Patents

Literature

468results about How to "Guaranteed thermal stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method and application of first-class solid polymer electrolyte

ActiveCN107069085AExcellent flexibilityExcellent thermal stabilitySolid electrolytesLi-accumulatorsCross-linkMolecular level

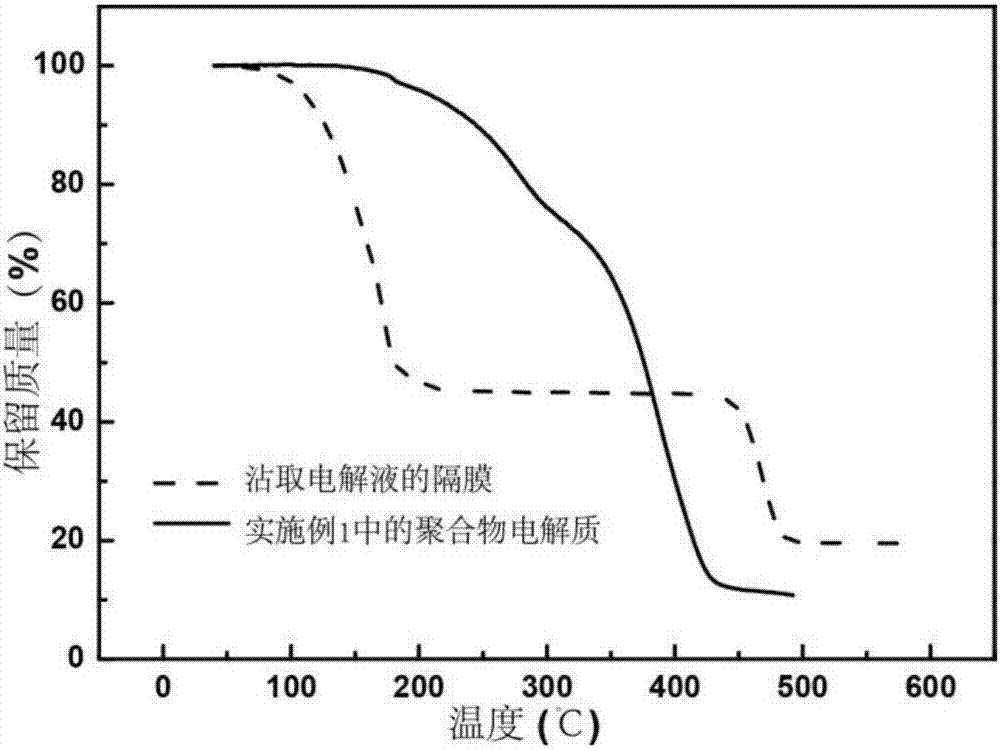

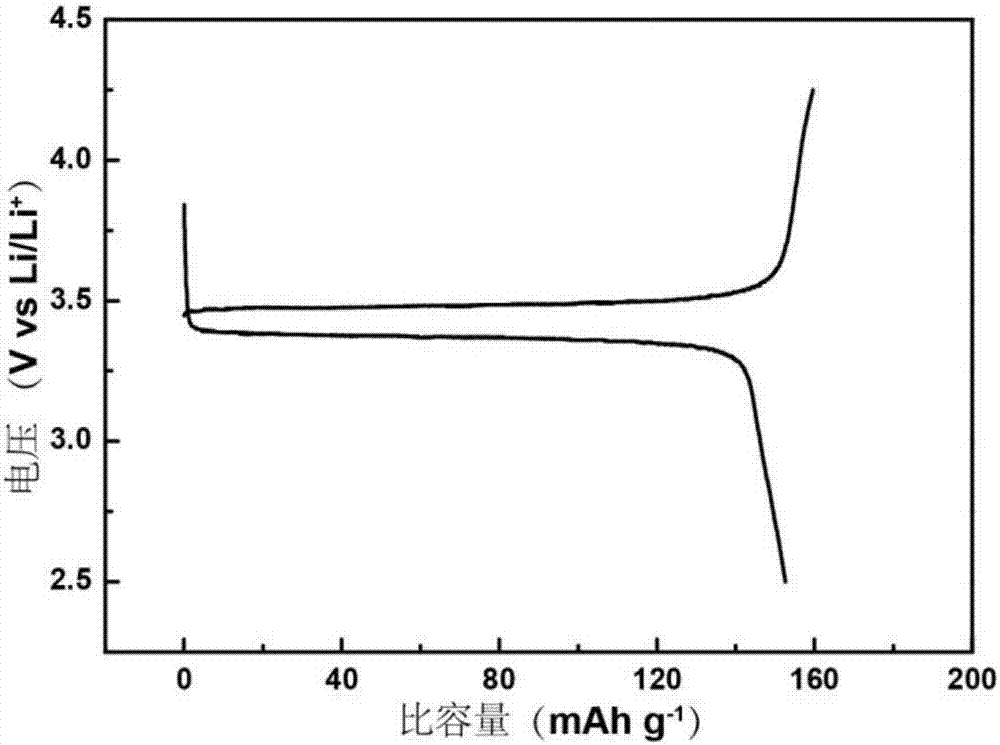

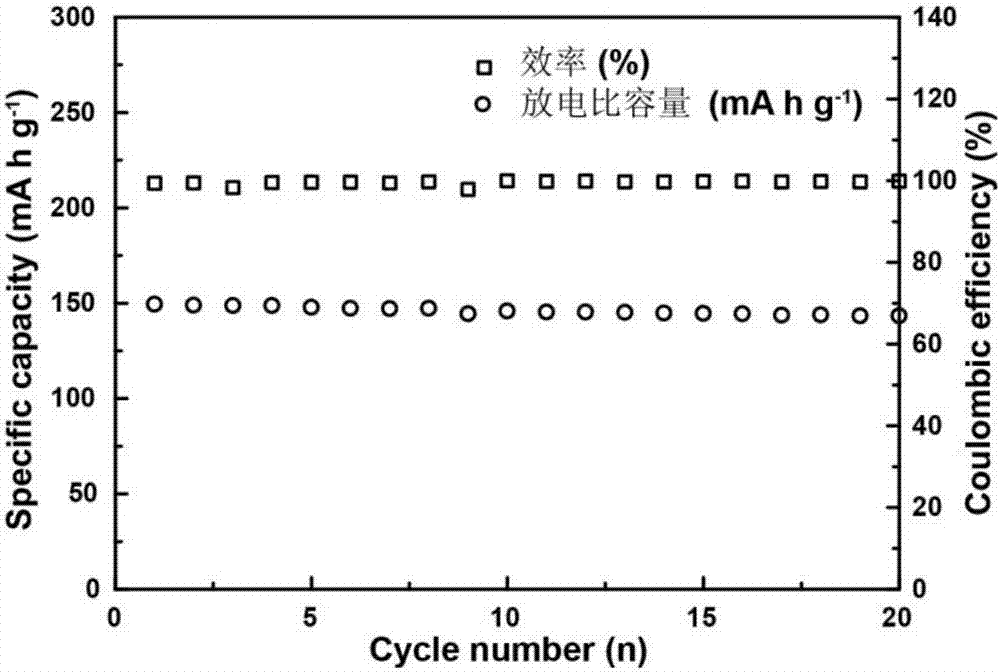

The invention discloses a preparation method of solid polymer electrolyte with good toughness and good thermal stability and application thereof in lithium batteries. The preparation method of the solid polymer electrolyte at least comprises the following steps: uniformly distributing a polymer cross-linked network linked with nanoparticles, another polymer monomer, conductive salt and an initiator on the molecular level to obtain polymeric precursor solution; coating a base material or the surface of an electrode with the polymeric precursor solution; and preparing solid polymer electrolyte which comprises the nanoparticles by polymerization. The method is high in controllability and simple and convenient to operate, and has good application prospect. The nanoparticles are introduced, so that the obtained solid polymer electrolyte has good flexibility; and meanwhile, by synergetic enhancement of another polymer, the solid polymer electrolyte has good thermal stability and excellent ionic conductivity.

Owner:BEIJING IAMETAL NEW ENERGY TECH CO LTD

Corundum-silicon nitride-silicon carbide composite pouring material

The invention discloses a corundum-silicon nitride-silicon carbide compound castable used for a blast tuyere zone of an ironmaking blast furnace. The corundum, the silicon nitride, the silicon carbide, aluminate cement, aluminum powder, silicon metal, ultrafine silica powder, alumina powder and polypropylene fiber are mixed to form the castable. Residual brick of compound brown corundum refractory brick can be fast poured and repaired at the blast tuyere zone of the ironmaking blast furnace. When building a blast furnace, residual brick can be direct poured and formed to replace the compound brown corundum refractory forming brick and no high temperature is needed to fire during the production process; therefore, the invention is also an energy saving refractory for the blast tuyere zone of the ironmaking blast furnace and cast-place construction is not limited by space; fast pouring masonry is carried out and fast drying method is adopted, thereby being an inorganic nonmetal refractory applied to fast-drying quick furnace building and repairing during the blast furnace repairing and the tuyere zone of the newly-built blast furnace. The invention can normally furnace dry with the blast furnace.

Owner:REFRACTORY MATERIAL OF SINOSTEEL CORP

Preparation of chlorinated polythylene

InactiveCN101280030AReduce chlorination timeThe degree of chlorination in depthPolymer scienceChlorinated polyethylene

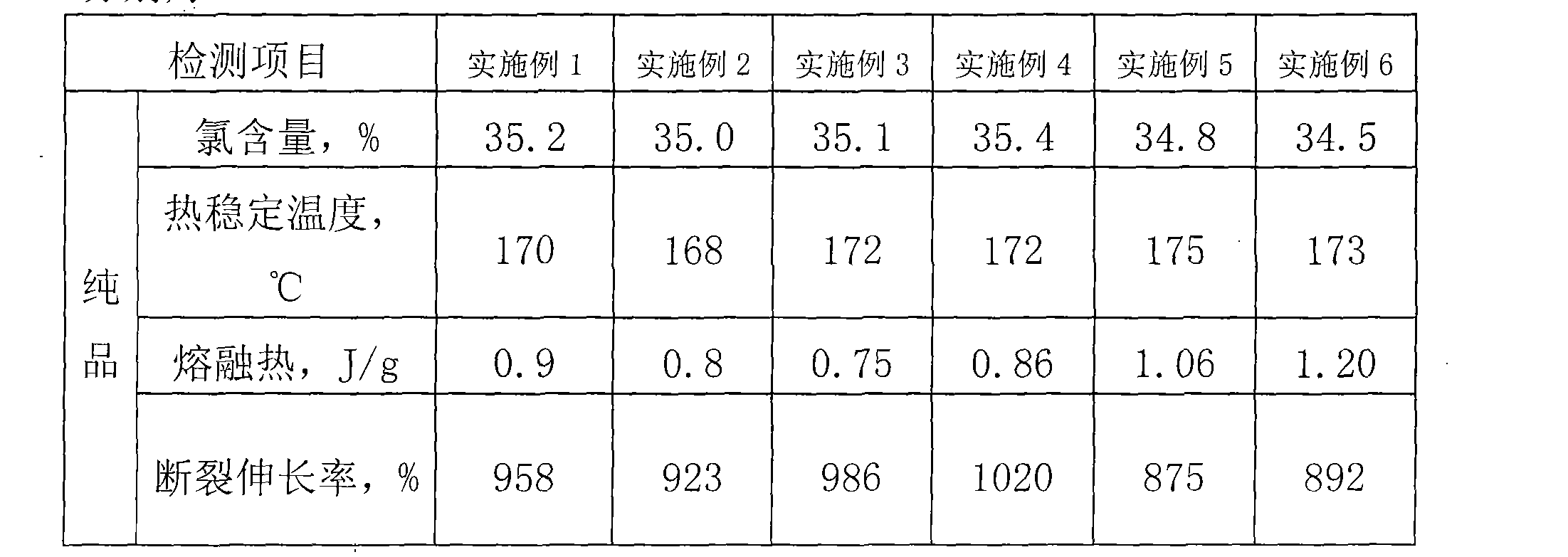

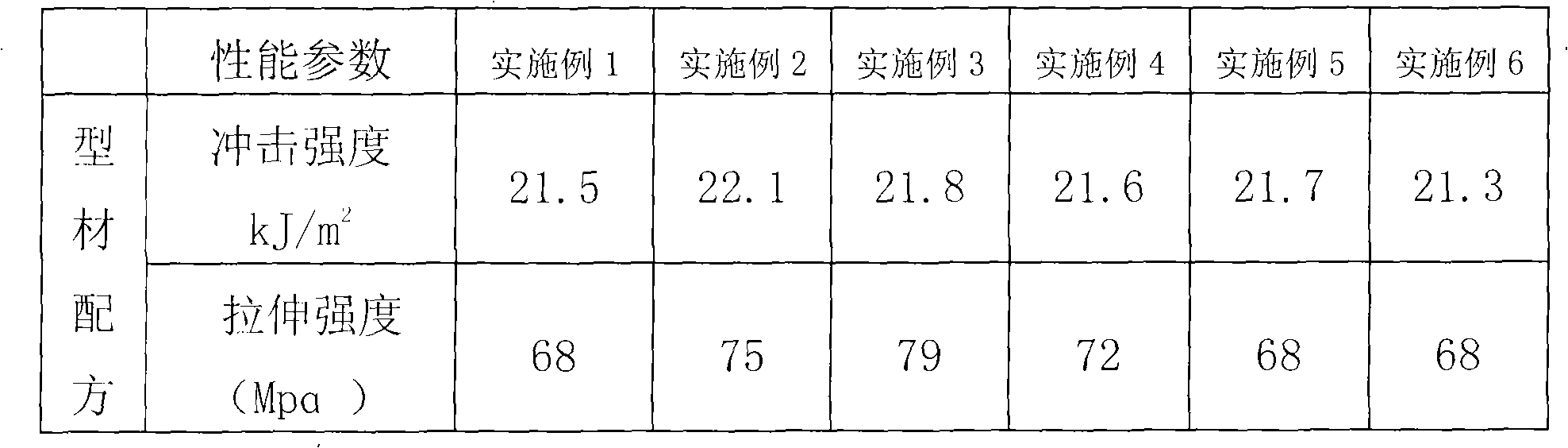

The invention belongs to plastic profile product modifier technical field and discloses a preparation method for a PVC anti-impact modifier chlorinated polyethylene. The invention is mainly technically characterized in that after dispersant, emulsifier, initiator and powdery high-density polyethylene resin are added into a chlorinating reactor with water inside in a stirring state, then the mixture is heated and processed through three chlorine reactions at different temperature ranges; after the reaction, the enwrapped HCl formed in the reactor is discharged; after repeated hot water washing, centrifugal dehydration and drying, calcium stearate, calcium carbonate and lanthanum carbonate are added to obtain the finished product through stirring, mixing and screening. As the high-density polyethylene resin in the preparation technology is high-mesh powdery material and three chlorine reactions are needed in the process, the chlorinated polyethylene prepared by the technology has higher thermal stable temperature and lower melting heat; if the chlorinated polyethylene serves as the anti-impact modifier of PVC products, the PVC product produced thereby has strong impact strength and tensile strength.

