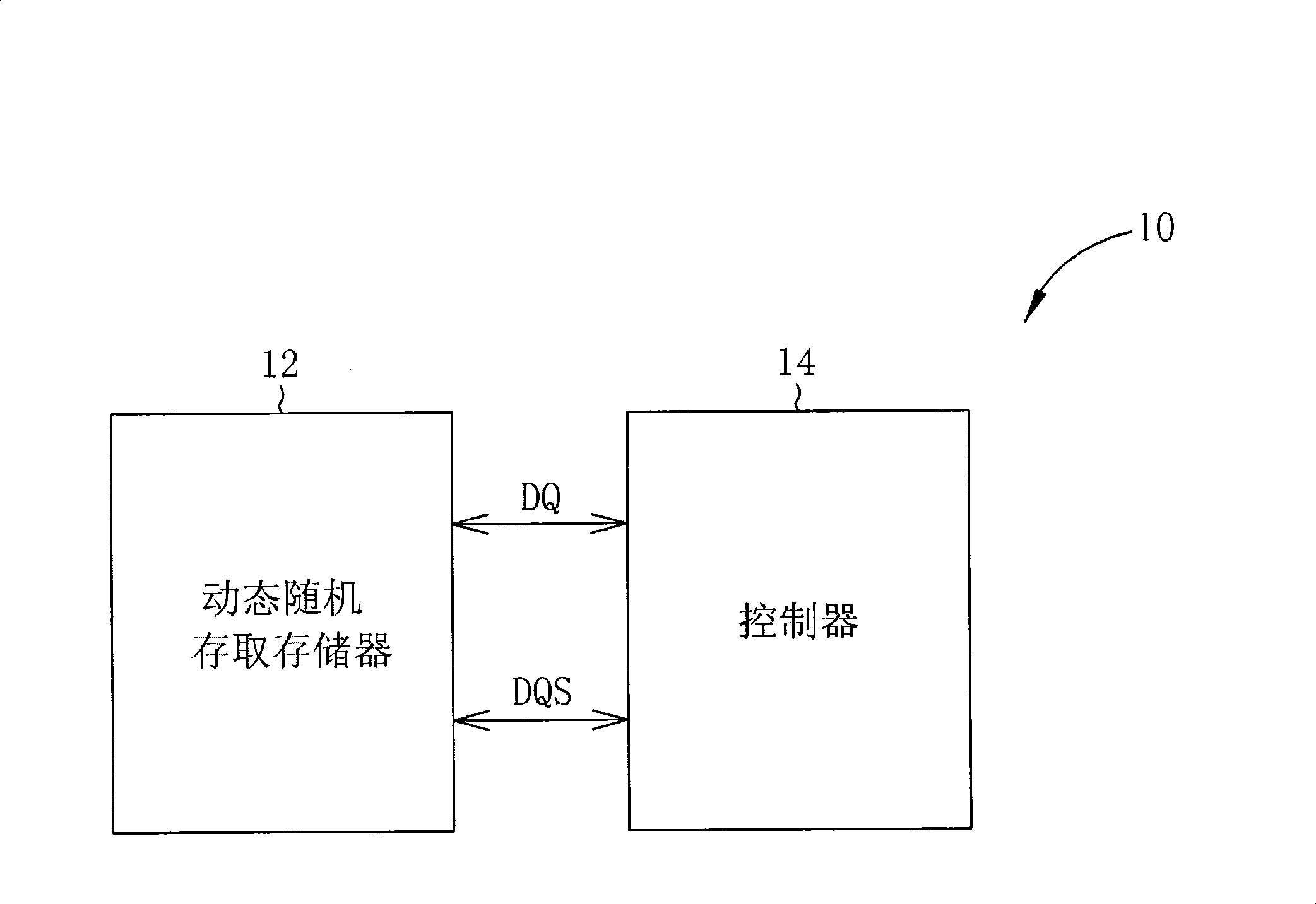

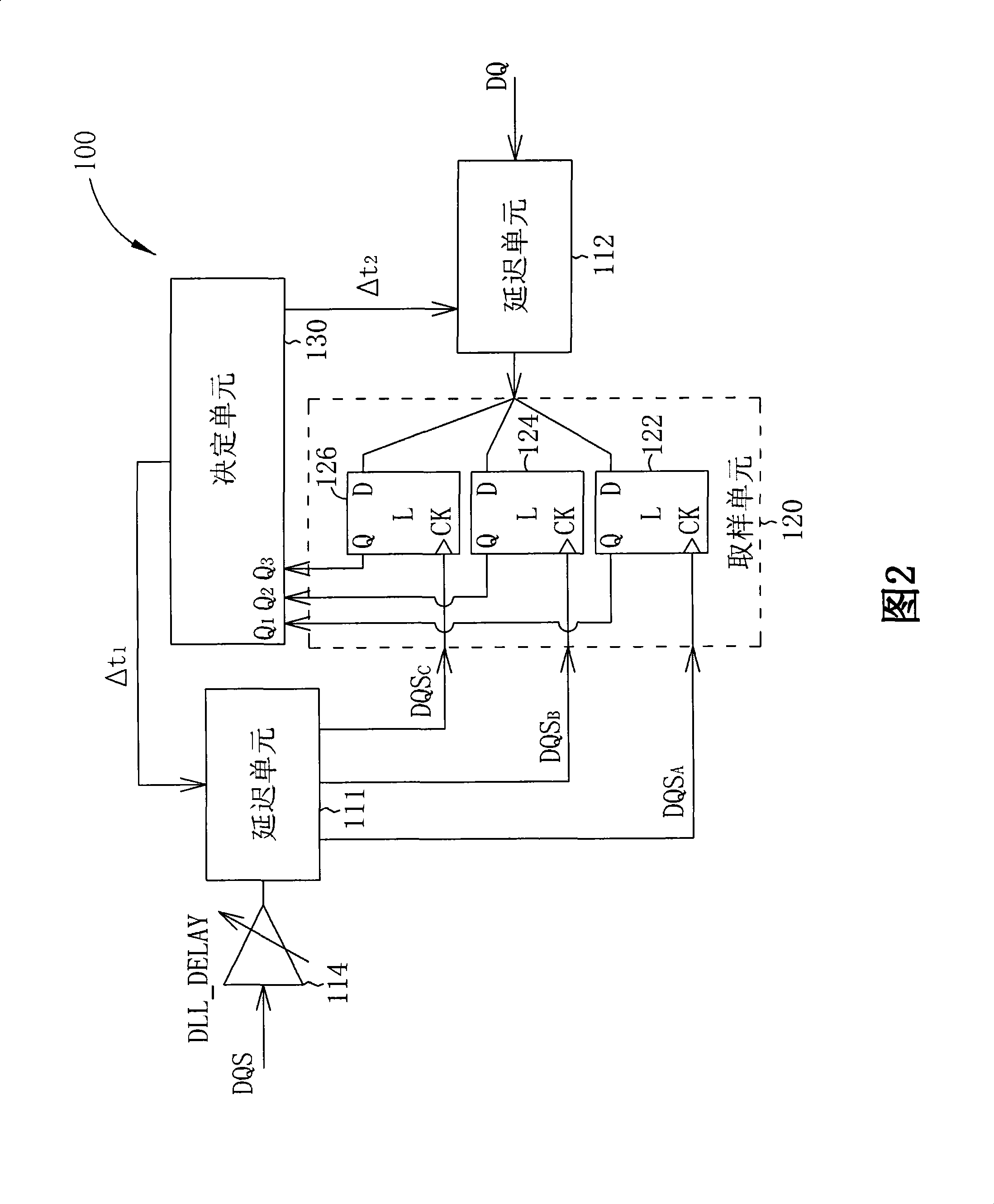

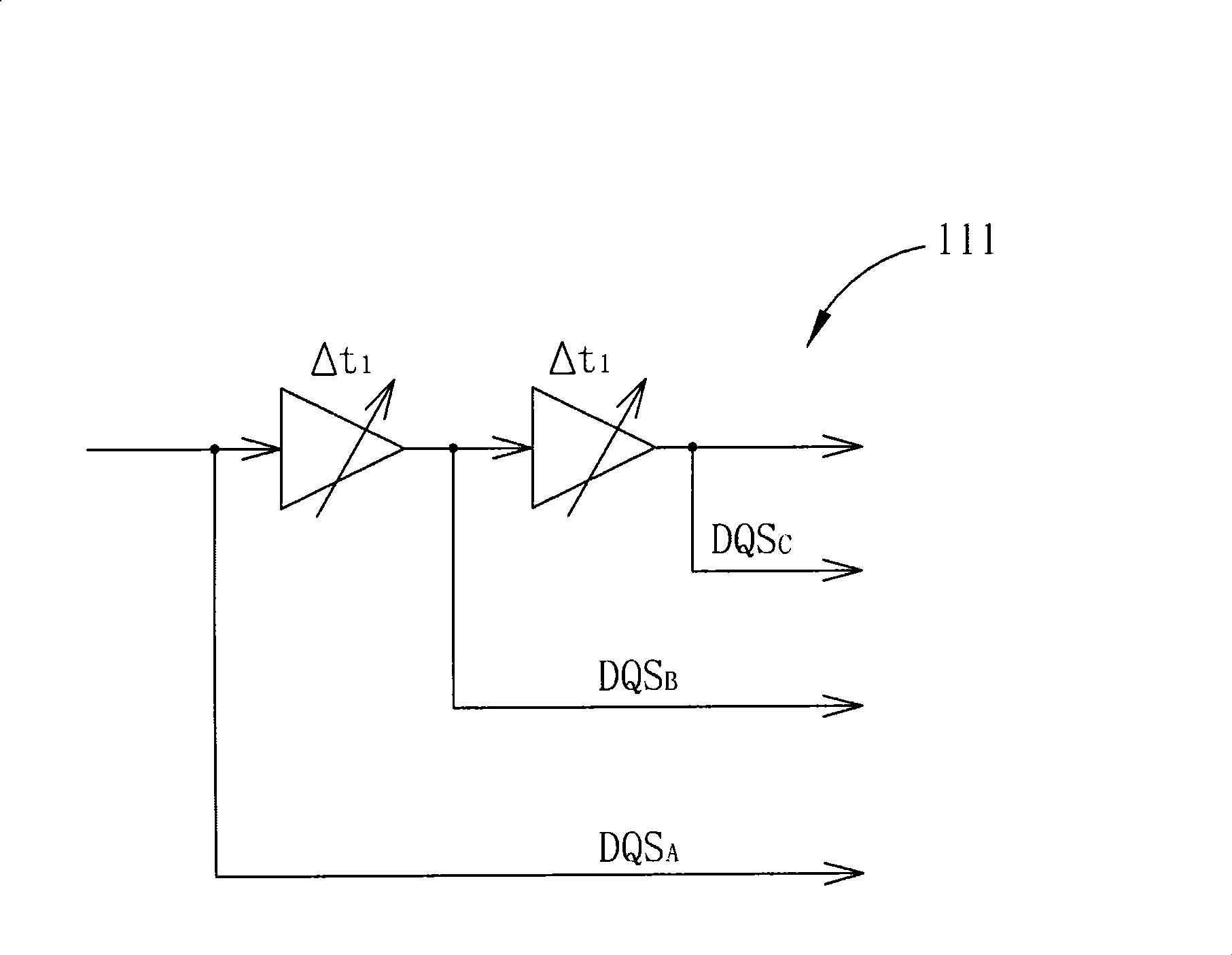

Memory control methods and circuit thereof

ActiveCN101364425ABest control performanceDynamically adjust sampling pointsDigital storageOriginal dataData signal

A memory control method for adjusting sampling points utilized by a memory control circuit receiving a data signal and an original data strobe signal of a memory includes: utilizing at least one delay unit to provide a plurality of sampling points according to the original data strobe signal; sampling according to the data signal by utilizing the plurality of sampling points; and analyzing sampling results to dynamically determine a delay amount for delaying the original data strobe signal, whereby a sampling point corresponding to the delayed data strobe signal is kept centered at data carried by the data signal. Therefore, the invention can dynamically adjust the sampling points to achieve a best memory control effect.

