Patents

Literature

50results about How to "Low gel rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grafting modification method for solution-polymerized styrene-butadiene rubber with low gel rate

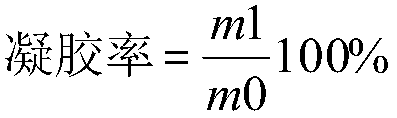

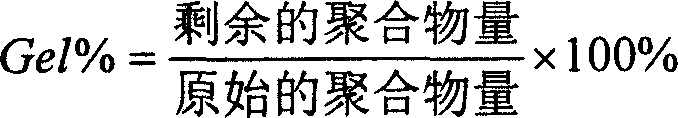

The invention relates to a preparation method of polar solution-polymerized styrene-butadiene rubber with low gel rate. The method involves grafting polar monomers on solution-polymerized styrene-butadiene rubber by means of free radical solution method, so as to change the polarity and further improve the interface bonding force of styrene-butadiene rubber and carbon black or white carbon black, so that the wet-skid resistance, wear resistance and dynamic mechanical property of vulcanized rubber are improved and the rolling resistance is reduced. The polar monomers used comprise maleic anhydride, acrylic acid, acrylamide, N-vinyl pyrrolidone and the like. The grafting rate of modified styrene-butadiene rubber is 1-5% and the gel rate is 1-3%; and the rubber polarity changes obviously.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

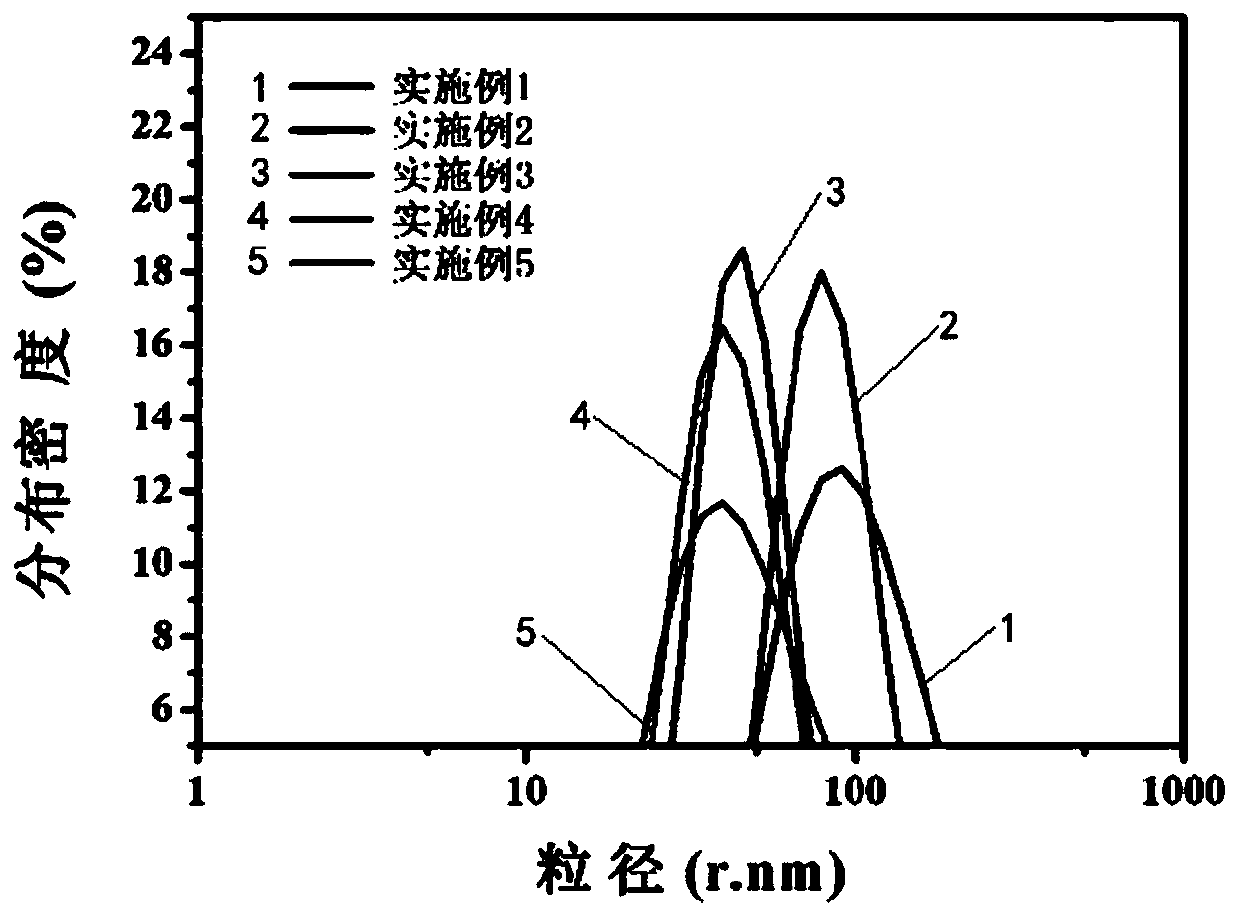

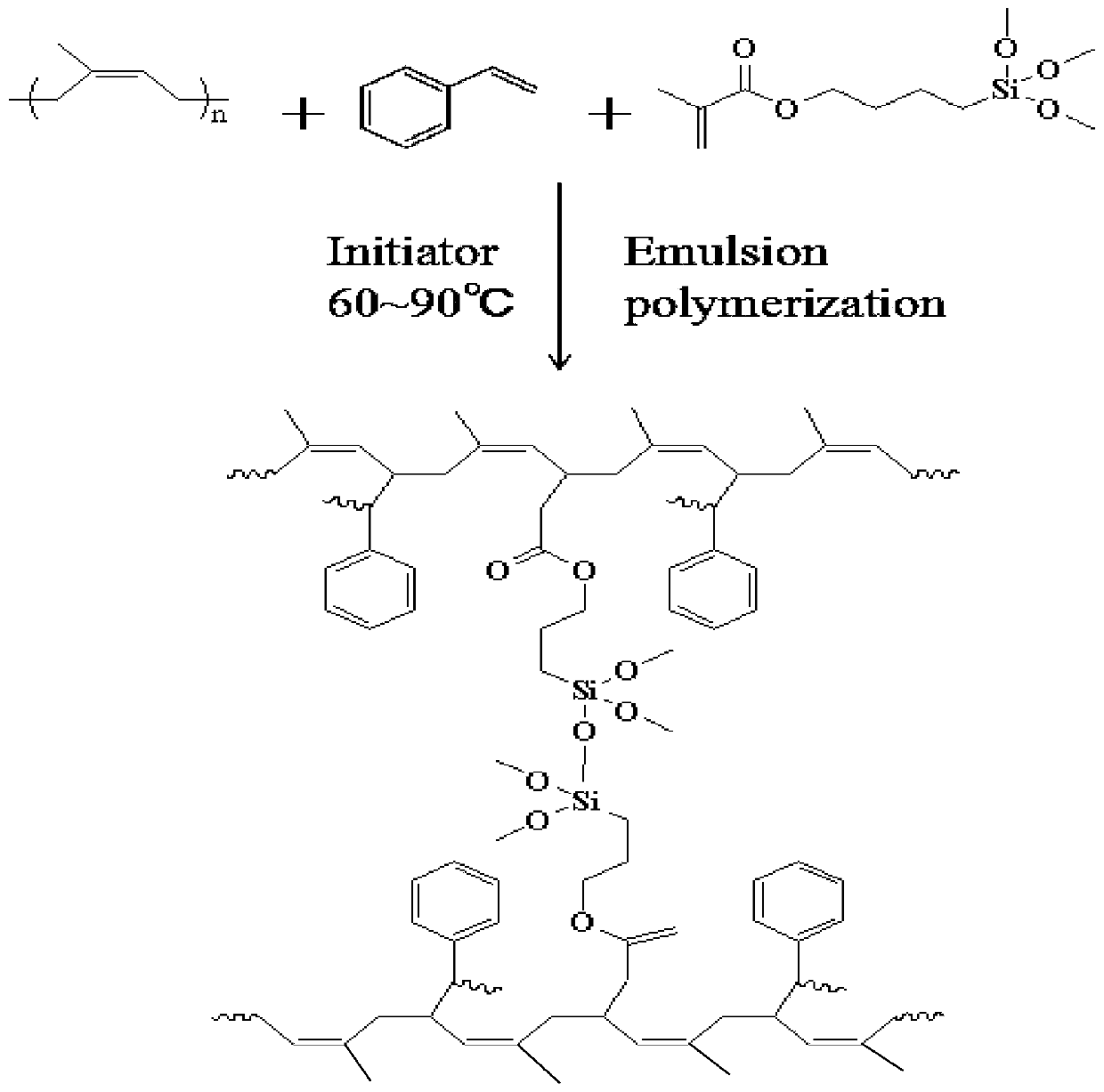

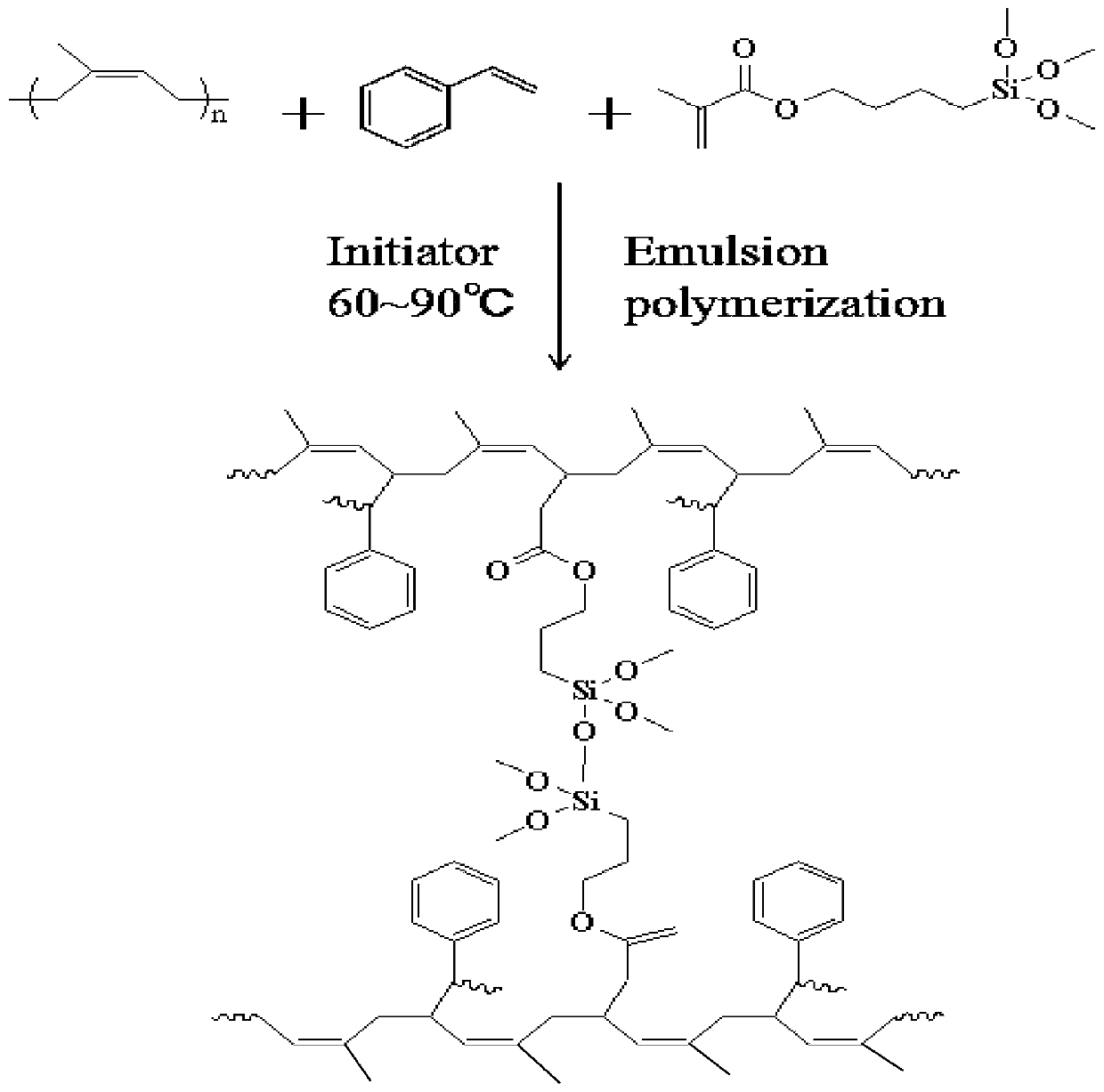

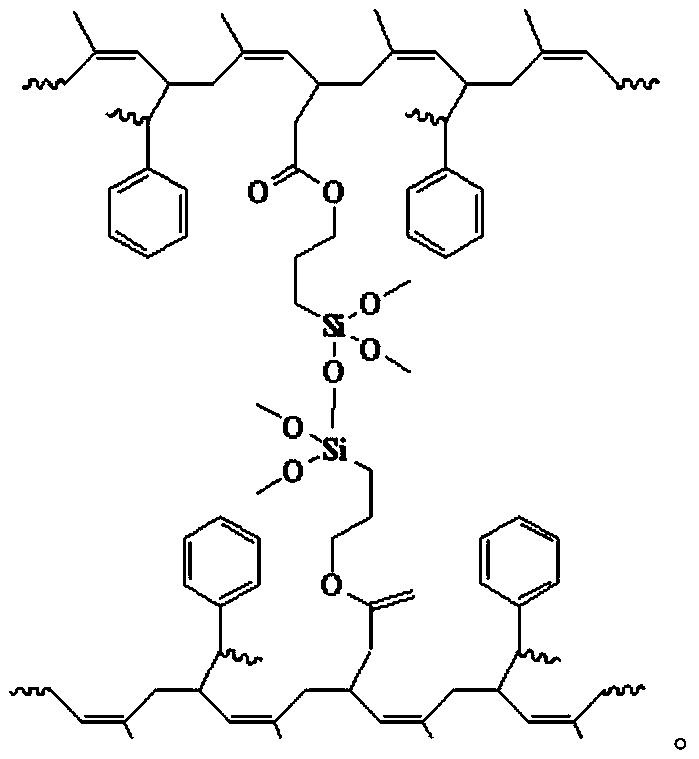

Waterborne silicone acrylate emulsion with core-shell structure and preparation method of waterborne silicone acrylate emulsion

InactiveCN107226883AGood moldabilityImprove hydrophobicityFireproof paintsAntifouling/underwater paintsPolymer scienceAcrylate polymer