Owner:HEBEI JINGXIN CHEM GRP CO LTD

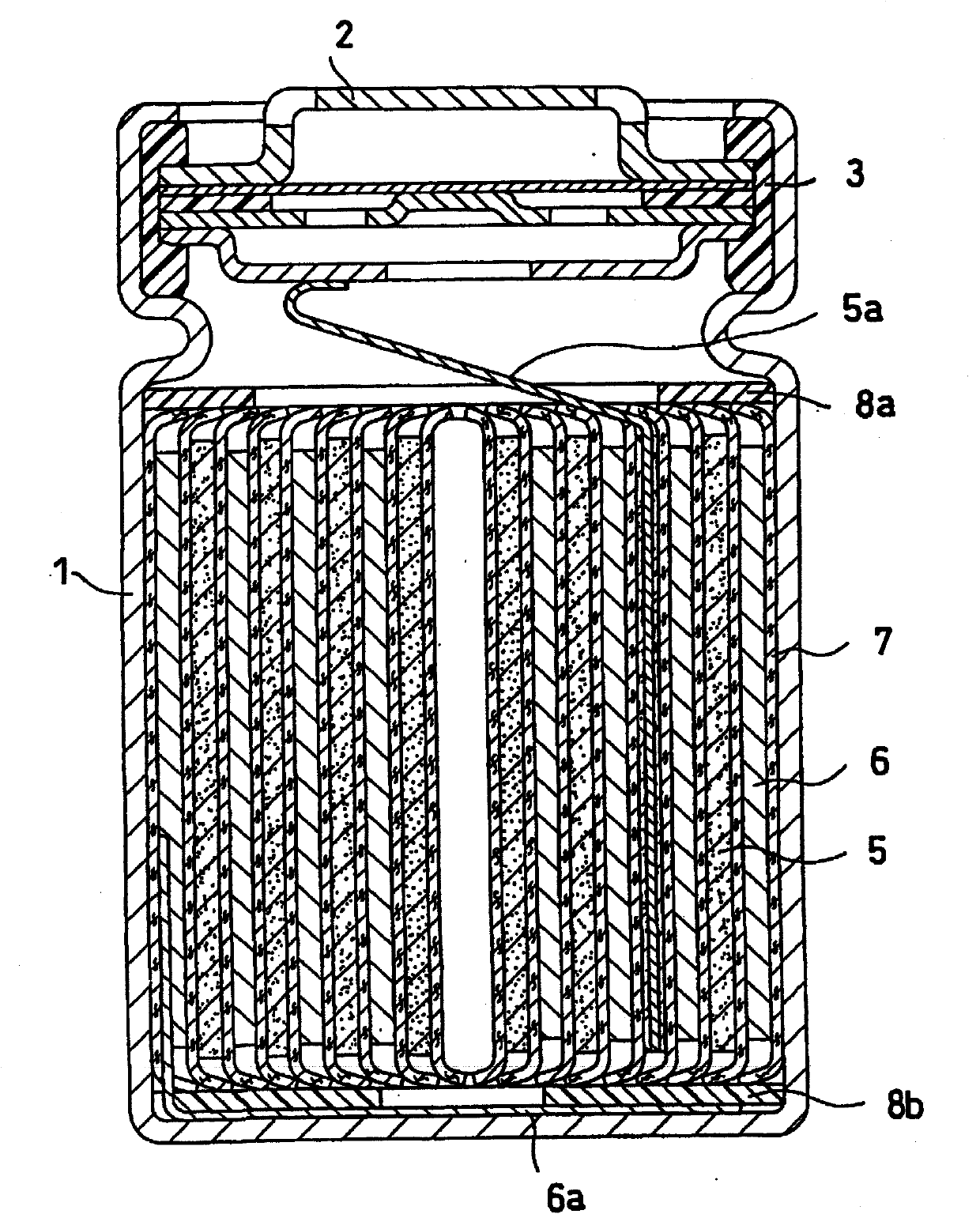

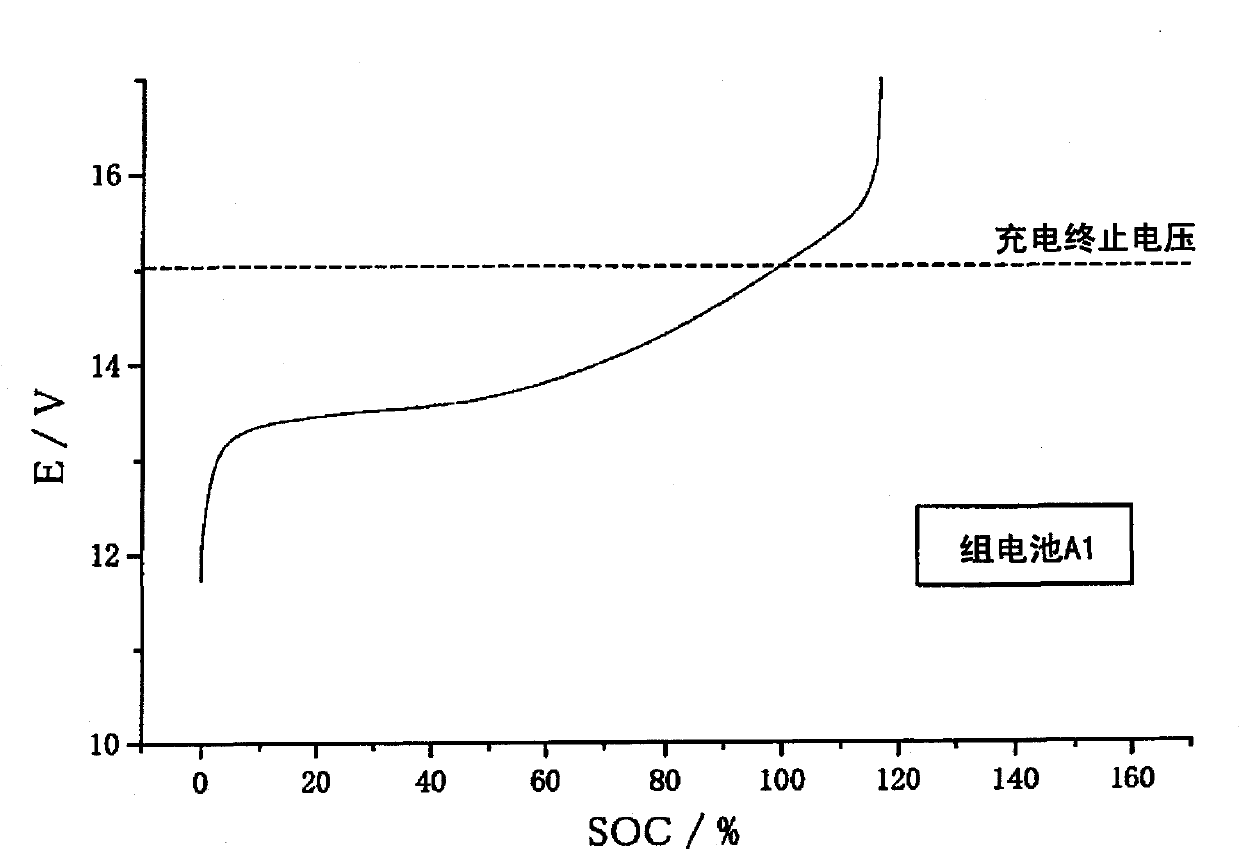

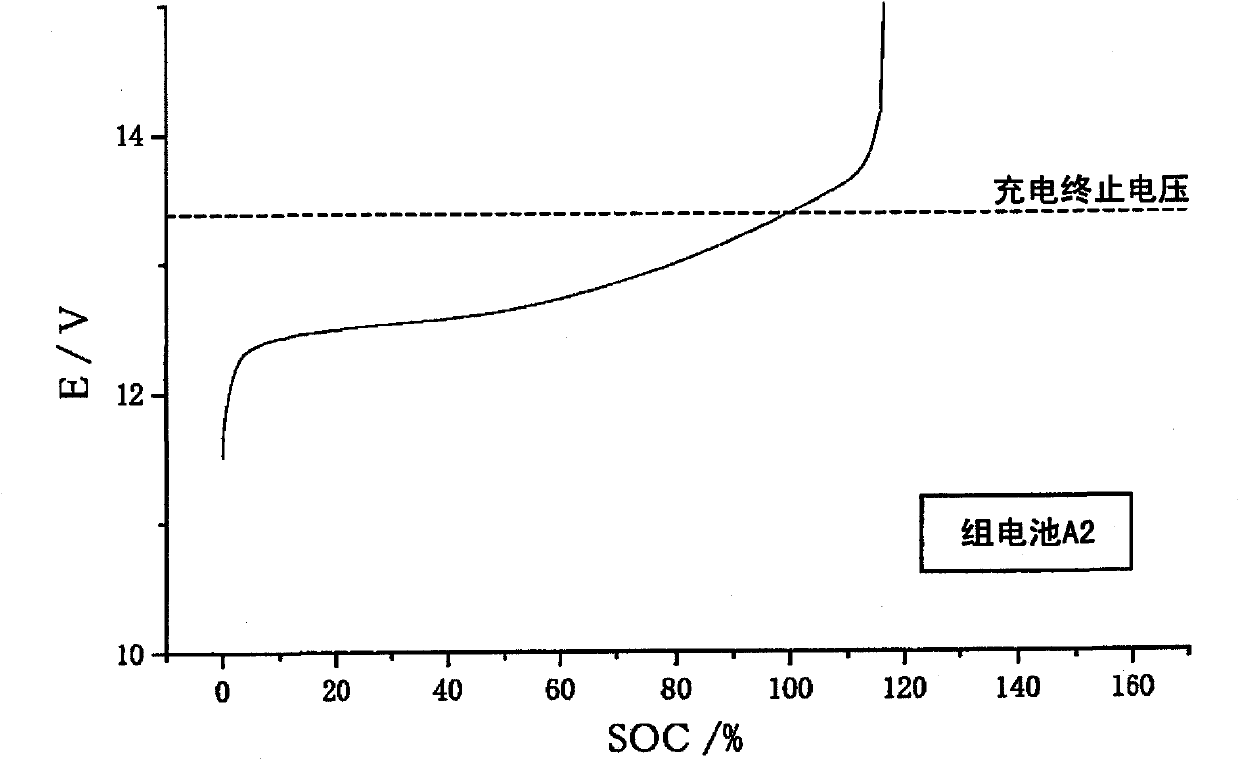

Battery pack

InactiveCN102027617AImprove long-term reliabilityImprove securityElectrode carriers/collectorsJackets/cases materialsElectricityElectrical battery

Disclosed is a battery pack formed by combining two types of secondary batteries that have different battery characteristics (charge voltage behavior) and that is equipped with a positive electrode, a negative electrode, a separator provided between the positive and negative electrodes, and a non-aqueous electrolyte. That is, the present invention relates to a battery pack in which at least one first single cell and at least one second single cell are electrically connected in series. The second single cell exhibits greater variation in the charge voltage at the end of the charging period and has greater battery capacity than the first single cell. In this way, a battery pack that has excellent long-term reliability that can safely prevent overcharging can be obtained.

Owner:PANASONIC CORP

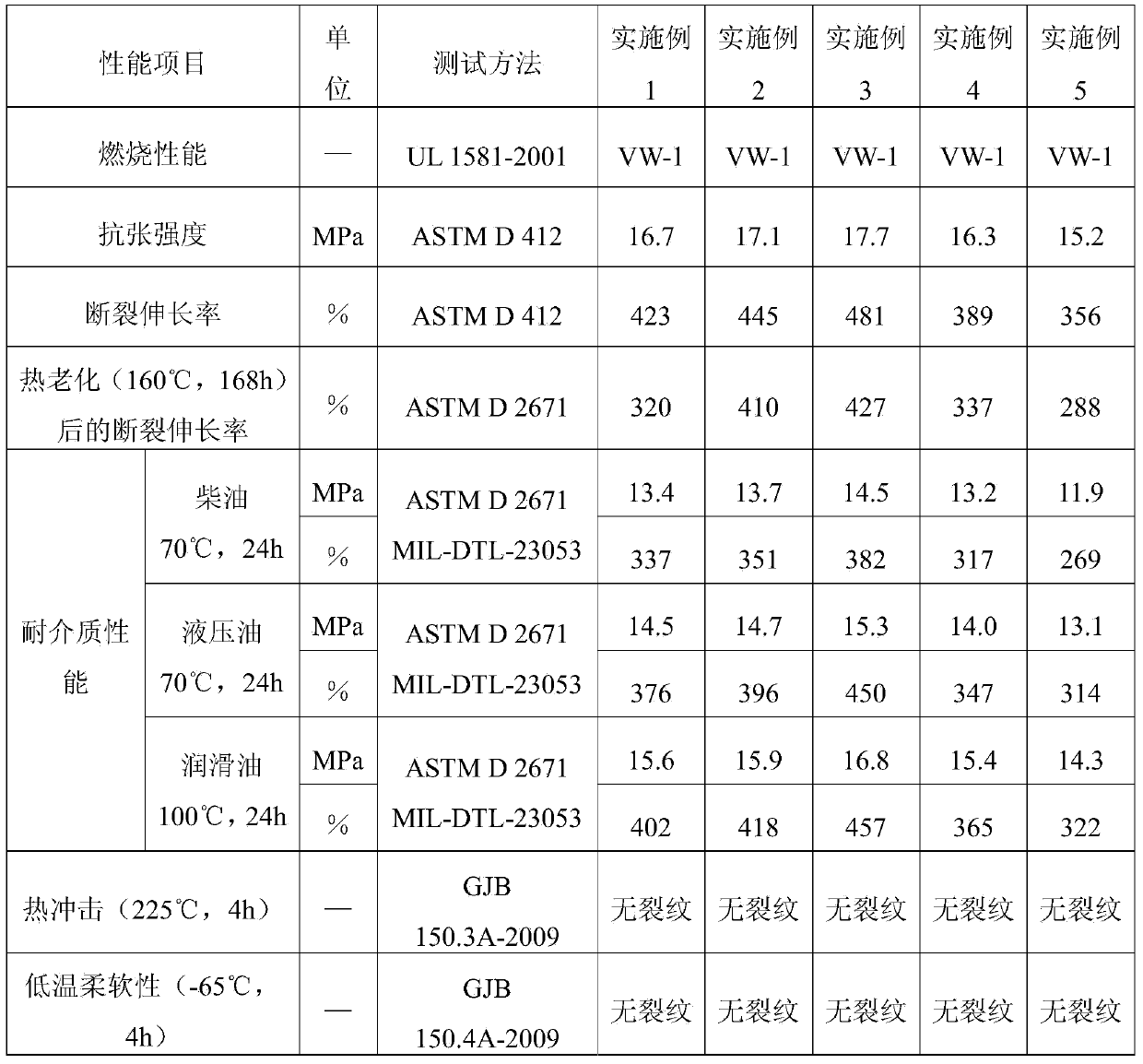

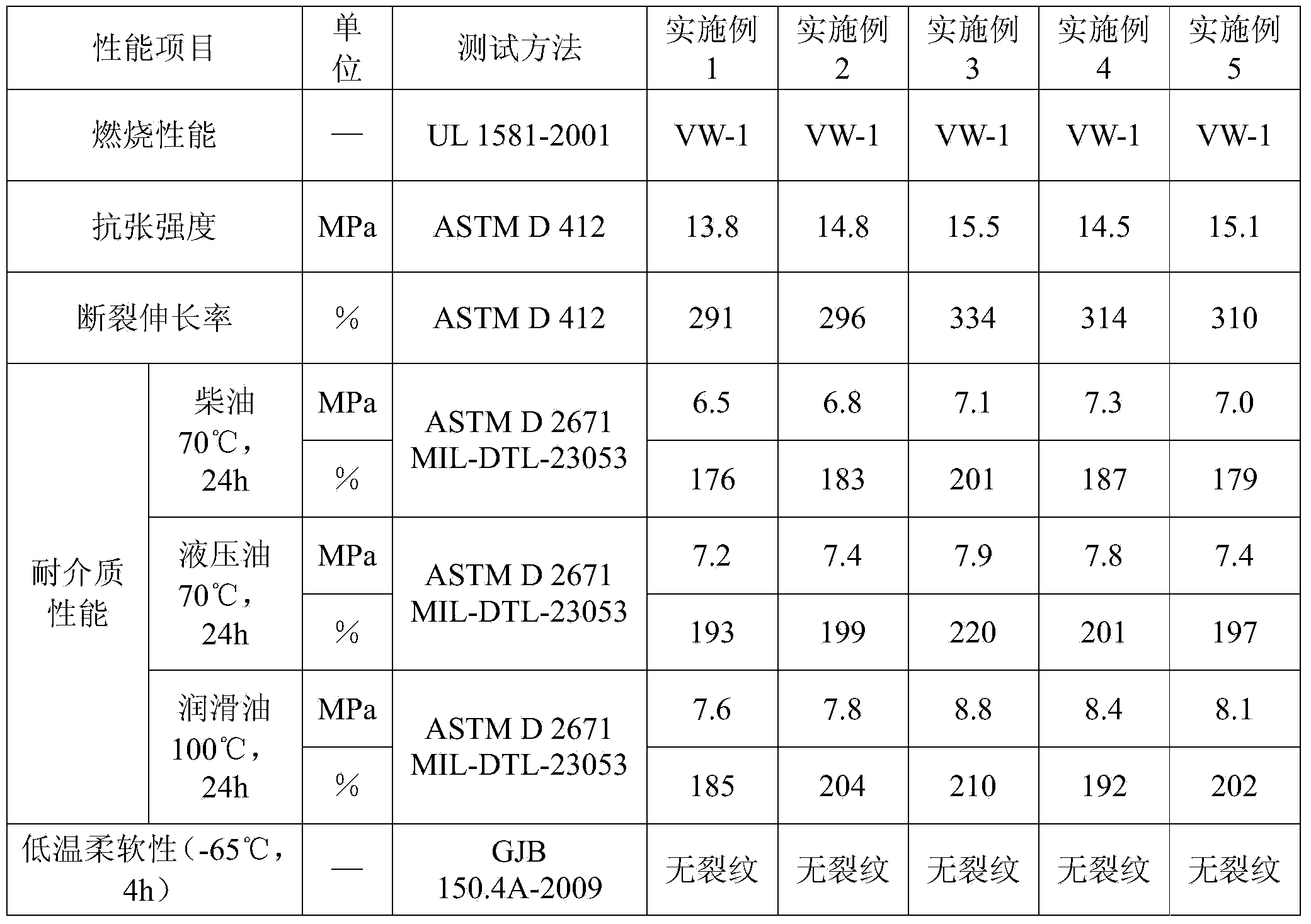

Thermoplastic polyester elastomer heat-shrinkable casing tube for automobile wire harness as well as preparation method and application of heat-shrinkable casing tube

The invention discloses a thermoplastic polyester elastomer heat-shrinkable casing tube for an automobile wire harness as well as a preparation method and an application of the heat-shrinkable casing tube. The heat-shrinkable casing tube comprises the following components in parts by weight: 50-80 parts of a thermoplastic polyester elastomer, 30-60 parts of halogen-containing resin, 5-15 parts of black masterbatch, 5-30 parts of diantimony trioxide, 0-100 parts of a flame retardant, 3-15 parts of a flame retardant synergist, 1-4 parts of a thermal stabilizer, 0.5-4 parts of an antioxidant, 0.5-2 parts of a silicone aid and 1-2.5 parts of a sensitizer. The preparation method comprises the following steps: mixing the thermoplastic polyester elastomer, the halogen-containing resin, the black masterbatch, diantimony trioxide, the flame retardant, the flame retardant synergist, the thermal stabilizer, the antioxidant and the silicone aid, adding the sensitizer, mixing, granulating, extruding to form a tube, performing irradiation crosslinking, stretching by expanding, shaping by cooling, flattening, and marking. The heat-shrinkable casing tube has the advantages of relatively low price, high-efficiency flame retardance, excellent mechanical property, low pollution, high-temperature oil resistance, acid-base corrosion resistance and capability of being applied in a severe working environment.