Owner:MEDIATEK INC

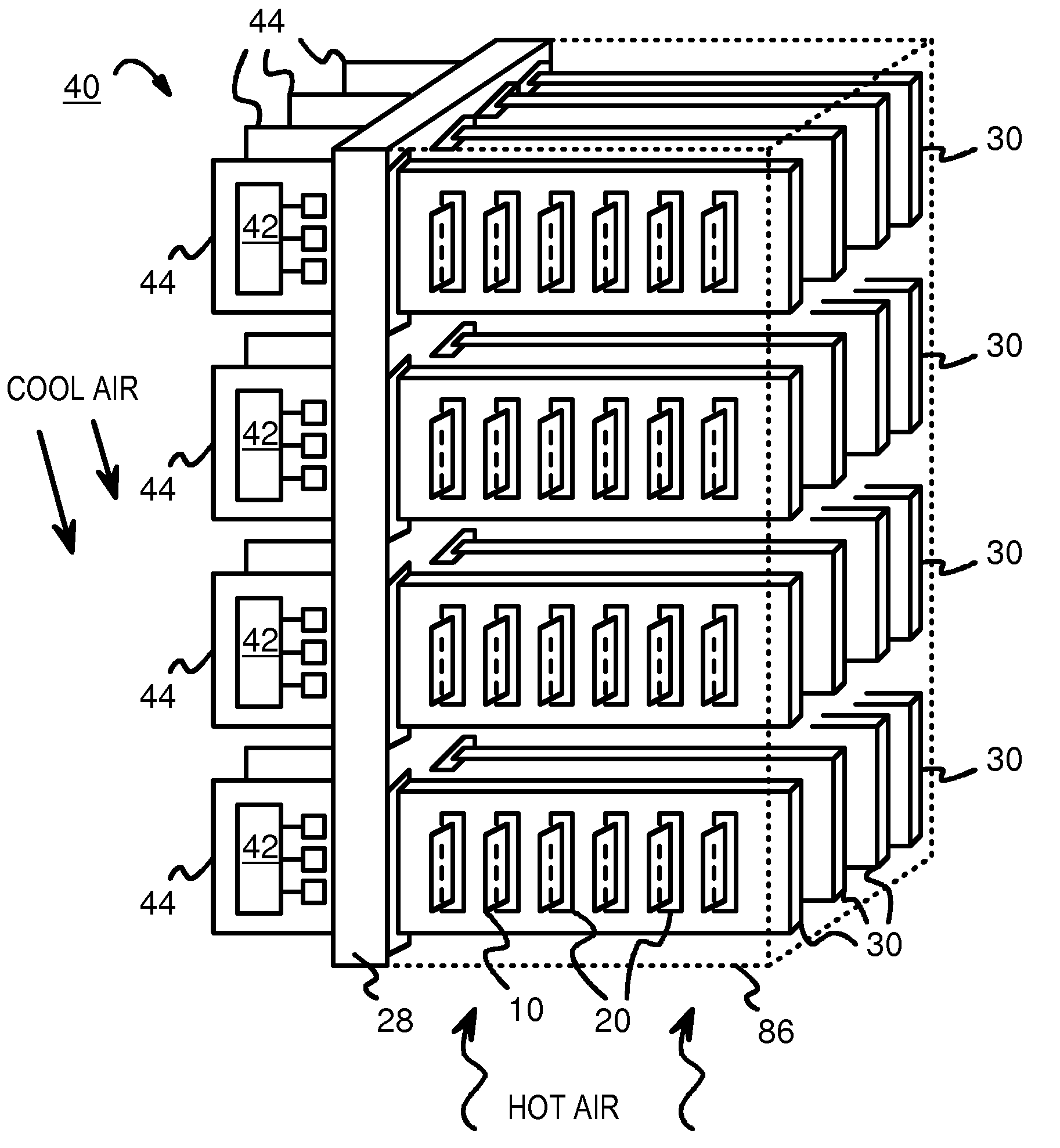

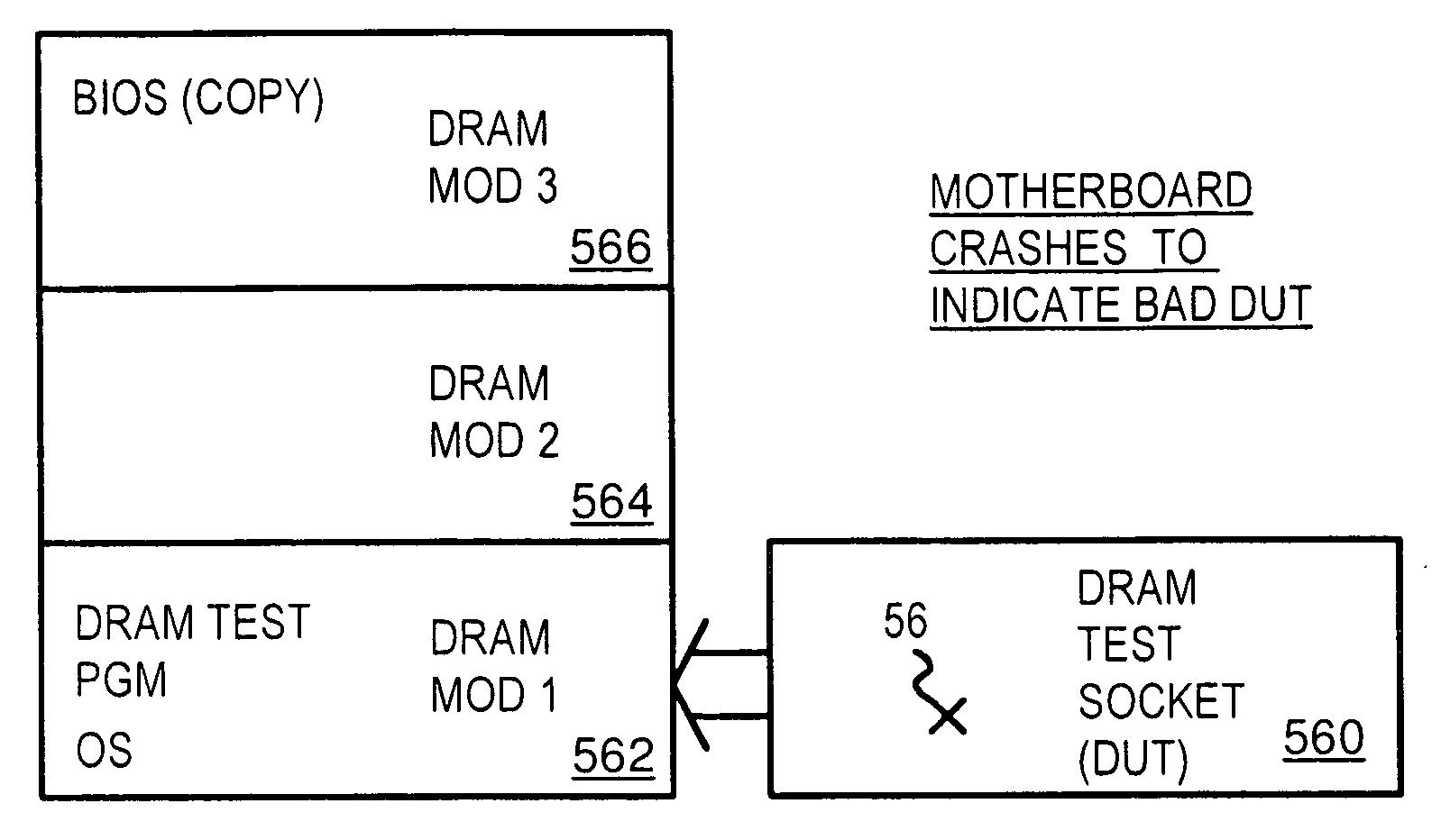

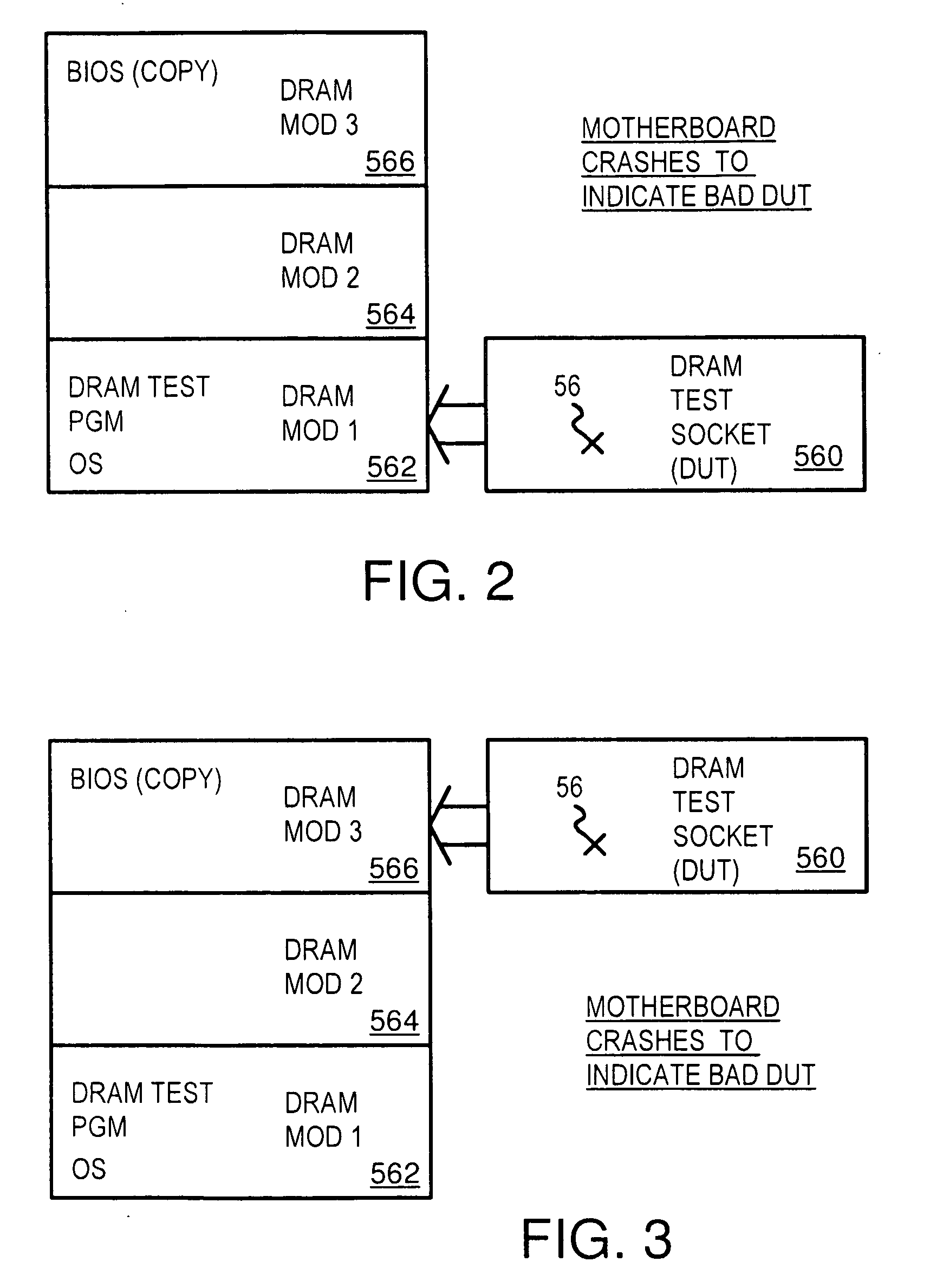

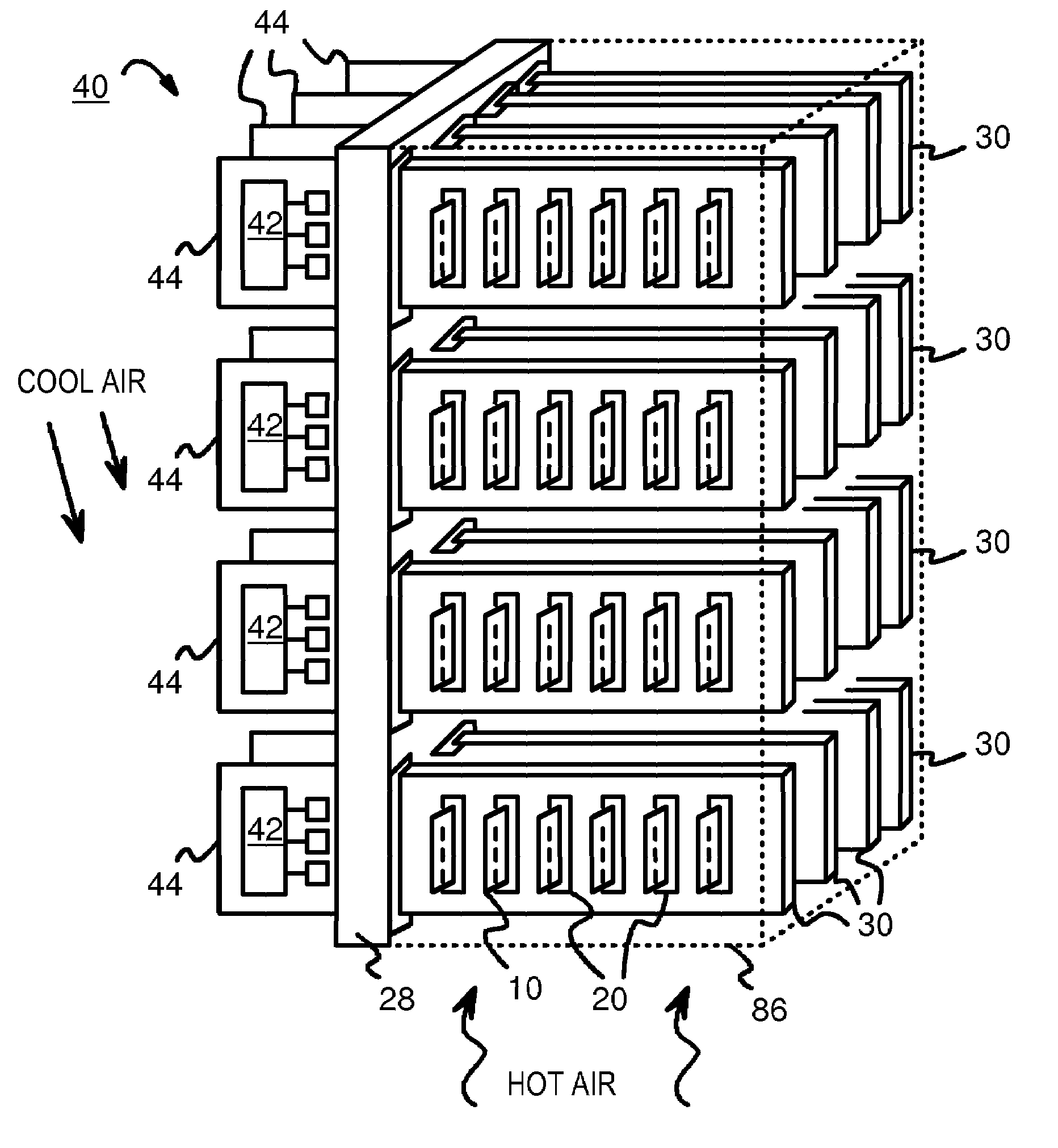

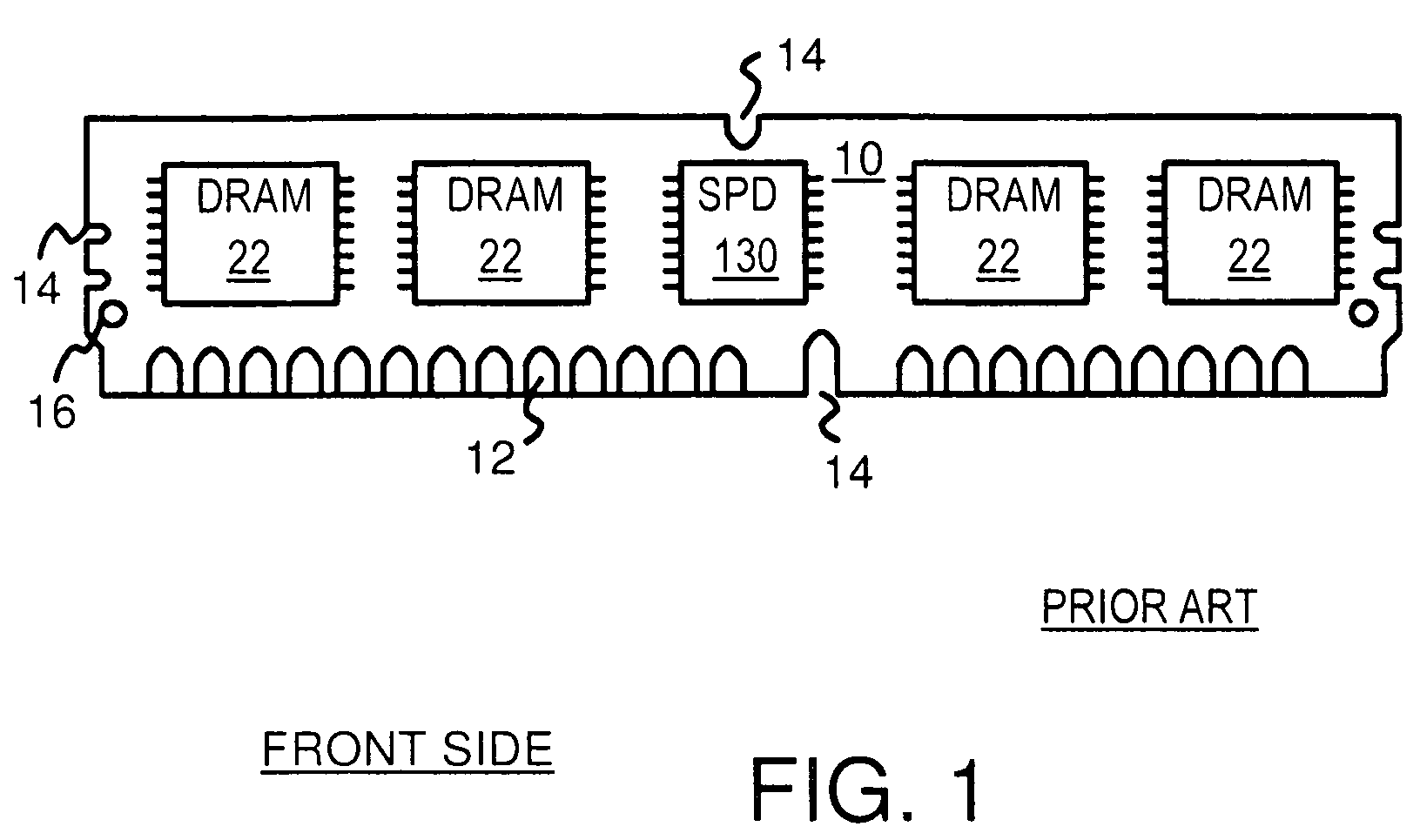

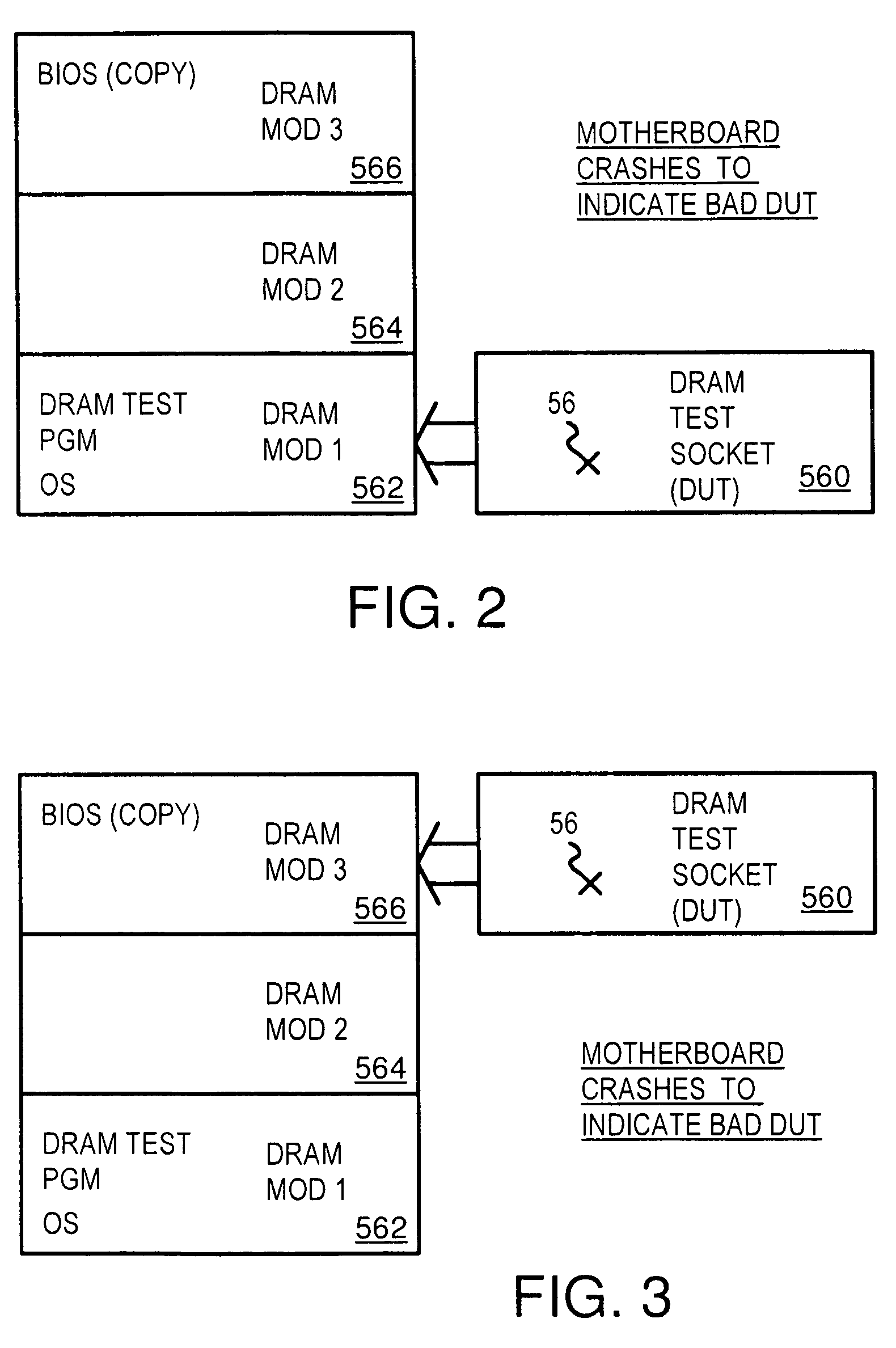

Fault Diagnosis of Serially-Addressed Memory Chips on a Test Adaptor Board To a Middle Memory-Module Slot on a PC Motherboard

A standard memory module socket is removed from a target DRAM module slot on the component side and the test adaptor board connects to the target DRAM module slot on the reverse (solder) side of a personal computer motherboard, or an extender card may be used. The target DRAM module slot is a middle slot, such as the second or third of four DRAM module slots. The first and fourth DRAM module slots are populated with known good memory modules storing the BIOS at a high address and an operating system image and a test program at a low address. The test program accesses a memory chip in a test socket on a test adaptor board that is connected to the target DRAM module slot to locate defects. The motherboard does not crash since the BIOS, OS image, and test program are not stored in the memory chip under test.

Owner:KINGSTON DIGITAL CO LTD

Manufacture process of shell fabric with memory function

InactiveCN102995463AFluffy and thickSoft touchDry-cleaning apparatus for textilesDyeing processYarnAcetic acid

The invention discloses a manufacture process of a shell fabric with a memory function. The manufacture process comprises the following steps of: implementing cloth matching by a springback yarn fabric with 50D, the total branch number of 281T, the warp density of 205T and the weft density of 76T; continuous annealing the fabric; desizing the fabric by adding 1g-4g of refining agent, 1g-3g of degreaser and 4g-6g of caustic soda flakes into the fabric; dyeing the fabric by adding 0.3g-1g of chelating agent, 1g-2.5g of leveling and dispersing agent, 0.3g-1g of mending agent, 0.3g-1g of pH conditioning agent and 1g-3g of carriers; performing reduction washing on the fabric by adding 1g-3g of acid reducing agent into the fabric; then dewatering, feeding clean water, and adding 0.3g-1g of glacial acetic acid into the fabric in 3-5 minutes; and spreading and sizing the fabric, and packaging the finished shell fabric after inspection is finished. According to the manufacture process, the fabric is processed and woven by springback yarns with recovery characteristics, corresponding auxiliaries are added into the fabric in the drying procedure, and thus the shell fabric is gorgeous, is flexible, smooth and comfortable in handfeel, is fluffy and thick and has the good memory function after being processed by special processes. When the surface of the shell fabric is grasped and washed, the crinkles on the surface of the shell fabric disappear after being wiped by hand, and the shell fabric is as smooth as before.

