Preparation method and application of organic silicon modified acrylate bedplate glue

An acrylate and organosilicon technology, applied in the field of preparation of organosilicon-modified acrylate platen glue, can solve the problems of poor viscosity, pollution, poor stability of platen glue, etc. The effect of bonding density and ensuring thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

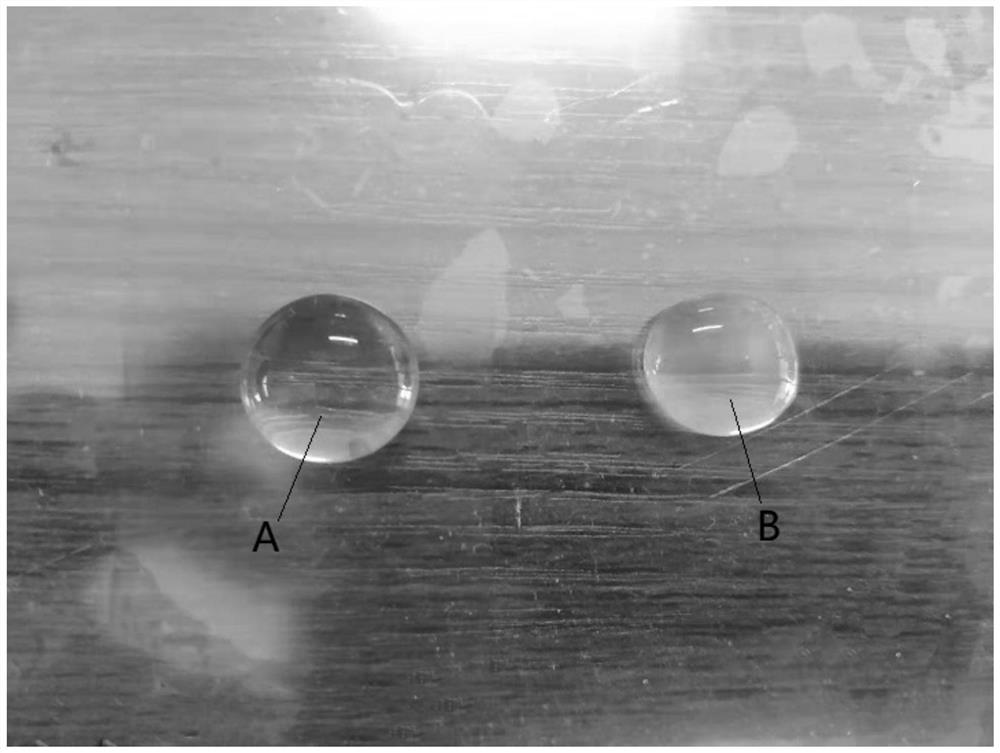

Image

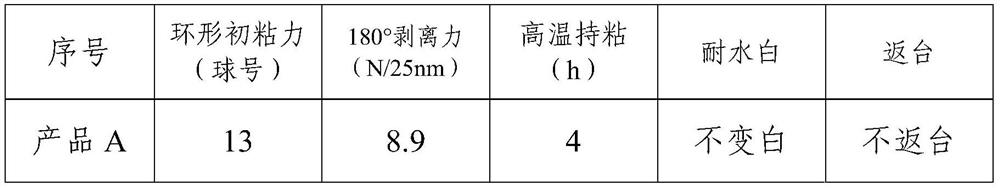

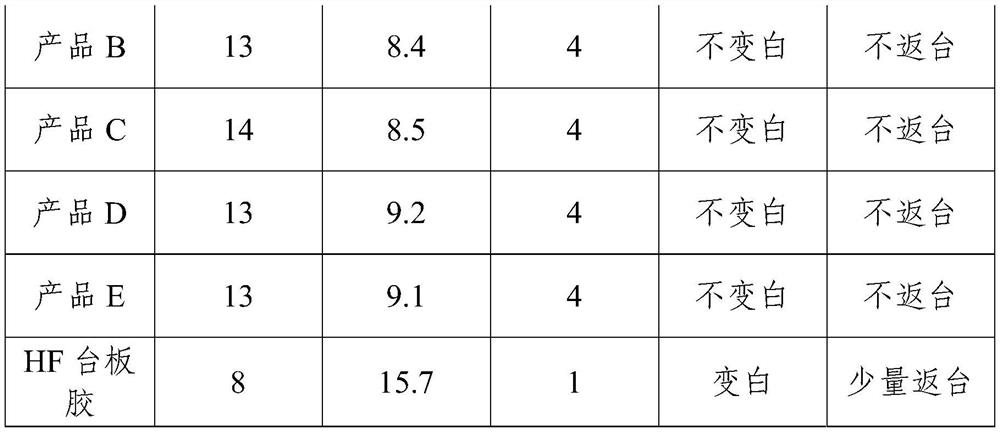

Examples

Embodiment 1

[0044] The preparation method of the organosilicon-modified acrylate platen adhesive provided in this embodiment comprises the following steps:

[0045] Step 1, pre-emulsion A preparation

[0046] Add 100kg of deionized water, 4kg of anionic emulsifier, 140kg of butyl acrylate, 100kg of isooctyl acrylate, 20kg of methyl methacrylate, 10kg of styrene, 2kg of acrylic acid, and self-crosslinking of acetoacetylated acrylic acid to reactor A. Monomer 2kg, 900r / min high-speed dispersion for 30min to prepare 378kg pre-emulsion A;

[0047] Step 2, the preparation of silicone pre-emulsion B

[0048] Add 100kg of the pre-emulsion A prepared in step 1 to the reactor B, add 2kg of vinyltriisopropoxysilane, and disperse at a high speed of 900r / min for 30min to obtain 102kg of silicone pre-emulsion B;

[0049] Step 3, preparation of seed emulsion

[0050] Add 240kg of deionized water, 20kg of the pre-emulsion A obtained in step 1, 0.1kg of potassium persulfate, and 0.6kg of sodium bicarb...

Embodiment 2

[0056] The preparation method of the organosilicon-modified acrylate platen adhesive provided in this embodiment comprises the following steps:

[0057] Step 1, pre-emulsion A preparation