Owner:广州凯恒科塑有限公司

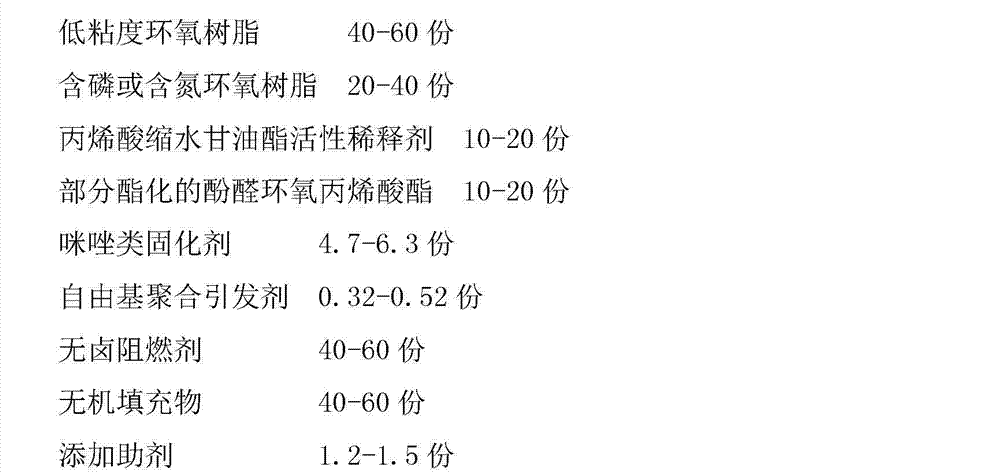

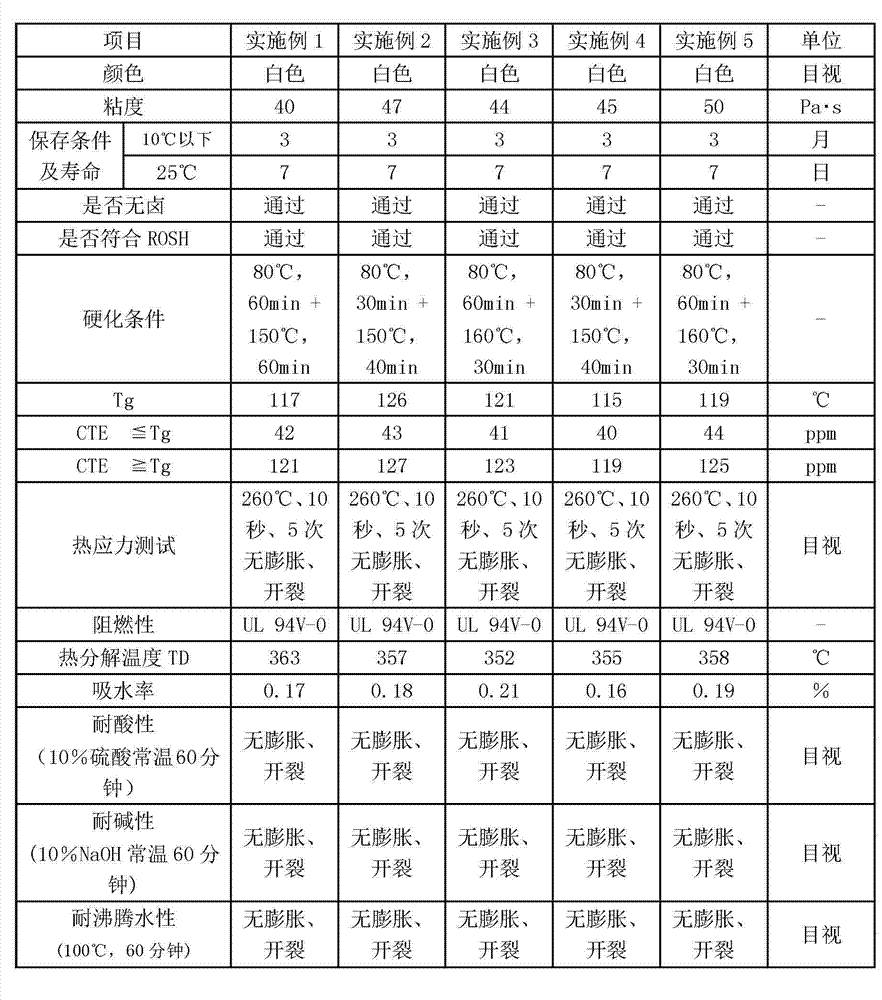

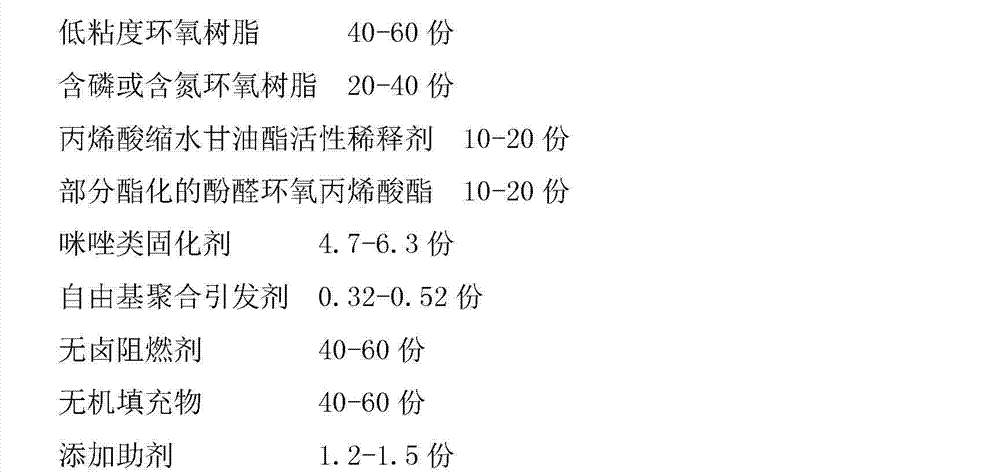

Halogen-free flame-retardant solvent-free double-curing ink composition and preparation method thereof

ActiveCN102732096ASmall coefficient of thermal expansionGuaranteed thermal stabilityInksSolvent freeThermal deformation

The invention relates to electronic materials and preparation, and aims to provide a halogen-free flame-retardant solvent-free double-curing ink composition and a preparation method thereof. The composition comprises the following components: low-viscosity epoxy resin, epoxy resin containing phosphorus or nitrogen, glycidyl acrylate reactive diluent, partially-esterified phenolic epoxy acrylate, imidazole curing agent, free radical polymerizing initiator, halogen-free flame retardant, inorganic filler and additives. The preparation method comprises the following steps of: mixing, dispersing and grinding the raw materials until the viscosity reaches 40 to 50 Pa.s per 25 DEG C, dispersing and uniformly agitating the raw materials after the grinding is stopped, and finally filtering, filling and packaging the raw materials. The halogen-free flame-retardant solvent-free double-curing ink composition has the advantages that the possibility of fire hazards caused by ink introduction when a hole is blocked can be reduced by virtue of halogen-free and flame-retardant performance; with adoption of a double-curing technology with free radical polymerizing and epoxide ring-opening addition polymerization, the halogen-free flame-retardant solvent-free double-curing ink composition has a high curing degree, a high temperature in thermal deformation, a low expansion coefficient, low water absorption and high heat resistance; the viscosity of the ink is easy to adjust, and thus the requirements on the use of the ink in different seasons can be ensured; and the curing material is moderate in rigidity and has the characteristic of grindability.