Owner:JINJIANG LONGXINGLONG DYEING & WEAVING INDALCO

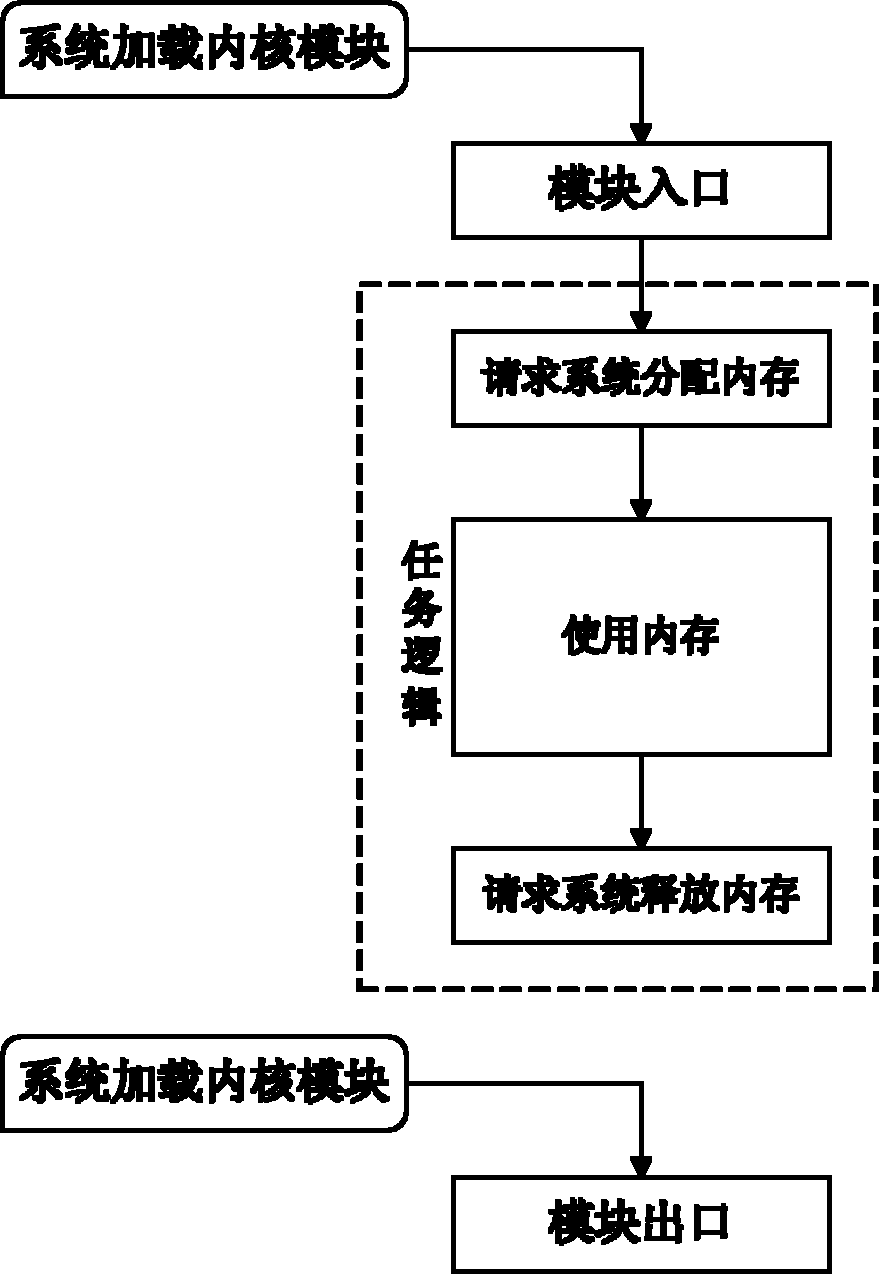

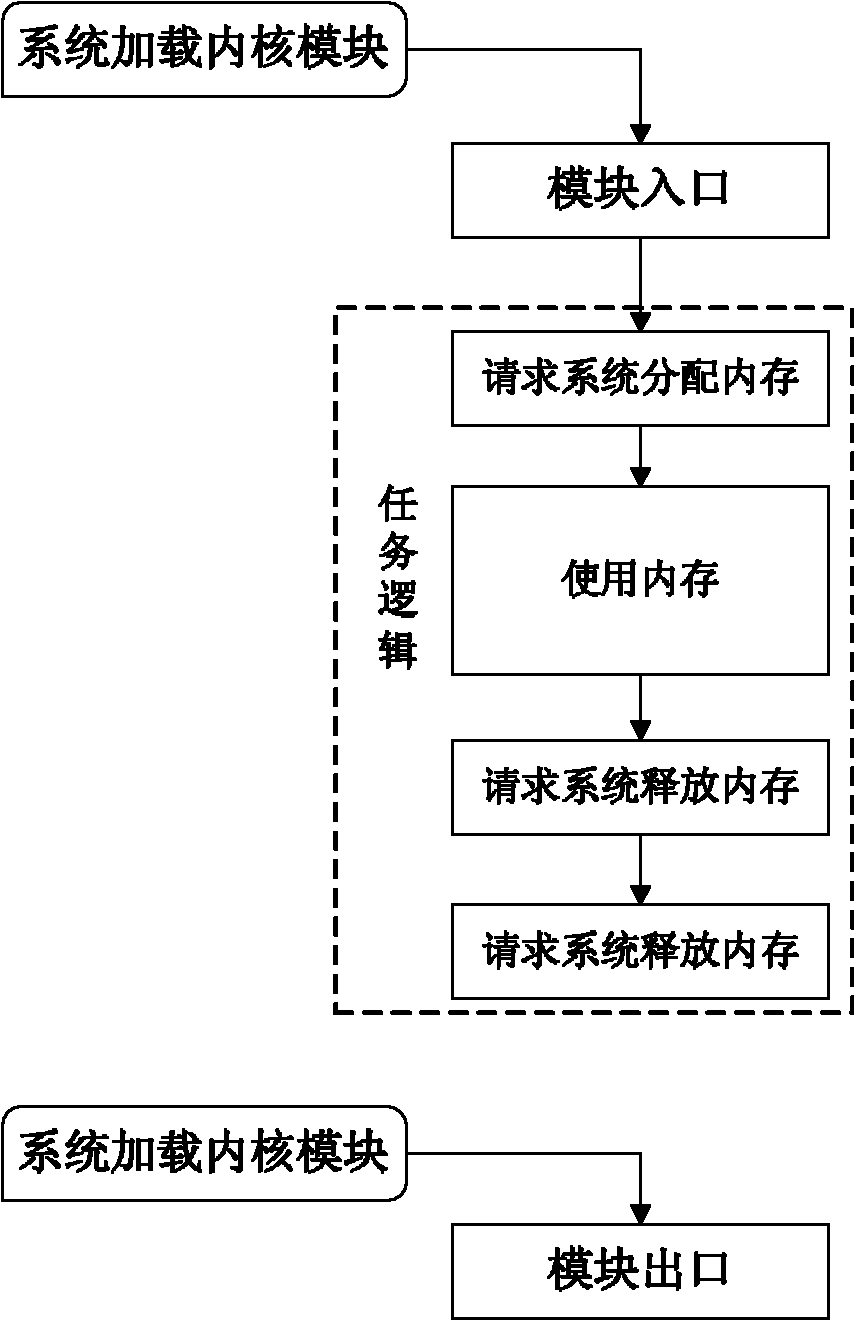

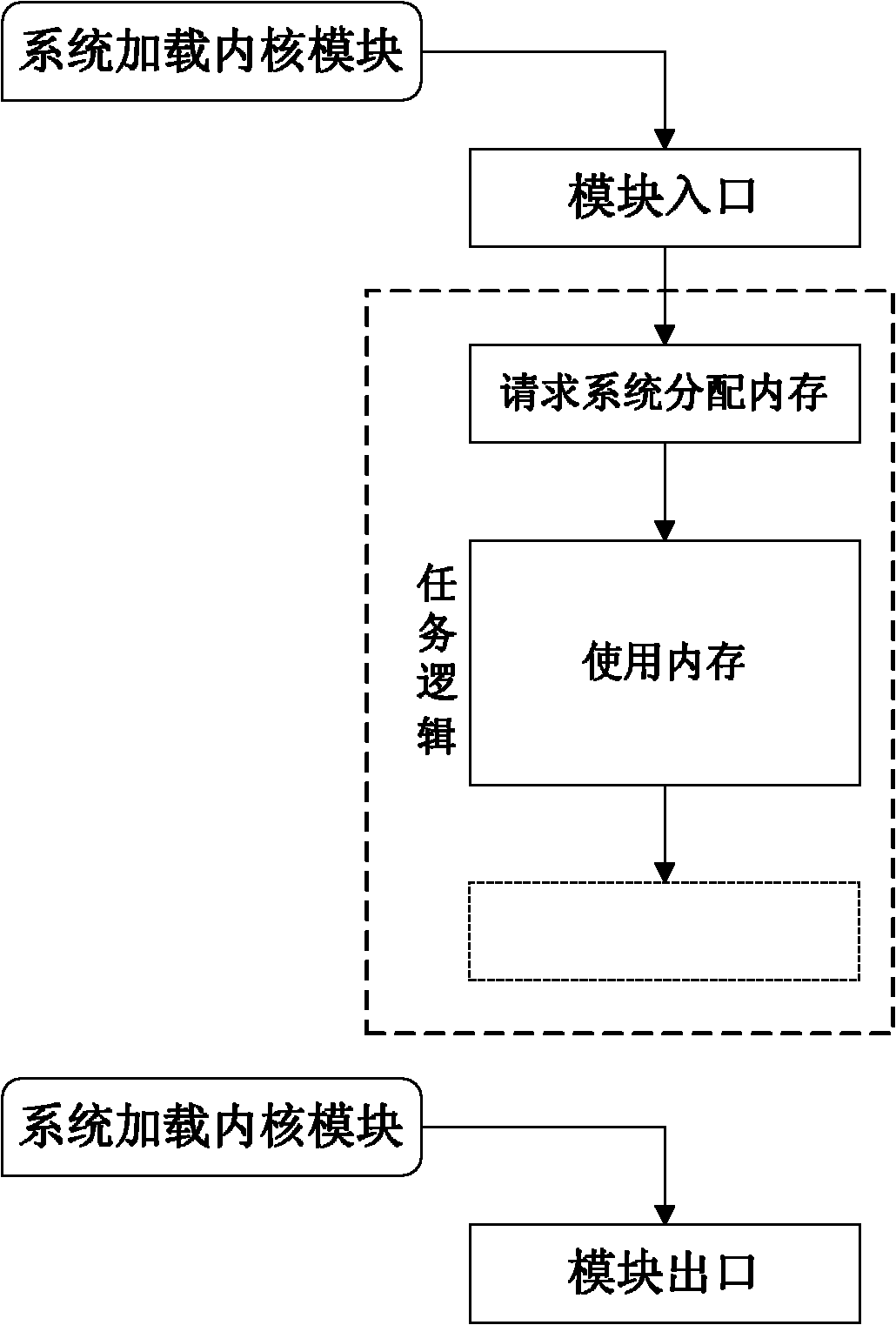

Kernel-module memory management method for preventing memory leaks and multiple memory releases

ActiveCN102103541AInhibition releaseTroubleshoot memory management issuesMemory adressing/allocation/relocationOperational systemArray data structure

The invention discloses a kernel-module memory management method for preventing memory leaks and multiple memory releases, and the method comprises the following implementation steps: 1) establishing an array of records; 2) when a kernel module requires a system to allocate memories, adding memory allocation records associated with the allocated memories into the array of records; 3) when the kernel module requires the system to release memories, searching memory allocation records associated with the memories to be released in the array of records, if the associated memory allocation records exist, executing memory release, and cancelling the memory allocation records; and if the associated memory allocation records do not exist, issuing an alarm of 'multiple releases'; and 4) when the kernel module exits, scanning the array of records, if the array of records still has memory allocation records, releasing the memories associated with the memory allocation records one by one according to the memory allocation records, and finally, clearing the array of records. By utilizing the method disclosed by the invention, the kernel modules can be prevented from having the phenomena of memory leaks and multiple memory releases; and the method has the advantages of good memory allocation capability, low congestion degree of an operating system, less occupied resources, small memory-footprint, and good adaptability.

Owner:NAT UNIV OF DEFENSE TECH

Manganese-based memory alloy with high-strength, plasticity and damping performances and production thereof

InactiveCN1818113AHigh yield strengthEnhance memoryTemperature control deviceShape-memory alloyManganese

The invention provided a high strength, plasticity and damping Mangonic. It is proper to make the propeller of the naval vessels and the ship craft, the anti-chatter bushing, the muffler shell, the memory function parts, glass frame, the medical silk guide, surgical sutures. The weight ratio of the composition is Cu 5.5-50%, Ni 1-10%, Cr 1-10%, N 0.05-0.5%, the residue is Mn. The alloy smelt to cast ingot by the median or high frequency atmospheric casting in the ceramic crucible, argon shield or the magnetic suspension smelting and the Ohno Continue Castings. The alloy has the high yield strength, good memory ability, hyperelastic and not easy to rustiness.

Owner:JIANGYIN POLYTECHNIC COLLEGE

Non-volatile semiconductor memory based on enhanced gate oxide breakdown

A semiconductor memory structure based on gate oxide break down is constructed in a deep N-well. Thus, the electrical field over the programmable element during the transient procedure of gate oxide break down can be controlled to achieve the best memory programming results. The conductivity of the programmed memory cell is increased greatly and conductivity variation between the memory cells is reduced. This is achieved by adding a body bias during the programming process. The body here refers to a P-well formed within the deep N-Well. Furthermore, the read voltage offset is reduced greatly with this new memory configuration. These improved programming results will allow faster read speed and lower read voltage. This new structure also reduces current leakage from a memory array during programming.

Owner:SYNOPSYS INC

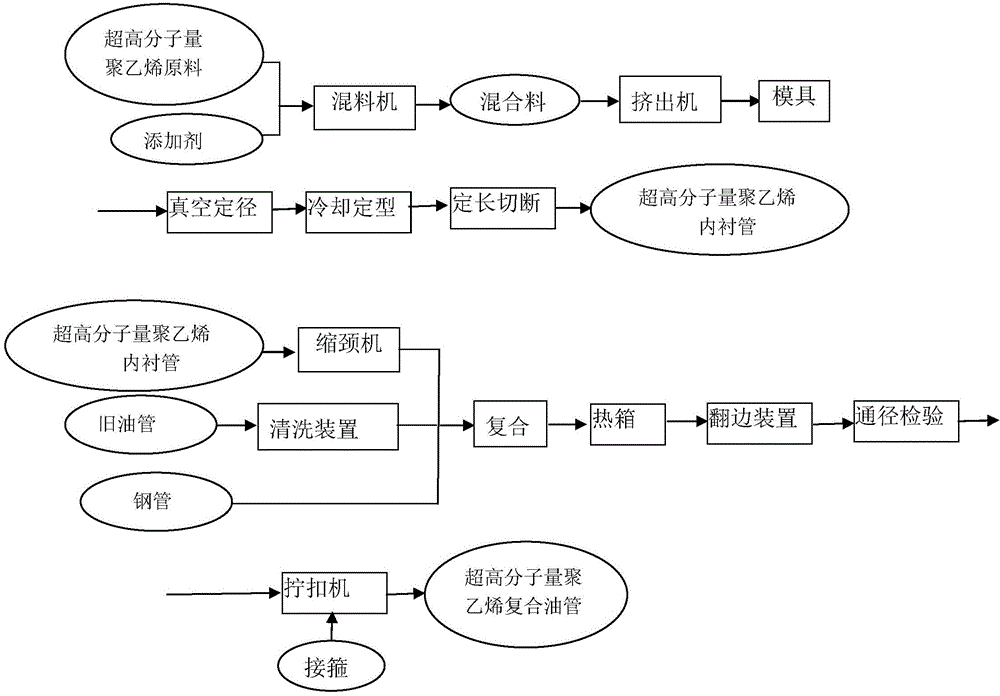

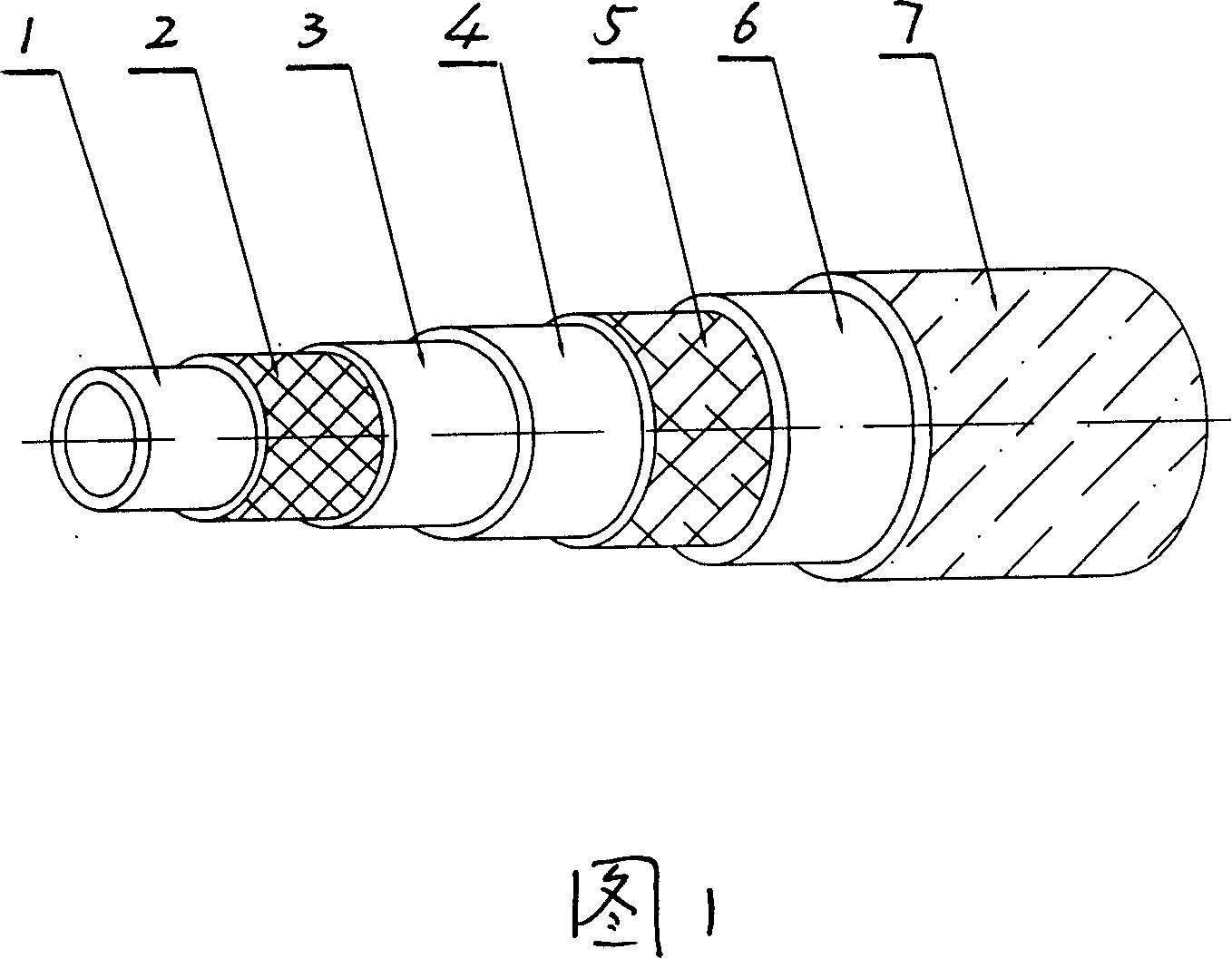

Production method and production system of ultrahigh molecular weight polyethylene compound oil pipe

ActiveCN103600503AImprove liquidityReduced wall thicknessTubular articlesTemperature resistanceWear resistance

The invention discloses a production method and a production system of an ultrahigh molecular weight polyethylene compound oil pipe. The method utilizes the memory property of the ultrahigh molecular weight polyethylene material and a special composite technology: conducting hole shrinkage treatment on an ultrahigh molecular weight polyethylene lining pipe with outer diameter larger than the inner diameter of a steel pipe, sheathing in the steel pipe, heating to restore inner diameter of the ultrahigh molecular weight polyethylene lining pipe, and forming the lining pipe with the steel pipe into an integral structure to reach a compactness and firmness without layering and stripping. By introducing additives, the invention greatly improves liquidity of the ultrahigh molecular weight polyethylene in order to produce the inner lining pipe with small wall thickness and reduce cost. The ultrahigh molecular weight polyethylene compound oil pipe provided by the invention comprehensively reserves specific superior performances of good memory property, high impact resistance, good temperature resistance, wear resistance, corrosion resistance, wax precipitation and fouling resistance of ultrahigh molecular weight polyethylene pipe. The invention also discloses a production system supporting the production method.