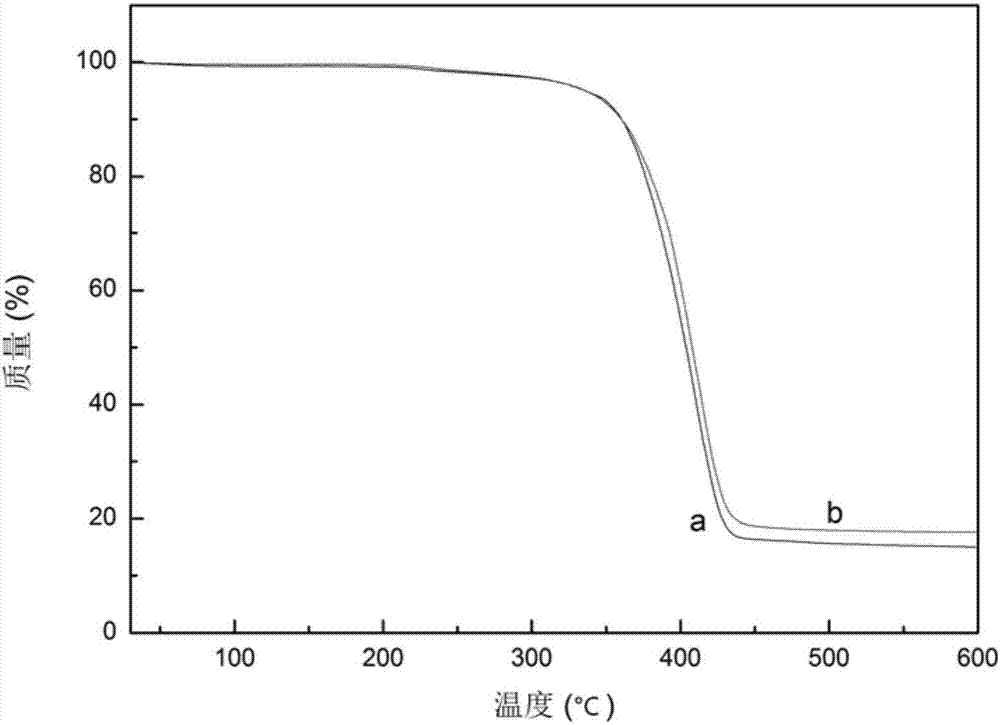

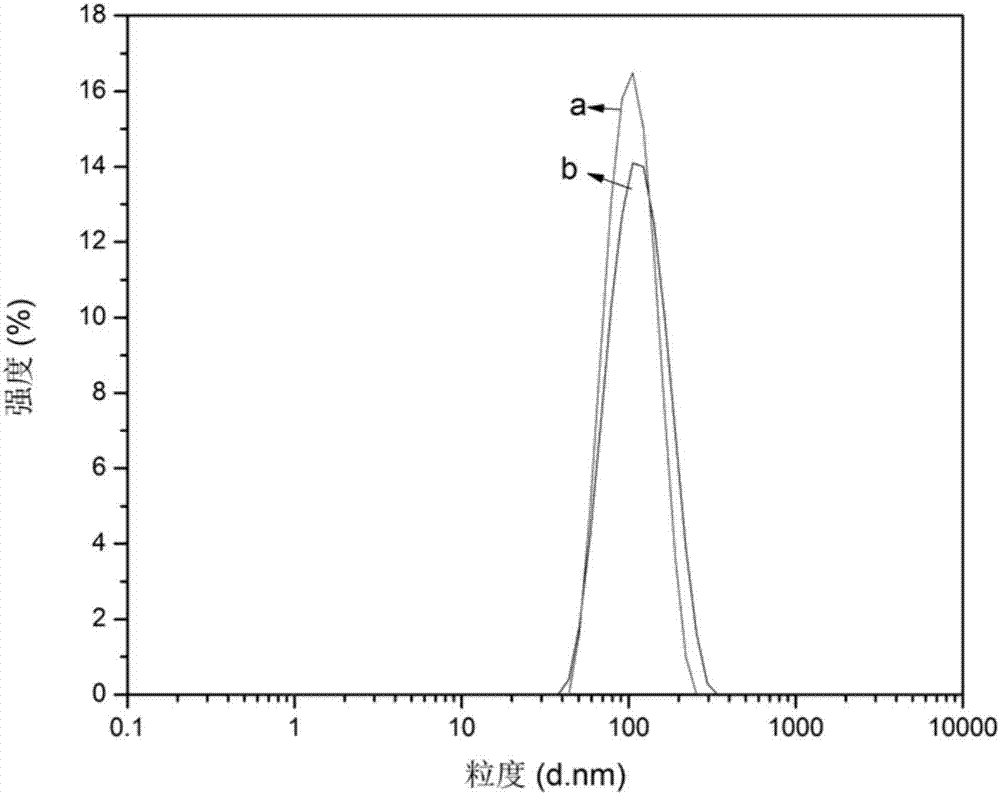

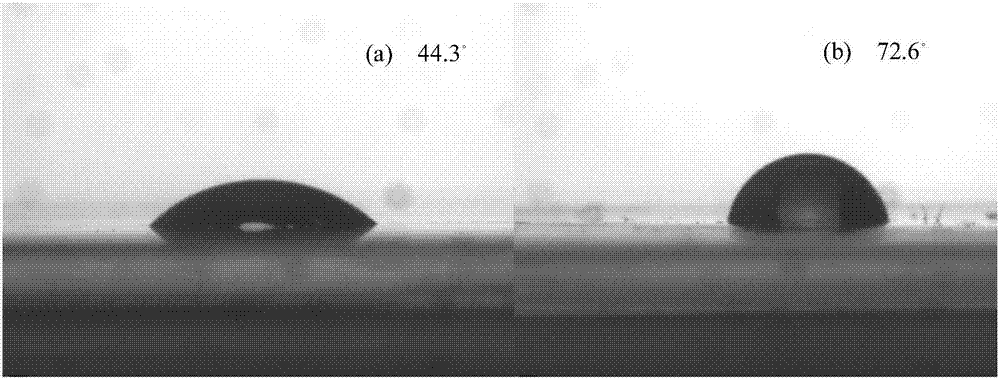

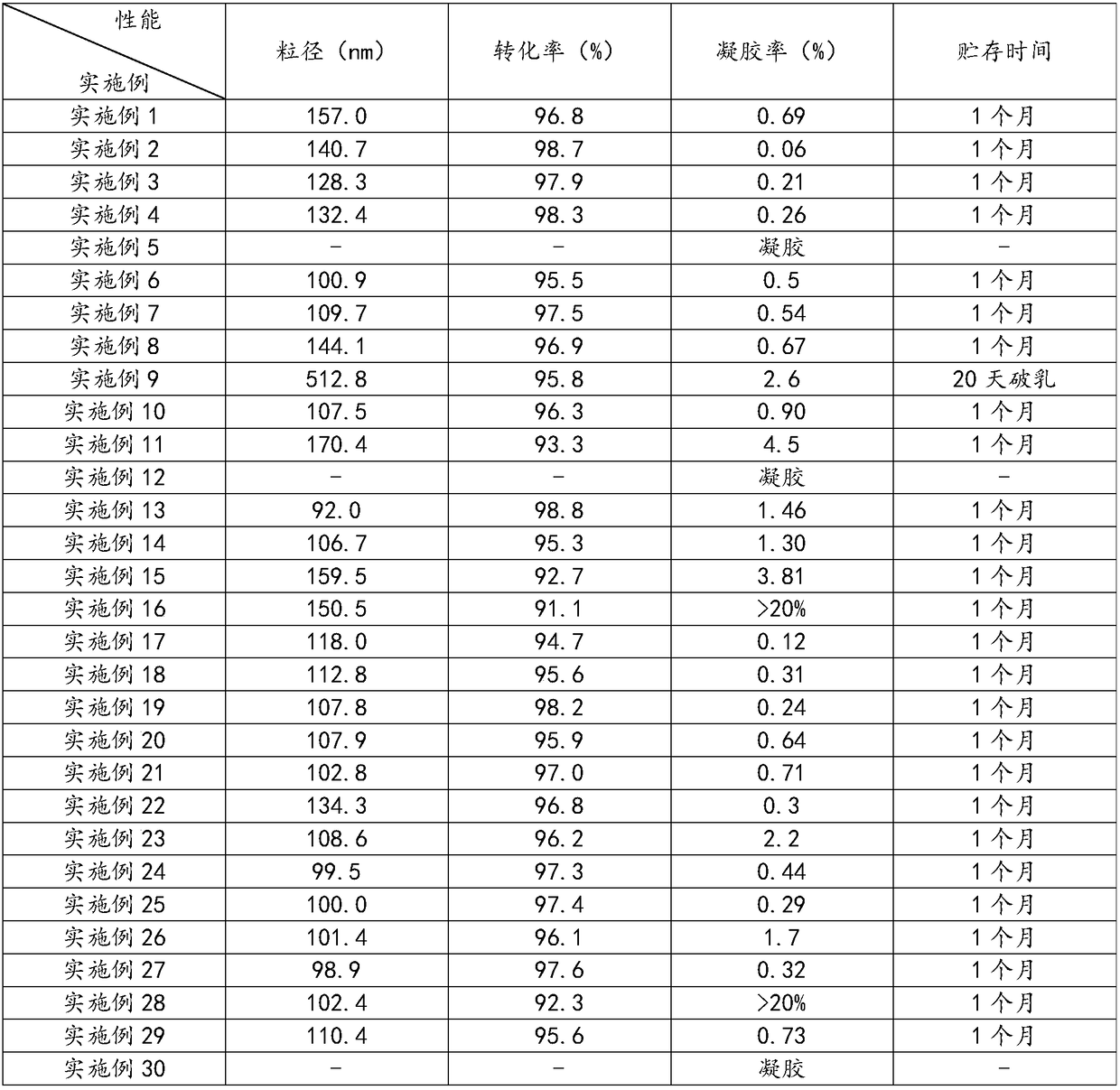

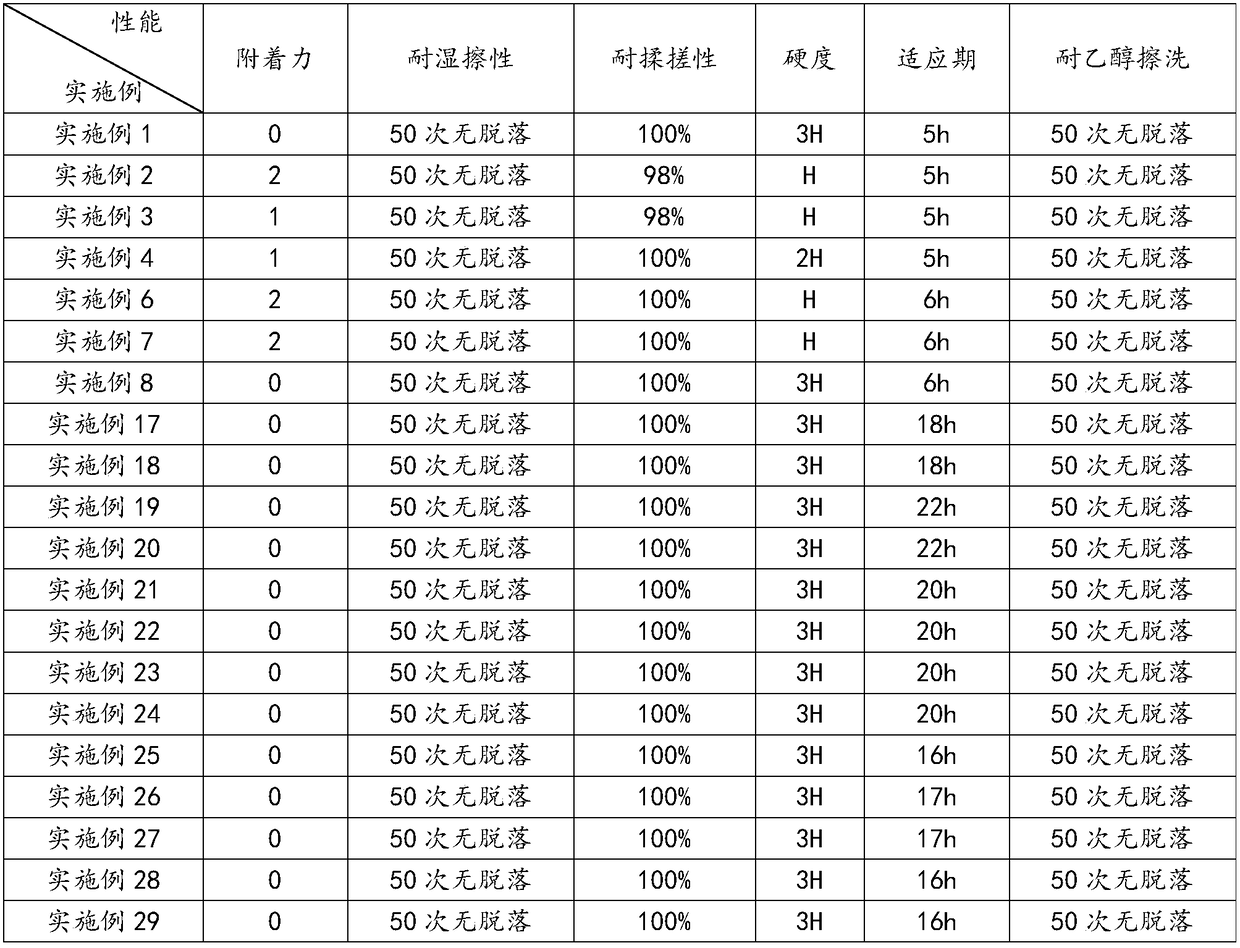

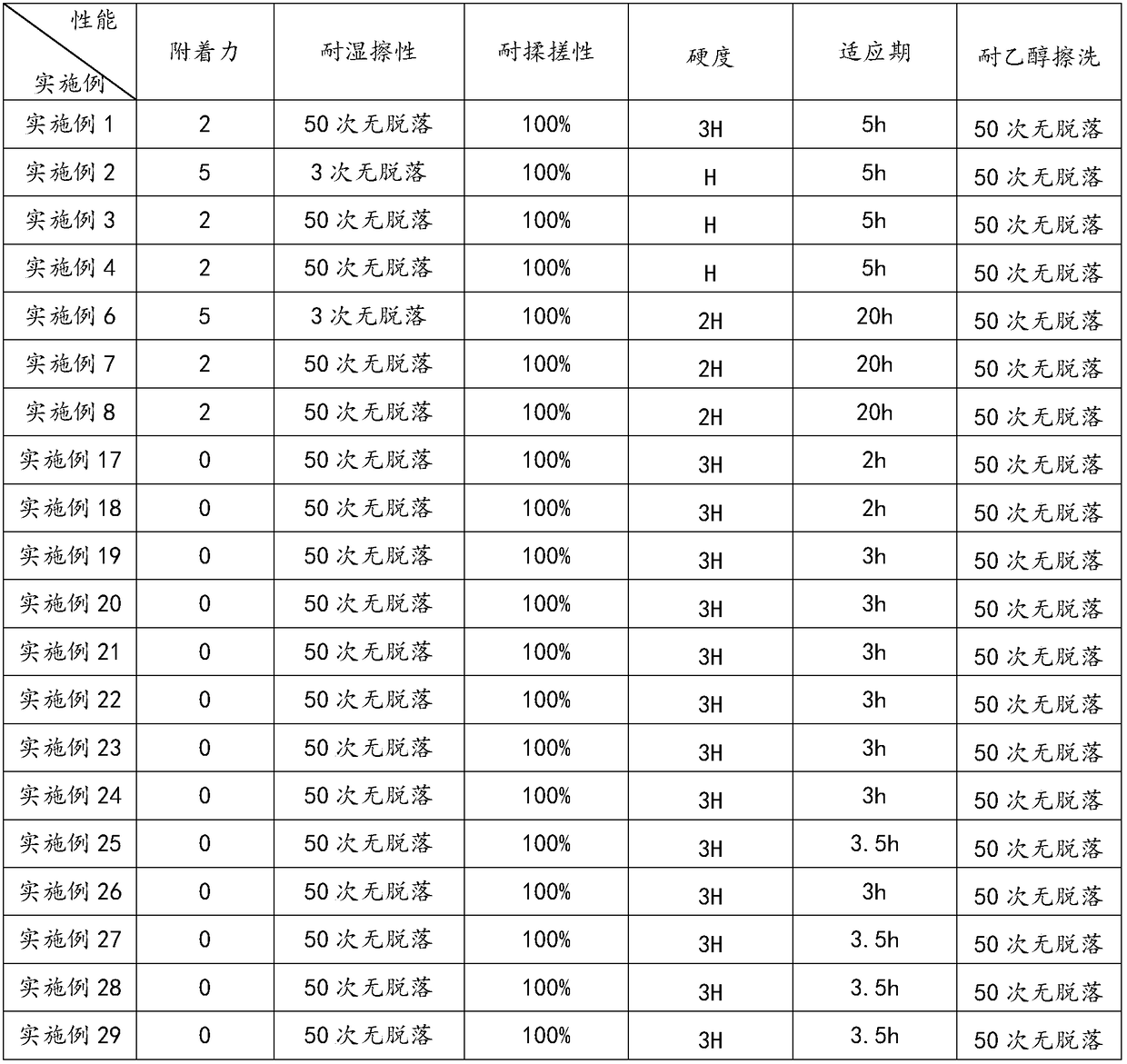

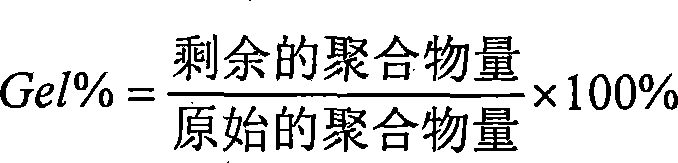

The invention discloses waterborne silicone acrylate emulsion with a core-shell structure and a preparation method of the waterborne silicone acrylate emulsion. The acrylate emulsion is prepared from the following components: methyl methacrylate, butyl acrylate, acrylic acid, an emulsifier, an initiator, organosilicon, ammonium hydroxide and deionized water. A semi-continuous seed emulsion polymerization method is combined with a starved condition feeding production process, and all monomers are added into a polymerization system at different stages, so organosilicone acrylate emulsion with the core-shell structure is prepared. The waterborne silicone acrylate emulsion disclosed by the invention has no toxin or pollution and the advantages of the organosilicon and an acrylate polymer; hardness, adhesive force, thermal stability, hydrophobicity, water resistance and other properties of an emulsion film are improved; the film forming property, water resistance and pollution resistance of the emulsion are improved, and minimum film forming temperature and other properties of the emulsion are reduced; the gel rate of emulsion polymerization is effectively reduced, and conversion rate and stability of the emulsion polymerization are improved.

Owner:NANCHANG UNIV

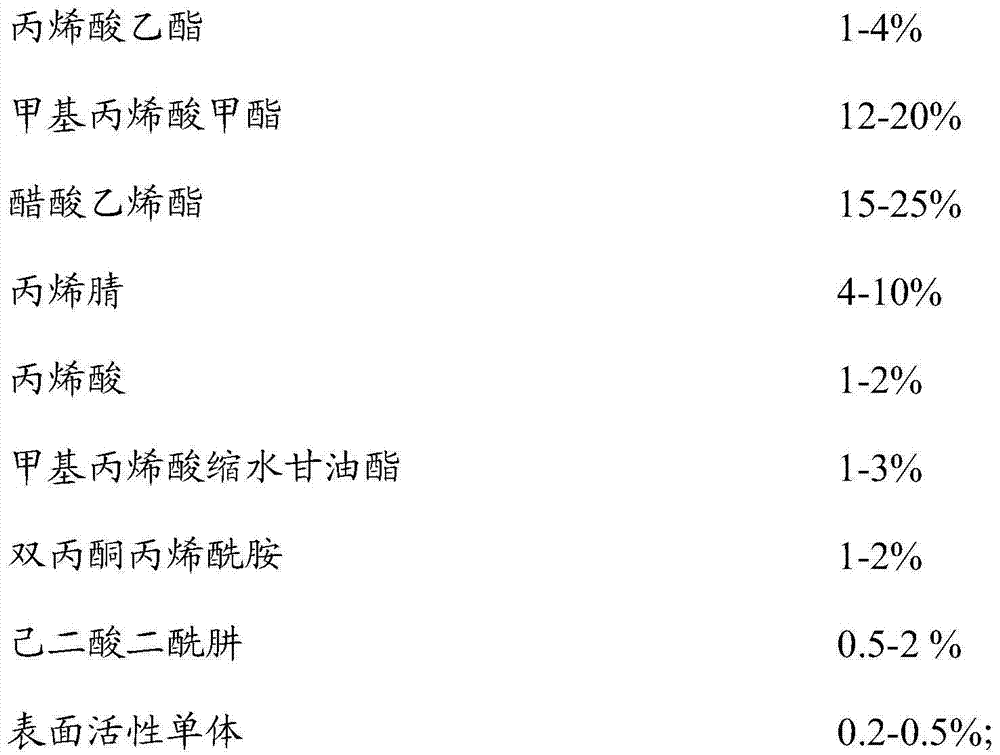

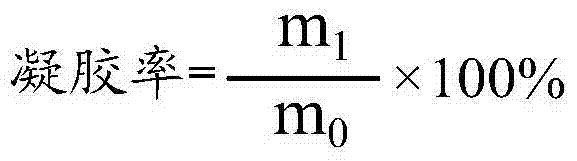

Preparing method of modified acrylate emulsion

A preparing method of a modified acrylate emulsion is disclosed. The modified acrylate emulsion is prepared by subjecting acrylate, methacrylate, vinyl acetate, acrylonitrile, acrylic acid, an organosilicone modified monomer, a crosslinking monomer, a surface active monomer, and the like to emulsion polymerization. The organosilicone modified monomer is linear organopolysiloxane containing alkenyl bonding to silicon. Polymerization is performed after the surface active monomer, the acrylate and / or the methacrylate are adopted to prepare a seed emulsion, thus reducing the using amount of an emulsifying agent, making polymerization stable and making the gel rate low.