Owner:ELEK & ELTEK ELECTRONICS KUNSHAN

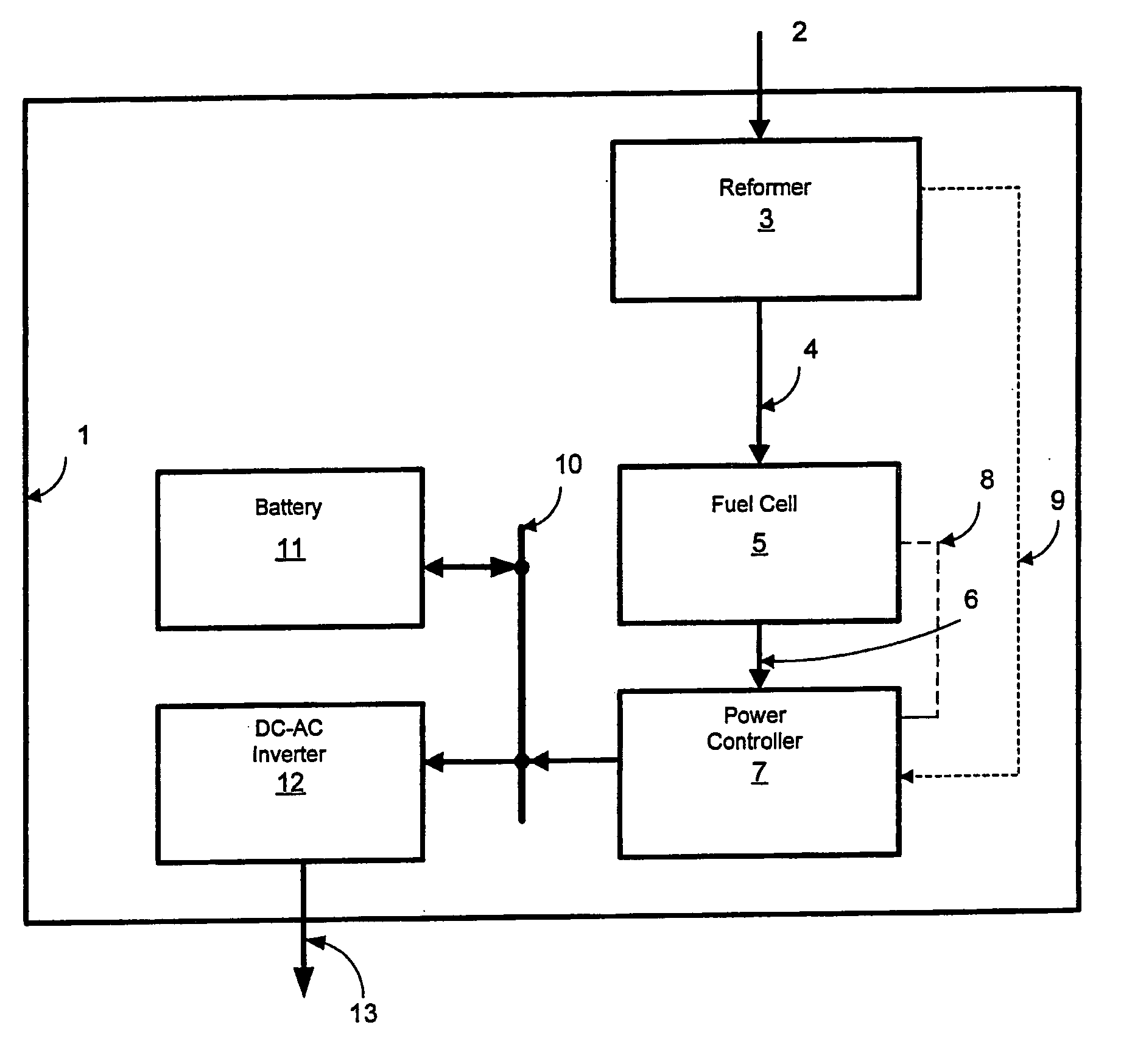

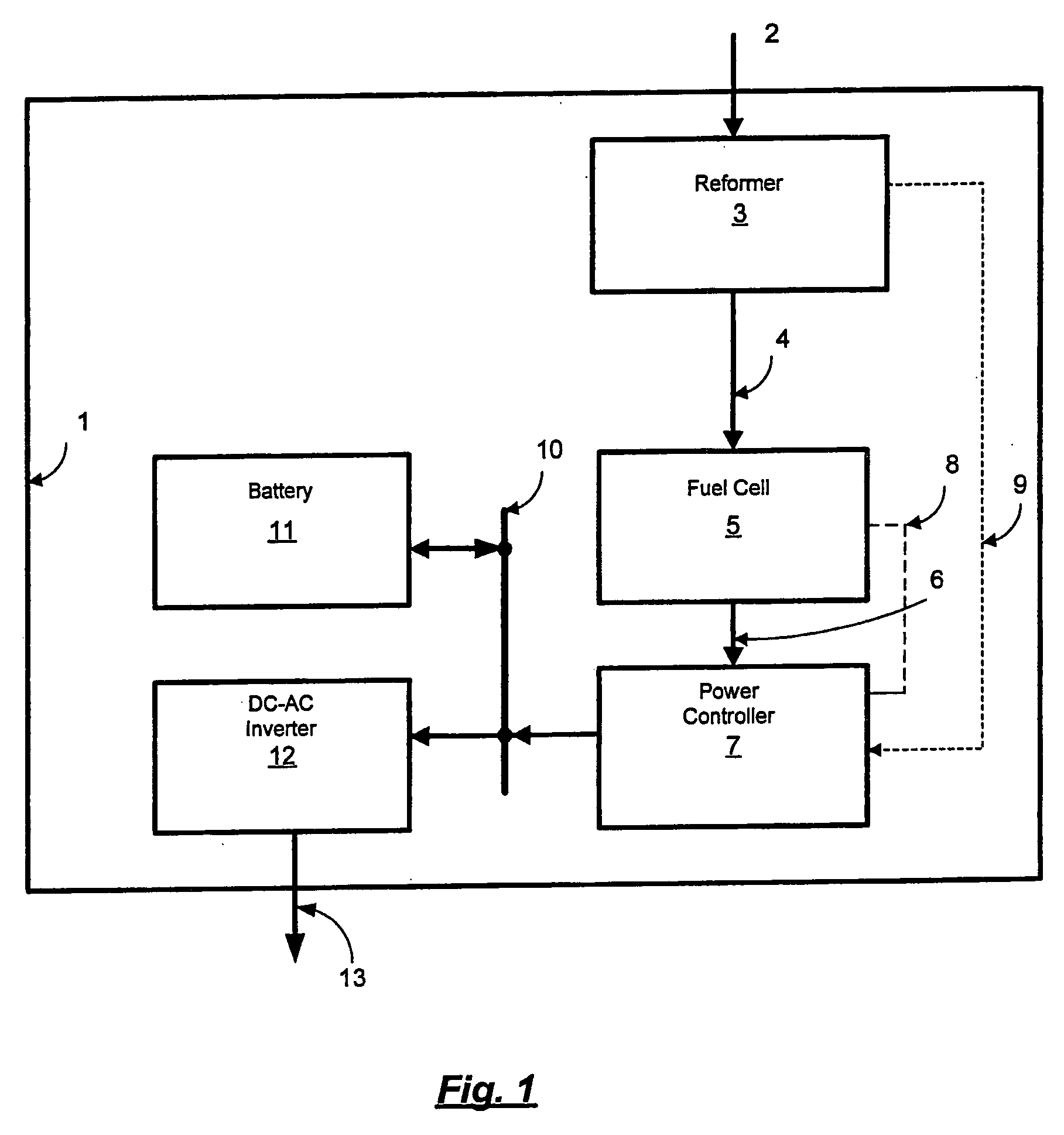

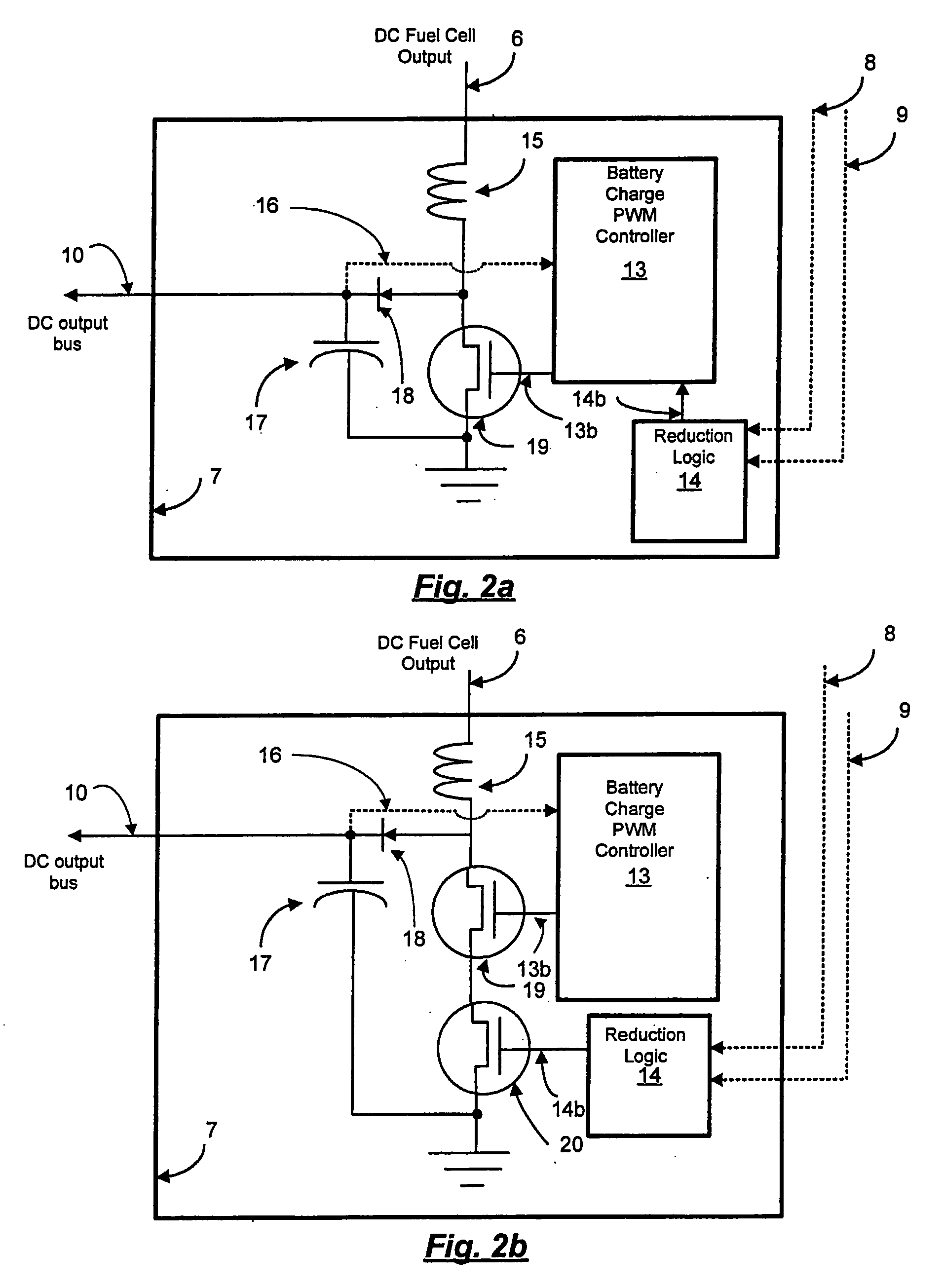

Power controller for fuel cell

InactiveUS20060051634A1Avoid physical damageSmall voltageFuel cells groupingFuel cell auxillariesElectric forcePower controller

A fuel cell power system includes a fuel cell stack having at least two fuel cell groups in series with each other and with each fuel cell group having more than one individual fuel cell, and a power controller which receives electrical power from the fuel cell stack and distributes the electrical power to an output bus. The power controller includes a DC-DC converter, and a reduction logic circuit operative to limit current through the DC-DC converter in response to voltage across each fuel cell group so that a minimum voltage is maintained across each fuel cell group. When used in combination with a hydrogen reformer, the reduction logic circuit is also operative to limit current through the DC-DC converter in response to hydrogen pressure supplied by the reformer to the fuel cell stack so that a minimum pressure is maintained for the hydrogen supplied to the fuel cell stack.

Owner:GENESIS FUEL TECH INC

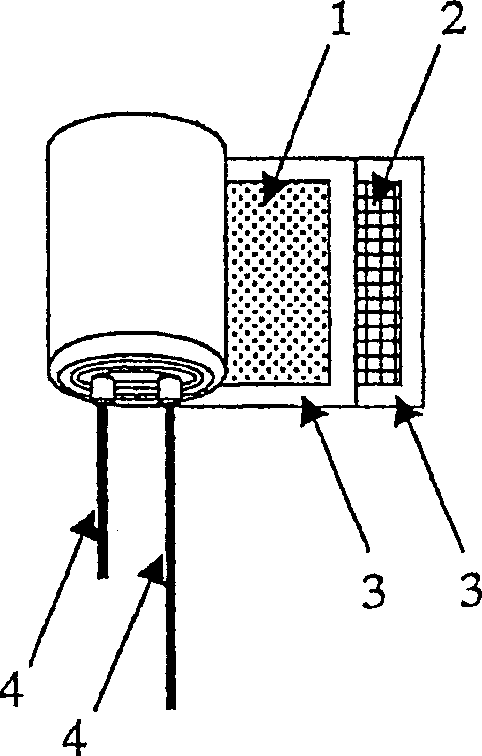

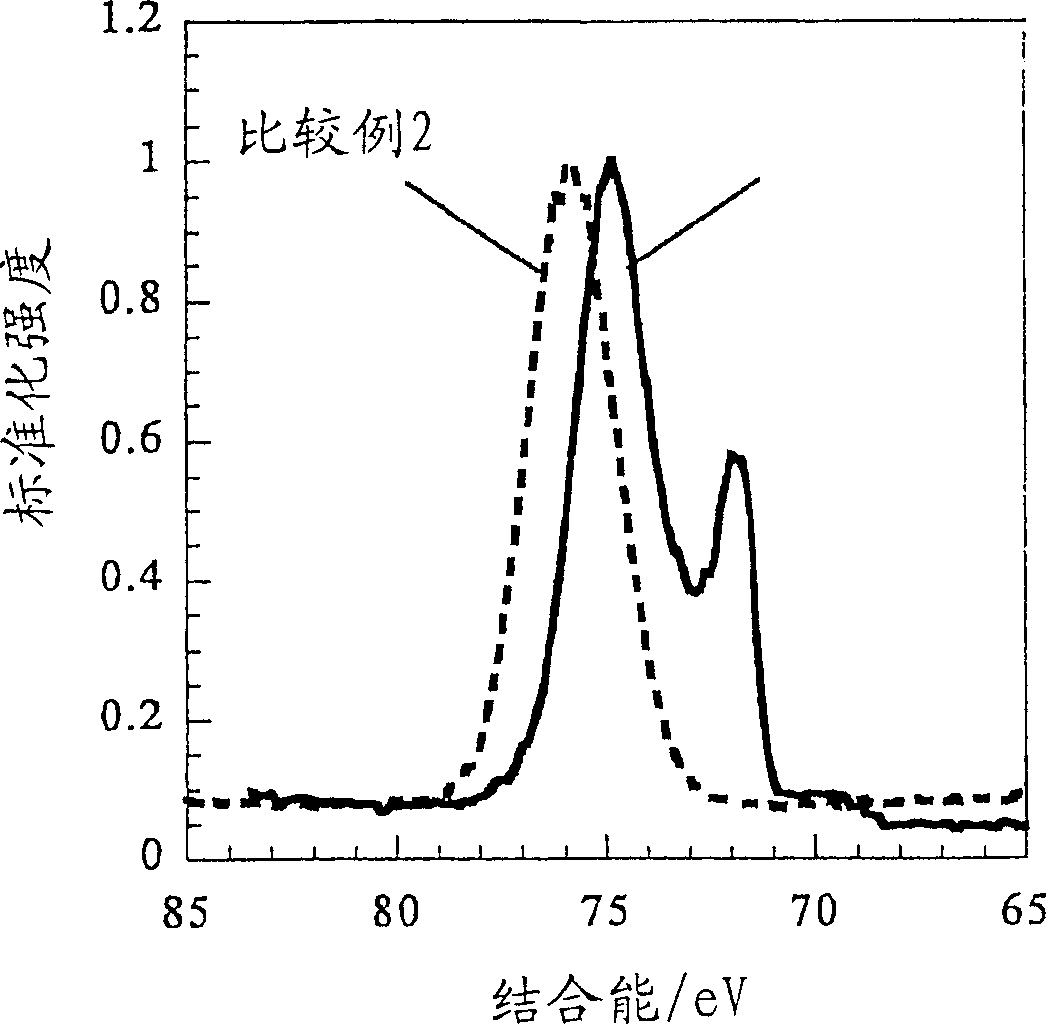

Electrolyte for electrolytic capacitor, electrolytic capacitor and process for producing tetrafluoroaluminate salt of organic onium

InactiveCN1708817AMaintain impedance characteristicsGuaranteed thermal stabilityElectrolytic capacitorsElectrolytic agentPeak value

To provide an aluminum electrolytic capacitor, an electrolytic solution for an electrolytic capacitor, an electrolytic capacitor using the electrolytic solution, and a method for producing an organic onium tetrafluoroaluminate useful for an aluminum electrolytic capacitor and the like. Among them, the aluminum electrolytic capacitor includes an anode, a cathode containing aluminum, and an electrolyte solution containing an onium salt containing fluorine anions, and is characterized in that: the concentration of water in the electrolyte solution is less than or equal to 1% by weight; or it is characterized in that: through X-ray photoelectron spectroscopy When analyzing the surface of the cathode in the aluminum electrolytic capacitor after heating at 125° C. for 50 hours by XPS method, the Al2p spectral peak is 74.0 eV to 75.8 eV. The electrolytic solution for electrolytic capacitors contains tetrafluoroaluminate of quaternary cyclic amidinium and a solvent, and the total amount of specific impurity compounds is less than or equal to 0.6% by weight.

Owner:MITSUBISHI RAYON CO LTD

Composite carrier catalyst used for glycol and synthesized from hydrogenation of alkyl oxalate, and preparation method thereof

ActiveCN102225338AHigh activityGuaranteed thermal stabilityOrganic compound preparationHydroxy compound preparationOxalateActive component

The invention relates to a composite carrier catalyst used for glycol and synthesized from hydrogenation of alkyl oxalate, and a preparation method thereof. The chemical formula of the composite carrier catalyst is CuO / ROx-Moy. Wherein, CuO accounts for 5-60 mass percent, ROx accounts for 10-90 mass percent, and Moy accounts for 0.1-60 mass percent, x as 1 / 2 of the highest valency of R, y is 1 / 2 of the highest valency of M, R is one of Si, Al, Zr and Ti, and M is one of Si, Al, Cr, Zr, Ti, B, Zn, Mo, Ce, Bi, La. Compared with the prior art, in the invention a composite carrier is employed in the catalyst used for glycol and synthesized from hydrogenation of alkyl oxalate. The carrier can effectively disperse the active component copper so as to make the sintering of copper grains hard andextend the service life of the catalyst. Meanwhile, the composite carrier can effectively adjust the surface acidity and basicity, reduce the generation of by-products, and improve the selectivity ofglycol. The total conversion rate of oxalate can reach over 99.9%, while the selectivity of glycol is above 95%. Thus, the catalyst of the invention can be used in the industrial production of glycol.

Owner:PUJING CHEM IND SHA +1

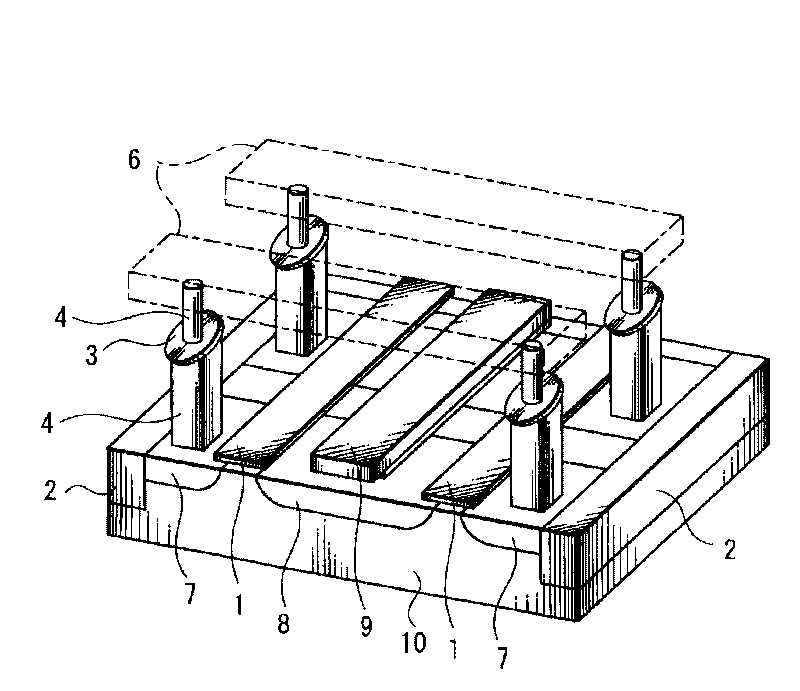

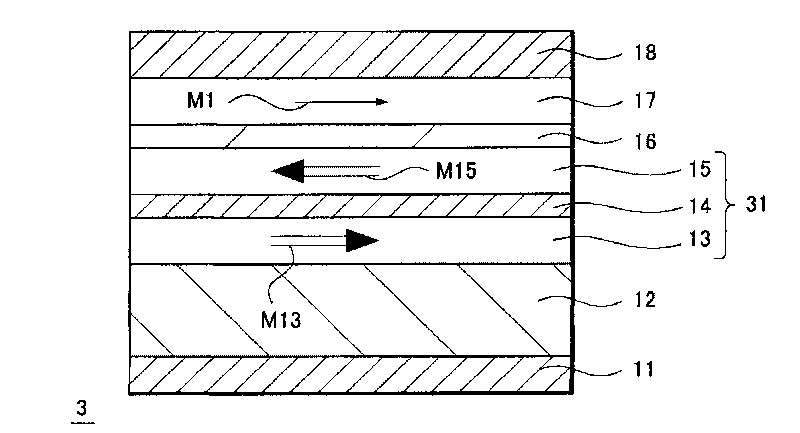

Storage element and memory

InactiveCN101743634AImprove coercive forceImprove thermal stabilityNanomagnetismNanoinformaticsInsulation layerMagnetization

A memory in which thermal stability is improved without increasing the writing current. The memory is provided with a storage element (3) having a storage layer (17) for holding information by the magnetization state of a magnetic body. A magnetization fixation layer (31) is provided on the storage layer (17) through an intermediate layer (16). The intermediate layer (16) consists of an insulator. Direction of magnetization M1 of the storage layer (17) is changed by injecting electrons subjected to spin polarization in the laminating direction, and information is recorded on the storage layer (17). Strain is applied to the storage layer (17)from an insulation layer on the periphery of the storage layer (17) having a smaller coefficient of thermal expansion as compared with the storage layer (17). The memory is also provided with wiring for supplying a current in the laminating direction of the storage element (3).