Owner:王庆昭

Polyurethane blended hollow fiber membrane and method for preparing same

InactiveCN1883778AWide applicabilityPracticalSemi-permeable membranesHollow fibre membranePolymer science

Owner:TIANJIN POLYTECHNIC UNIV

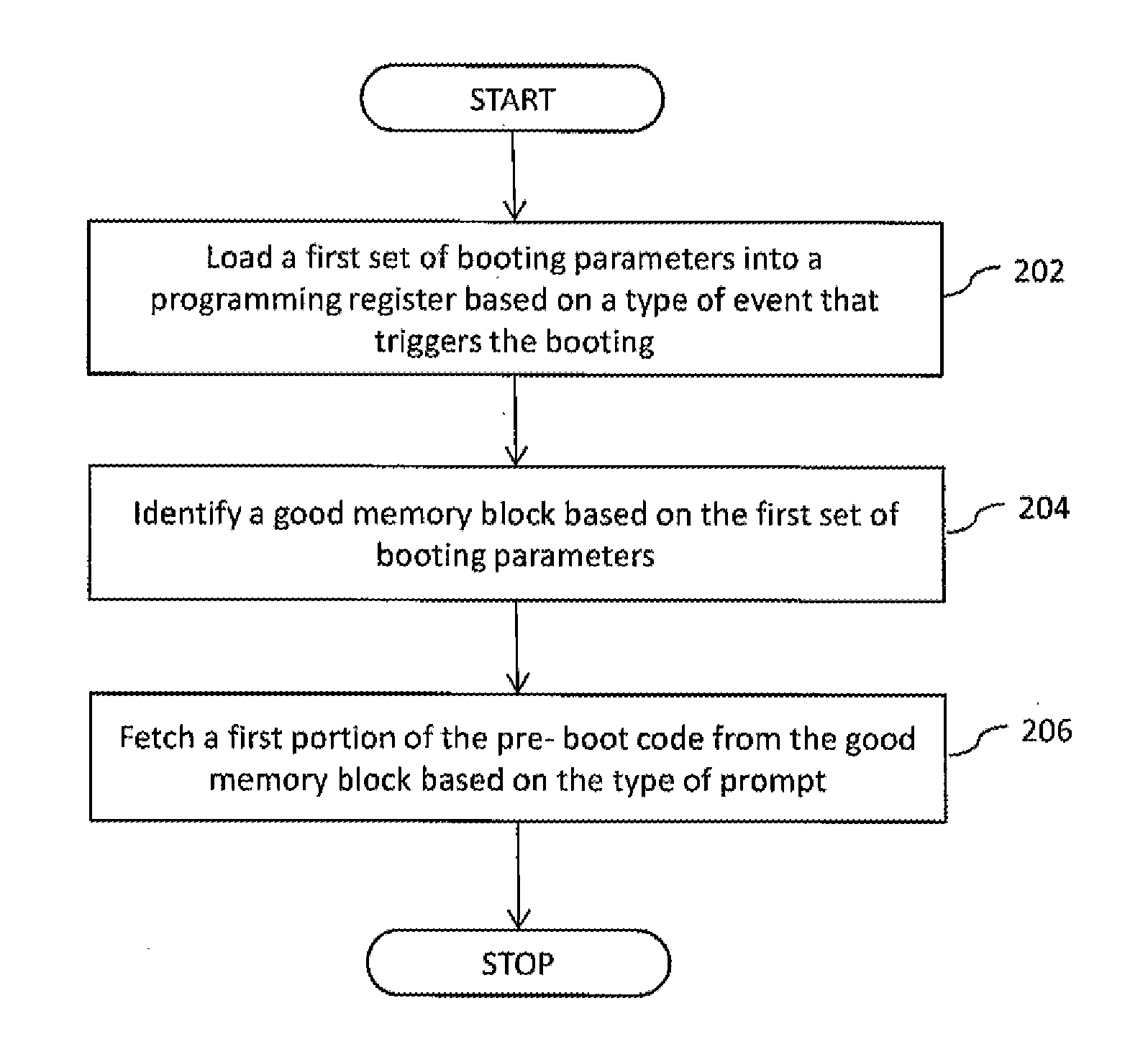

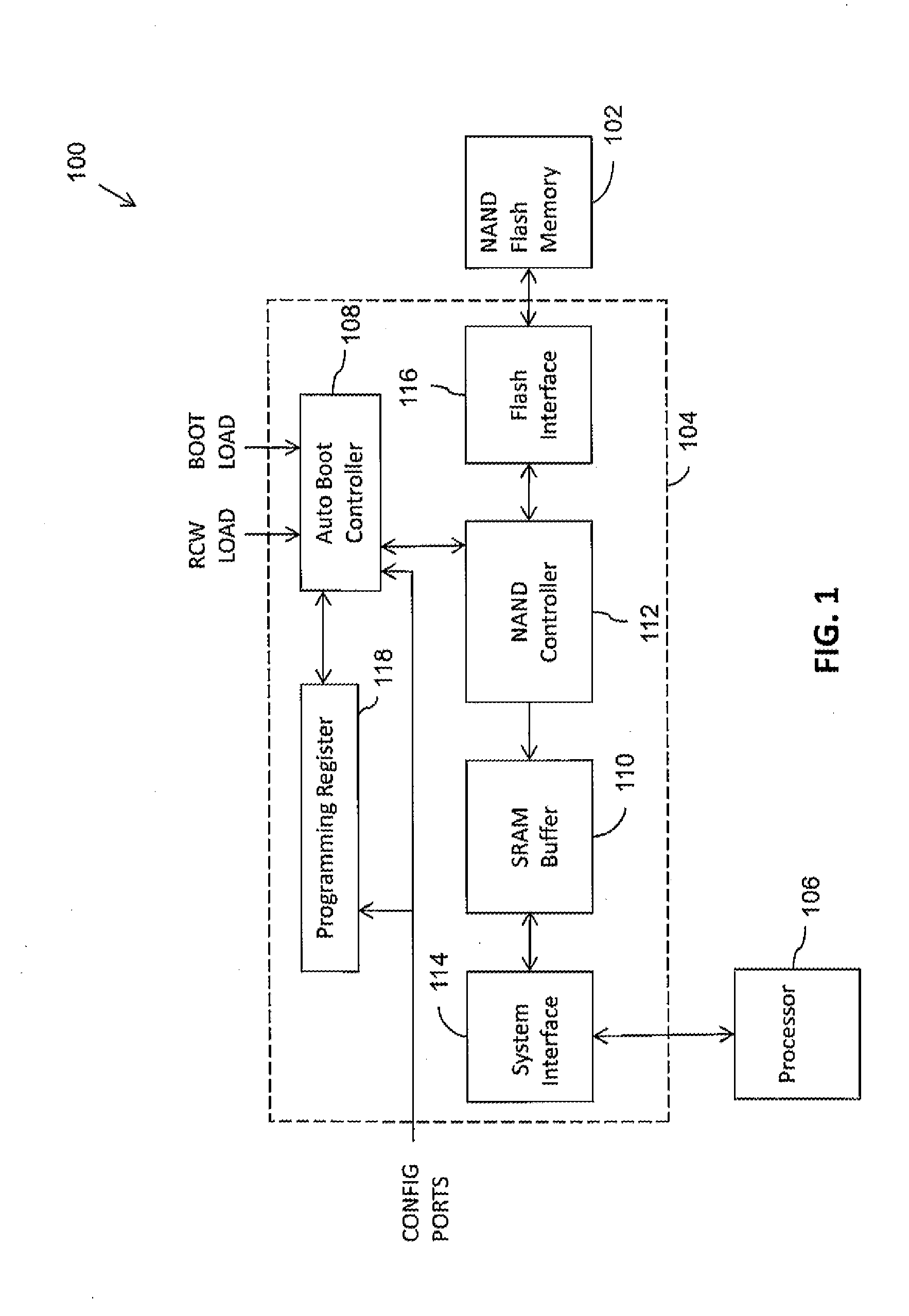

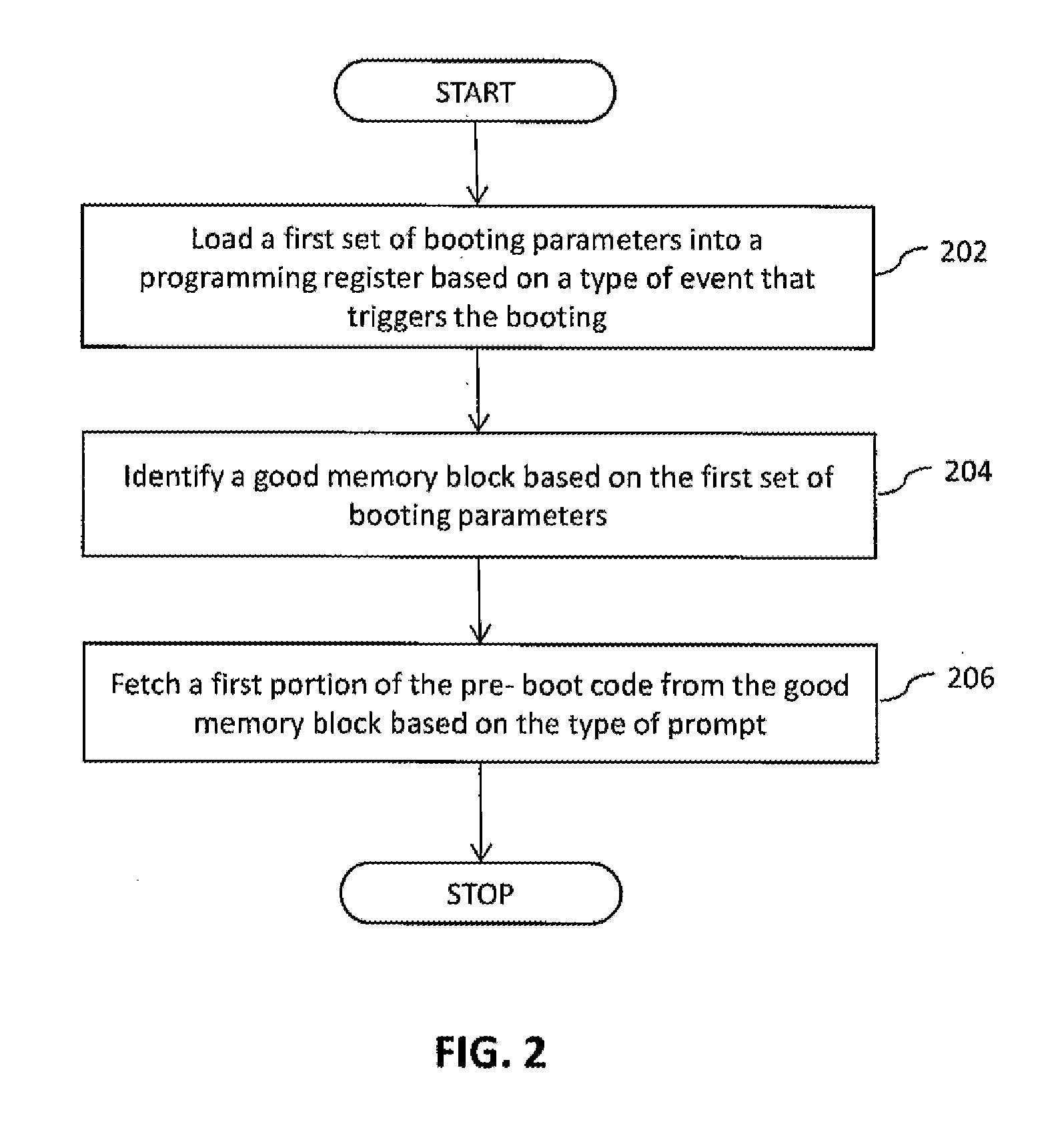

Method and system for booting electronic device from NAND flash memory

A method and system for booting an electronic device from a NAND flash memory includes a NAND flash controller that receives an event trigger for fetching a pre-boot code stored in the NAND flash memory. Based on the event trigger type, booting parameters are loaded into the controller including a boot frequency of the NAND flash memory. The controller searches for a good memory block in which the pre-boot code is stored by checking the first and second or the first and last pages of a memory block and fetches a portion or the entire pre-boot code based on the event trigger type at the boot frequency.

Owner:NXP USA INC

Manufacturing method for partially-good memory modules with defect table in EEPROM

ActiveUS7642105B2Semiconductor/solid-state device testing/measurementSolid-state devicesGoal systemRead-only memory

A manufacturing method makes memory modules from partially-good DRAM chips soldered to its substrate. The partially-good DRAM chips have a number of defective memory cells that is below a test threshold, such as 10%. Packaged DRAM chips are optionally pre-screened and considered to pass when the number of defects found is less than the test threshold. A defect table is created during testing and written to a serial-presence-detect electrically-erasable read-only memory (SPD-EEPROM) on the memory module. The memory module is finally tested on a target-system tester that reads the defect table during booting, and redirects memory access to defective memory locations identified by the defect table. The memory modules may be burned in or tested at various temperatures and voltages to increase reliability.

Owner:KINGSTON DIGITAL CO LTD

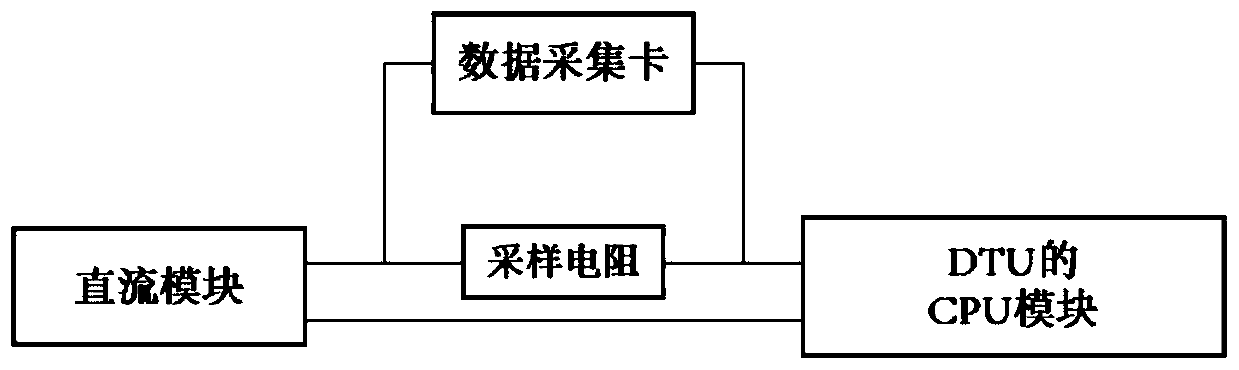

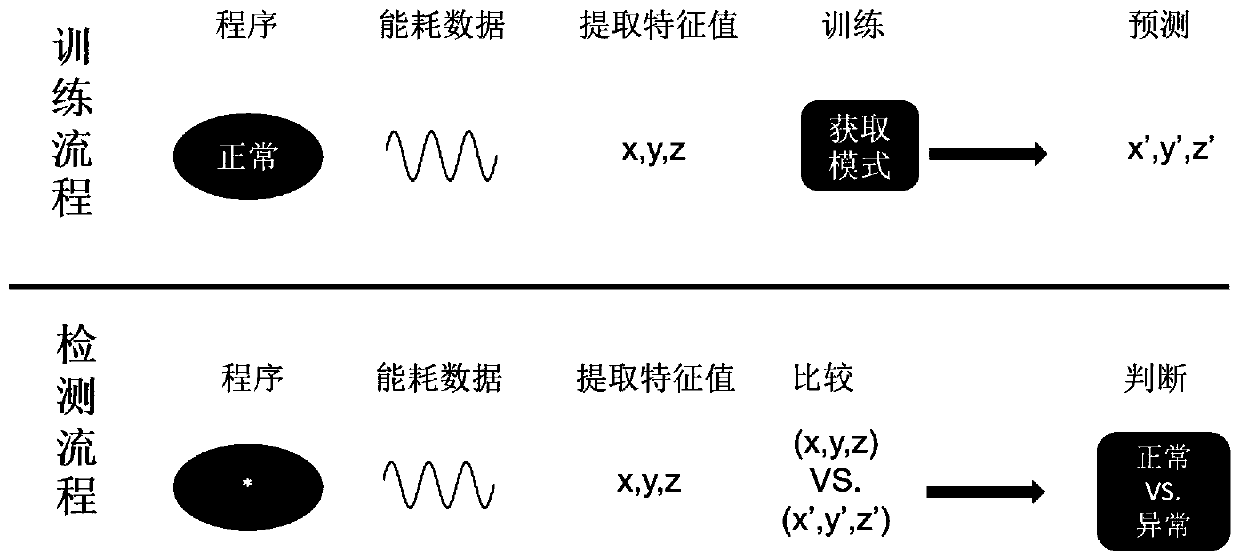

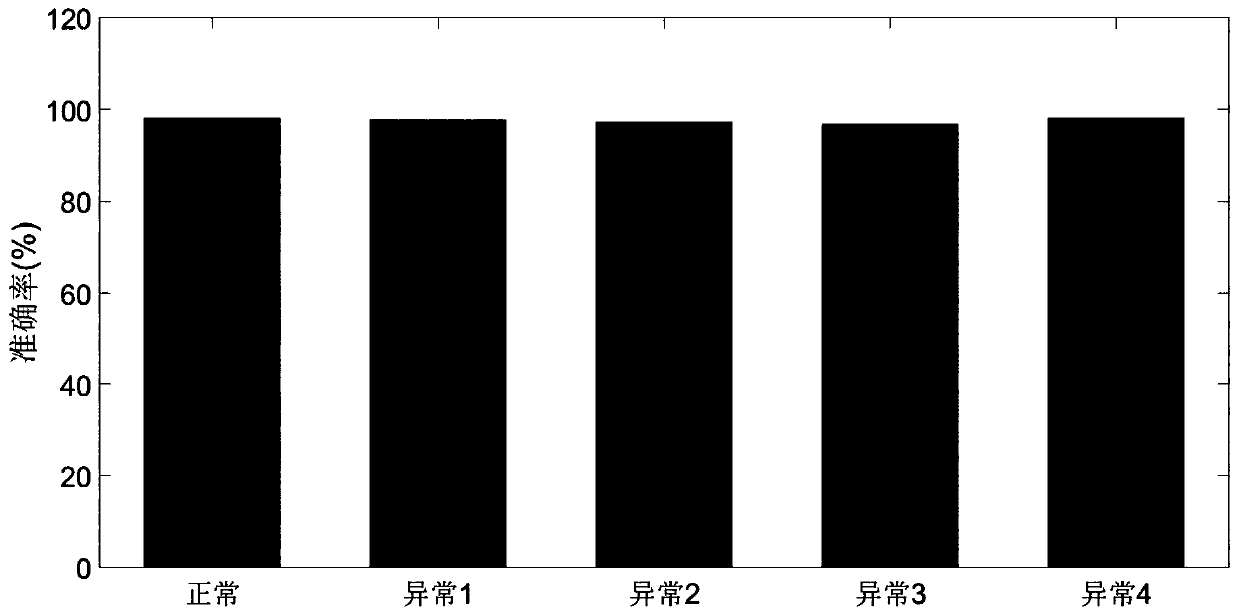

DTU safety monitoring method based on side channel

InactiveCN110390357AGuaranteed accuracyStrong memoryCharacter and pattern recognitionTransmissionSmart gridSafety monitoring

The invention discloses a DTU safety monitoring method based on a side channel, and belongs to the technical field of power terminal equipment safety. The invention helps solve the defects that an existing method is insufficient in safety protection and needs a negative sample to carry out model training. By analyzing the characteristics of power consumption data, a feature vector capable of reflecting DTU power consumption data changes is selected, and an appropriate machine learning algorithm is selected on the basis of the feature vector. LSTM has good memory capability on long-term information and is good at capturing internal structure information of the time series. Therefore, KSTM can predict the time series on different time scales, can well fit the original time series information, and uses the time series prediction capability of LSTM to achieve the purpose of anomaly detection. The method is a non-intrusive safety monitoring method, does not occupy operation resources of equipment, and does not introduce new potential attack points. The method is beneficial to improving the overall safety protection level of an intelligent power grid and guaranteeing safe and stable operation of the intelligent power grid.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +1

Continuously reinforced plastic heat-preserving composite pipeline used for oil field ground and its manufacturing technique

InactiveCN101153674AMemoryImprove insulation effectRigid pipesTubular articlesCross-linked polyethyleneSealant

The present invention discloses a continuous reinforced plastic composite pipe and the production technique for buried heat insulation of oil field; the continuous reinforced plastic composite pipe consists of an anticorrosive coating, a reinforced layer and a coating layer; crosslinked polyethylene foamed material is continuously rolled on the continuous reinforced plastic composite pipe to form a continuous insulating course, and fluid sealant layers are respectively coated between the coating layer and the insulating layer, the insulating layer and the protective layer. The reinforced layer is weaved by metal steel wires; the anticorrosive coating and the coating layer are made of crosslinked polyethylene material; the protective layer is made of polyethylene; the insulating course is made of crosslinked polyethylene foam. The pipe of the present invention is a long-distance flexible continuous pipe; the insulating course is made of crosslinked polyethylene flexible material; the continuous reinforced plastic composite pipe has good memory, rebound resilience and concentricity inside and outside the pipeline and ensures that the continuous heat insulation pipeline prevents being squashed after being coiled and buried; thereby the thickness of the insulating course is consistent and achieving better heat insulation effect. The pipeline paved by the invention, even if the local part is damaged, water can be effectively prevented to seep into the insulating course in order to ensure the heat insulation effect.