Owner:SHENZHEN ANPIN SILICONE MATERIAL

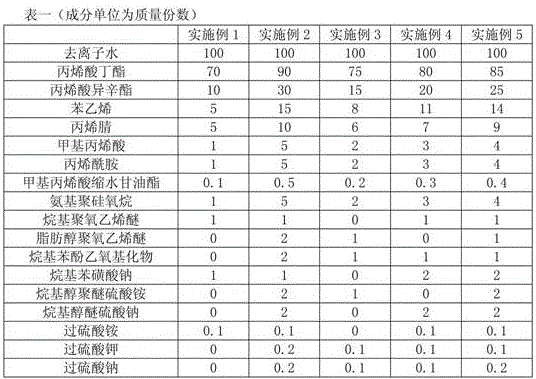

Acrylate elastic emulsion with excellent low-temperature breaking elongation and preparation method thereof

ActiveCN106632823AHigh elongation at breakImprove flexibilityCoatingsIsooctyl acrylateGlycidyl methacrylate

The invention discloses acrylate elastic emulsion with excellent low-temperature breaking elongation, comprising, by weight, 100 parts of deionized water, 70-90 parts of butyl acrylate, 10-30 parts of 2-ethylhexyl acrylate, 5-15 parts of styrene, 5-10 parts of acrylonitrile, 1-5 parts of methacrylic acid, 1-5 parts of acrylamide, 0.1-0.5 part of glycidyl methacrylate, 1-5 parts of aminopolysiloxane, 2-10 parts of an emulsifier, and 0.1-0.5 part of persulfate. The acrylate elastic emulsion has excellent low-temperature breaking elongation.

Owner:上海巴德富实业有限公司

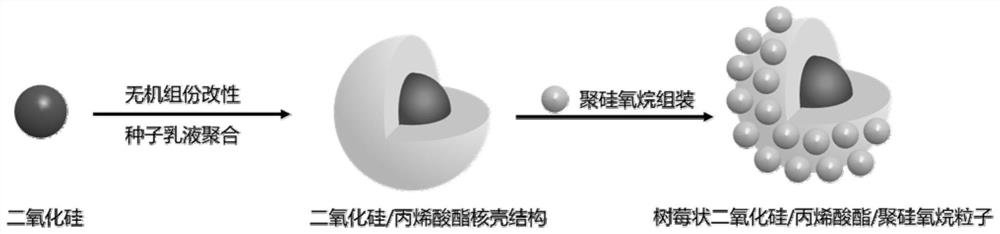

Silicon dioxide/polyacrylate/polysiloxane composite emulsion as well as preparation method and application thereof

ActiveCN112280043ALow gel rateEasy to prepareAntifouling/underwater paintsPaints with biocidesPolymer scienceSilicon oxide

The invention relates to a silicon dioxide / polyacrylate / polysiloxane composite emulsion as well as a preparation method and application thereof. The preparation method mainly comprises the steps of silica sol modification, preparation of silicon dioxide / acrylate core-shell structure emulsion and preparation of silicon dioxide / acrylate / polysiloxane composite emulsion. The preparation method comprises the following steps: firstly, modifying silica sol, then preparing a composite emulsion with a more stable silicon dioxide / acrylate system and a low gel rate (less than 0.5%) by utilizing a seed growth polymerization method, and introducing active groups such as amino and epoxy into acrylate, so that the composite emulsion can be effectively assembled and compounded with subsequently added polysiloxane nanoparticles. Therefore, the raspberry-shaped silicon dioxide / acrylate / polysiloxane organic-inorganic hybrid emulsion with excellent performance is prepared. A silica component in the particles of the emulsion provides hardness support; the acrylate provides a film-forming property; the polysiloxane provides weather resistance, color retention and stain resistance.

