Polyolefin/styrene series elastomer/conductive carbon black electro shape memory material and preparation method thereof

A conductive carbon black and styrene-based technology, which is applied in the field of shape memory polymer blend materials and their preparation, can solve the problems of affecting the mechanical properties of materials, poor shape memory function, increasing processing difficulty, etc., and achieves reasonable composition and matching. The effect of high recovery rate and easy production scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] First, 38.4 parts of SEBS, 10 parts of conductive carbon black, and 9.6 parts of polyethylene wax were added to an ordinary internal mixer, the temperature was raised to a melt temperature of 200 ° C, and blended for 15 minutes; then the resulting SEBS blend was mixed with 32 parts HDPE with a melt flow rate of 5-8g / 10min, 8 parts of conductive carbon black, 0.2 parts of DCP, and 1.8 parts of maleic anhydride are blended in an ordinary internal mixer at a melt temperature of 200°C for 10 minutes. That is, get the SMPM.

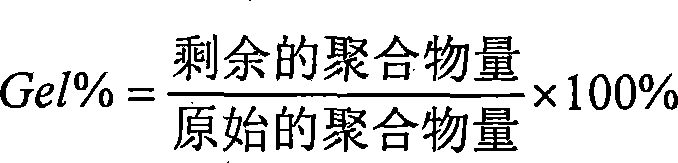

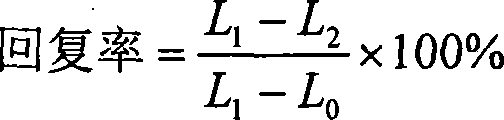

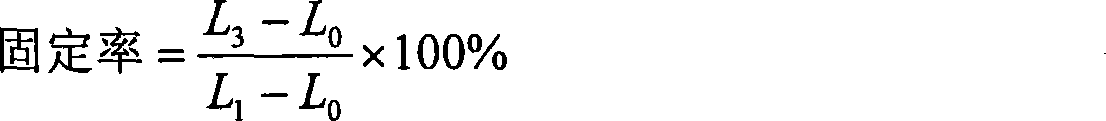

[0066] The shape recovery rate of the SMPM is 85-90%, the fixation rate is 85-87%, the tensile strength is 9-12MPa, the recovery time is 40-60s, the recovery voltage is 200v, and the gel rate is 3-5%.

Embodiment 2

[0068] First add 40 parts of SIS, 6 parts of conductive carbon black, and 8 parts of oxidized polyethylene wax into an ordinary internal mixer, heat up to a melt temperature of 180 ° C, blend for 10 minutes and pelletize; then pelletize the pelletized SIS The mixture is mixed with 32 parts of LDPE with a melt flow rate of 9-11g / 10min, 12 parts of conductive carbon black, 1.7 parts of polyethylene wax, and 0.3 parts of AD. , blending at a melt temperature of 185°C for 2 minutes to obtain SMPM.

[0069] The shape recovery rate of the SMPM is 88-90%, the fixation rate is 83-87%, the tensile strength is 10-15MPa, the recovery time is 60-80s, the recovery voltage is 180-200v, and the gel rate is 5-7%.

Embodiment 3

[0071] Add 40 parts of SEBS, 30 parts of PP with a melt flow rate of 1.5-3g / 10min, 20 parts of conductive carbon black, 8 parts of polypropylene wax, 0.2 parts of DCP, and 1.8 parts of silane coupling agent into a high-speed mixer for premixing After uniformity, put into a twin-screw extruder, and blend for 6 minutes at a melt temperature of 165°C to obtain SMPM.

[0072] The shape recovery rate of the SMPM is 85-90%, the fixation rate is 80-85%, the tensile strength is 9-13MPa, the recovery time is 50-70s, the recovery voltage is 210-220v, and the gel rate is 1-3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com