Owner:长春高祥特种管道有限公司

Novel dyeing and finishing technique for PTT shape memory fabric

InactiveCN101503852AEnhance memorySolve the prone to color flowersHeating/cooling textile fabricsTextile treatment by spraying/projectingDisperse dyeTO-18

The invention discloses a novel dyeing and finishing process for PTT shape memory fabric, belongs to the technical field of textile fabric production, and comprises the following steps: 1, evenly washing gray cloth; 2, manually unwinding; 3, stitching threads, namely stitching thread ends along the edge of the cloth; 4, refining at a temperature of between 70 and 80 DEG C for 15 to 20 minutes; 5, pre-setting at a temperature of between 120 and 130 DEG C and a speed of between 40 and 50 m / min; 6, dyeing, wherein the starting dyeing temperature of disperse dye is between 26 and 32 DEG C, the rate of temperature rise is between 0.5 and 1 DEG / min and the temperature of between 70 and 80 DEG C is kept for 10 minutes in the starting dyeing process; and then the temperature is raised at the same rate to be between 100 and 110 DEG C for heat preservation for 30 to 60 minutes, a sample is dyed, the temperature is reduced to 70 DEG C at the same rate and water is discharged; 7, performing reduction washing in water with a temperature between 60 and 80 DEG C for 15 and 20 minutes; and 8, sizing a finished product at a temperature of between 110 and 125 DEG C for 12 to 18 seconds. The novel dyeing and finishing process solves the problems of the easy occurrence of dyeing defects, color traces, scratches, chicken paw prints, and the like in the prior dyeing and finishing process, and endows the memory fabric with good memory performance to improve the product quality.