[0058] Add 110kg of deionized water, 3kg of anionic emulsifier, 130kg of butyl acrylate, 110kg of isooctyl acrylate, 25kg of methyl methacrylate, 15kg of styrene, 2.5kg of acrylic acid, self-crossed acetoacetylated acrylic acid into reactor A. Combined monomer 2.5kg, 850r / min high-speed dispersion for 30min to prepare pre-emulsion A 398kg;

[0059] Step 2, the preparation of silicone pre-emulsion B

[0060] Add 110kg of pre-emulsion A to reactor B, add 2.5kg of vinyltriisopropoxysilane, and disperse at a high speed of 850r / min for 30min to obtain 112.5kg of silicone pre-emulsion B;

[0061] Step 3, preparation of seed emulsion

[0062] Add 250kg of deionized water, 15kg of the pre-emulsion A obtained in step 1, 0.1kg of potassium persulfate, and 0.5kg of sodium bicarbonate into the react...

Embodiment 3

[0068] The preparation method of the organosilicon-modified acrylate platen adhesive provided in this embodiment comprises the following steps:

[0069] Step 1, pre-emulsion A preparation

[0070] Add 120kg of deionized water, 5kg of anionic emulsifier, 160kg of butyl acrylate, 100kg of isooctyl acrylate, 30kg of methyl methacrylate, 10kg of styrene, 3kg of acrylic acid, and self-crosslinking of acetoacetylated acrylic acid to reactor A. 3kg of monomer, 1000r / min high-speed dispersion for 25min to prepare 430kg of pre-emulsion A;

[0071] Step 2, the preparation of silicone pre-emulsion B

[0072] Add 120 kg of pre-emulsion A to reactor B, add 3 kg of vinyltriisopropoxysilane, and disperse at a high speed of 1000 r / min for 25 minutes to obtain 123 kg of silicone pre-emulsion B;

[0073] Step 3, preparation of seed emulsion

[0074] Add 240kg of deionized water, 15kg of the pre-emulsion A obtained in step 1, 0.07kg of potassium persulfate, and 0.5kg of sodium bicarbonate int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com