Preparation method of compound organic silicon modified core-shell styrene acrylic latex

A technology of core-shell styrene-acrylic latex and core-shell styrene-acrylic latex, which is applied in the direction of adhesive types, dyeing methods, hydrocarbon copolymer adhesives, etc., and can solve the problem that the surface is easily damaged and the overall performance of the latex cannot be fully obtained. Improve problems such as delamination and delamination to achieve the effect of smooth surface, increased conversion rate and reduced gel rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

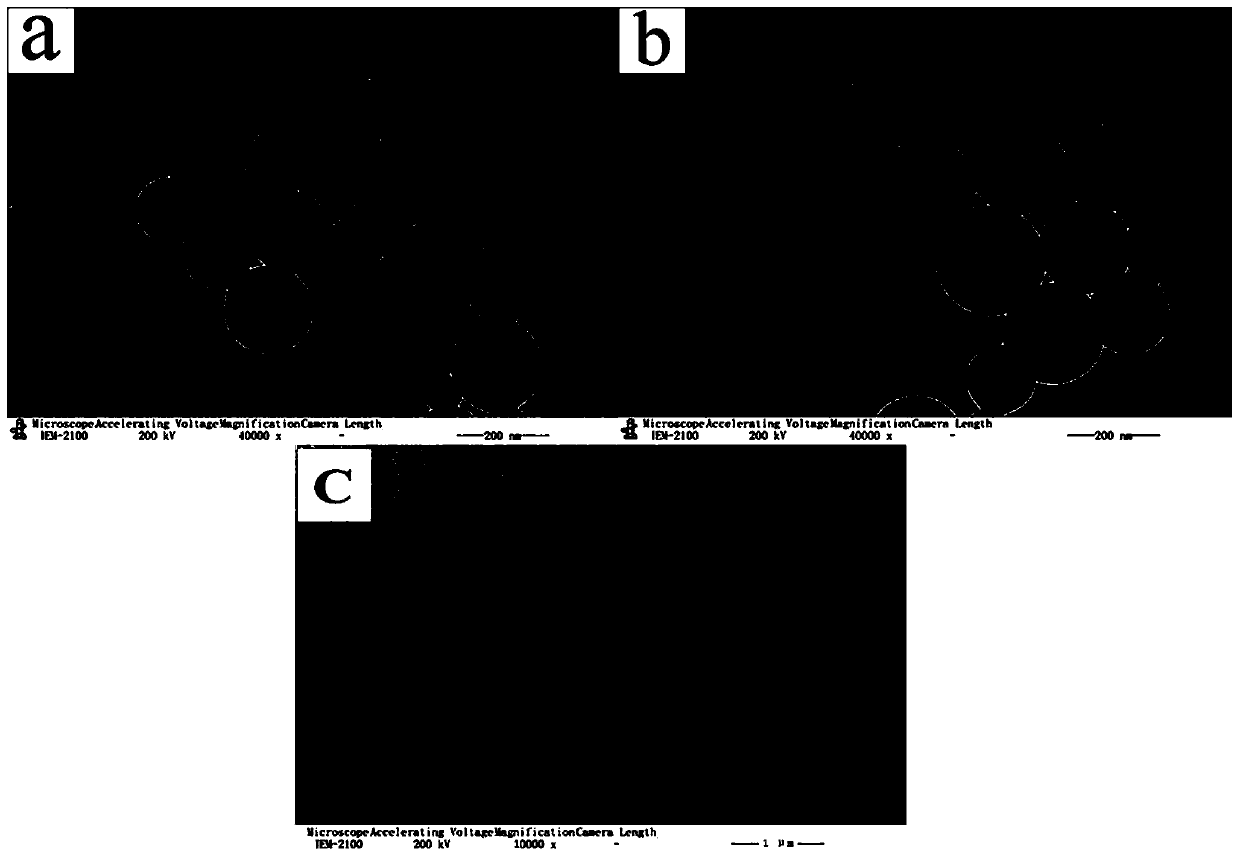

Image

Examples

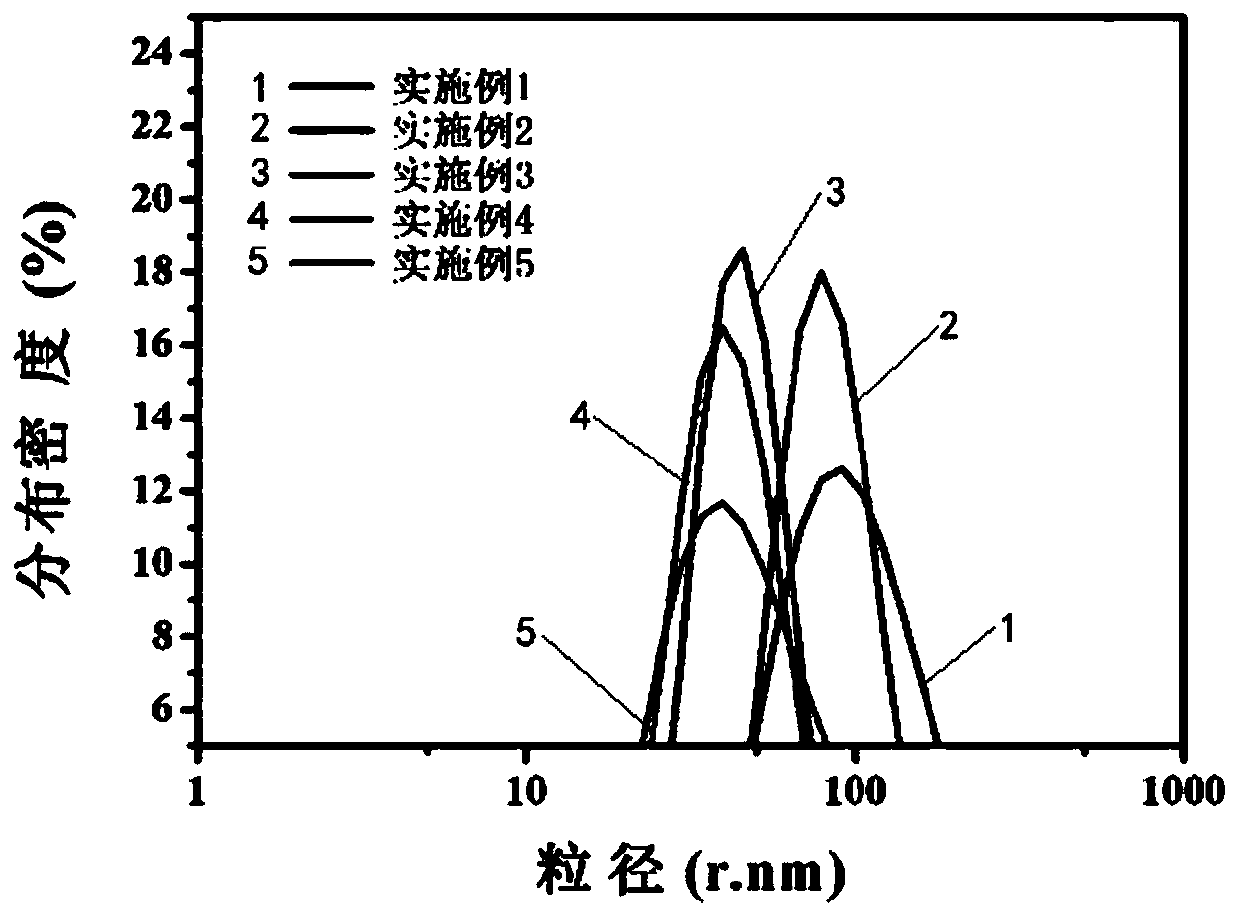

Embodiment 1

[0055] A composite silicone modified core-shell styrene-acrylic latex, comprising the following components:

[0056]

[0057] The composite emulsifier is composed of lauryl glucoside and sodium cardanol polyoxyethylene ether sulfonate with a mass ratio of 1:2.

[0058] The composite silicone monomer is composed of γ-methacryloxypropyltrimethoxysilane and vinyltrimethoxysilane with a mass ratio of 1.7:1.

[0059] The buffer reagent is composed of acetic acid and sodium acetate with a mass ratio of 1.4:1 and a concentration of 0.2 mol / L.

[0060] A kind of preparation method of composite organosilicon modified core-shell styrene-acrylic latex of the present invention is carried out by the following operation steps:

[0061] (1) Mix 30g of butyl acrylate, 25g of isooctyl acrylate, 60g of deionized water, 2g of complex emulsifier and 0.2g of isopropanol, and stir for 40 minutes under the action of 40000Hz ultrasonic waves to obtain pre-emulsion A.

[0062] (2) Dissolve 0.4g o...

Embodiment 2

[0070] A composite silicone modified core-shell styrene-acrylic latex, comprising the following components:

[0071]