Owner:ZHEJIANG DONGSHENG DYEING & PRINTING CO LTD

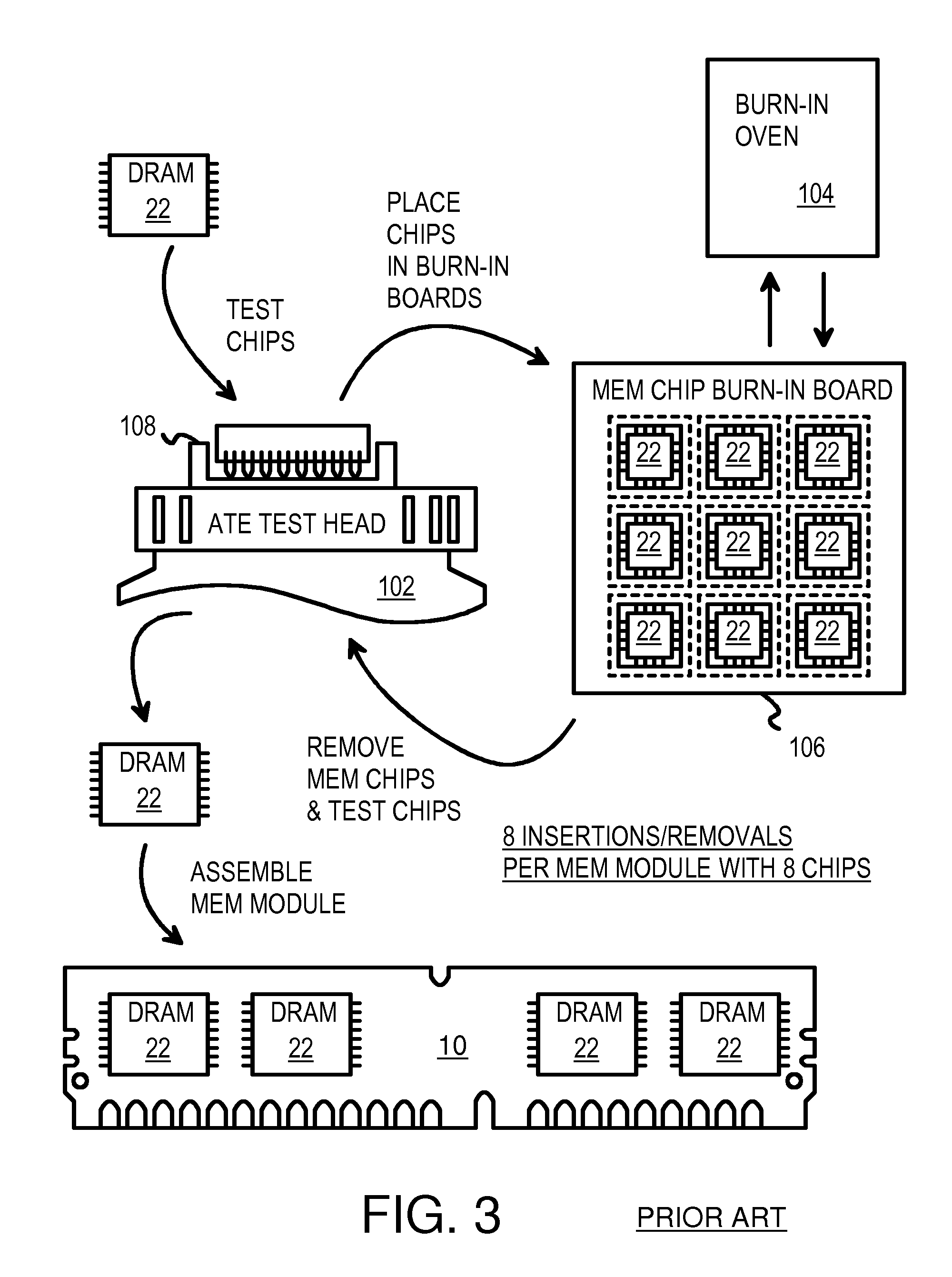

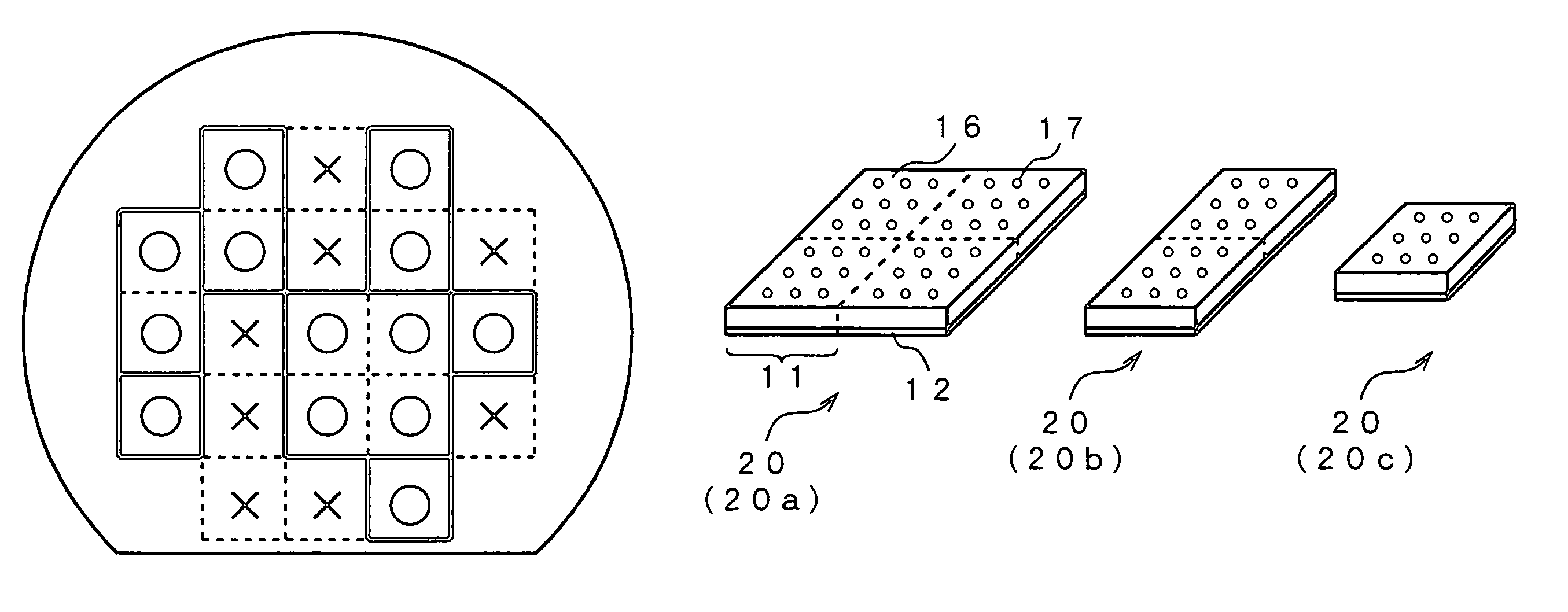

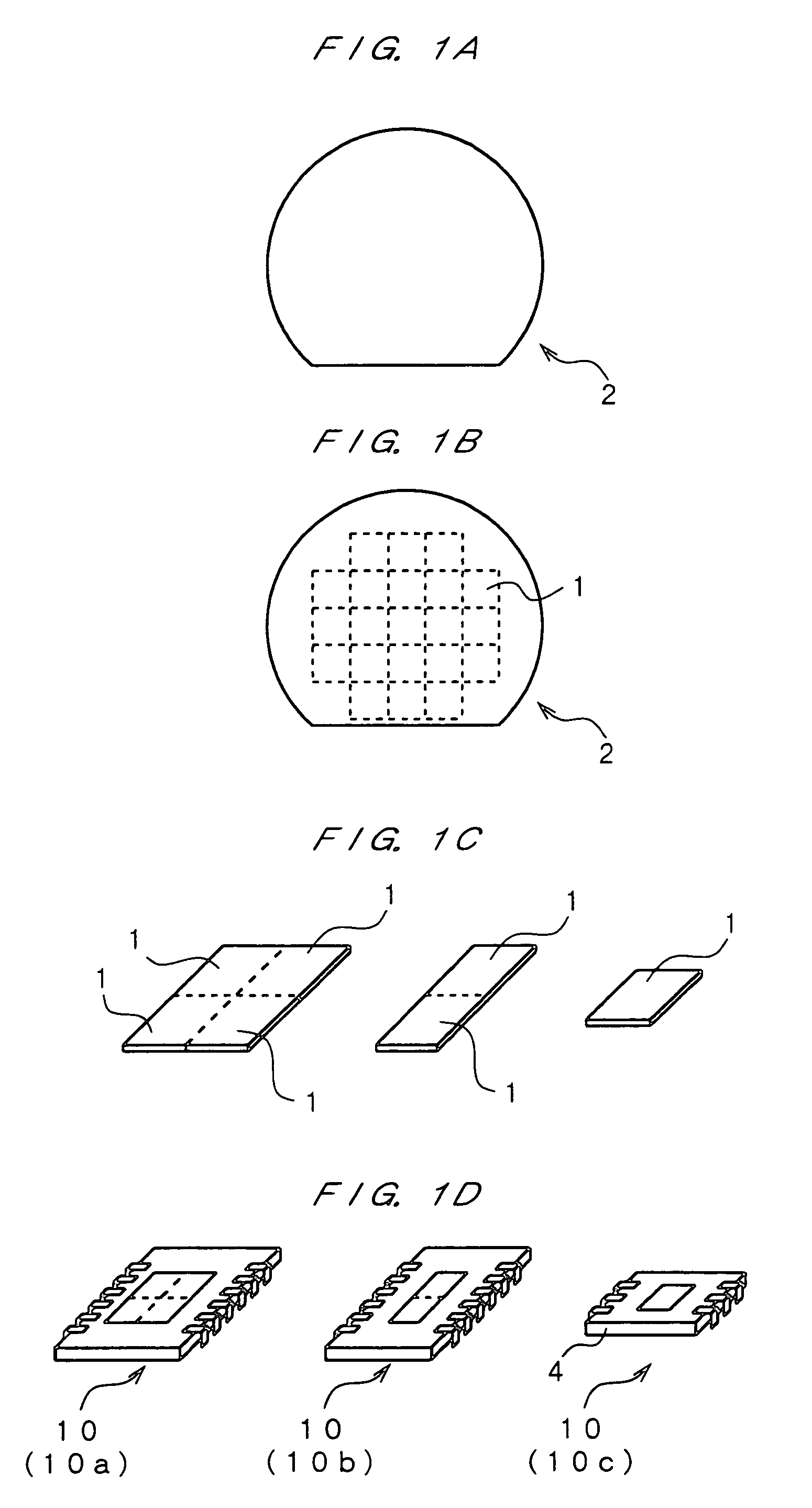

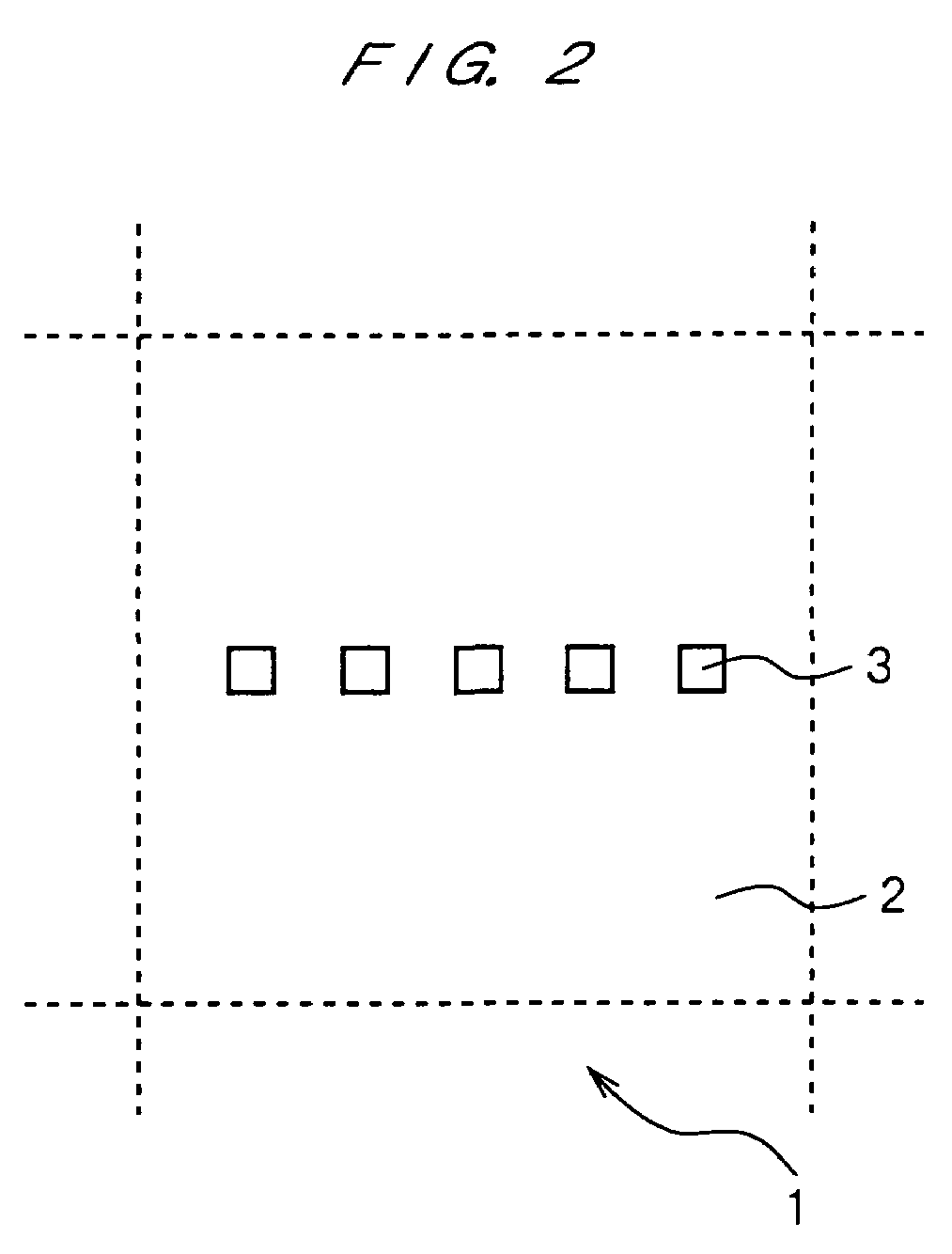

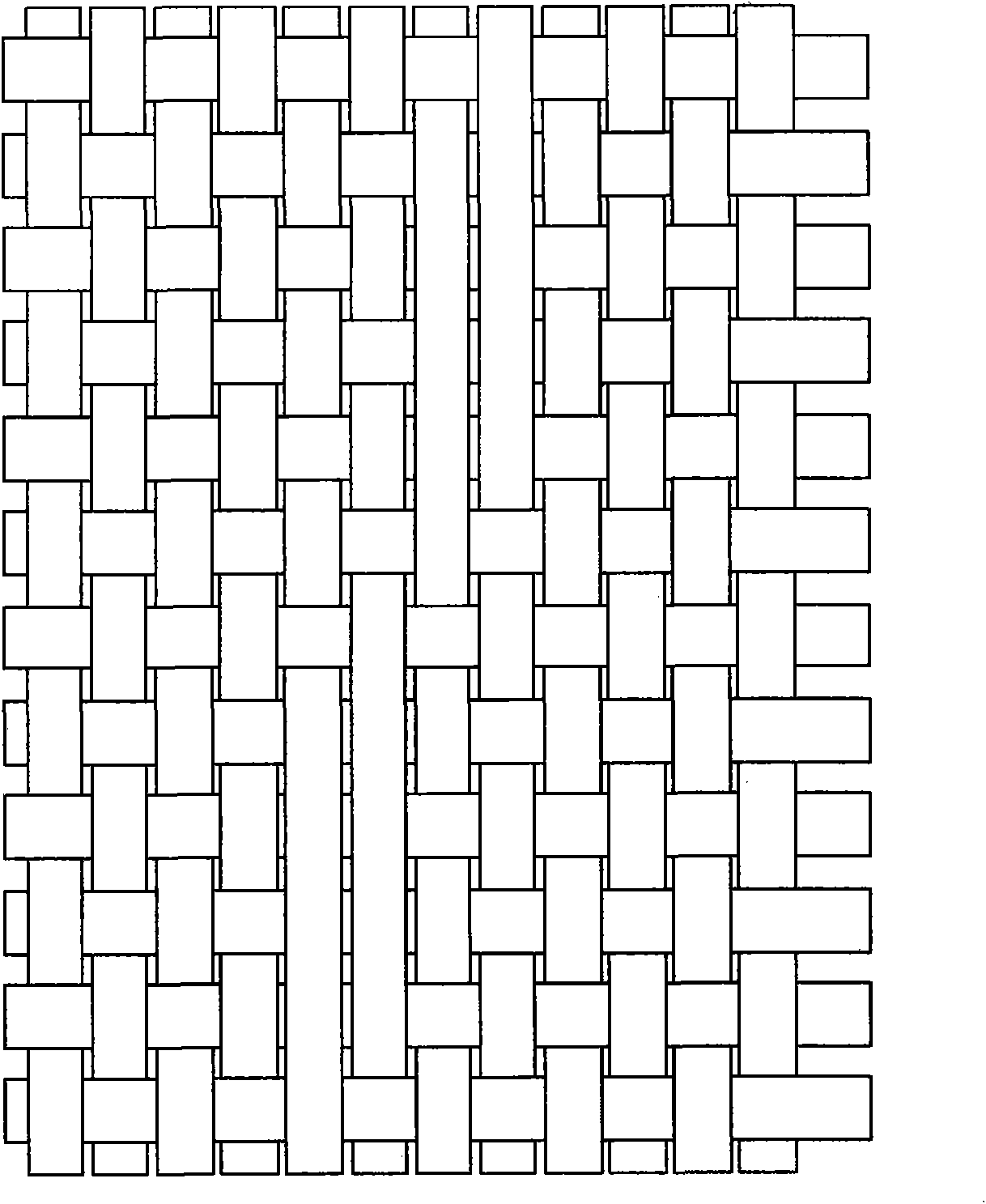

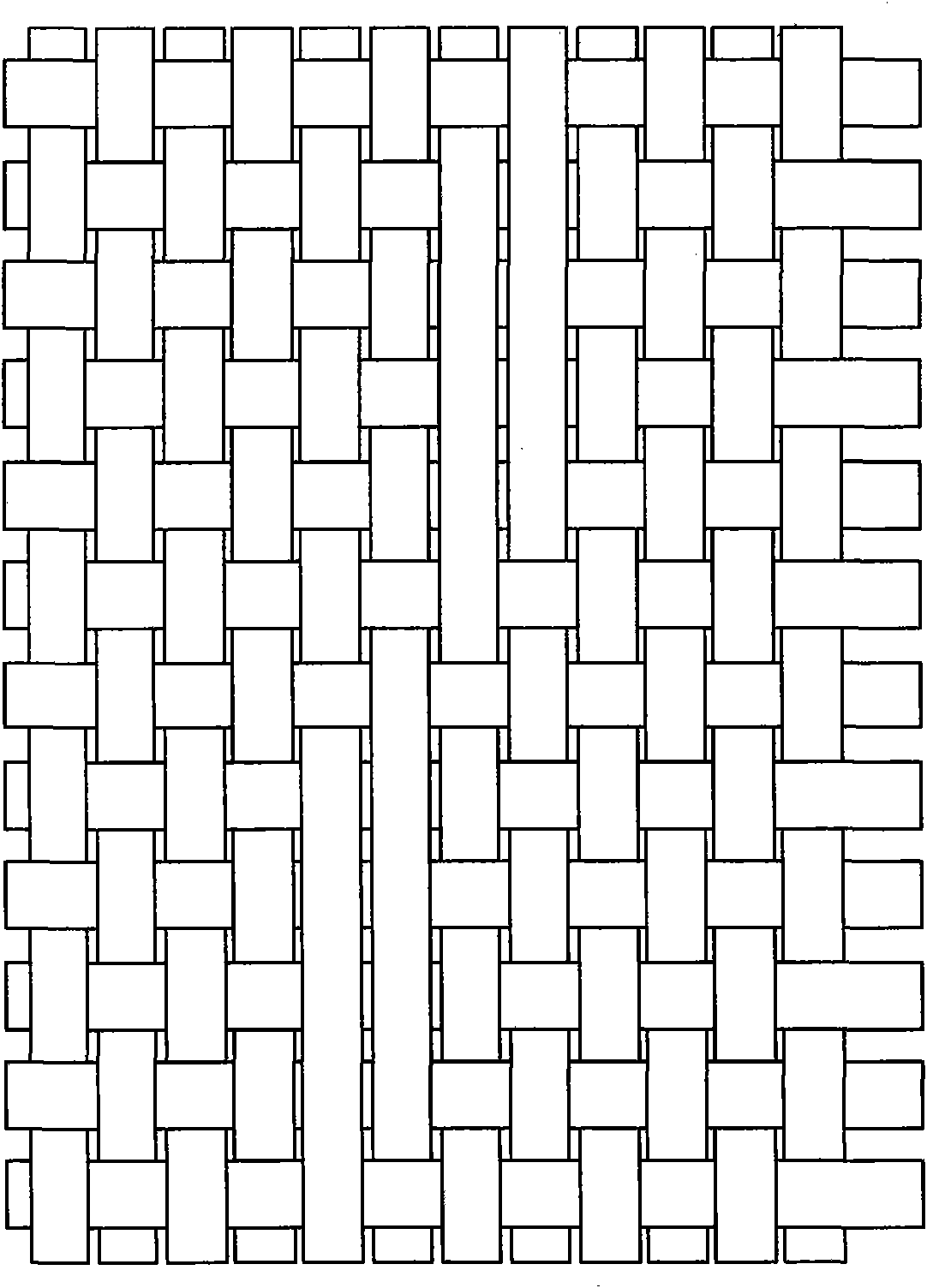

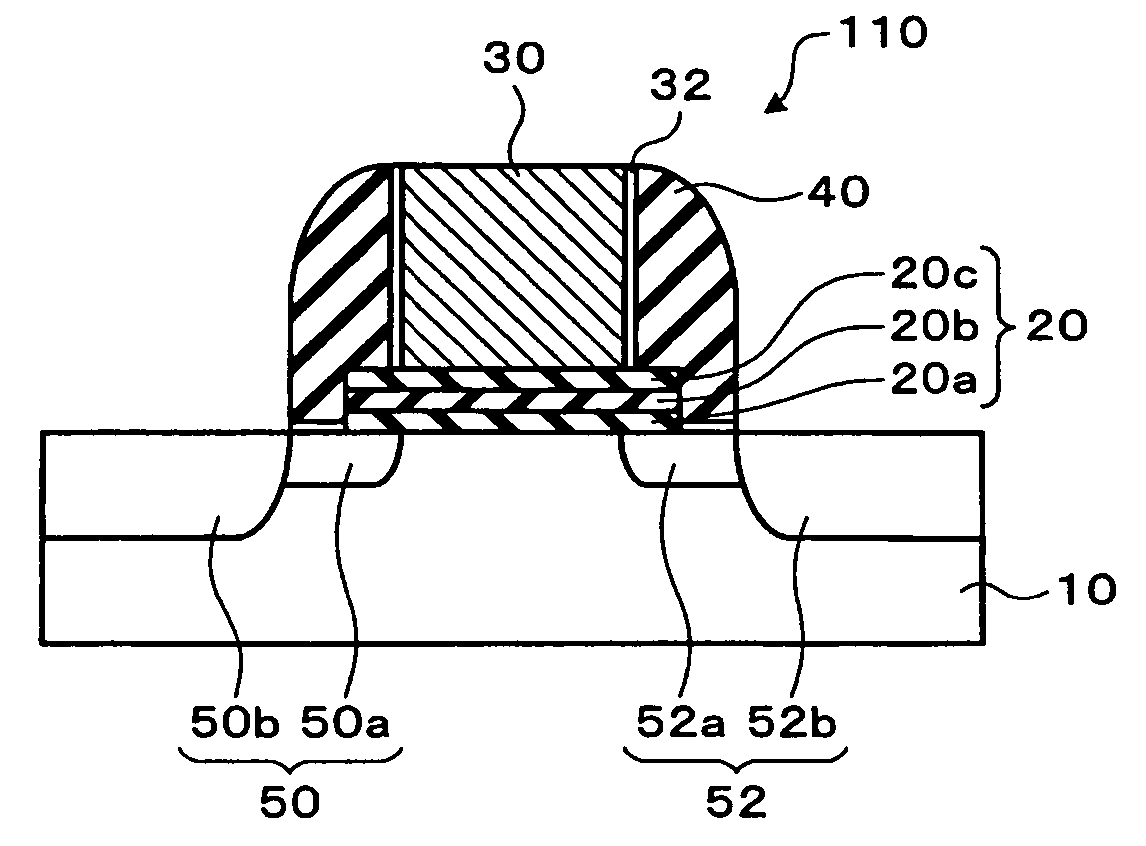

Semiconductor device and method for manufacturing the same

InactiveUS6969623B1Efficient preparationReduce defective rateSemiconductor/solid-state device testing/measurementSolid-state devicesMemory chipHigh density

A semiconductor device and a method for manufacturing the semiconductor device mountable with high density, which includes a simplified process but is capable of reducing a defect rate. A plurality of identical memory chips are formed on a semiconductor wafer, and a go / no-go test is conducted on all the memory chips. The semiconductor wafer is cut and divided into pieces that each consists of one, or two, or four good memory chips, and they are mounted on a substrate to form a memory module.

Owner:INVENSAS CORP

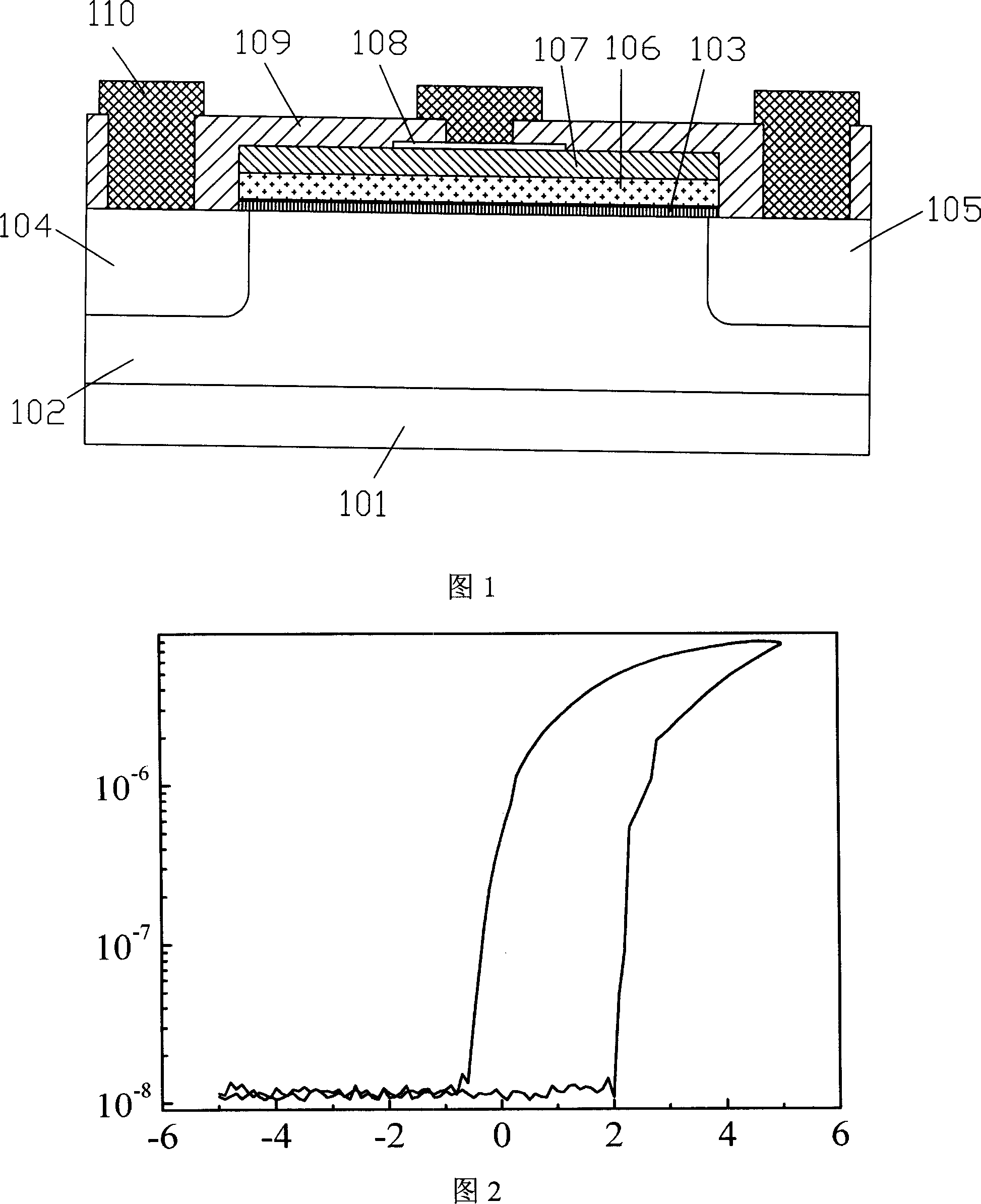

Ferroelectric field effect transistor storage device structure and preparation method

InactiveCN101000926AOvercome the shortcomings of poor interface and high working voltageEasy to storeSolid-state devicesSemiconductor/solid-state device manufacturingMemory effectFerroelectric thin films

The invention relates to a structure of ferroelectric memory and its preparation method, which specifically relates to a ferroelectric memory preparation technology of MFPIS structure. This invention includes: an upper electrode, a source region and a drain region. There are a PZT ferroelectric thin film, a multicrystal Si, an insulating layer, a well and a Si substrate, and the upper electrode lies on the PZT ferroelectric thin film. There are several beneficial effects of the invention, to overcome the general ferroelectric memory effect component contact surface difference, the working voltage high shortcoming, and have the good memory capability. This invention also provided the preparation method of this ferroelectric field effect transistor, and this preparation craft is simple, and compatible with the semiconductor manufacture craft.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