Owner:SONY CORP

Intermediate-high temperature acid-corrosion-resisting glass fiber treating compound and preparation method thereof

InactiveCN103964708AImprove temperature and weather resistanceGood adhesive properties and thermal stabilityPrepolymerEmulsion

The invention relates to an intermediate-high temperature acid-corrosion-resisting glass fiber treating compound and a preparation method thereof. The method comprises the following steps: putting bisphenol-A epoxy resin and benzoyl peroxide into a flask, and carrying out stirring and rising temperature; then dropwise adding methacrylic acid, and preserving heat; cooling the obtained product, adding paraxylene and dibutyltin dilaurate to continue to stir, dropwise adding vinyltriethoxysilane, and preserving heat to obtain a pale yellow modified epoxy resin prepolymer; adding deionized water and emulsifier into the flask, and then carrying out full stirring and heating for dissolving; adding the modified epoxy resin prepolymer slowly, and continuing to stir after dropwise adding; rapidly cooling the obtained film former emulsion to room temperature, then mixing the film former emulsion, a coupling agent, nanosilicon dioxide, a lubricating agent and an antistatic agent so as to obtain the glass fiber treating compound. The method has the benefit that the temperature resistance of a film former is improved. The treating compound can improve the performance retention rate of glass fiber reinforced plastics materials under the intermediate-high temperature acidic condition.

Owner:WUHAN UNIV OF TECH

Strong-base corrosion-resistant ceramic glaze and preparation method thereof

The invention discloses a strong-base corrosion-resistant ceramic glaze. The ceramic glaze comprises the following components: a boron frit, quartz powder, spodumene, calcined zinc oxide, calcined talcum powder, kaolin, zirconium silicate, a toner and the like. The preparation method comprises the following steps: preparing materials according to mass parts of the components, carrying out ball milling to obtain glaze, sieving the glaze discharged out of a ball mill to obtain glaze slurry, adding water and an electrolyte to respectively adjust the concentration and thixotropy of the glaze slurry, dipping a glaze blank in the glaze slurry, carrying out drying, then putting the glaze blank into a roller kiln, and carrying out firing at a temperature of 1210-1240 DEG C to obtain a high-densityborosilicate glass body. Various pigments are wrapped in the glass body for protection, the firing temperature is low, compactness of the fired glaze is guaranteed, a complete glaze glass body with high density, high gloss and pore-free glaze surface is achieved, and Si-O bonds formed in the glaze glass are protected from being damaged, so that corrosion of strong bases can be resisted.

Owner:HUNAN HUALIAN CHINA IND

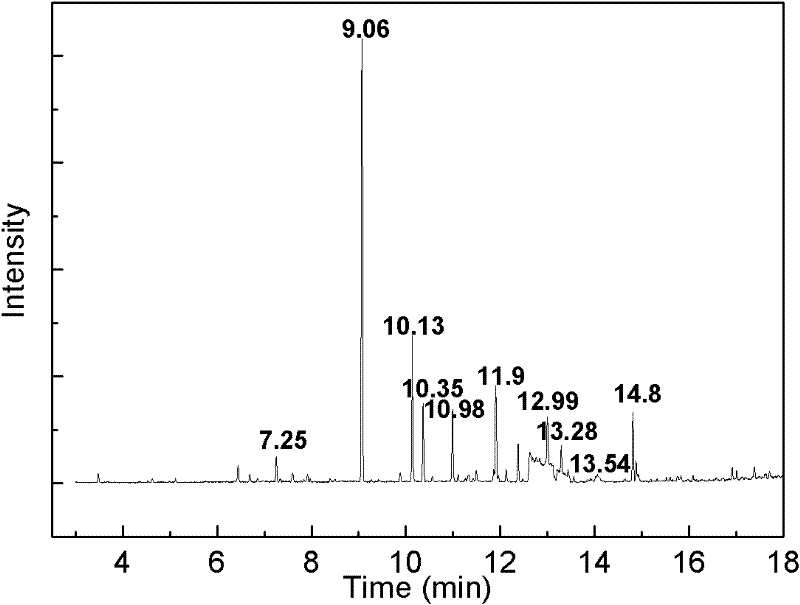

Noble metal catalyst used in hydrocracking and isomerization of Fischer-Tropsch synthetic wax and preparation method therof

ActiveCN101698148AHigh activityGuaranteed thermal stabilityMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatmentIsomerizationPore distribution

The invention provides a noble metal catalyst used in hydrocracking and isomerization of Fischer-Tropsch synthetic wax and a preparation method thereof. The a catalyst carrier comprises the following components: 70 to 85 weight percent of amorphous silicon aluminum and 15 to 30 weight percent of alumina adhesive, wherein active components are selected from noble metal Pt and Pd elements (in a molar ratio of 0.1 to 0.6) and the noble metal active components account for 0.1 to 1 weight percent of the carrier; the specific surface area of the catalyst is 150 to 400m2 / g, while the pore volume is 0.3 to 1.4ml / g and the NH3-TPD total acidity is between 0.5 and 1.5mmol / g; and 4 to 15nm pore distribution accounts for 60 to 90 percent of total pore volume respectively. The preparation method comprises the following steps: (1) adding the alumina adhesive, 1 to 5 weight percent pore-forming agent CMC of the amorphous silicon aluminum and 1 to 3 weight percent extrusion-aid agent sesbania powder into the amorphous silicon aluminum of required weight, extruding the mixture on an extruder after mixed kneading and roller compaction, and drying and baking to obtain the carrier; and (2) loading active components Pt and Pd noble metal elements by a common dipping method and then carrying out vacuum drying to obtain the catalyst through calcination.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

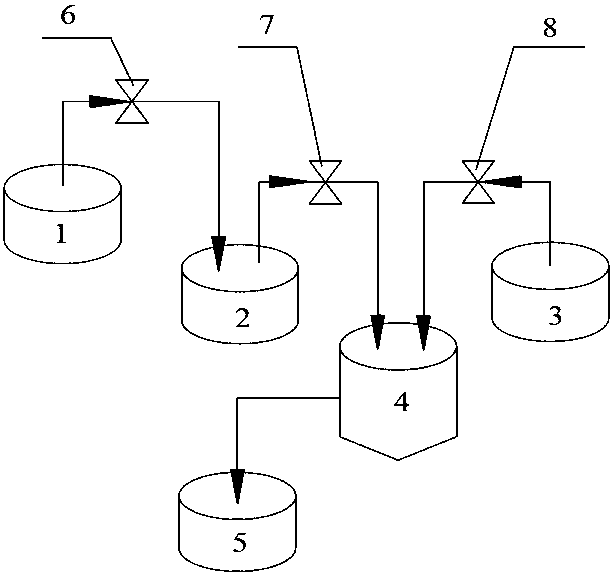

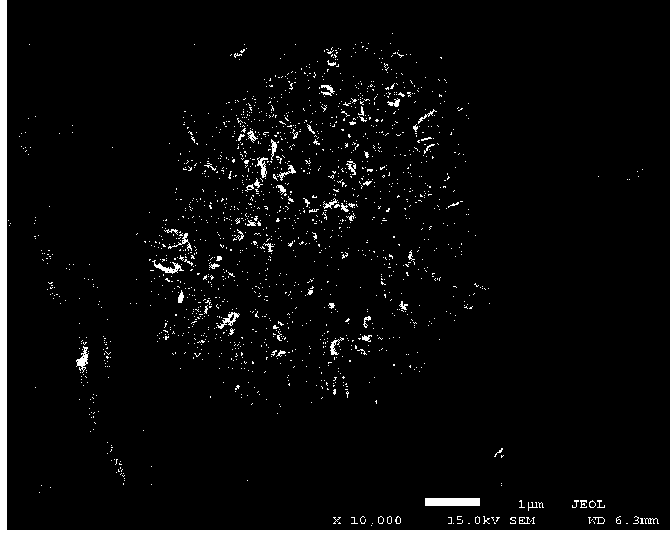

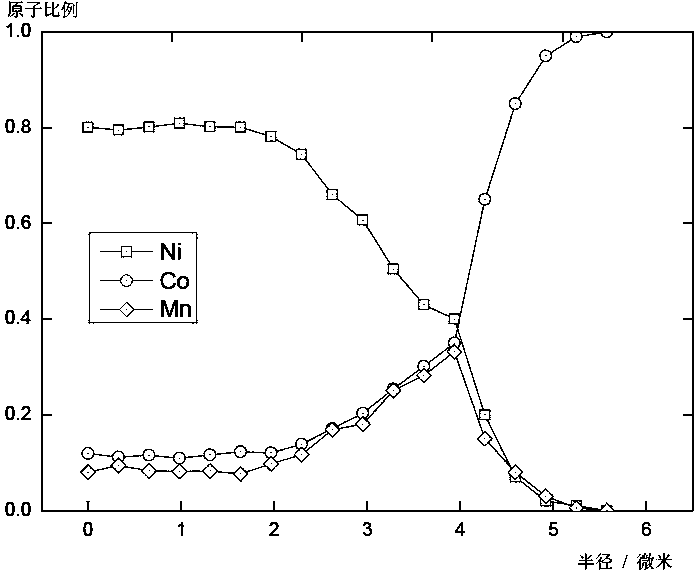

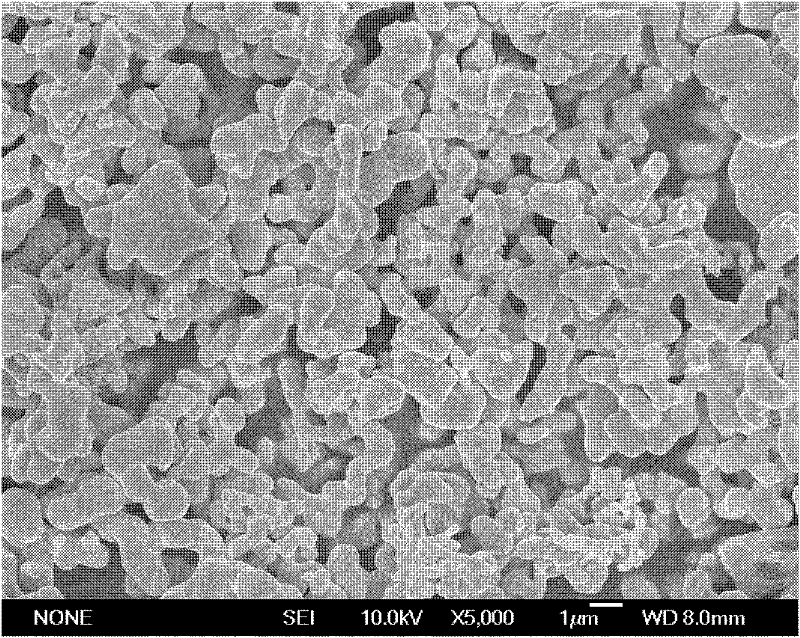

Anode active material for lithium cell and method for manufacturing same

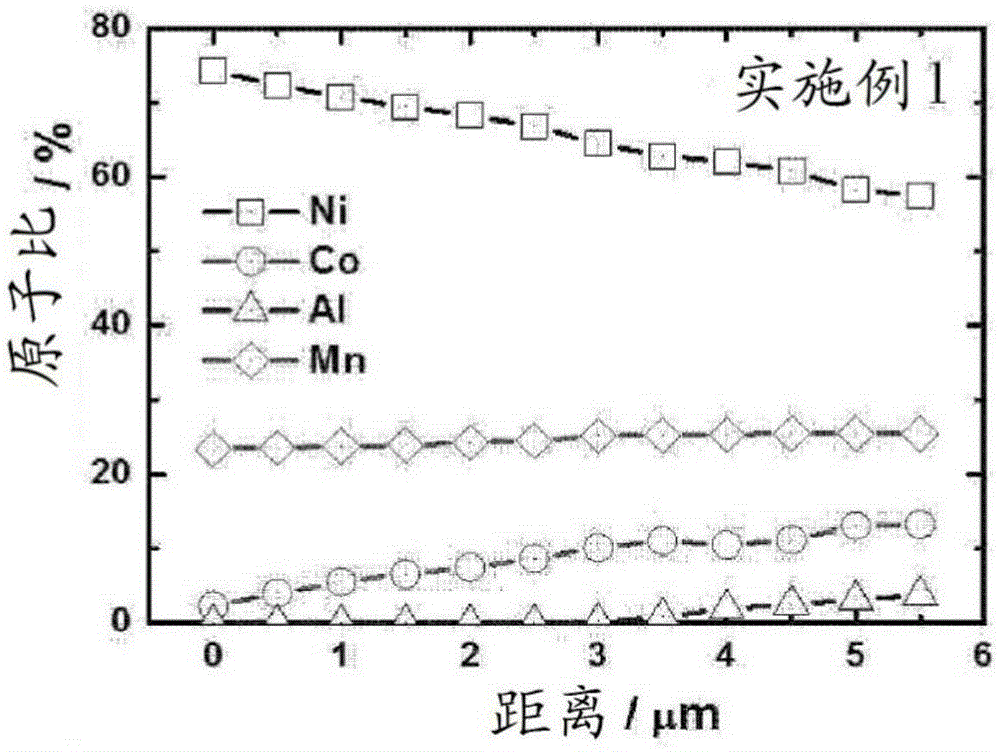

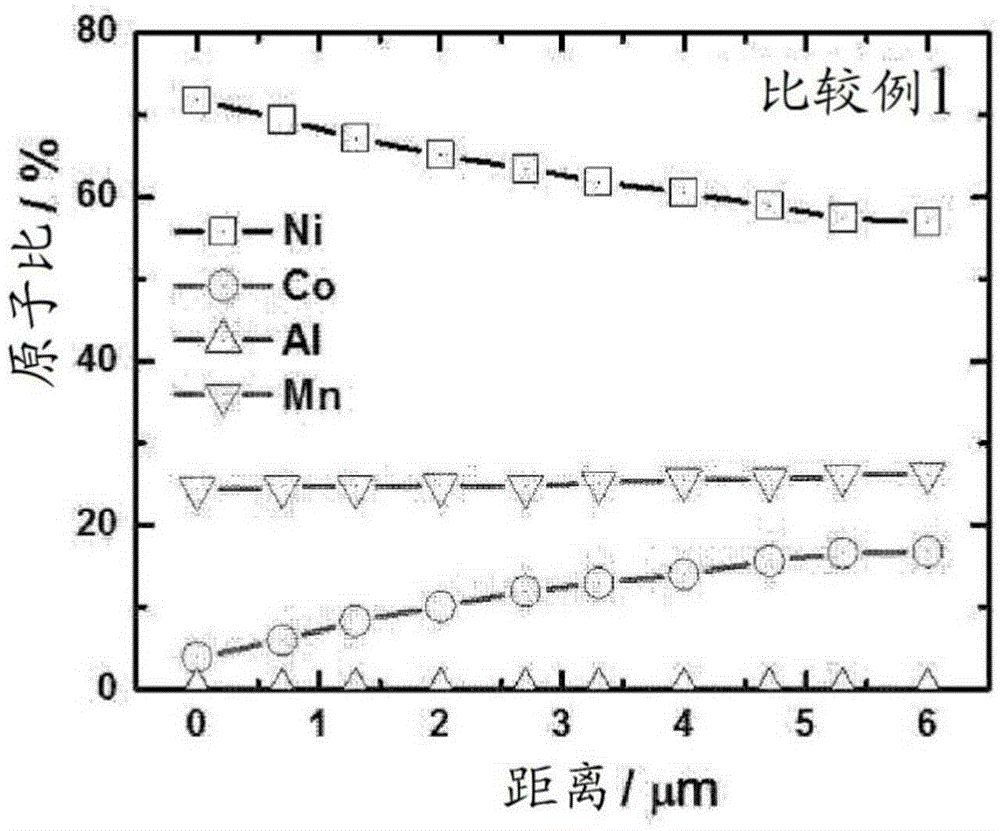

ActiveCN105378985AStable structureInhibit thermalizationSecondary cellsNon-aqueous electrolyte accumulator electrodesConcentration gradientMetal

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

High-temperature oil-resistant and flame-retardant chlorinated polyethylene heat-shrinkable tubing as well as preparation method and application thereof

The invention discloses high-temperature oil-resistant and flame-retardant chlorinated polyethylene heat-shrinkable tubing as well as a preparation method and an application thereof. The heat-shrinkable tubing comprises the following components: chlorinated polyethylene, resin A, resin B, a polymer compatibilizer, black masterbatch, antimonous oxide, a flame retardant synergist, a halogen-free flame retardant, a thermal stabilizer, hydrotalcite, an antioxidant, a sensitizer and a silicone additive. The method comprises the following steps: firstly, banburying the antimonous oxide, the flame retardant synergist, the halogen-free flame retardant and hydrotalcite; adding and banburying the chlorinated polyethylene, the resin A, the resin B, the polymer compatibilizer, the black masterbatch, the thermal stabilizer, the antioxidant and the silicone additive; finally adding a sensitizer and banburying, and then palatalizing, and extruding to form the tubing; and carrying out irradiation crosslinking, expanding drawing, cooling sizing, and marking, so as to obtain the high-temperature oil-resistant and flame-retardant chlorinated polyethylene heat-shrinkable tubing. The high-temperature oil-resistant and flame-retardant chlorinated polyethylene heat-shrinkable tubing has the advantages of being low in price, efficient, flame-retardant, excellent in mechanical property, low in pollution, high in high-temperature oil resistance, and good in resistance to acid and alkali corrosion, and can be applied to a bad working condition.