Owner:三棵树(上海)新材料研究有限公司

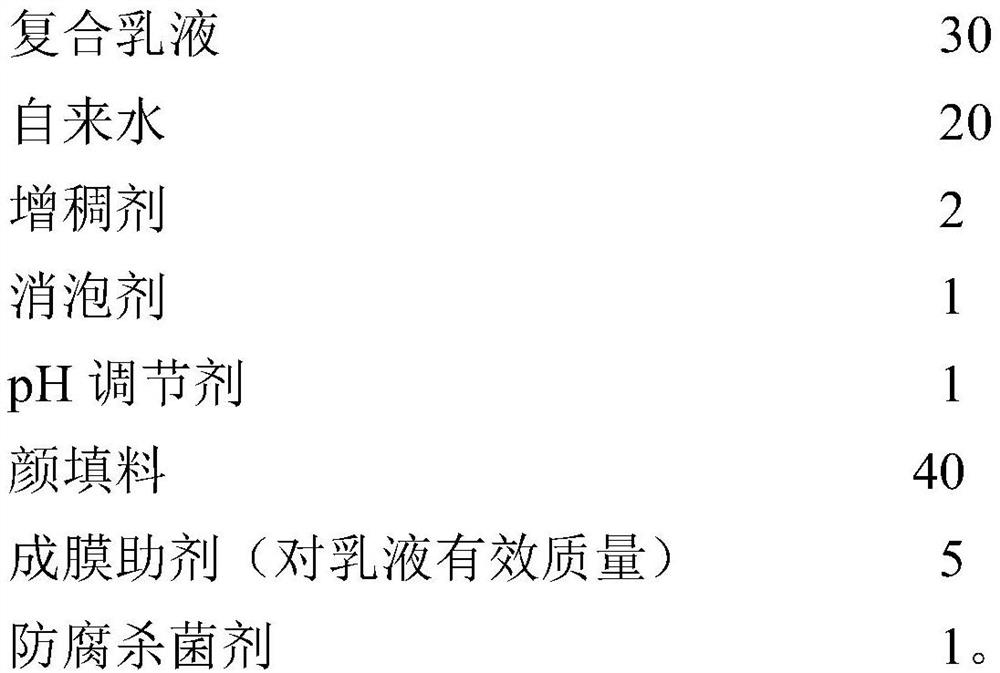

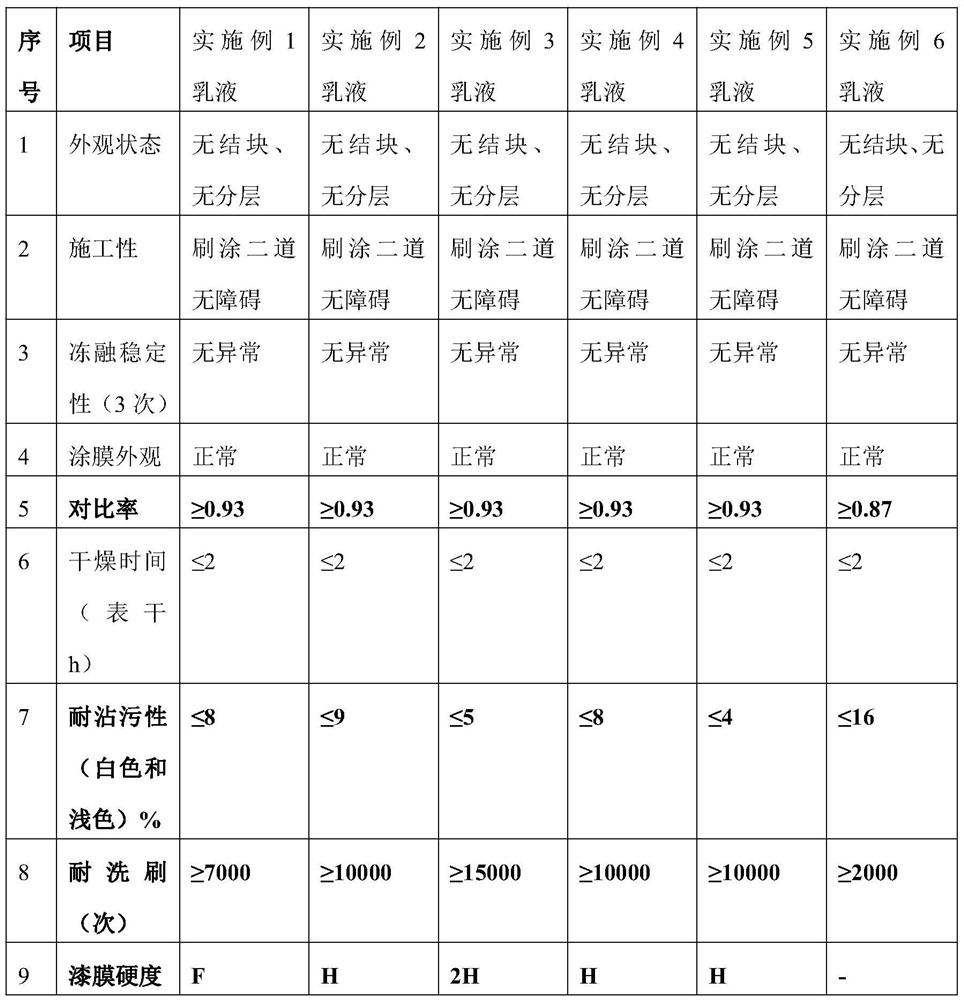

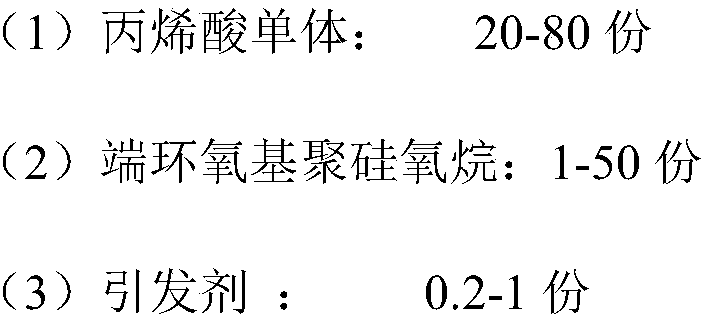

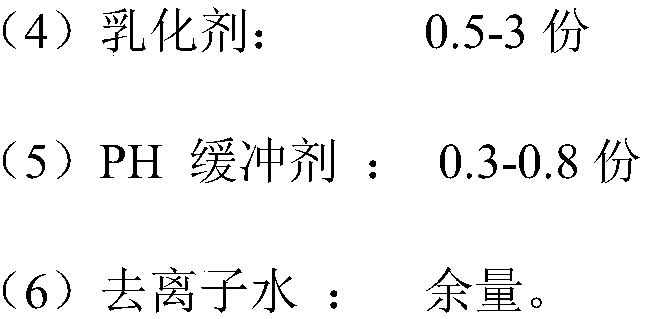

Organic silicon modified acrylic emulsion and preparation method thereof

The invention provides an epoxy organosiloxane modified acrylic emulsion and a preparation method thereof. The emulsion is specifically obtained by performing emulsion polymerization on an acrylic monomer, a single-end epoxy polysiloxane, an initiator, an emulsifier, a pH buffering agent and deionized water, wherein epoxy organosiloxane is a linear organopolysiloxane having an epoxy group bonded to silicon at one end. The invention further provides the preparation method of the modified acrylate emulsion; and the method comprises the steps of dissolving the single-end epoxy polysiloxane by using the acrylic monomer, preparing a pre-emulsion by emulsification, preparing a seed emulsion from acrylate and / or methacrylate and the emulsifier, and adding the pre-emulsion dropwise into the seed emulsion to complete the polymerization reaction. According to the method provided by the invention, the emulsion obtained by the method has good adhesion, surface hand feel, water resistance and stainresistance.

Owner:GUANGZHOU SILOK POLYMER

Polyolefin/styrene series elastomer blending shape memory material and preparation method thereof

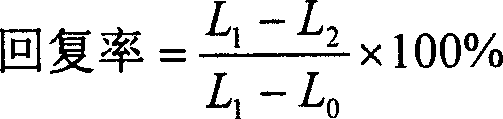

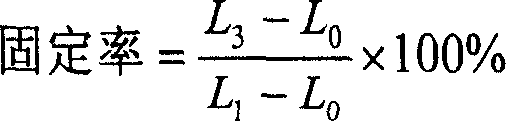

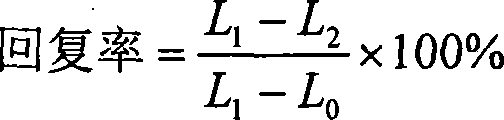

The present invention discloses shape memory material of co-mixed polyolefin / styrene elastomer. The shape memory material contains polyolefin 20-80 weight portions, styrene elastomer 20-80 weight portions, plasticizer 10-30 weight portions, chemical crosslinking agent 0.1-1 weight portions and co-crosslinking agent 1-10 weight portions. It has tensile strength not lower than 12 MPa, gel rate not higher than 10 wt%, restoring rate at 100 deg.c 80 not lower than wt%, fixing rate at 20 deg.c not lower than 80 wt%, restoring response temperature not lower than 30 deg.c and restoring period not more than 6 sec. The present invention also discloses the preparation process of the shape memory material.

Owner:SICHUAN UNIV

Core-shell type polysilsesquioxane/hydroxyl acrylate composite emulsion and preparation method thereof

The invention discloses core-shell type polysilsesquioxane / hydroxyl acrylate composite emulsion and a preparation method thereof. The preparation method comprises the following steps: by taking polysilsesquioxane as the core, performing cross-linking entanglement on a silane coupling agent polymer and an internal layer in the middle; by taking a hydroxyl functional monomer as a main functional monomer on the shell layer, performing copolymerization with other acrylic monomers, thereby obtaining the 'hard-core soft-shell' water-based hydroxyl acrylate emulsion. The composite emulsion disclosedby the invention is composed of three parts, namely the core, the intermediate layer and the shell, the core is the polysilsesquioxane prepared from trialkoxysilane and a vinylsilane coupling agent; the intermediate shell is a copolymer of an acrylic monomer and the vinylsilane coupling agent; the vinylsilane coupling agent accounts for 3-10wt% of the mass of the total monomer on the intermediatelayer; the component of the shell layer is a copolymer of a hydroxyl functional monomer and an acrylic monomer; and the hydroxyl functional monomer accounts for 10-50wt% of the amount of the total monomer. Due to the existence of the hydroxyl functional monomer, the composite emulsion has excellent mechanical property after curing, and has excellent properties such as high adhesive force of plastics.

Owner:BEIJING UNIV OF CHEM TECH

Polyolefin/styrene series elastomer/conductive carbon black electro shape memory material and preparation method thereof

The invention discloses a polyolefine / styrene system elastomer / graphitized carbon black electro-shaped memory material, which is characterized in that the components of the material by weight are: polyolefine 20-40 portions, styrene system elastomer 30-40 portions, graphitized carbon black 18-22 portions, plasticizer 6-10 portions, cross linker 0-2 portions and auxiliary cross linker 0-10 portions, the elongation at break is 300-550 percent, recovery (150-200V AC) 80-95 percent, fixed ratio (20 DEG C) 80-96 percent, recovery responding temperature 60-100 DEG C and recovery time 20-80s. The invention further discloses a preparation method of the material. The electro-shaped memory material of the invention not only has good memory performance, low cost and good comprehensive mechanical property, but also has good processing property, thereby being processed repeatedly, which is favorable for recycling. The raw material used in the method of the invention has low cost and simple technique, thereby needing no special processing equipment and being easy to be popularized and applied.

Owner:SICHUAN UNIV

Preparation method of compound organic silicon modified core-shell styrene acrylic latex

InactiveCN109942736AAvoid problemsImprove conversion rateDyeing processCoatingsPotassium persulfateIsooctyl acrylate

The invention relates to a preparation method of a compound organic silicon modified core-shell styrene acrylic latex. The styrene acrylic latex is prepared from the following raw material in parts byweight: 50-80 parts of styrene, 20-40 parts of butyl acrylate, 15-35 parts of iso-octyl acrylate, 2-6 parts of a compound emulsifying agent, 1-8 parts of compound organic silicon, 0.2-0.6 part of butyl acrylate, 0.2-1.2 parts of potassium persulfate, 0.2-0.6 part of isopropanol and 100-200 parts of deionized water. According to the universal compound organic silicon modified styrene acrylic latex, the deficiencies of a single organic silicon modified styrene acrylic latex can be made up, and the weather resistance is improved; and by utilizing a semi-continuous core-shell emulsion polymerization technique, the gel rate of the emulsion can be decreased in the polymerization process, and the prepared latex can be applied to printing coatings.

Owner:QINGDAO UNIV OF SCI & TECH

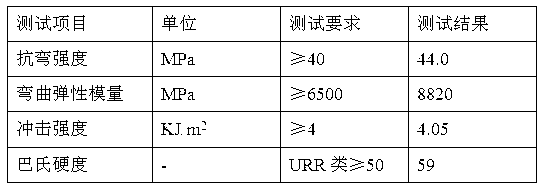

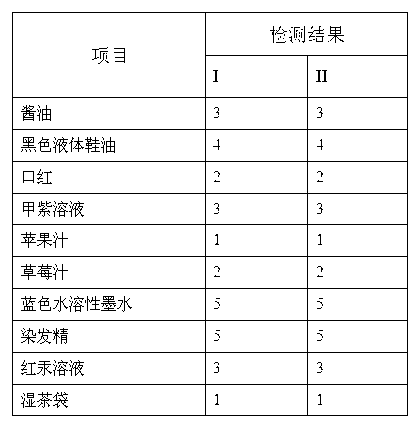

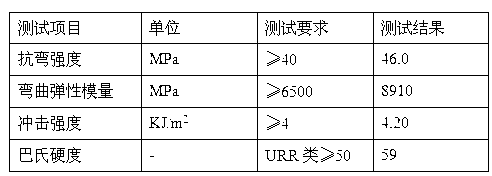

Styrene-acrylic emulsion for manufacturing artificial stone, preparation method, and artificial stone prepared from styrene-acrylic emulsion

The invention provides a styrene-acrylic emulsion for manufacturing artificial stone for solving the problems of lots of harmful VOCs (volatile organic compounds) existing in artificial stone, as well as high shrinkage percentage, low flame retardance, bad corrosion resistance, low hardness and the like of products, and provides a preparation method for the emulsion, and artificial stone prepared from the emulsion. The artificial stone is excellent in chemical corrosion resistance, pollution resistance, heat resistance and water resistance, and great in hardness.

Owner:广东海顺新材料科技有限公司

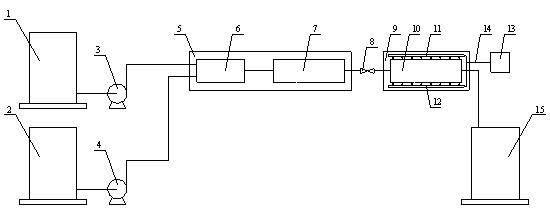

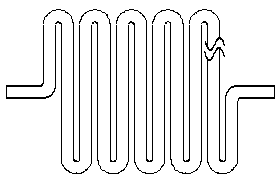

Microreaction method and device for continuous preparation of low-dispersion acrylic resin

PendingCN109762103AIncrease contact areaIncrease viscosityChemical/physical/physico-chemical processesAcrylic resinMechanical property

The invention discloses a microreaction method and device for continuous preparation of low-dispersion acrylic resin. The microreaction method includes the steps: an acrylic monomer solution and an initiator solution are transported into a micromixer through a metering pump to be mixed evenly according to the condition that the molar ratio of an acrylic monomer to an initiator is (40 to 200):1; mixed liquor discharged from the micromixer enters a delayed reaction channel to react for 3-15 min, the temperature in the micromixer and the delayed reaction channel is 60-140 DEG C, and the reactionpressure is 0.1-1 MPa; and mixed liquor discharged from the delayed reaction channel enters a quenching reaction channel, the mixed liquor in the quenching reaction channel is subjected to ultrasonicprocessing, the dwell time is 1-3 min, and the low-dispersion acrylic resin is obtained. According to the microreaction method and device for continuous preparation of the low-dispersion acrylic resin, molecular weight distribution coefficients are narrow, impurities are less, the batch is stable, mechanical performance is excellent, the reaction time is short, and energy consumption is low.

Owner:GUIZHOU MICRO CHEM TECH CO LTD

Acrylate emulsion for plastic base materials and method for preparing acrylate emulsion

InactiveCN108570123AIncrease the degree of cross-linkingHigh hardnessCoatingsOrganic acidFunctional monomer

The invention discloses acrylate emulsion for plastic base materials. The acrylate emulsion comprises, by weight, 40-60 parts of deionized water, 10-20 parts of butyl acrylate, 25-35 parts of methyl methacrylate, 5-10 parts of styrene, 2-5 parts of hydrophilic unsaturated organic acid, 1-3 parts of functional monomers, 1-3 parts of surfactants, 0.1-1 part of initiators and 1-3 parts of pH (potential of hydrogen) regulators. The invention further provides a method for preparing the acrylate emulsion. The acrylate emulsion and the method have the advantage that the acrylate emulsion prepared bythe aid of the method is excellent in adhesion, solvent resistance, chemical resistance, water resistance, gloss fullness and paint preparation tolerance.