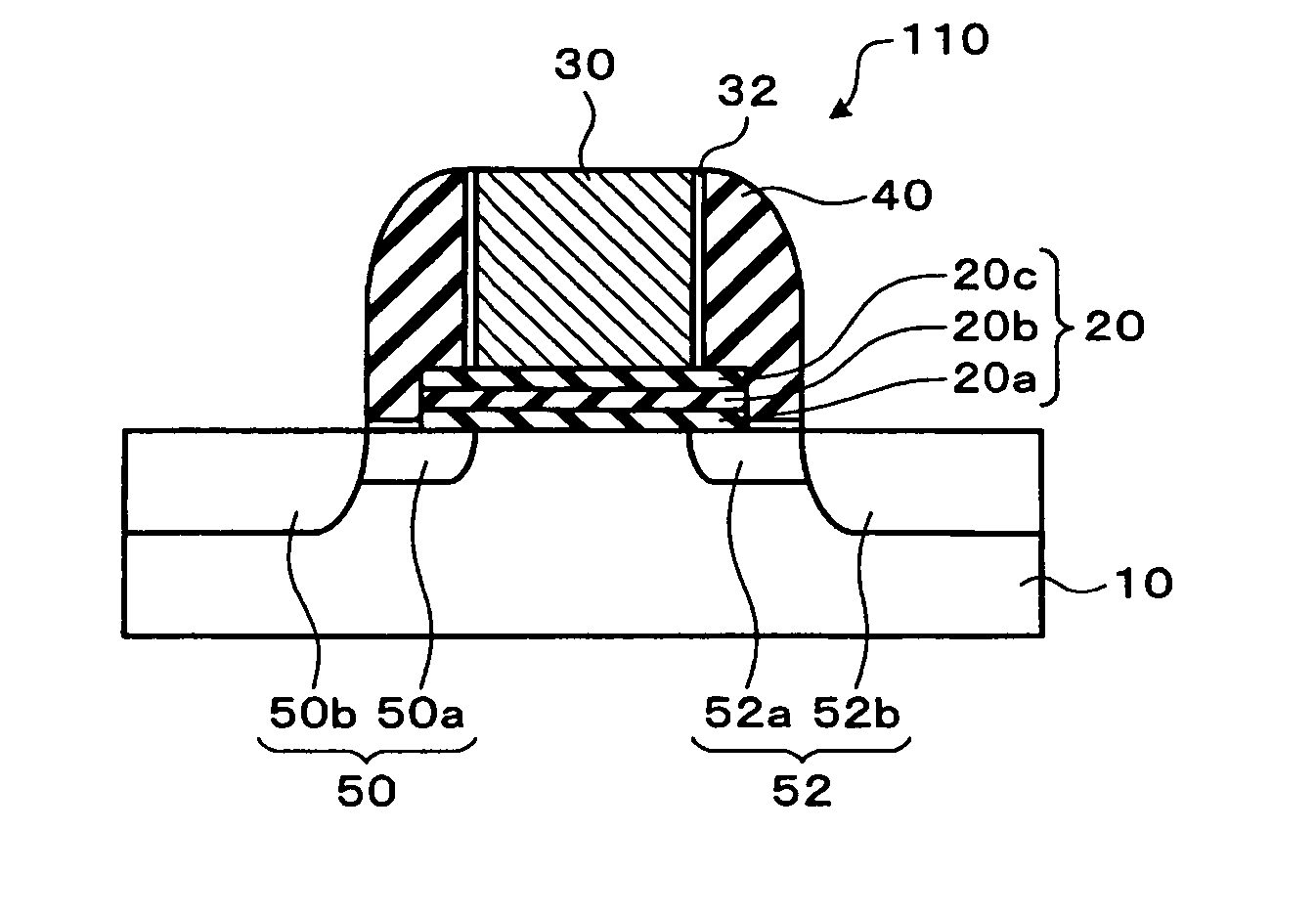

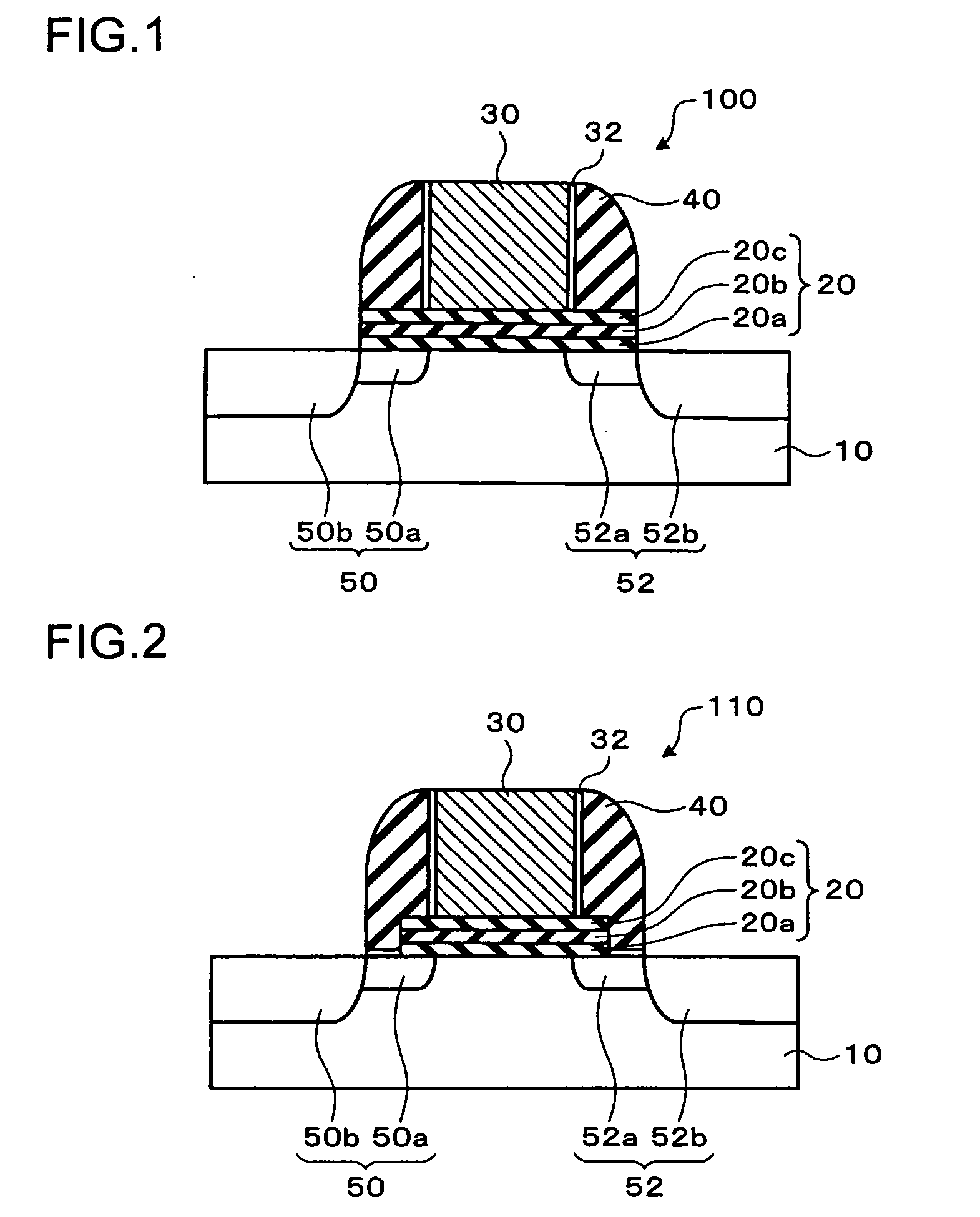

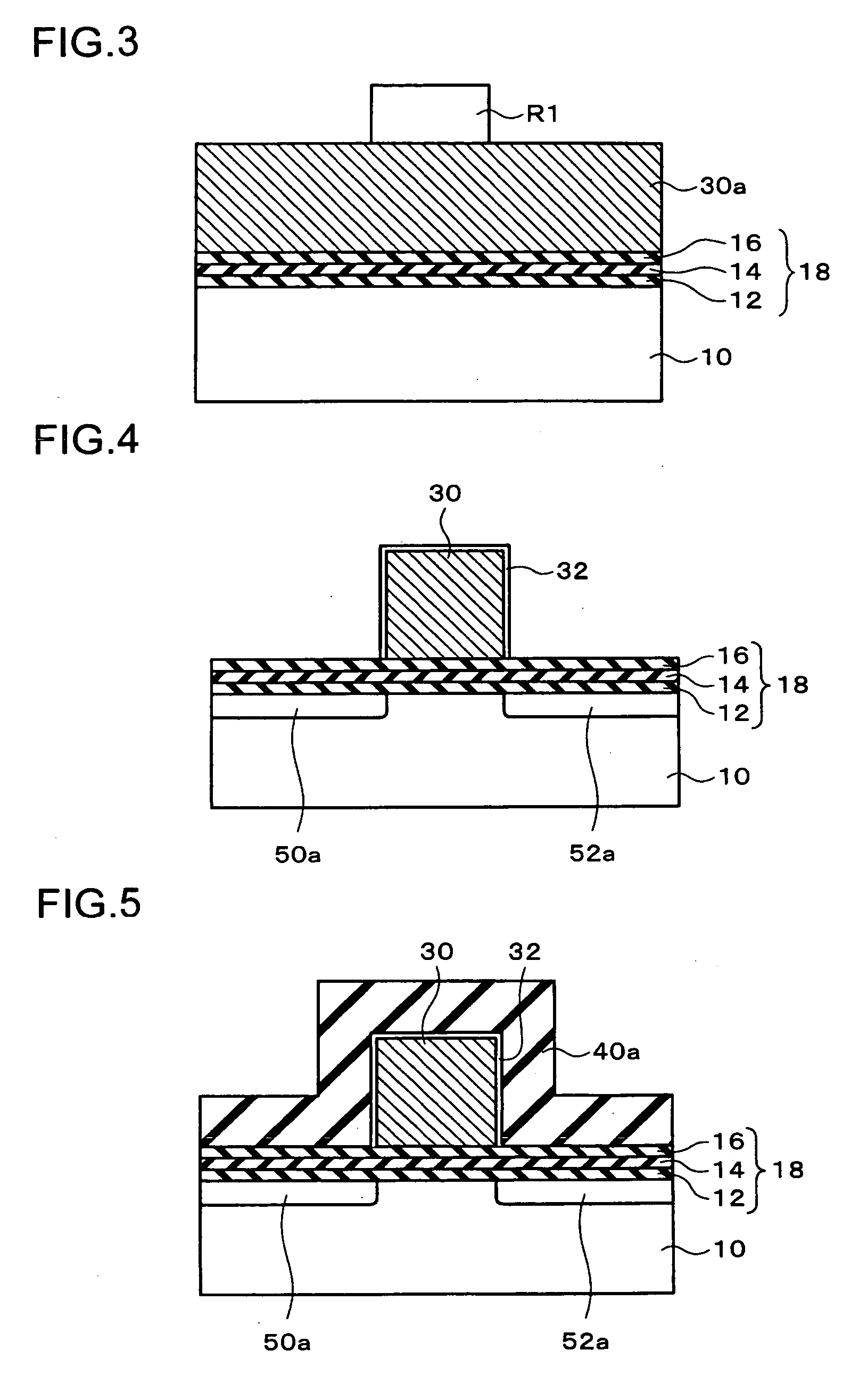

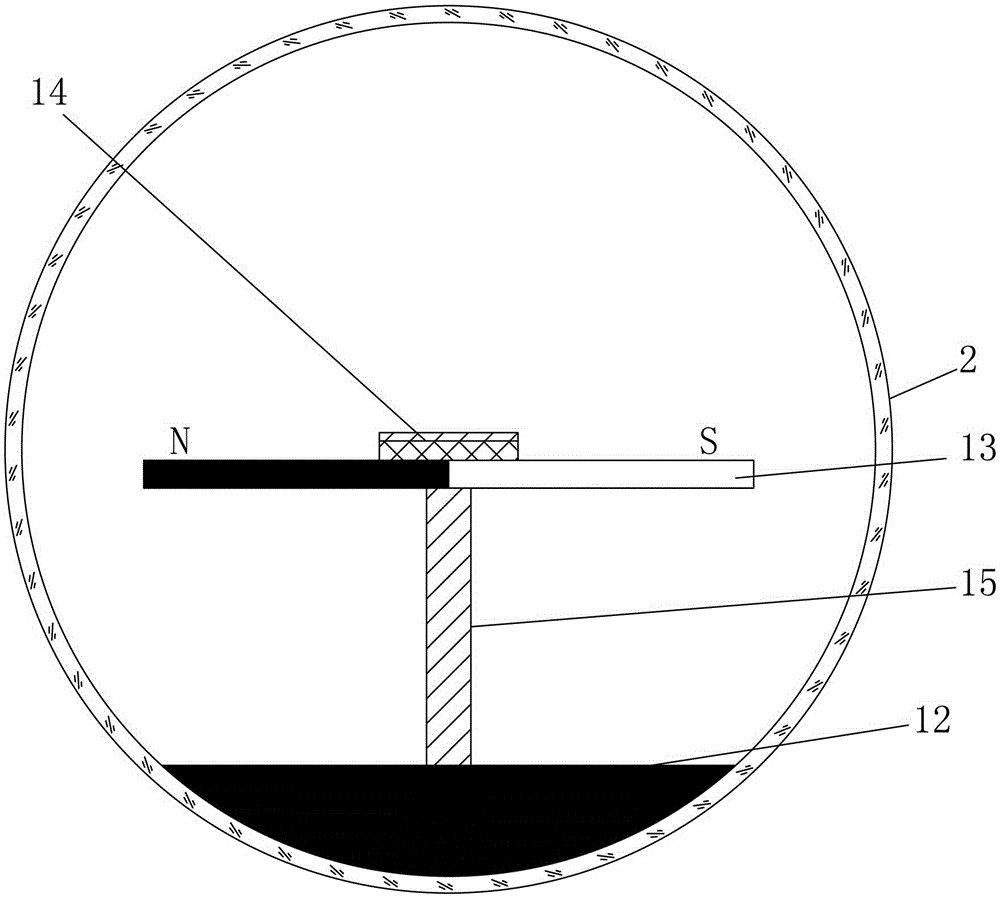

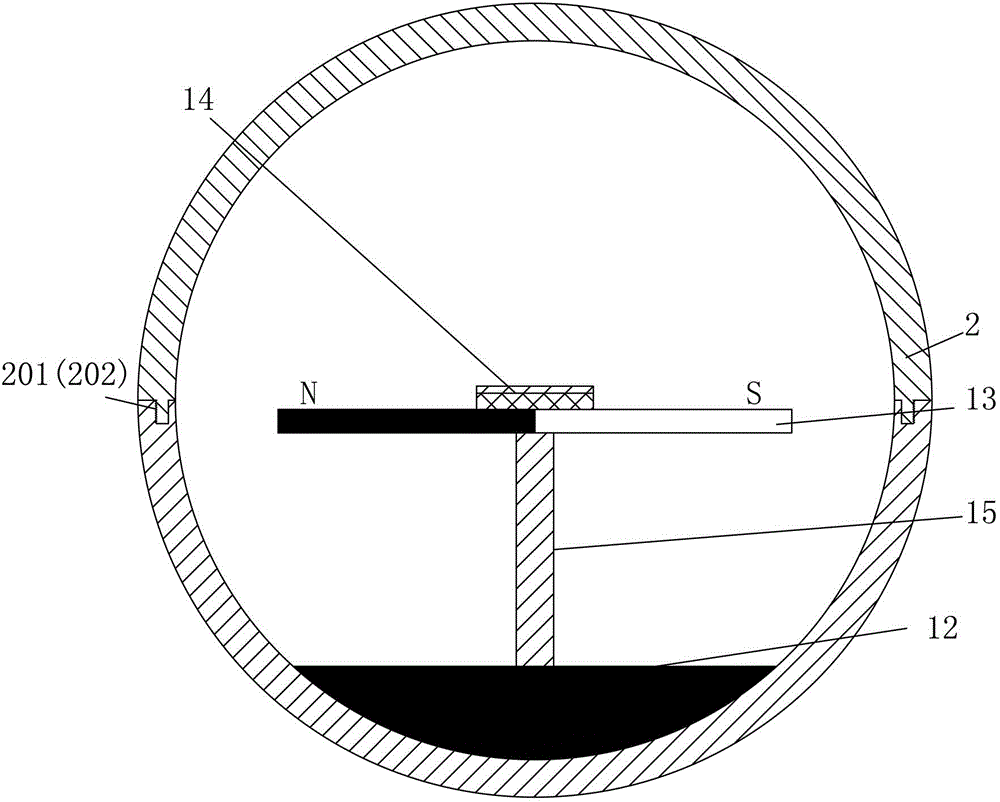

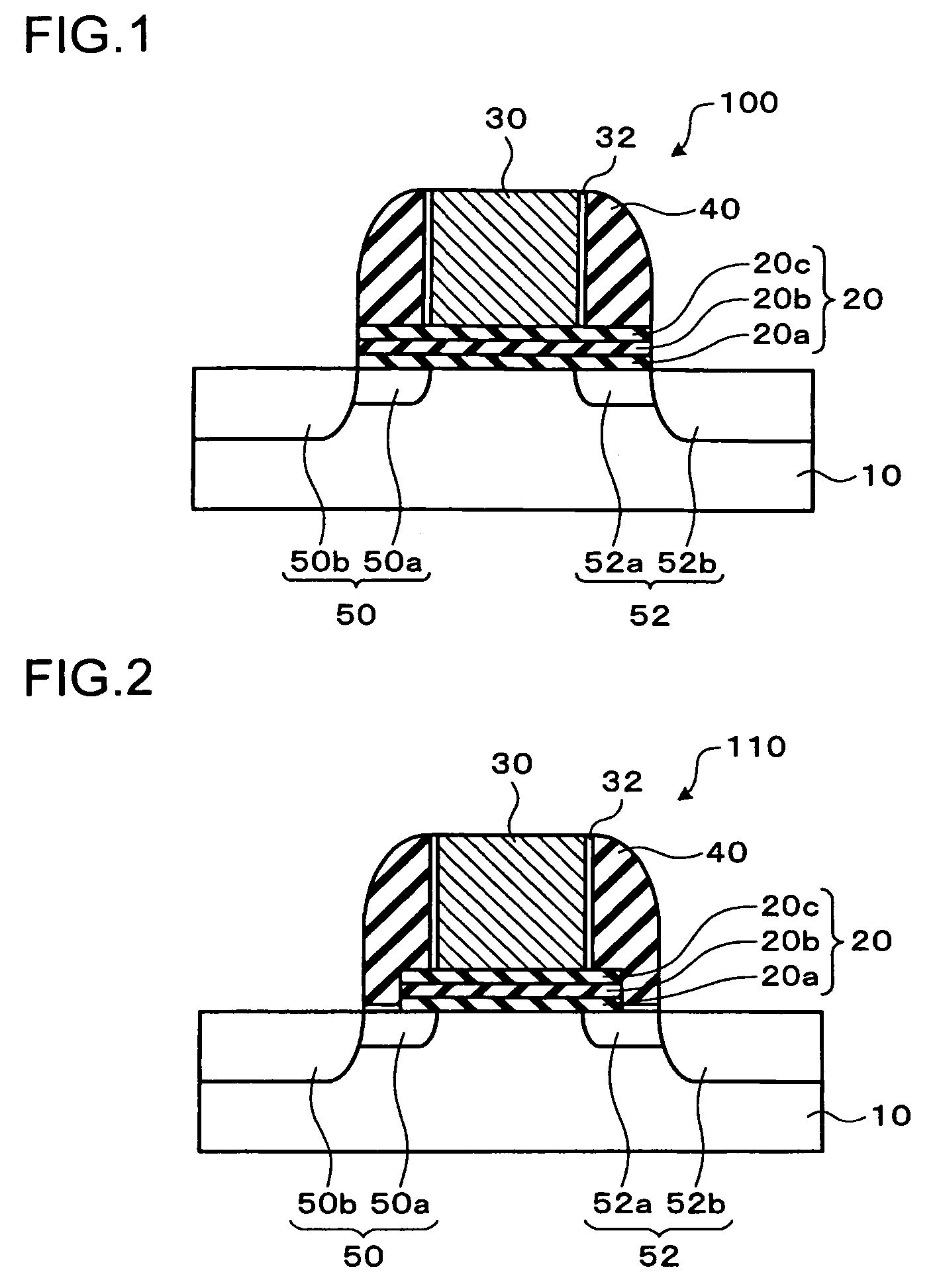

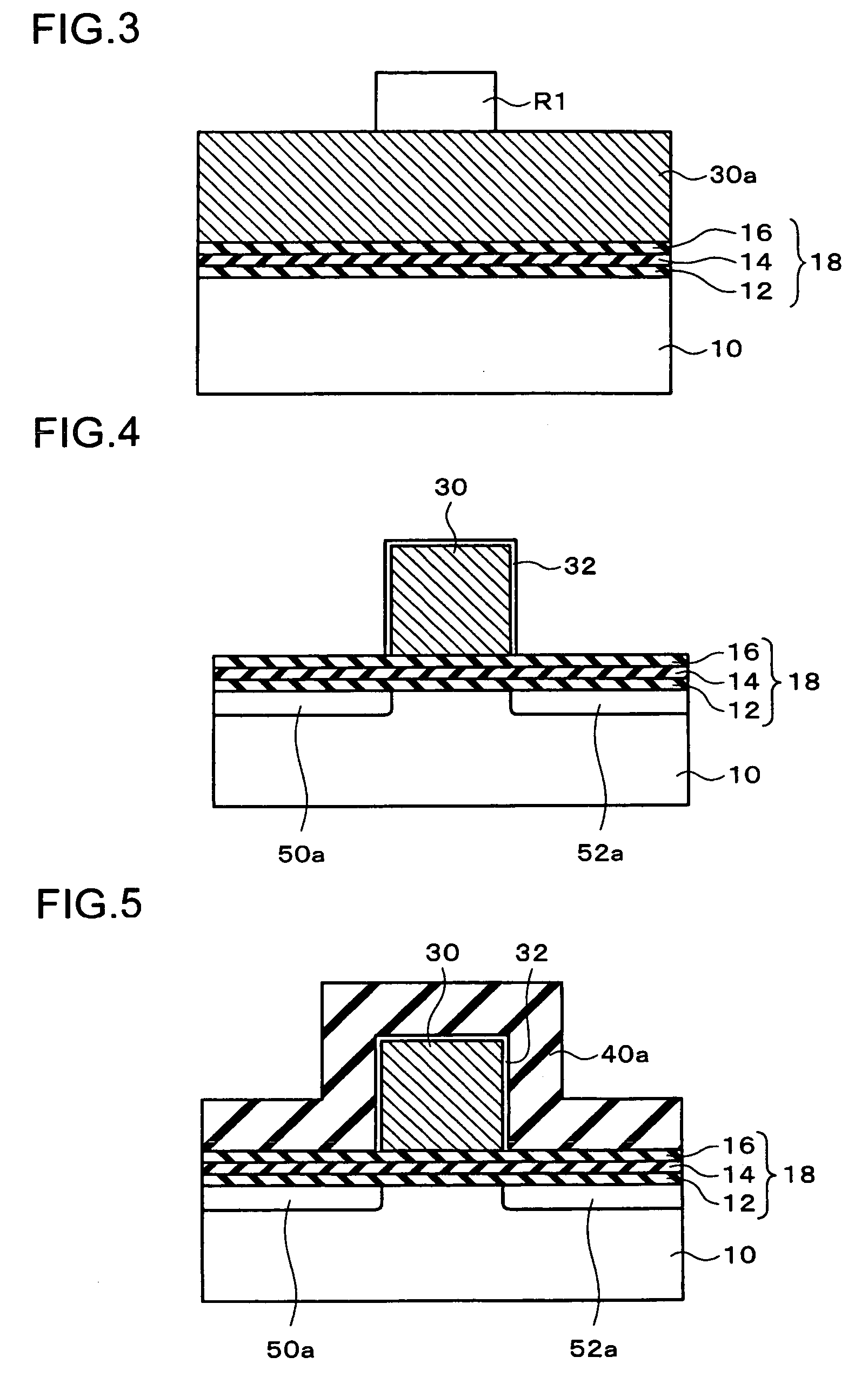

Semiconductor storage device and method of manufacturing the same

InactiveUS20050029567A1Restore crystal defectImprove featuresTransistorSolid-state devicesTrappingSemiconductor storage devices

A semiconductor storage device showing a good memory characteristic, and a manufacturing method thereof, includes a semiconductor layer, a stacked body including a first insulating layer, a charge trapping layer, and a second insulating layer that are provided above the semiconductor layer, a gate electrode provided above the stacked body, a side wall insulating layer provided at the side of the gate electrode, and impurity regions and provided in the semiconductor layer. The end surface of the stacked body is positioned outside the end surface of the gate electrode.

Owner:SEIKO EPSON CORP

Vertical-twill fabric

The invention discloses a vertical-twill fabric, which comprises mutually interlaced warps and wefts. The warps and wefts have a structure of combined vertical twill and bamboo joint patterns; the warps are terylene semi-gloss black yarn fully-drawn yarns; and the wefts are memory-type PTT fabric. The invention overcomes the shortcomings of the prior art and provides vertical-twill fabric representing bamboo joints and having unique vertical patterns and good memory effect.

Owner:JIANGSUYIWEIXIN INVESTMENT DEV

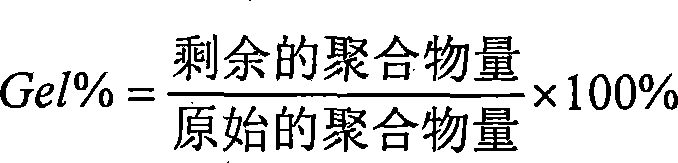

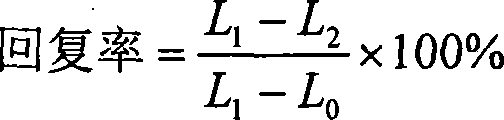

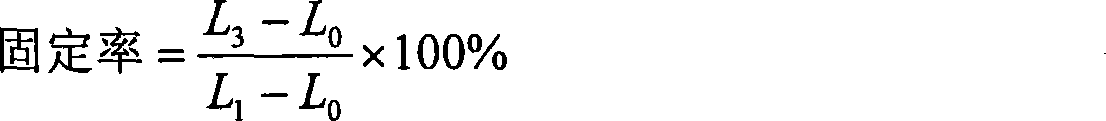

Biodegradable shape-memory material based on D,L-polylactic acid and preparation method thereof

The invention provides a biodegradable shape-memory material based on D,L-polylactic acid and a preparation method thereof. The shape-memory material is characterized in that: terminal hydroxy D,L-polylactic acid (PDLLA) is used as a soft segment; a carbamido chain segment formed by diisocyanate and reactive hydrogen-containing bifunctional small molecule diamine is used as a hard segment; and when a shape-memory temperature is between 30 and 60 DEG C and a deformation rate is about 300 percent, a shape fixed rate is between 96 and 100 percent and a shape recovery rate is between 94 and 100 percent. The shape-memory material has the excellent characteristics of strong deformation retentivity, high recovery rate and good memory repeatability, and simultaneously has biodegradability and property controllability. A recovery temperature is controlled to the vicinity of a body temperature by adjusting compositions of a polymer. The biodegradable shape-memory material has an important application value in the aspects of surgical minimally invasive surgery and an implant body material of a medical appliance.