Owner:广州凯恒科塑有限公司

Preparation method of ziroconium oxide composite nano crystal material

ActiveCN1830810AGuaranteed stabilityGuaranteed thermal stabilityZirconium oxidesOxide compositeChemistry

A nanocrystal of zirconium-lanthanum oxide or RE oxide composition is prepared through hydrolyzing to become core, compounding by codeposition, coupling, calcining and pulverizing to obtain a sosoloid. It has high crystal-phase stability and thermal stability, and can be used as the catalyst of the tail gas of car.

Owner:天津海赛纳米材料有限公司

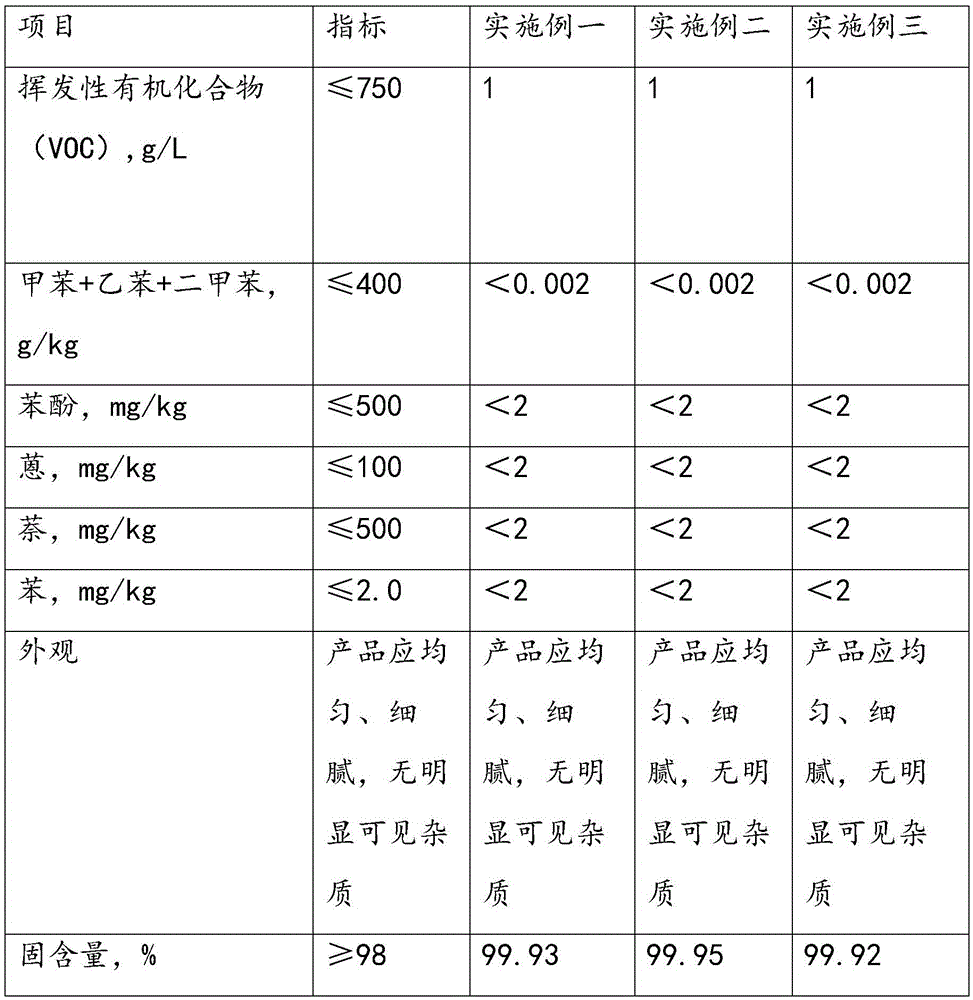

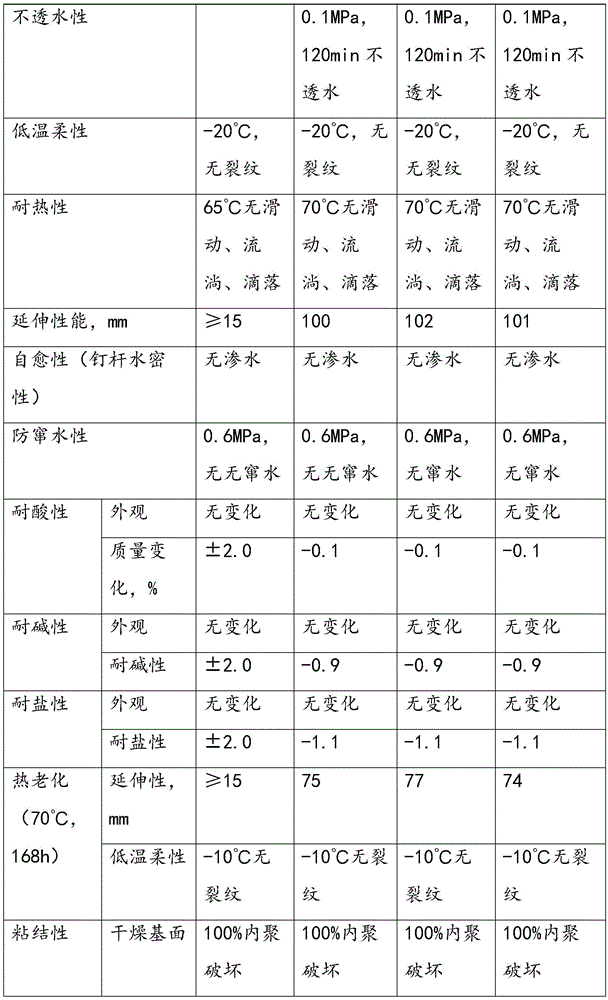

Non-curable root puncture-resistant waterproof coating and preparation method thereof

InactiveCN105542662AImprove high temperature stabilityImprove low temperature ductilityBituminous coatingsSelf-healingPlasticizer

The invention discloses a non-curable root puncture-resistant waterproof coating. The key points of the technical scheme are as follows: the non-curable root puncture-resistant waterproof coating is prepared from the following components in percentage by weight: 9-11 percent of a softening agent, 55-68 percent of 90# asphalt, 1-2 percent of SBS (Styrene- Butadiene-Styrene), 4-6 percent of SBR (Styrene Butadiene Rubber), 15-25 percent of a filling material, 0.2-0.3 percent of a stabilizing agent, 1-1.5 percent of a plasticizer and 0.6-1 percent of a root retarder and is excellent in root puncture resistance effect and good in self-healing property, heat aging resistance, heat stability and cohesive property.

Owner:BEIJING YUANDAHONGYU WATERPROOF MATERIAL CO LTD

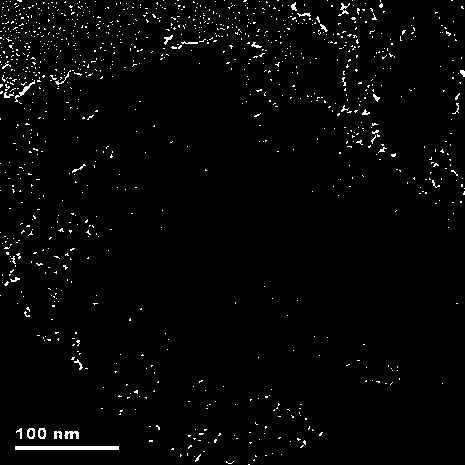

Preparation method of graphene-supported stannic oxide quantum dot negative electrode material for lithium ion battery

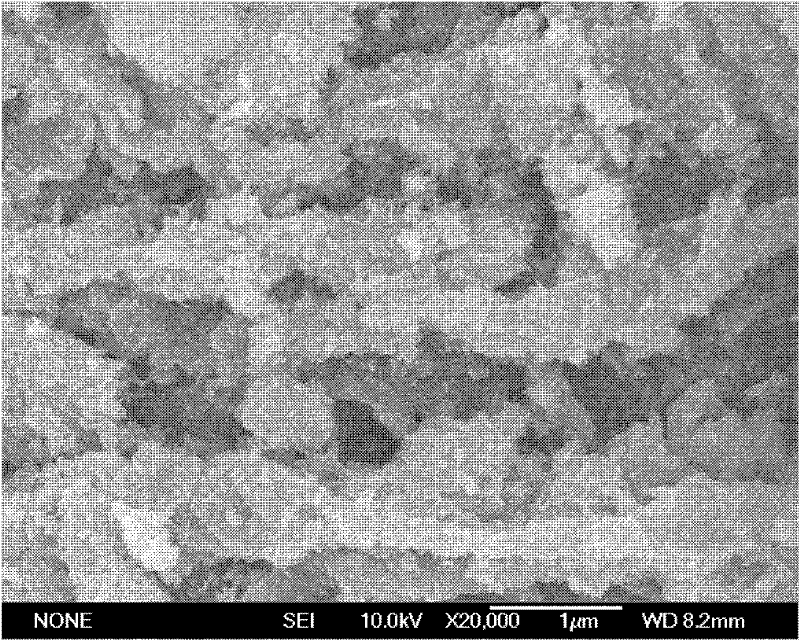

InactiveCN103441254ATight and evenly attachedHigh lithium storage capacityCell electrodesLithium-ion batteryReducing agent

The invention discloses a preparation method of a graphene / stannic oxide quantum dot composite electrode material for a lithium ion battery. In the sample preparation process, that graphene-supported stannic oxide quantum dots are synthesized under relatively mild experiment conditions by utilizing a wet chemical method, and urea is adopted as a reducing agent to reduce graphite oxide, so that the preparation method has the advantages of simple and controllable reaction conditions and low production cost; by introducing graphene, not only can the conductivity of the composite material be improved but also volume change in the stannic oxide charge-discharge process can be effectively buffered; therefore the composite material shows good cycling stability.

Owner:QINGDAO UNIV OF SCI & TECH

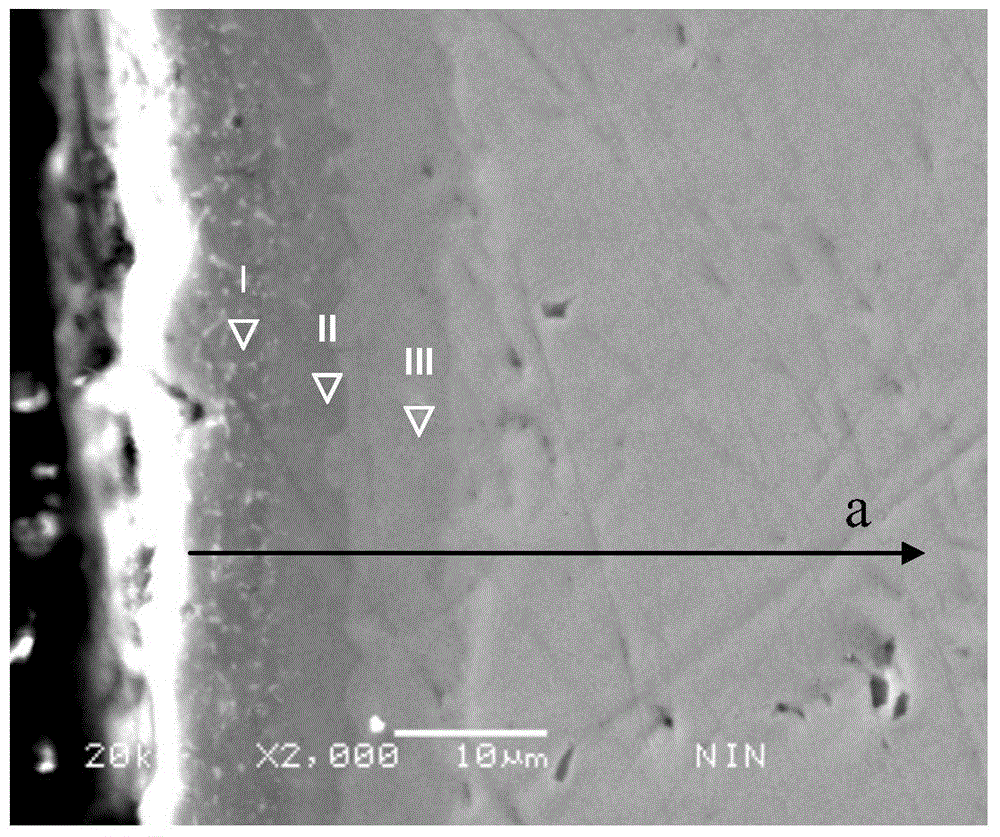

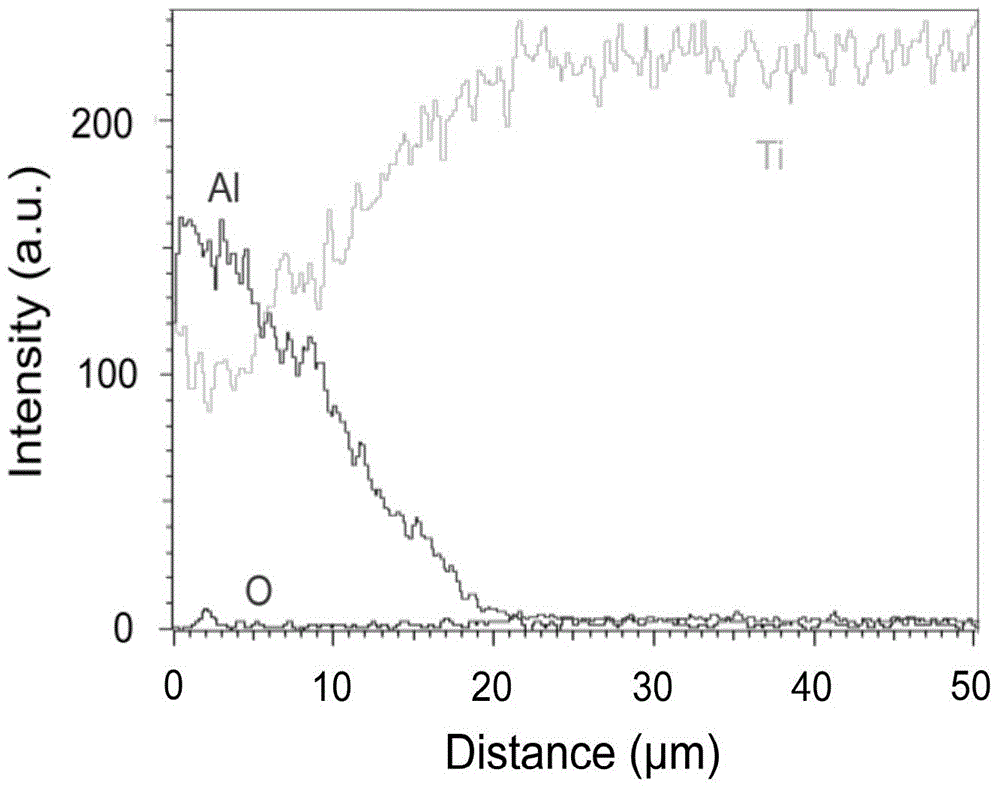

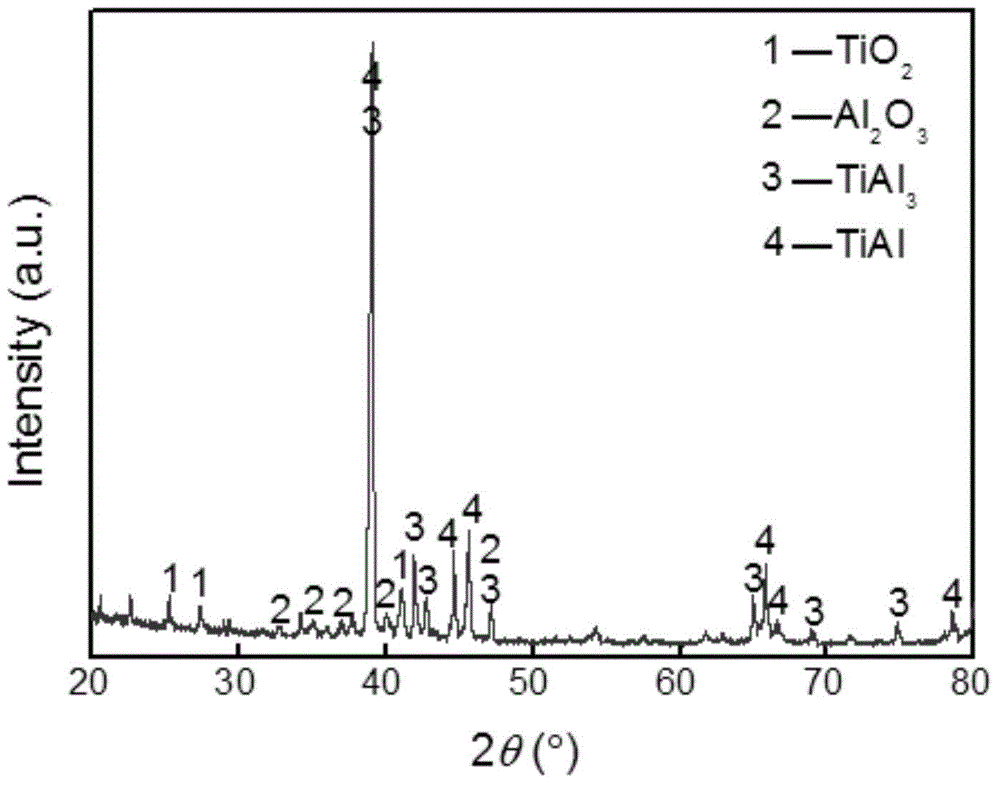

Preparation method of titanium substrate surface high-temperature antioxidant composite coating