Owner:佛山市顺德区巴德富实业有限公司

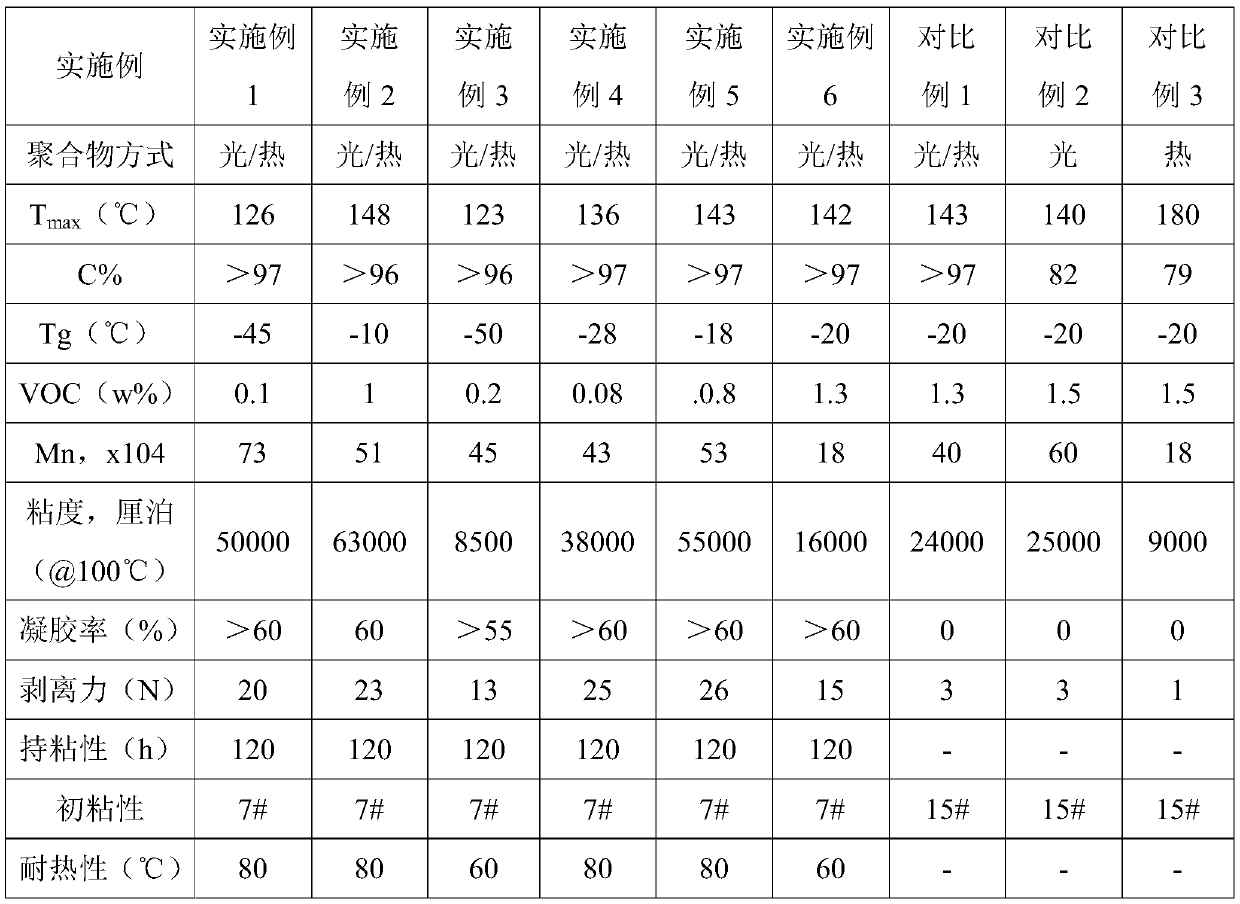

Photo-thermal free radical polymerization preparation method and application of vinyl polymer

InactiveCN110423304ARapid rise in temperatureShort reaction timeEster polymer adhesivesN-vinyl-pyrrolidone polymer adhesivesPolymer scienceReaction temperature

The invention discloses a photo-thermal free radical polymerization preparation method of a vinyl polymer and an application of the polymer. The method uses a photo / thermal composite initiator to initiate polymerization of a vinyl monomer, firstly a photoinitiated polymerization reaction is performed, and a thermal polymerization reaction is performed after the thermal polymerization reaction temperature is achieved. The method for preparing the vinyl polymer provided by the invention can reduce energy consumption, reduce reaction time, and improve production efficiency, and the product has amore uniform structure, better performance, a lower gelation rate or even no gel and a higher conversion rate of the monomer; and the vinyl polymer prepared by the method can be used for coating and photocrosslinking products.

Owner:成都辉聚光电材料有限公司

Synthetic method of waterproof acrylate emulsion

The invention discloses a synthetic method of a waterproof acrylate emulsion. The synthetic method comprises the following steps: 1) 2-8 parts by weight of an emulsifier and 50-70 parts by weight of water are placed in an emulsification kettle, 10-25 parts of an acrylic monomer are added for polymerization after the emulsifier is dissolved, and a pre-emulsion is obtained; 2) 0.2-1.0 part of the emulsifier and 8-10 parts of the water are placed into a reaction kettle and heated to 85-90 DEG C, 50-60 parts of the pre-emulsion, 0.2-1.0 part of an initiator and 2-5 parts of a silane coupling agent KBM-503 are added, the mixture reacts under a heat preservation condition for 1-2 h, then the temperature is reduced to 65-75 DEG C, reaction is performed under the heat preservation condition for 20-60 min, cooling is performed, the pH value of a reactant is regulated to 8-9, filtering is performed, and a product is obtained, wherein the emulsifier comprises 30%-50% by mass of DSB and the balance of the emulsifier OP-10. The emulsion has good stability and lower gel rate and only contains very few coagula.

Owner:GUILIN HEXIN WATERPROOF DECORATION MATERIAL

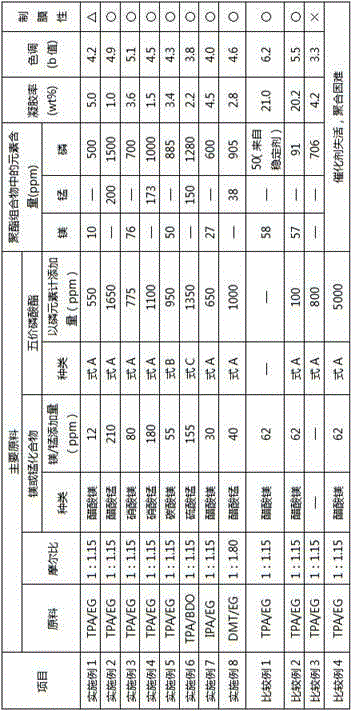

Polyester composition, and preparation method and applications thereof

The invention discloses a polyester composition, and a preparation method thereof. The polyester composition is mainly prepared via reaction of an aromatic dibasic acid or an esterification product of the aromatic dibasic acid with an aliphatic dihydric alcohol; contains 500 to 1500ppm of a pentavalent phosphate based on the amount of phosphorus element in the amount of the polyester composition, and 10 to 200ppm magnesium element or manganese element based on the total amount of the polyester composition. Gelation rate of the polyester composition after thermal treatment at 300 DEG C in a nitrogen oxygen gas mixture with oxygen concentration of 1% is lower than 5wt%. The polyester composition can be applied to the field of thin films.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Preparation method of silicone-modified DNRL grafted copolymer

InactiveCN109970918AImprove antibacterial propertiesGood biocompatibilityPolymer scienceBiocompatibility Testing

The invention relates to a preparation method of a silicone-modified DNRL (deproteinized natural rubber latex) grafted copolymer. Raw materials of the silicone-modified DNRL grafted copolymer comprise, by weight, 40-80 parts of DNRL (w = 30%), 10-20 parts of a hard monomer, 1-5 parts of a silicone monomer, 10-30 parts of deionized water, 0.05-0.2 part of an initiator and 0.3-0.8 part of an emulsifier. NRL is deproteinized, and then interacts with lipids to improve the antibacterial property and biocompatibility of the natural rubber, so the DNRL can be applied in the field of medical treatmentand public health. The silicone monomer is added in the later stage of grafting of styrene with the DNRL, so the tensile property, the weather resistance and the hydrophobic property of the DNRL grafted copolymer are improved. The method adopting a semi-continuous seed emulsion polymerization process has the advantages of increase of the grafting rate and the conversion rate of the DNRL, green and environmentally-friendly process and broad application prospect.

Owner:QINGDAO UNIV OF SCI & TECH

External wall elastic emulsion with antistatic effect and method for preparing external wall elastic emulsion

InactiveCN108148478AThe number of hydroxyl groups increasedImprove hydrophilicityAntifouling/underwater paintsPaints with biocidesIsooctyl acrylateFunctional monomer

The invention discloses external wall elastic emulsion with an antistatic effect and a method for preparing the external wall elastic emulsion. The external wall elastic emulsion comprises, by weight,90-120 parts of deionized water, 10-30 parts of iso-octyl acrylate, 60-80 parts of butyl acrylate, 20-35 parts of styrene, 5-15 parts of methyl methacrylate, 0.1-2 parts of acrylic acid, 0.1-1.5 parts of methacrylic acid, 0.1-1 part of acrylamide, 0-0.5 part of methacrylamide, 0-0.5 part of hydroxyethyl acrylate, 3-10 parts of acrylonitrile, 0.5-3 parts of acid anhydride functional monomers, 0.5-4 parts of diethanolamine, 0.1-3 parts of modified organophosphate high polymers, 1-8 parts of emulsifiers, 0.1-5 parts of initiators and 0.3-4.5 parts of ammonia water. The external wall elastic emulsion and the method have the advantages that the antistatic effect can be realized by the external wall elastic emulsion, the external wall elastic emulsion is excellent in stain resistance, and the excellent normal-temperature and low-temperature elasticity of the external wall elastic emulsion can be kept.

Owner:上海巴德富实业有限公司

Method for manufacturing grin lens

ActiveUS20110107794A1High porosityIncrease productionOptical articlesGlass shaping apparatusDopantPolymer science