Owner:CHONGQING UNIV

Fault diagnosis of serially-addressed memory chips on a test adaptor board to a middle memory-module slot on a PC motherboard

A standard memory module socket is removed from a target DRAM module slot on the component side and the test adaptor board connects to the target DRAM module slot on the reverse (solder) side of a personal computer motherboard, or an extender card may be used. The target DRAM module slot is a middle slot, such as the second or third of four DRAM module slots. The first and fourth DRAM module slots are populated with known good memory modules storing the BIOS at a high address and an operating system image and a test program at a low address. The test program accesses a memory chip in a test socket on a test adaptor board that is connected to the target DRAM module slot to locate defects. The motherboard does not crash since the BIOS, OS image, and test program are not stored in the memory chip under test.

Owner:KINGSTON DIGITAL CO LTD

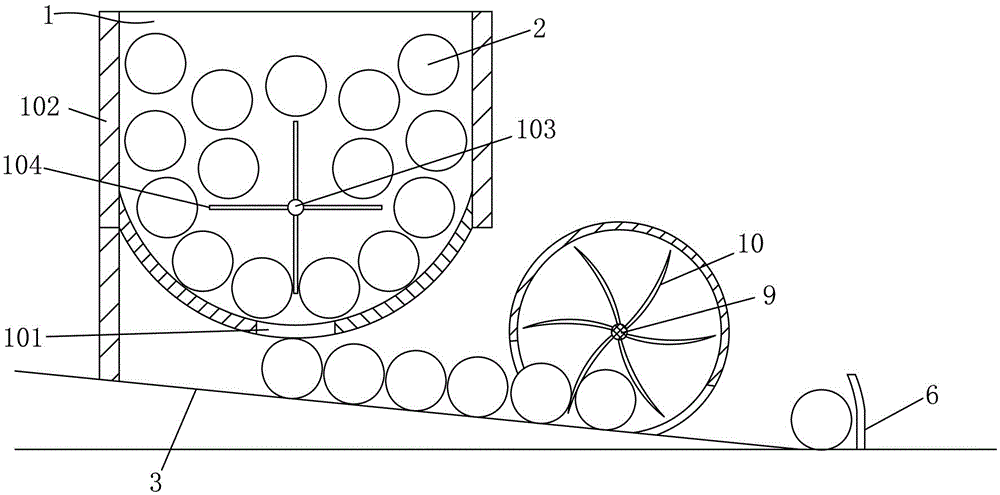

English word learning device

The invention provides an English word learning device. With the English word learning device, learning for students becomes interesting; the brain activity is enhanced; the memorizing capability is strengthened; the memory sequence becomes disorder and the good memory retention is realized; and bodies of students can be built to a certain extent. A sliding way that is inclined downwardly from a ball falling opening is arranged below the ball falling opening of a ball falling device; an axial bottom end of the sliding way is connected with a horizontal flat ball stopping plate; and magnetic units that are opposite to each other and have different magnetic poles are arranged at two radial side walls of the flat ball stopping plate, so that a magnetic field is generated between the two radial side walls of the flat ball stopping plate. Two opposite standing plates are arranged at the middle part of the sliding way; a rotating shaft is fixed between the standing plates; and a plurality of arc arms are distributed at the periphery of the rotating shaft uniformly. Learning balls include upper transparent half balls and lower transparent half balls; the lower ends of the lower half balls are filled with weights to form tumbler structures; magnetic needles that are symmetric relative to rotation points are arranged horizontally at the upper parts of the lower half balls in a rotating mode; and word placing boards perpendicular to the magnetic needles are arranged on the tops of the magnetic needles.

Owner:陈建宝

Semiconductor device

InactiveUS7217972B2Improve featuresImprove reliabilityTransistorSolid-state devicesTrappingSemiconductor package

A semiconductor storage device showing a good memory characteristic, and a manufacturing method thereof, includes a semiconductor layer, a stacked body including a first insulating layer, a charge trapping layer, and a second insulating layer that are provided above the semiconductor layer, a gate electrode provided above the stacked body, a side wall insulating layer provided at the side of the gate electrode, and impurity regions and provided in the semiconductor layer. The end surface of the stacked body is positioned outside the end surface of the gate electrode.

Owner:SEIKO EPSON CORP

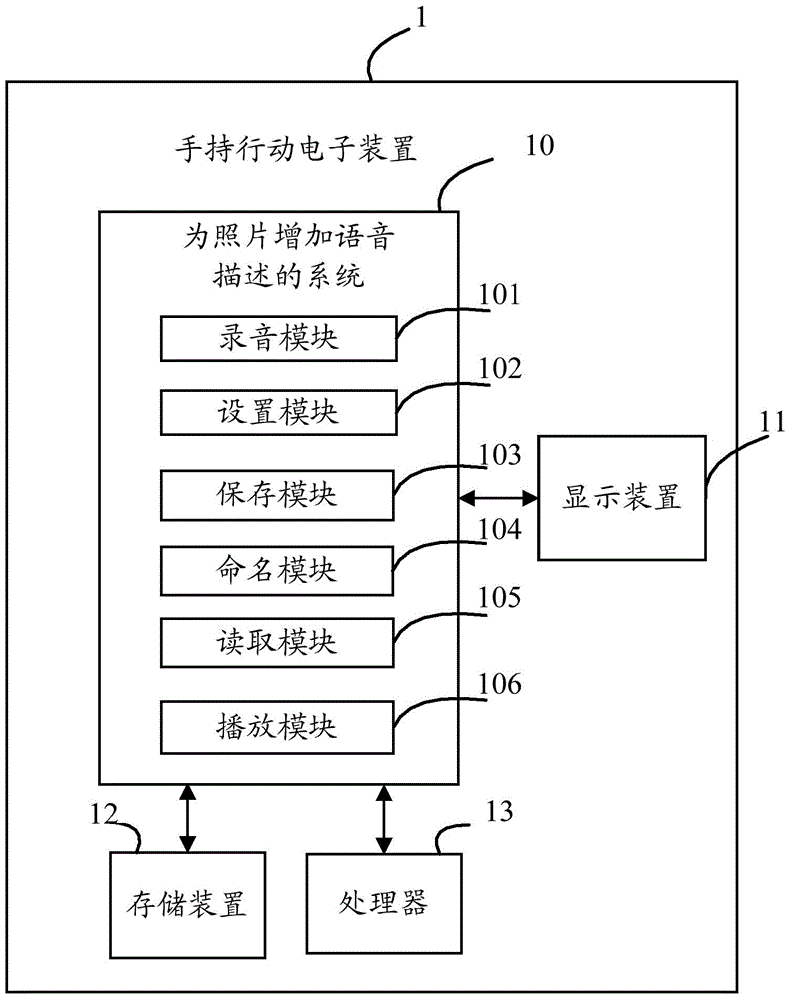

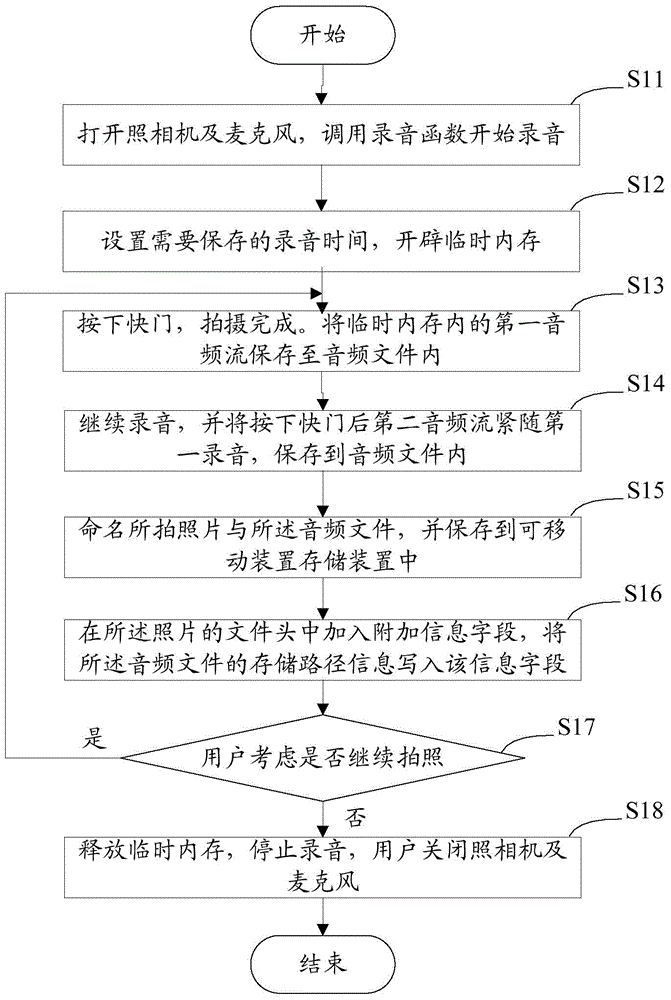

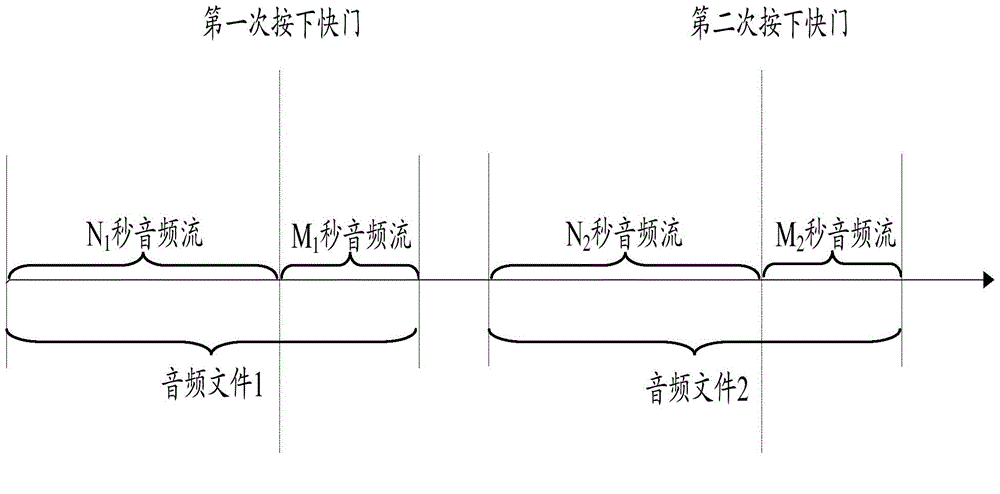

System and method of adding voice description to photo

The invention discloses a method of adding voice description to a photo. The method comprises steps: a camera and a microphone are opened, a recording function is called, and recording is started; time of recording which needs to be stored is set, and a temporary memory is opened up; a shutter is pressed, shooting is completed, and first audio is stored in a flowing mode to an audio file; recording is continued, second audio is stored in a flowing mode to the audio file, and the audio file is stored to a storage device of a handheld motion electronic device; the audio file and the photo are named to have the same file name but different postfixes; and an additional information field is added to the file header of the photo, storage path information is written to the information field, and the photo is stored in the storage device of the handheld motion electronic device. The invention also provides a system for adding voice description to the photo. By using the system and the method of the invention, a user can hear voice recorded in the case of shooting while browsing photos, and endless beautiful memories and laughter are brought to the user.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

Polyolefin/styrene series elastomer/conductive carbon black electro shape memory material and preparation method thereof

The invention discloses a polyolefine / styrene system elastomer / graphitized carbon black electro-shaped memory material, which is characterized in that the components of the material by weight are: polyolefine 20-40 portions, styrene system elastomer 30-40 portions, graphitized carbon black 18-22 portions, plasticizer 6-10 portions, cross linker 0-2 portions and auxiliary cross linker 0-10 portions, the elongation at break is 300-550 percent, recovery (150-200V AC) 80-95 percent, fixed ratio (20 DEG C) 80-96 percent, recovery responding temperature 60-100 DEG C and recovery time 20-80s. The invention further discloses a preparation method of the material. The electro-shaped memory material of the invention not only has good memory performance, low cost and good comprehensive mechanical property, but also has good processing property, thereby being processed repeatedly, which is favorable for recycling. The raw material used in the method of the invention has low cost and simple technique, thereby needing no special processing equipment and being easy to be popularized and applied.

Owner:SICHUAN UNIV

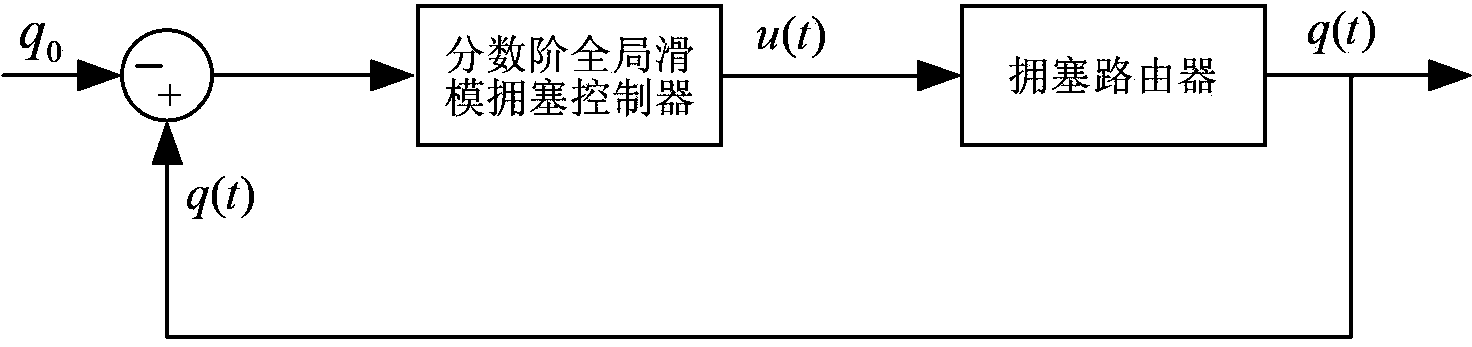

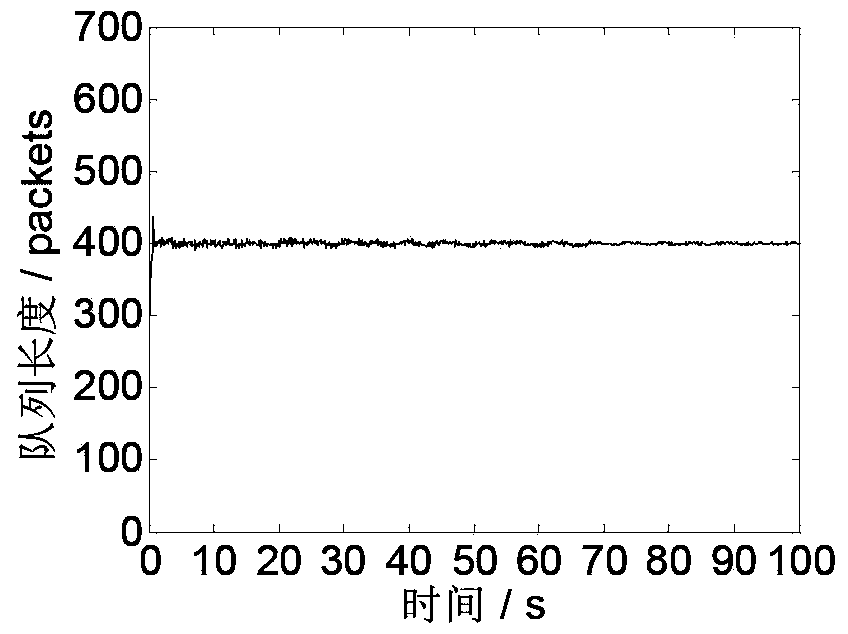

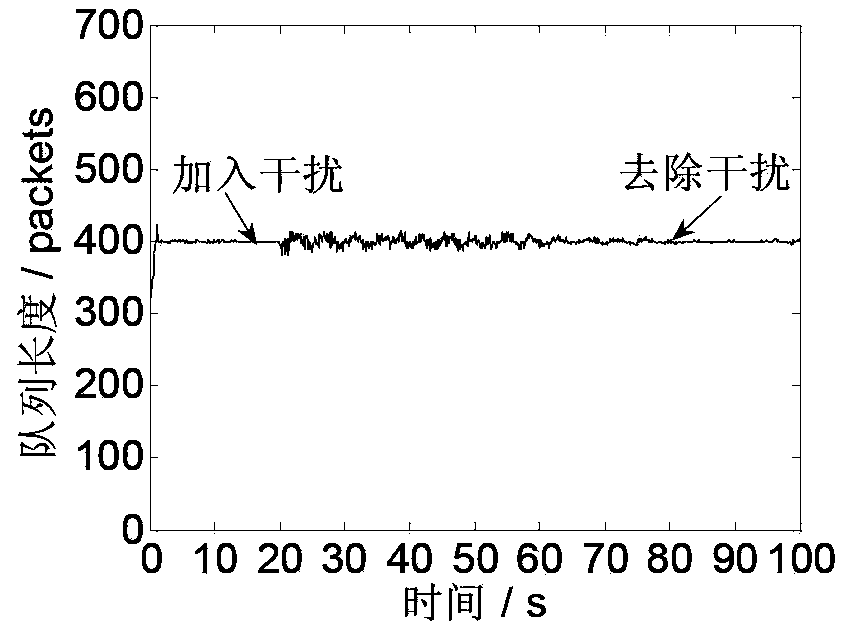

Fractional-order global sliding-mode Internet congestion control method

InactiveCN103354526AImprove robustnessReduce chatteringData switching networksRobustificationQuality of service

The invention relates to a fractional-order global sliding-mode Internet congestion control method, belonging to the field of Internet congestion control. To solve congestion problems existing in the Internet, the method utilizes strong robustness of a global sliding mode and good memory of fractional order to improve the congestion control effect. A parameter perturbation item is introduced into a network congestion control model to represent change of practical network parameters. A gradually-stable global sliding-mode surface with a fractional order item is designed to effectively inhibit influence of time-varying parameters to a system. A designed fractional-order sliding-mode controller can effectively reduce buffeting phenomena, so that operation of the system is similar to a sliding-mode movement on the sliding-mode surface. According to the method of the invention, congestion of the network is effectively inhibited, and service quality of the network is improved.

Owner:LIAONING UNIVERSITY

Low temperature thermoplastic material

The invention relates to a medical polymer material, in particular to a polymer thermoplastic material. The polymer thermoplastic material is composed of 60-90 parts of polycaprolactone, 0.1-5 parts of a crosslinking assistant, and 10-50 parts of filler. The production process steps include: 1. material mixing, 2. granulation, 3. extrusion / injection molding, 4. punching and cutting, and 5. irradiation at an irradiation dose of 0.1KGy-20KGy. If the irradiation is less than 0.1kGy, the crosslinking is insufficient, and operation after heating is inconvenient, if the irradiation is greater than 20KGy, the elongation at break of the material is too low, and the material fractures easily. The thermoplastic material provided by the invention can be softened and molded into arbitrary shape at lowtemperature, can restore the hardness and strength of plastic itself after cooling, and has the advantages of light weight, strong plasticity, certain strength, strong X ray permeability, good memory, strong repeat mouldability, no irritation to skin and easy rapid degradation in soil after abandonment, thus being an ideal medical external fixation material. The low temperature thermoplastic material provided by the invention is mainly used for fixation of radioactive therapy, bone surgery fixation, making of orthopaedic and rehabilitation braces, etc.

Owner:广州天泓医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com