ActiveCN104674218AImprove high temperature oxidation resistanceContinuous and dense structureVacuum evaporation coatingSurface reaction electrolytic coatingOxide ceramicsOxidation resistant

The invention discloses a preparation method of a titanium substrate surface high-temperature antioxidant composite coating. The preparation method comprises the following steps: I, carrying out the surface polishing treatment for a titanium substrate, oxidizing the titanium substrate subjected to the surface polishing treatment to obtain a titanium substrate with a titanium dioxide ceramic layer on the surface, and depositing metal aluminum on the titanium dioxide ceramic layer to obtain the titanium substrate with a titanium dioxide ceramic layer and an aluminum coating on the surface; and II, carrying out the vacuum heat treatment for the titanium substrate with the titanium dioxide ceramic layer and the aluminum coating on the surface, and obtaining a high-temperature antioxidant composite coating on the surface of the titanium substrate. The high-temperature antioxidant composite coating consisting of Ti and Al intermetallic compounds and oxide ceramics can be prepared on the surface of the titanium substrate, and the high-temperature antioxidant composite coating structure is continuous and compact and has no hole defect; moreover, the surface of the high temperature antioxidant composite coating is provided with an Al2O3 membrane, the Al2O3 membrane can prevent an oxygen element from diffusing into the titanium substrate, and the high temperature antioxidant capability of the titanium substrate can be improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

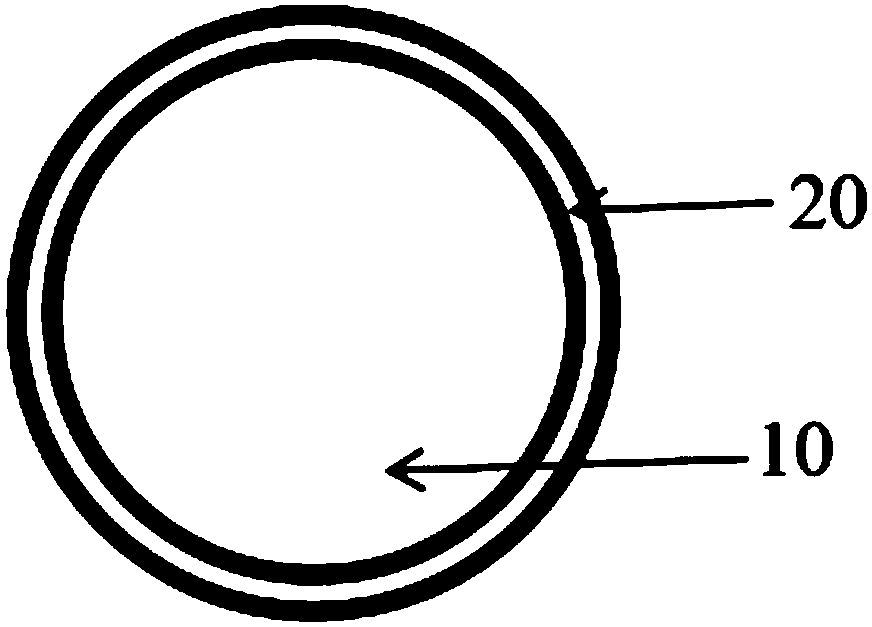

Method for preparing iron/copper compound coated magnesium diborate superconductive long wire

InactiveCN1945759AGuaranteed success rateGuaranteed thermal stabilitySuperconductors/hyperconductorsSuperconductor devicesMagnesium diborideThermal stability

This invention relates to a preparation method for an iron / copper compound packet wrapping MgB2 super-conduction long wires including: processing an iron tube and a copper tube of a certain specification, jacketing the iron tube into the copper tube, putting Mg powder, B powder and doped materials into a ball mill tank, then adding acetone reagent to dip the materials and mill the balls, vacuum-drying the ball-mill sample under ordinary temperature to get the material powder to be pressed to a cylinder with 10-600 MPa pressure and put into an iron tube, then to be pressed tightly and seal the port to get a compound packet wire in a certain diameter and length after swaging, rolling the hole and drawing, which is processed under 650-950deg.C for 0.5-5h to get a MgB2 super conduction wire with compound iron / copper.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Alloy material, valve retainer, and preparation method and installation method thereof

ActiveCN102994917AGuaranteed wear resistanceGuaranteed thermal stabilityMachines/enginesLift valveAlcohol fuelAlloy

The invention provides an alloy material, a valve retainer prepared from the alloy material, and a preparation method and an installation method of the valve retainer, and belongs to the technical field of auto spare parts. The invention can solve problems of weak corrosion resistance and abrasion resistance of an existing alloy material and a valve retainer prepared from the alloy material in an alcohol fuel engine. The invention improves formula of the alloy material, the preparation process and installation method of the valve retainer. The valve retainer provided by the invention has excellent wear resistance and corrosion resistance, and improved machinability, tensile strength and yield strength.

Owner:CHERY AUTOMOBILE CO LTD

Automatic ignition powder for gas generator of air bag restraint system of automobile and preparation method of automatic ignition powder

ActiveCN105777458AEasy to igniteAppropriate thermal decomposition temperatureNon-explosive/non-thermic compositionsDecompositionRare earth

The invention provides automatic ignition powder for a gas generator of an air bag restraint system of an automobile and a preparation method of the automatic ignition powder.The automatic ignition powder contains fuel, oxidant and flame accelerator; the flame accelerator is rare earth and perovskite type composite metal oxide; the general formula of the flame accelerator is La1-xAxMnO3, wherein A is Ce and / or Cu, and x is greater than zero and less than one.According to the automatic ignition powder, the specific flame accelerator is adopted and can effectively promote a redox reaction in the powder, thereby thermal decomposition of the automatic ignition powder is promoted, the decomposition temperature of the powder is lowered, and automatic ignition performance of the powder is improved.

Owner:BYD CO LTD

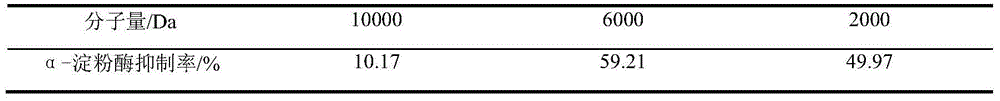

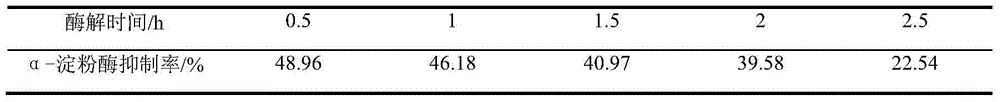

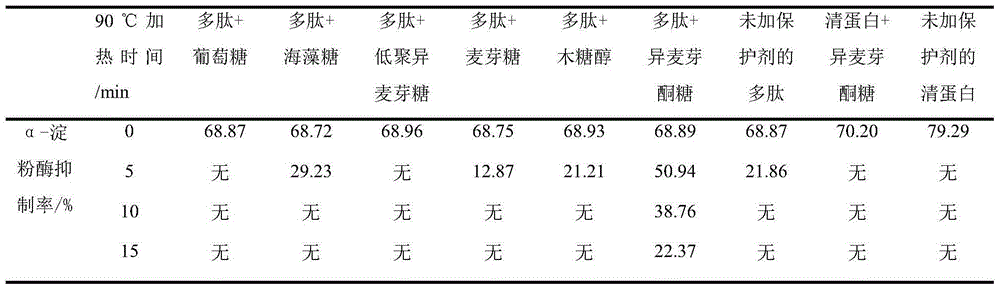

Functional white kidney bean polypeptide and preparation method and application thereof

ActiveCN104131057AGuaranteed thermal stabilityReduce dissolutionHydrolysed protein ingredientsMetabolism disorderUltrafiltrationWHITE KIDNEY BEAN

The invention provides functional white kidney bean polypeptide and a preparation method and an application thereof. With white kidney bean as a raw material, white kidney bean firstly undergoes extraction to obtain white kidney bean albumin; after centrifugation of albumin and ultrafiltration for removal of impurities, acid proteinase is used for enzymolysis; after enzyme deactivation, centrifugation is carried out and a supernatant is taken; after ultrafiltration of the supernatant and concentration, isomaltulose is added according to a certain proportion; and after uniform agitation, vacuum or spray drying is carried out to obtain a polypeptide product. The polypeptide product has high thermostability and an effect of inhibiting alpha-amylase activity, and can be applied to fat-reducing and hypolipemic health food.

Owner:郑理德

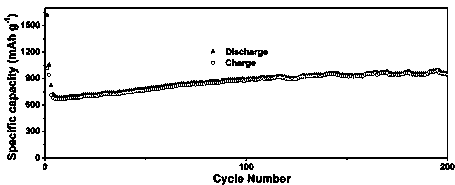

Lithium battery cathode material and preparation method thereof

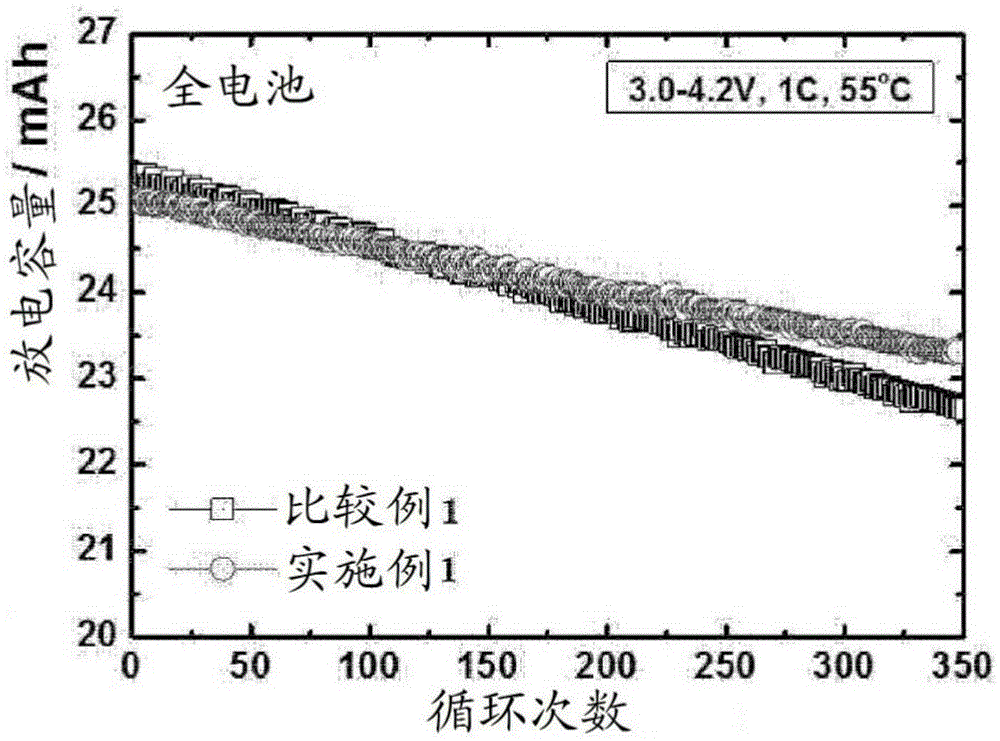

ActiveCN104347866AIncrease capacityImprove cycle performanceCell electrodesSecondary cellsCobalt saltCoprecipitation

The invention provides a lithium battery cathode material and a preparation method thereof. The preparation method comprises the following steps: S1, performing coprecipitation reaction on a solution A and an alkali solution for 5-25 h; S2, pumping a solution B into the solution A at a constant speed, and continuing to perform coprecipitation reaction on the whole mixed solution and the alkali solution when the solution B is pumped; S3, continuing to perform coprecipitation reaction on a solution C and the alkali solution, and drying the obtained precursor after the reaction is terminated; and S4, mixing the precursor with a lithium salt, and sintering to obtain the lithium battery cathode material. The molar ratio of Ni, Co and Mn in the solution A is equal to (1-2x):x:x, and 0<x<=0.25; the molar ratio of Ni, Co and Mn in the solution B is equal to (1-2y):y:y, and 0.25<=y<0.5; and the solution C is an aqueous solution of a cobalt salt. The provided lithium battery cathode material has the advantages of high capacity, high heat stability, high cycle performance, high electrochemical performance and low cost, and has the first efficiency up to 92% or more.

Owner:BYD CO LTD

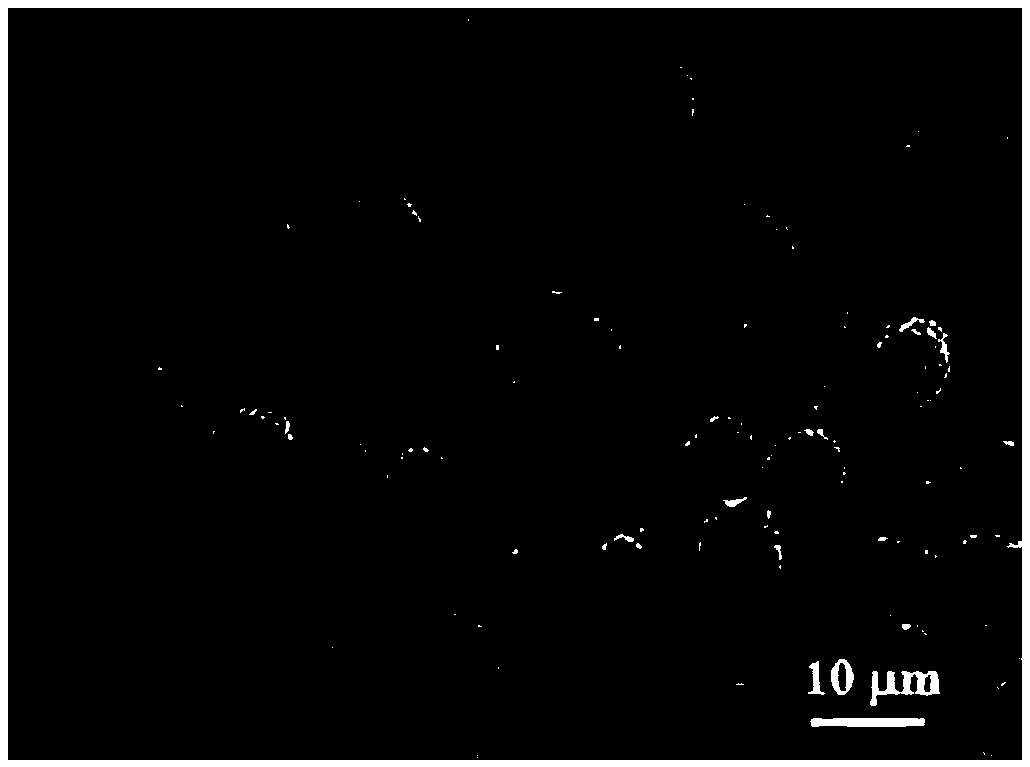

Biomass tar cracking catalyst

InactiveCN102335606AAvoid makingImprove thermal stabilityMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionChemistryTransition metal

The invention provides a biomass tar cracking catalyst. The catalyst takes granular calcium oxide or magnesium oxide or biomass pyrolytic carbon or ash formed after husk is gasified or a mixture of the granular calcium oxide, the magnesium oxide, the biomass pyrolytic carbon and the ash as a carrier and takes supported transition metal element Co as an active component, wherein the content of Co is over 15% of the mass of the catalyst, and the transition metal element Co has the grain diameter of 0.5-2mum and the apparent density of 0.6-1.2g / cm<3>. The catalyst is used at the temperature of 650-1000 DEG C. By using the catalyst, tar generated in the biomass gasification process is cracked and mainly converted into H2, CH4 and a small amount of accumulated C, and the cracking rate can be up to 100%. Compared with the traditional tar cracking catalyst, the biomass tar cracking catalyst has low use temperature, high catalytic activity, simple preparation process and easiness in industrialized production.