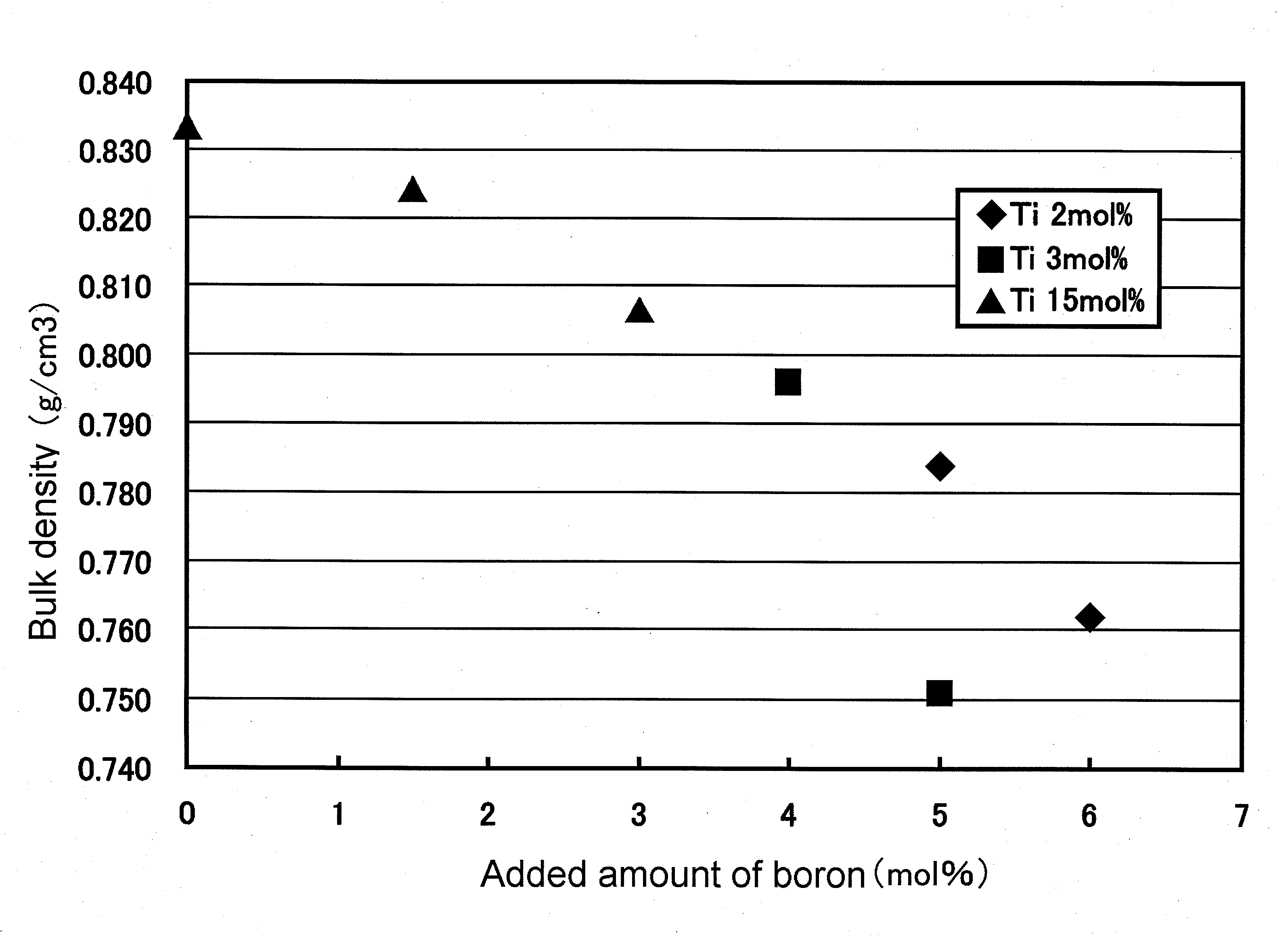

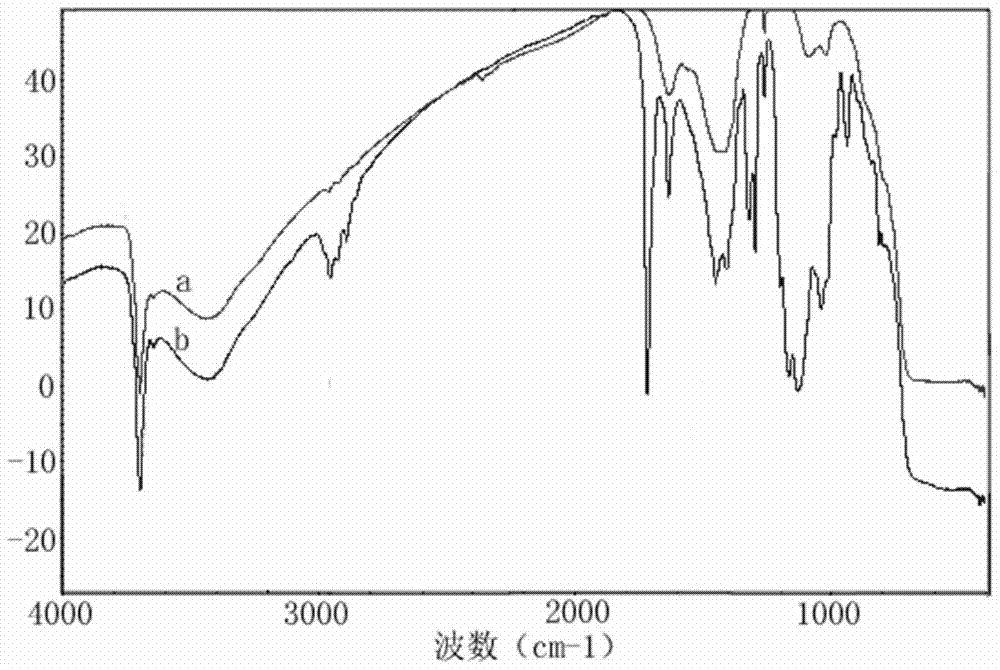

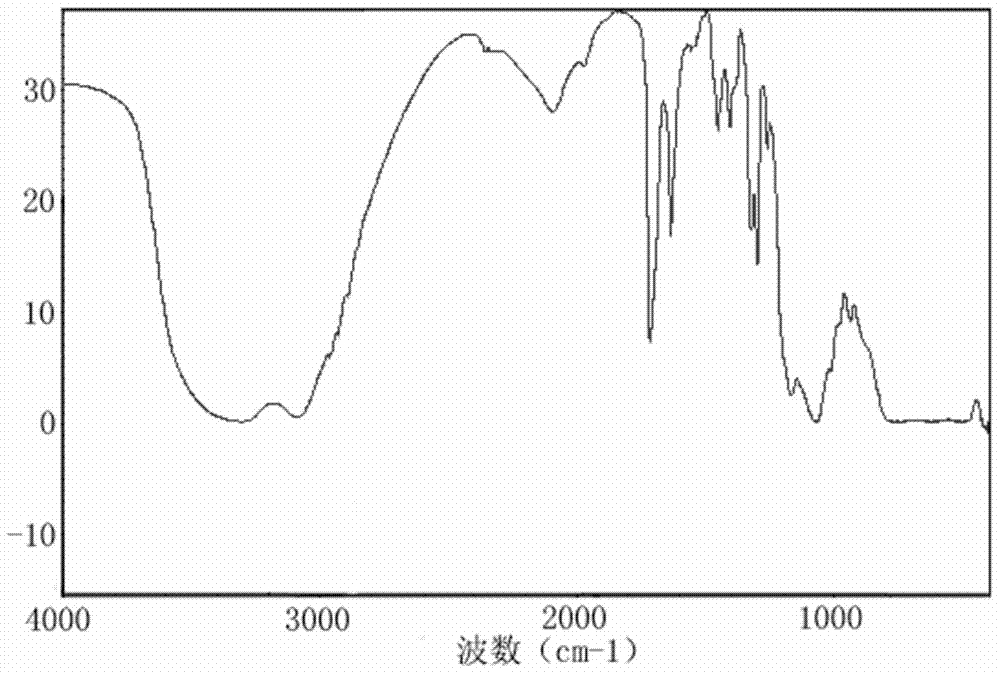

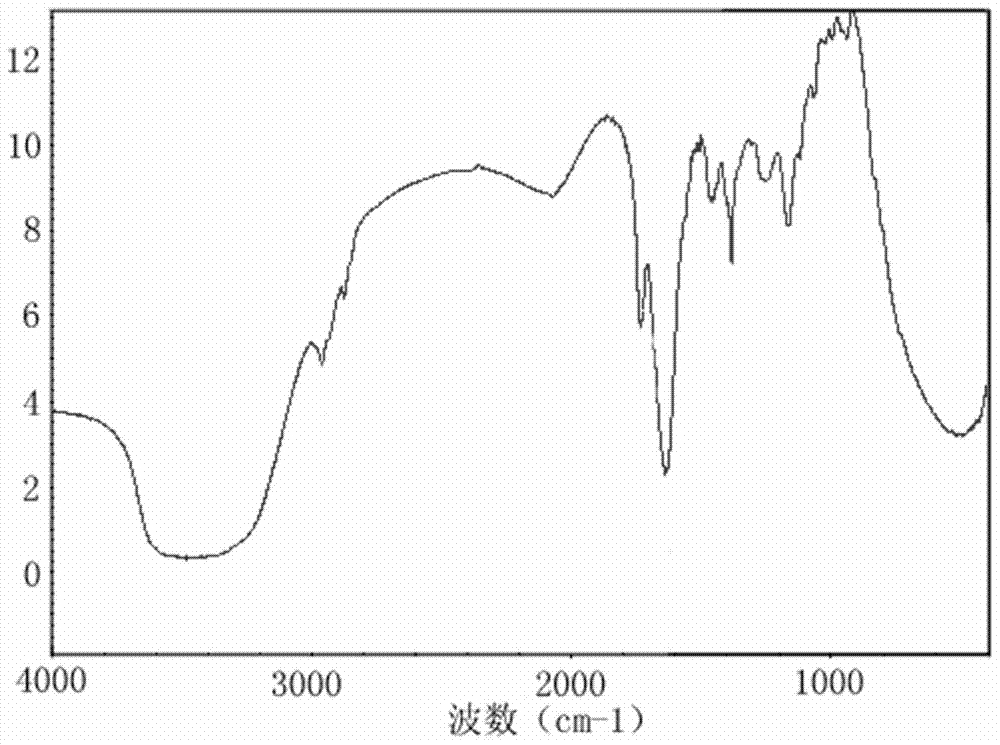

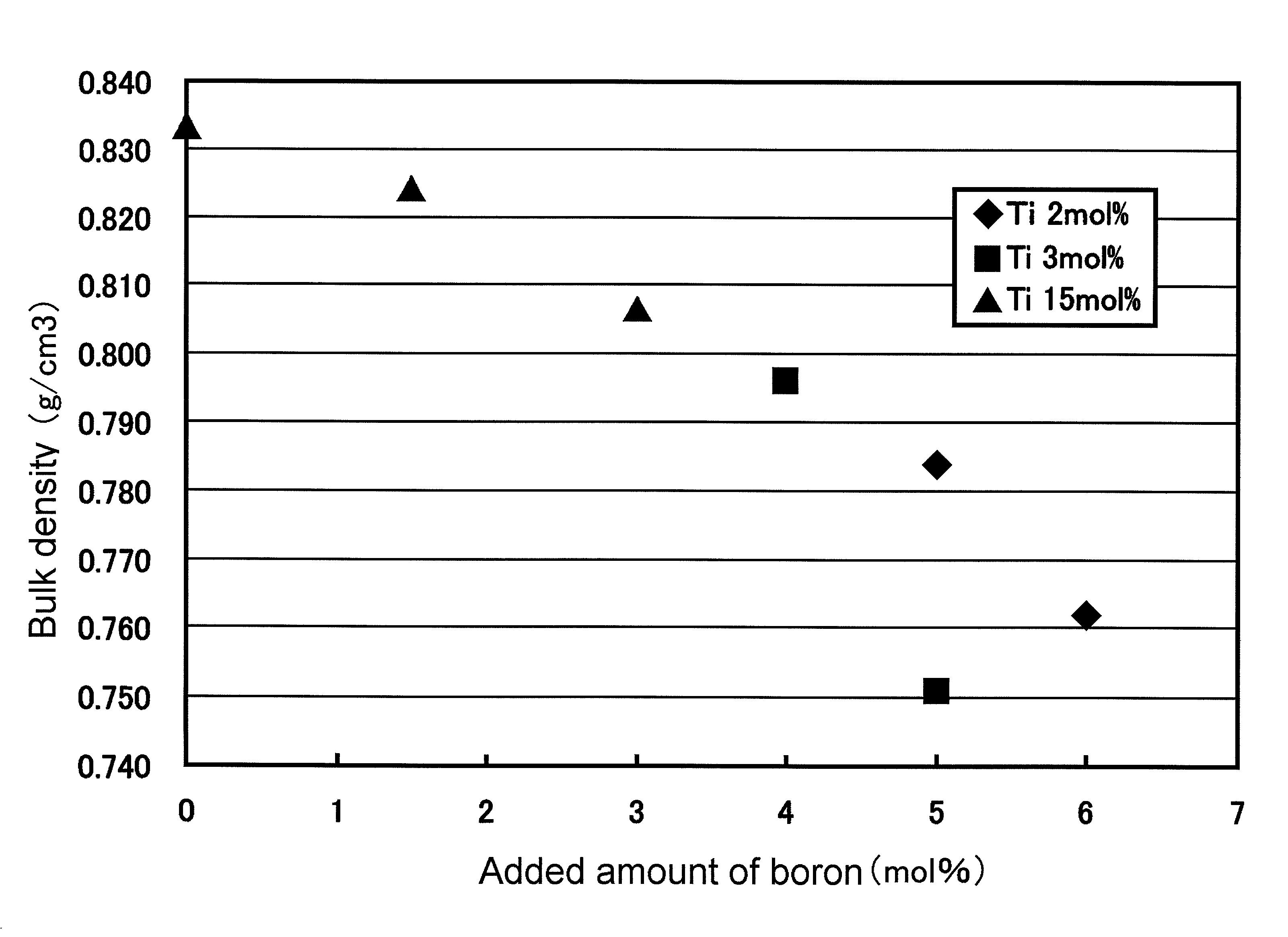

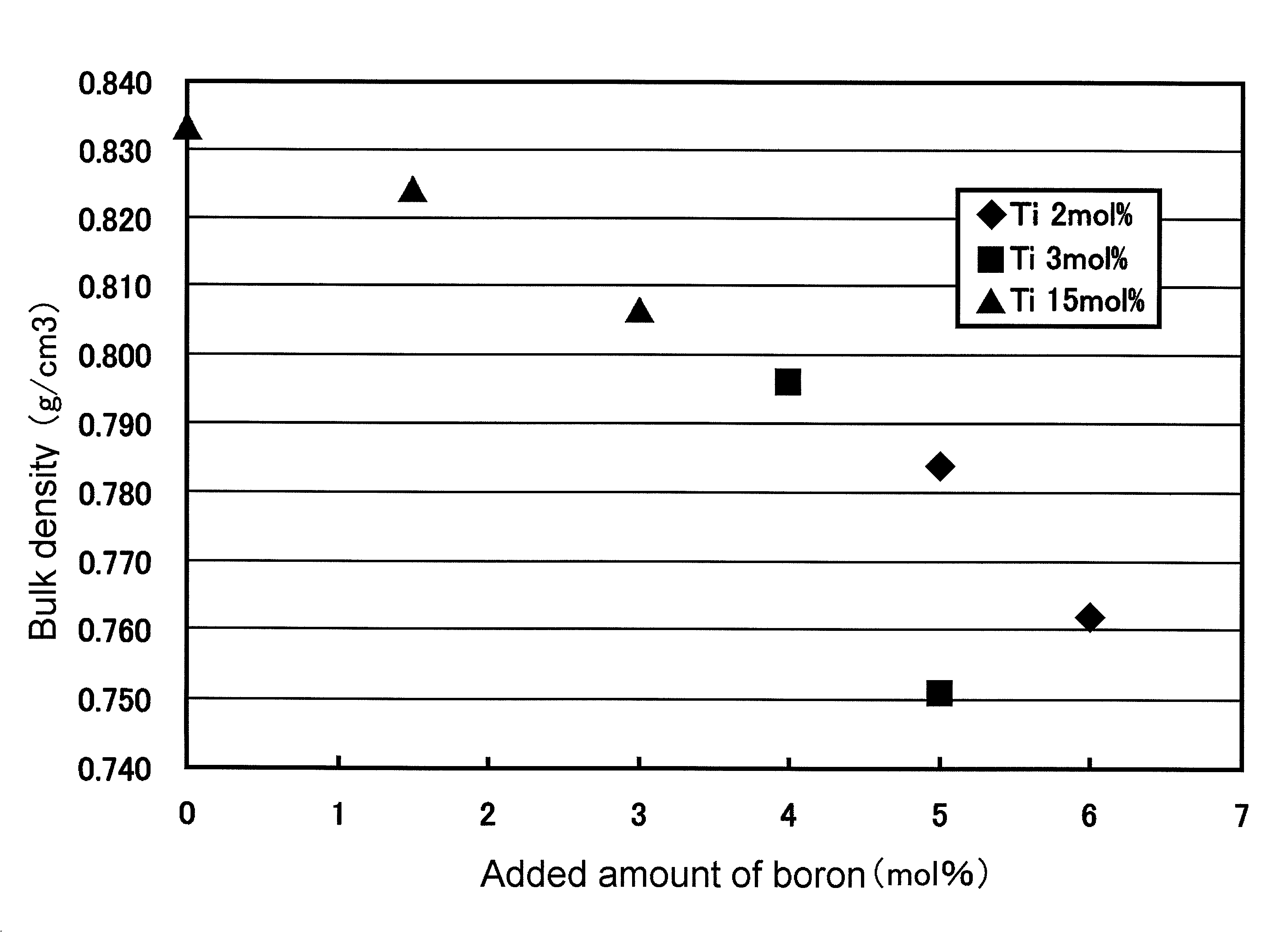

[Object] In manufacturing a GRIN lens by a sol-gel method, an operation for preparing a wet gel is facilitated and cracking in a base material during sintering and foaming during drawing are prevented.[Solution] The object is achieved by obtaining a GRIN lens by producing a wet gel from an alcohol solution containing a silicon alkoxide, a dopant alkoxide, and a boron alkoxide as the main ingredients, leaching the same, drying the same to form a dry gel, and sintering and drawing the same.