[0072] The composite emulsifier is composed of lauryl glucoside and sodium cardanol polyoxyethylene ether sulfonate with a mass ratio of 1:2.

[0073] The composite silicone monomer is composed of γ-methacryloxypropyltrimethoxysilane and vinyltrimethoxysilane with a mass ratio of 1.7:1.

[0074] The buffer reagent is composed of acetic acid and sodium acetate with a mass ratio of 1.4:1 and a concentration of 0.2 mol / L.

[0075] A kind of preparation method of composite organosilicon modified core-shell styrene-acrylic latex of the present invention is carried out by the following operation steps:

[0076] (1) Mix 28g of butyl acrylate, 24g of isooctyl acrylate, 60g of deionized water, 2g of complex emulsifier and 0.2g of isopropanol, and stir for 40 minutes under the action of 40000Hz ultrasonic waves to obtain pre-emulsion A.

[0077] (2) Dissolve 0.4g o...

Embodiment 3

[0085] A composite silicone modified core-shell styrene-acrylic latex, comprising the following components:

[0086]

[0087]

[0088] The composite emulsifier is composed of lauryl glucoside and sodium cardanol polyoxyethylene ether sulfonate with a mass ratio of 1:2.

[0089] The composite silicone monomer is composed of γ-methacryloxypropyltrimethoxysilane and vinyltrimethoxysilane with a mass ratio of 1.7:1.

[0090] The buffer reagent is composed of acetic acid and sodium acetate with a mass ratio of 1.4:1 and a concentration of 0.2 mol / L.

[0091] A kind of preparation method of composite organosilicon modified core-shell styrene-acrylic latex of the present invention is carried out by the following operation steps:

[0092] (1) 25g of butyl acrylate, 20g of isooctyl acrylate, 50g of deionized water, 2g of complex emulsifier and 0.2g of isopropanol were mixed, and stirred for 40 minutes under the action of 40000 Hz ultrasonic waves to obtain pre-emulsion A.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com