Owner:HUAZHONG NORMAL UNIV

Chlorinated polyvinyl chloride resin and preparation method and application

InactiveCN104231130AEasy to plasticizeImprove processing fluidityChlorinated polyvinyl chlorideOxygen

The invention discloses a chlorinated polyvinyl chloride resin and its preparation method and application. The preparation method comprises the following steps: in an oxygen-free atmosphere, chlorine is introduced, at the speed of 20-40m<3>.h<-1>.(1000kg polyvinyl chloride resin)<-1>, into a mixed system of polyvinyl chloride resin, an initiator and a dispersant and water or hydrochloric acid; the speed of introducing chlorine is adjusted to 20-32m<3>.h<-1>.(1000kg polyvinyl chloride resin)<-1>, 30-50 m<3>.h<-1>.(1000kg polyvinyl chloride resin)<-1> and 20-32 m<3>.h<-1>.(1000kg polyvinyl chloride resin)<-1> respectively; and introduction of chlorine is stopped, and a reaction continues. The total amount of introduced chlorine during the above steps meets the following requirement: chlorine content of the chlorinated polyvinyl chloride resin reaches 63.5-65.5 wt%. The chlorinated polyvinyl chloride resin provided by the invention is easy to plastify and has good processing fluidity and heat-resistant stability.

Owner:SHANGHAI CHLOR ALKALI CHEM

Composite cathode material, preparation method and lithium ion battery

ActiveCN108832093AImprove thermal stabilityGuaranteed thermal stabilityCell electrodesSecondary cellsManganeseSodium-ion battery

The invention relates to a composite cathode material, comprising a base cathode material and a magnesium aluminate material MgAl2O4 coating the surface of the base cathode material. Preferably, the base cathode material is a nickel-cobalt-manganese ternary cathode material LiNixCoyMnzO2 or a nickel-cobalt-aluminum ternary cathode material LiNixCoyAlzO2, wherein x+y+z=1, 0 (x, y, z (1. The invention also relates to a preparation method of the composite cathode material and a lithium ion battery. The MgAl2O4 on the surface of the cathode material can protect the cathode material in the inner layer, improve the thermal stability of the cathode material, and thus improve the cycle stability and safety of the battery.

Owner:SOUNDON NEW ENERGY TECH CO LTD

Preparation of chlorinated polyvinyl chloride resin for pipe fittings

InactiveCN101486778AGuaranteed thermal stabilityImprove heat stabilityPipe fittingChlorinated polyvinyl chloride

The invention discloses a method for preparing chlorinated polynvinyl chloride resin for pipe fittings, comprising the following steps of: suspending polyvinyl chloride resin in water or hydrochloric acid solution, and adding initiator and dispersant; leading in chlorine at the temperature of 40-90 DEG C, on the basis of 10-35 kg of PVC and at the chlorine-leading speed of 10-30 L / min, closing an off gas valve after chlorine-leading lasts for 5-10 min, and raising the temperature till 90-100 DEG C, and then leading in the chlorine at the speed of 4-30 L / min for 30-50 min; and raising the temperature till 100-110 DEG C, then leading in the chlorine at the speed of 8-60 L / min for 60-140 min, then raising the temperature till 110-125 DEG C, leading in the chlorine at the speed of 4-30 L / min for 30-60 min, then stopping the chlorine leading-in, and continuing the reaction for 30-60 min so as to obtain the product. The CPVC resin prepared by the method has good heat resistance stability and good processing fluidity and is applicable to the fabrication of the pipe fittings by means of injection molding.

Owner:SHANGHAI CHLOR ALKALI CHEM

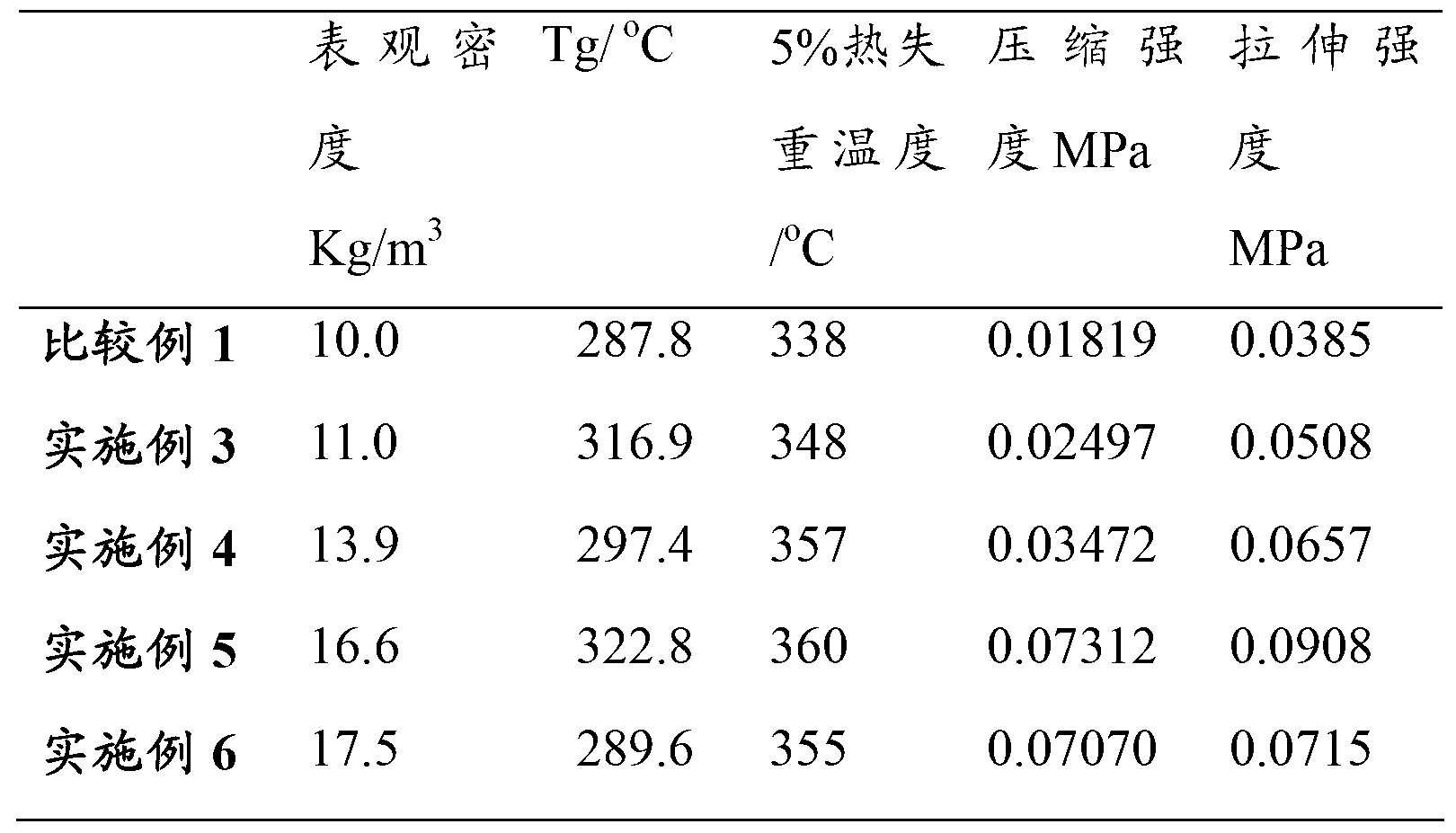

Polyimide foam and preparation method thereof

The invention provides a preparation method of polyimide foam. The method comprises the steps of reacting diamine with dianhydride in a solvent to obtain a first solution; mixing the dianhydride, a foaming agent, a catalyst and a surfactant in a solvent to obtain a second solution; mixing the first solution with the second solution, adding polyaryl polymethylene polyisocyanate dissolved in a solvent, stirring and foaming to obtain a foam intermediate; and carrying out imidization on the foam intermediate to obtain the polyimide foam. According to the invention, a novel polymer with a semi-interpenetrating network structure, which is formed by linear polyamide acid and crosslinked polyamide acid, is provided; due to the introduction of the linear polyamide acid, the defect that the crosslinked polyimide foam made from polyisocyanate and dianhydride is insufficient in flexibility is remedied; the foam property is improved through changing the body structure, so that the material flexibility is increased while the heat stability can be kept; and the polyimide foam obtained by adopting the preparation method provided by the invention is simple in process and low in density.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

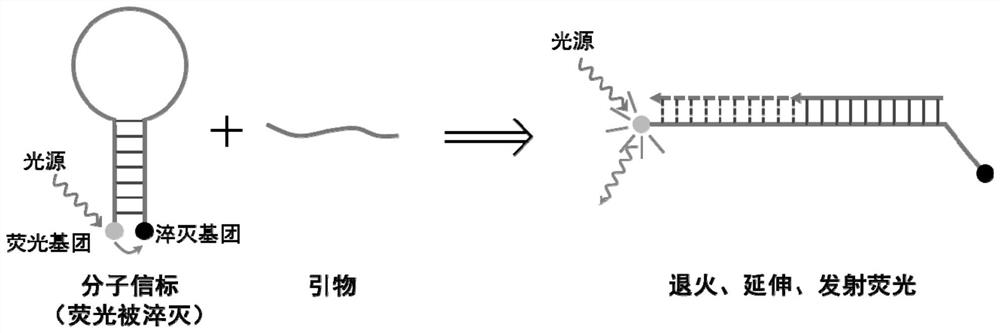

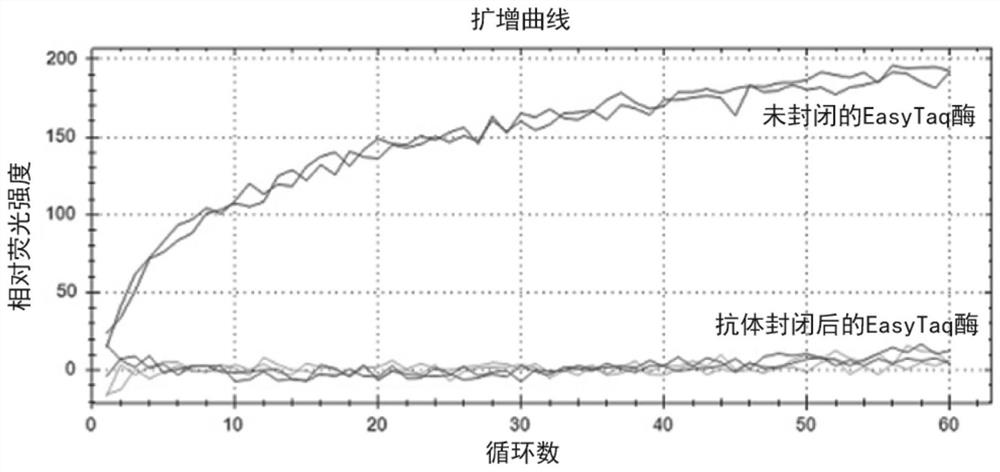

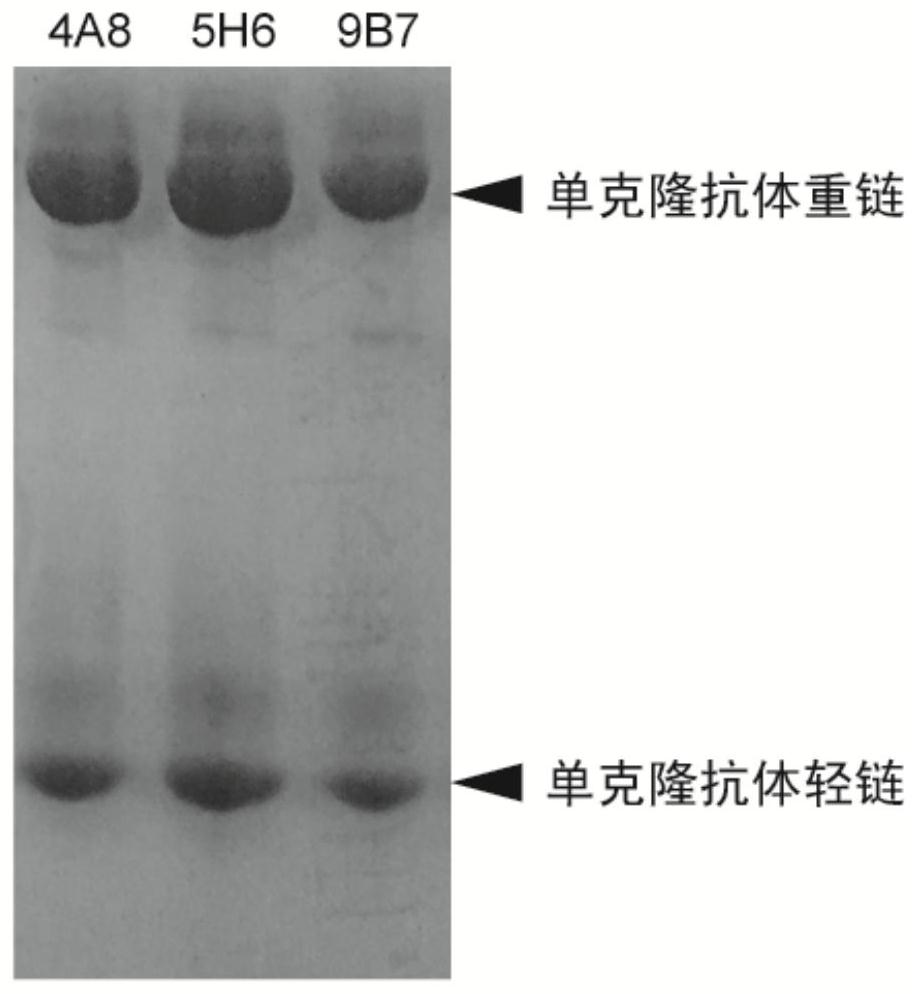

Taq DNA polymerase monoclonal antibody combination as well as reaction system and application thereof

ActiveCN111808197AHigh activityGuaranteed thermal stabilityMicrobiological testing/measurementTransferasesAntiendomysial antibodiesEnzyme

The invention discloses a Taq DNA polymerase monoclonal antibody combination as well as a reaction system and application thereof. The invention firstly discloses the Taq DNA polymerase monoclonal antibody combination. The combination comprises a monoclonal antibody 4A8 and a monoclonal antibody 9B7. The invention further discloses application of the antibody combination in reducing non-specific amplification of Taq DNA polymerase and / or ensuring thermal stability of Taq DNA polymerase, and a reaction system and a kit containing the antibody combination. The antibody combination and the optimized reaction solution can fully seal the active region of Taq DNA polymerase under the condition of low temperature, effectively reduce non-specific amplification and ensure the thermal stability of the enzyme, and can still effectively maintain the durability of the enzyme activity under the condition of higher amplification cycle number.

Owner:BEIJING TRANSGEN BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com