Owner:TOYO SEIKAN GRP HLDG LTD

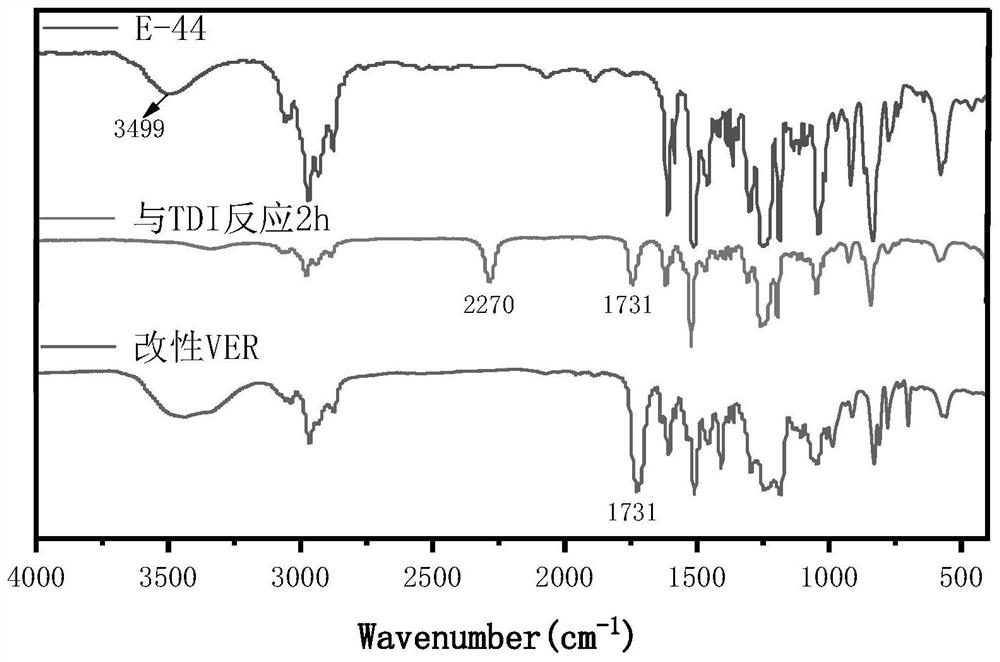

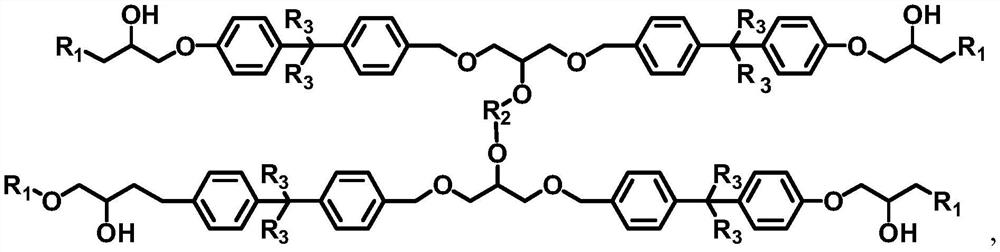

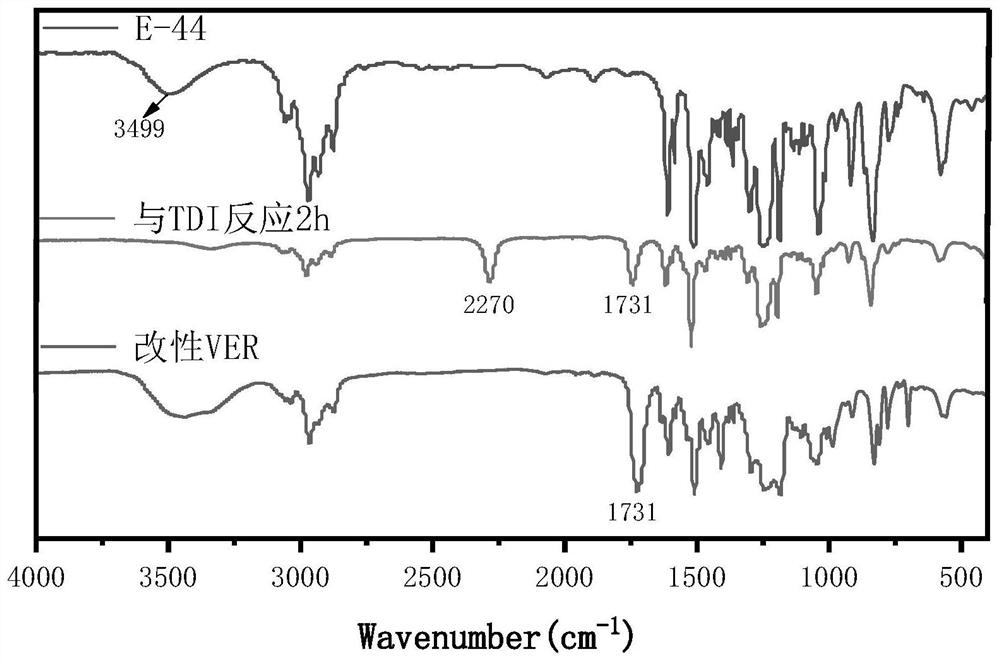

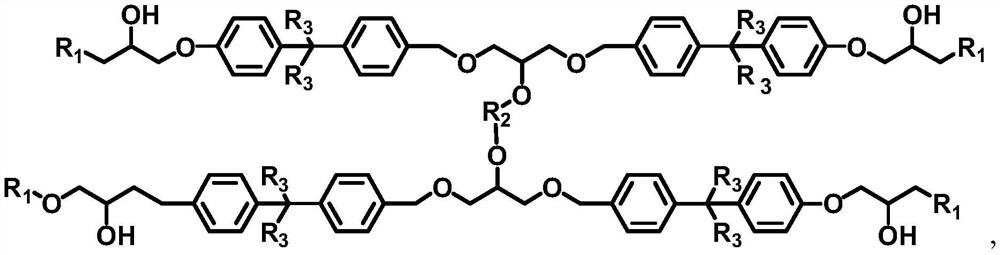

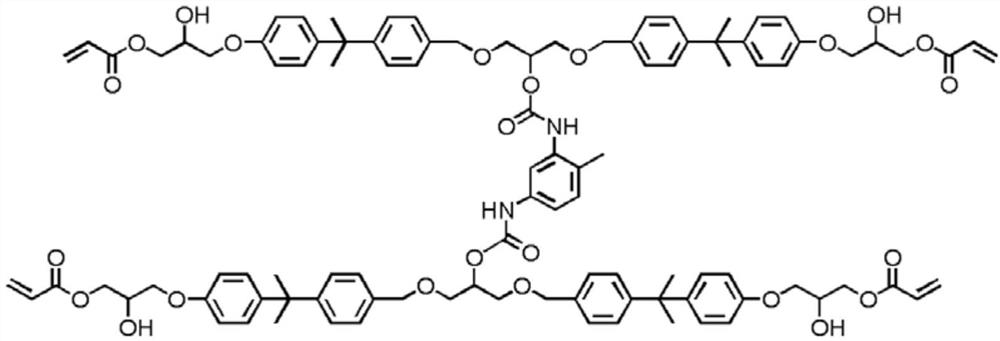

Modified vinyl ester resin and preparation method thereof, toughened and modified vinyl ester resin with good air-drying property, and preparation method and application of toughened and modified vinyl ester resin

The invention belongs to the technical field of high polymer materials, and particularly relates to modified vinyl ester resin and a preparation method thereof, toughened and modified vinyl ester resin with good air-drying property, and a preparation method and application thereof. The preparation method comprises the following steps: carrying out chain extension reaction on epoxy resin and diisocyanate in the presence of a catalyst, reacting unsaturated monobasic acid with an epoxy group, and adding a reactive diluent after the reaction is completed to obtain modified vinyl ester resin; and mixing the plant oil-based oligomer with the modified vinyl ester resin in proportion to obtain the toughened and modified vinyl ester resin with good air-drying property. The modified vinyl ester resin and the toughened and modified vinyl ester resin with good air-drying property not only have good air-drying property and high curing speed, but also have excellent mechanical properties and corrosion resistance.

Owner:SOUTH CHINA AGRI UNIV +1

Polyester modified core shell self crosslinking styrene-acrylate emulsion and preparation method thereof and anticorrosion coating therewith

InactiveCN101659735BImprove adhesionIncrease calcium ion stabilityAnti-corrosive paintsPolyesterSodium Bentonite

The invention relates to a polyester modified core shell self crosslinking styrene-acrylate emulsion and a preparation method thereof and an anticorrosion coating therewith, wherein polyester with multi-branched structure and containing carboxyl is introduced into the core shell of the latex particle of the styrene-acrylate emulsion; the Tg of the shell layer is -30-0 DEG C and the Tg of the corelayer is 10-80 DEG C; in a monomer composing the core layer of the latex particle, a functional monomer containing glycidyl accounts for 0.5-3 percent; and in a monomer composing the shell layer of the latex particle, polyester accounts for 5-20 percent, and a functional monomer containing carboxyl accounts for 1.5-5 percent. The stability of calcium ions in the emulsion is obviously improved; and the anticorrosion coating containing the styrene-acrylate emulsion has the formula (by weight parts): 40-50 of the styrene-acrylate emulsion, 10-30 of ferrotitanium powder, 20 of iron oxide red, 12-20 of kaolin, 10-30 of bentonite and 0.1-1 of dispersing agent. The compactness and hardness and the compositive corrosion resistance of the coating are obviously improved for the polyester introducedinto the latex particle and the self crosslinking structure.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +1

A kind of bulk flame-retardant acrylate emulsion and its preparation method and application

The invention discloses a preparation method of ingrain fireproofing type acrylate emulsion. The preparation method of the ingrain fireproofing type acrylate emulsion comprises the following steps: adding vinyl silane into ethyl alcohol dispersed with metal hydroxide flame retardant particles for reacting, so that vinyl silane is grafted on the surfaces of the metal hydroxide flame retardant particles, namely flame retardant metal hydroxide functional monomers are obtained; and carrying out emulsion polymerization on the flame retardant metal hydroxide functional monomers and polymeric monomers including acrylic acid monomers and / or acrylate monomers, so that the ingrain fireproofing type acrylate emulsion with high solid content, low gel rate and good stability is obtained. The ingrain fireproofing type acrylate emulsion can be used for preparing latex paint with good flame retardant property and mechanical properties.

Owner:HUNAN INST OF TECH +1

Method for manufacturing grin lens

ActiveUS8763430B2High porosityIncrease productionGlass shaping apparatusOptical light guidesDopantAlcohol

[Object] In manufacturing a GRIN lens by a sol-gel method, an operation for preparing a wet gel is facilitated and cracking in a base material during sintering and foaming during drawing are prevented.[Solution] The object is achieved by obtaining a GRIN lens by producing a wet gel from an alcohol solution containing a silicon alkoxide, a dopant alkoxide, and a boron alkoxide as the main ingredients, leaching the same, drying the same to form a dry gel, and sintering and drawing the same.

Owner:TOYO SEIKAN GRP HLDG LTD

A preparing method for polyester composition

The invention discloses a preparing method for a polyester composition. An esterification reaction between aromatic dicarboxylic acid and aliphatic dihydric alcohol is firstly performed in the method;an antimony compound, an inorganic acid containing phosphorus, or an organic compound containing phosphorus and phosphoric acid alkali metal salt are added to the reaction system from the end of esterification reaction to the beginning of a polymerization reaction to begin the polymerization reaction; in the time period from the inherent viscosity of the polymerized reactant reaching 0.5dl / g to the end of the polymerization reaction, a manganese compound is added to the reaction system to the continue the polymerization reaction until the end of the polymerization reaction. The gel fraction of the polyester composition prepared through the method is under 5wt% in a N2 / O2 gas mixture (oxygen concentration is 1 vol%) after thermal treatment of 300DEG C * 6hr and the polyester composition can be used for preparing thin films and fibers with little foreign material.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

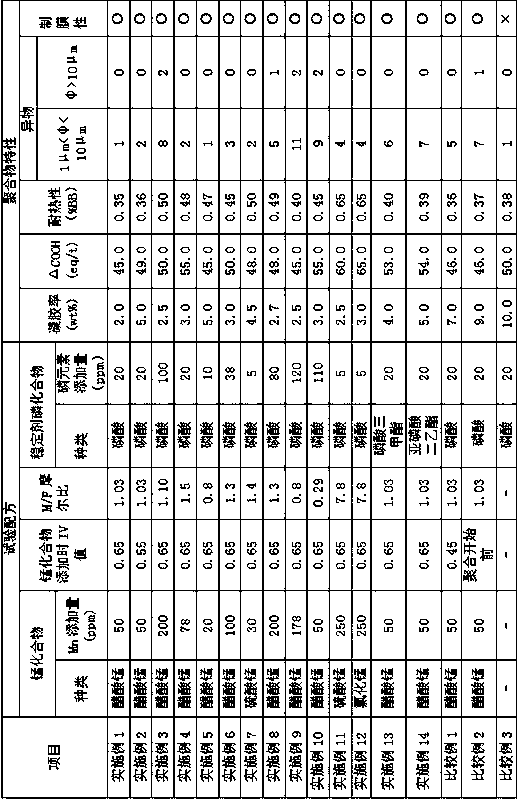

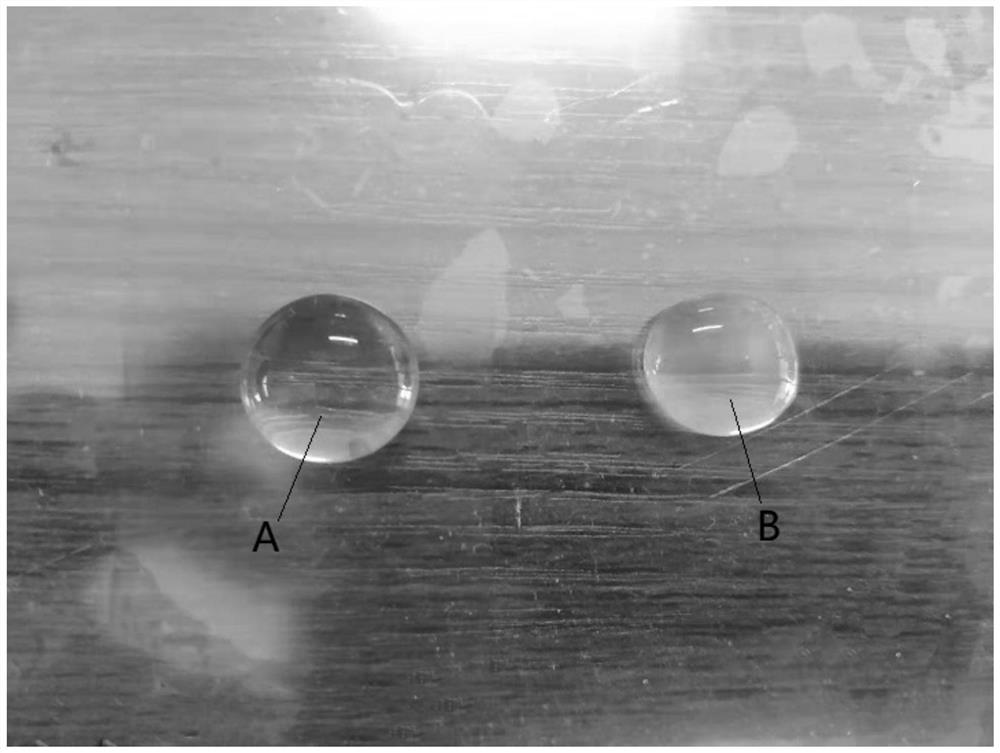

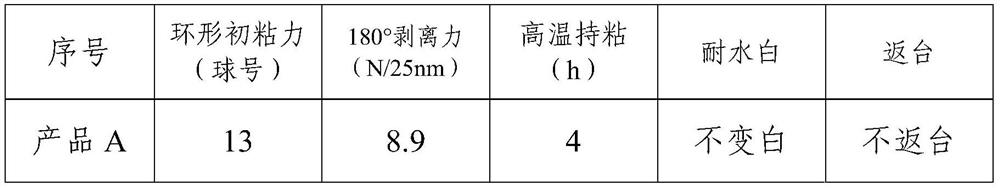

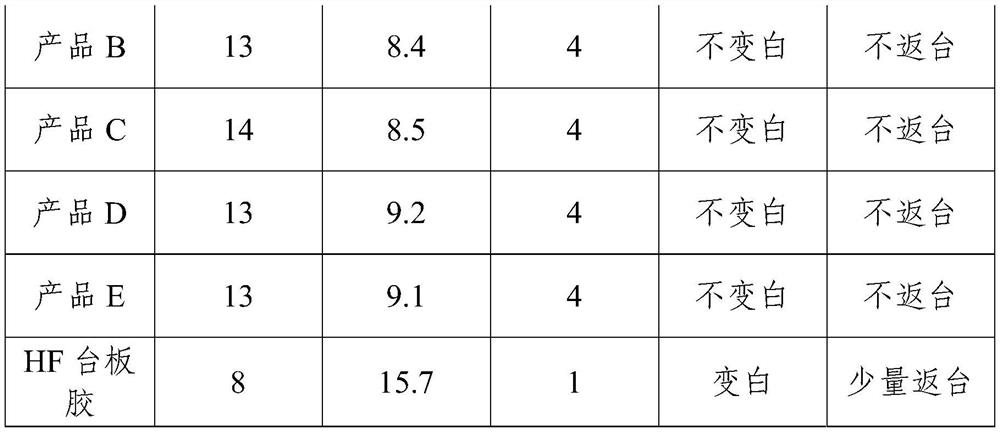

Preparation method and application of organic silicon modified acrylate bedplate glue

ActiveCN112662345AImprove hydrophobicityGuaranteed thermal stabilityEster polymer adhesivesIsooctyl acrylateSodium bicarbonate

The invention discloses a preparation method of organic silicon modified acrylate bedplate glue. The bedplate glue is prepared from the following components in parts by weight: 200-380 parts of ionized water, 4-5 parts of anionic emulsifier, 120-160 parts of butyl acrylate, 80-120 parts of isooctyl acrylate, 20-30 parts of methyl methacrylate, 10-20 parts of styrene, 2-5 parts of acrylic acid, 2-5 parts of acetylated modified acrylic acid self-crosslinking monomer, 2-4 parts of vinyltriisopropoxysilane, 0.05-0.1 part of potassium persulphate, 0.4-0.6 part of sodium bicarbonate 0.5-1 part of a cohesion accelerator SA500, 0.1-0.2 part of an anantiseptic agent, 0.1-0.2 part of a water-based defoaming agent and 0.5-1 part of an associative thickener; and the pH value is adjusted to 7-8 with ammonia water. The bedplate glue can be applied to high-temperature and high-humidity resistant environments such as a flat screen machine, an elliptical machine and an octopus machine in machine printing. The product provided by the invention has higher moisture resistance and thermal stability and higher yellow resistance and high temperature resistance, and an emulsion has higher strength and heat resistance and has high viscosity but no reverse adhesion.

Owner:LIAONING FIXED STAR FINE CHEM

Polyester composition, preparation method therefor and use of polyester combination

The invention discloses a polyester composition and a preparation method therefor. The polyester composition is prepared through carrying out melt blending on polyester and a trivalent phosphorous compound. The polyester composition contains, relative to the total weight of the polyester composition, 10ppm to 200ppm of magnesium or manganese and 600ppm to 10,000ppm of phosphorus, and the gel ratio of the polyester composition is lower than 5wt% after the polyester composition is subjected to heat treatment at the temperature of 300 DEG C in a nitrogen-oxygen gas mixture, of which the oxygen gas concentration is 1%. The polyester composition can be applied to the field of films and the like.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Single-component water-based silicon-fluorine modified acrylate emulsion wood lacquer and preparation method thereof

ActiveCN113980502AEasy to gatherSelf-aggregation controlCoatingsSodium bicarbonate(Hydroxyethyl)methacrylate

The invention discloses a single-component water-based silicon-fluorine modified acrylate emulsion wood lacquer and a preparation method thereof. The preparation method comprises the following steps: S1, weighing a certain amount of water, an emulsifier, butyl acrylate, methyl methacrylate, acrylonitrile, styrene, acrylic acid and hydroxyethyl methylacrylate; S2, mixing the raw materials to obtain a pre-emulsion A; S3, mixing a part of the pre-emulsion A, vinyl triisopropoxy silane and a silicon-fluorine modified resin to obtain an organic silicon-fluorine pre-emulsion B; S4, mixing water, part of the pre-emulsion A, ammonium persulfate and sodium bicarbonate to obtain a solution, heating the solution to 80-85 DEG C, and stirring until the solution presents blue light; S5, adding an ammonium persulfate aqueous solution and the pre-emulsion A, adding the organic silicon-fluorine pre-emulsion B after the pre-emulsion A is added, then heating to 85-90 DEG C, keeping the temperature for 2-3 hours, then cooling to 65-70 DEG C, adding tert-butyl hydroperoxide and sodium erythorbate, and keeping the temperature for 0.5-1 hour; and S6, cooling to room temperature, adding a preservative and a defoaming agent, and then adjusting the pH value to 7-8 to obtain a finished product.

Owner:LIAONING FIXED STAR FINE CHEM +1

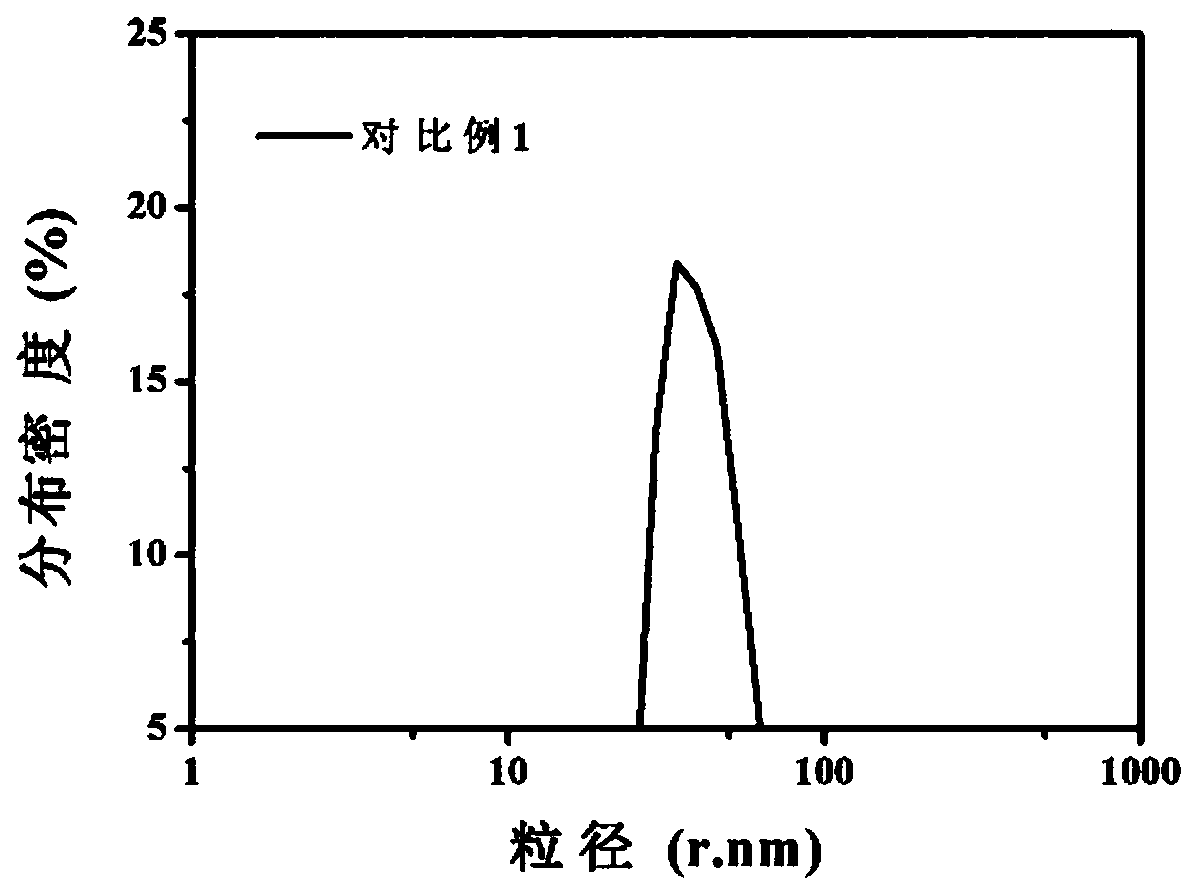

A kind of preparation method of fluorine-containing pure acrylic emulsion

The invention relates to the field of technologies for polymerizing emulsion, in particular to a method for preparing fluorine-containing pure acrylic emulsion. The method includes mixing emulsifiers, hard monomers, soft monomers, functional monomers, fluorine-containing monomers, water-soluble thermal initiators, chelating agents and entanglement molecular weight regulators with one another to obtain mixtures and stirring the mixtures; shearing the mixtures at high stirring speeds of 800-1000 rpm; carrying out reaction; adding inhibitors into the mixtures and terminating the reaction. The method has the advantages that the water-soluble fluorine-containing pure acrylic emulsion is prepared by means of polymerizing emulsion free radical, technological reaction steps are simple, applied chemicals are clean and environmentally friendly, the method is high in monomer conversion rate and low in gel rate, and the fluorine-containing pure acrylic emulsion is uniform in particle size distribution and is in a stable state; the fluorine-containing pure acrylic emulsion can be used for gluing the surfaces of paper, so that the waterproof, oil-proof and surface strength performance and the like of the paper can be obviously improved.

Owner:山东信慧智能产业园有限公司 +1

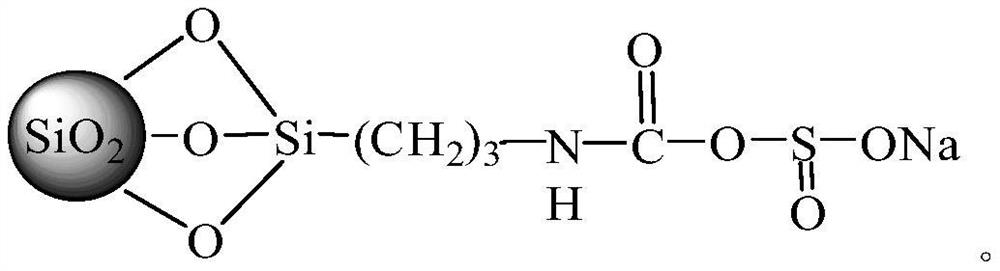

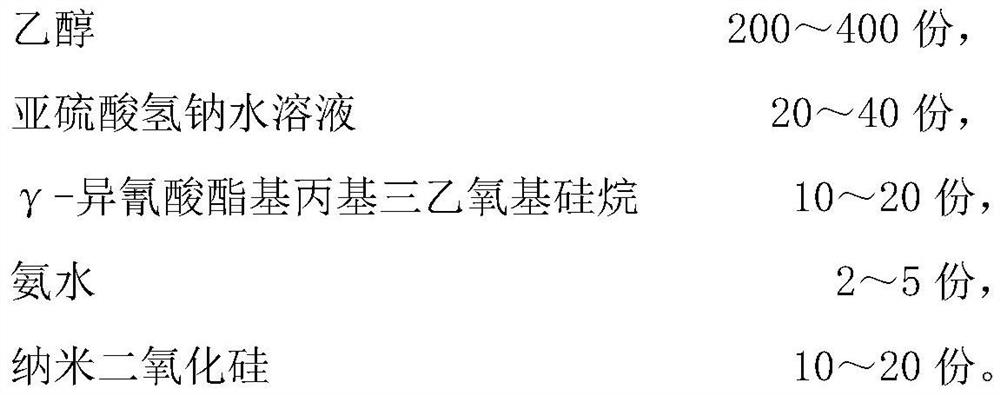

A kind of nanoparticle type in situ initiator and its preparation method and application

The invention discloses a nano particle type in-situ initiator, a preparation method and application thereof. The preparation method of the present invention comprises: first reacting γ-isocyanatopropyl triethoxysilane and sodium bisulfite for 30 to 35 minutes, using ethanol as a solvent and hydrolysis inhibitor, then adding ammonia and nano silicon dioxide to react after heating up. ~4 hours, then centrifuged and rinsed with ethanol, dried to obtain the nanoparticle-based in situ initiator. In the present invention, through the chemical modification of nano-silica particles, the surface has initiator activity. During the in-situ miniemulsion polymerization process, the nano-particle initiator can initiate acrylate polymerization, so that the acrylate polymer is directly grafted on the particles. Surface, thereby reducing the gel rate, improving the water resistance and mechanical strength of the resin.

Owner:HANGZHOU TRANSFAR FINE CHEM CO LTD +1

Modified vinyl ester resin and preparation method thereof, toughened modified vinyl ester resin with good air-drying property, preparation method and application thereof

The invention belongs to the technical field of polymer materials, and in particular relates to a modified vinyl ester resin and a preparation method thereof, a toughened modified vinyl ester resin with good air-drying property, a preparation method and application thereof. In the present invention, after the epoxy resin and the diisocyanate are chain-extended under the catalyst, the unsaturated monobasic acid is used to react with the epoxy group, and after the reaction is completed, an active diluent is added to obtain the modified vinyl ester resin; the vegetable oil-based oligomer and The modified vinyl ester resin is mixed in proportion to obtain a toughened modified vinyl ester resin with good air-drying properties. The modified vinyl ester resin and the toughened and modified vinyl ester resin with good air-drying properties not only have good air-drying properties and fast curing speed, but also have excellent mechanical properties and corrosion resistance.

Owner:SOUTH CHINA AGRI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com