Electrolyte for electrolytic capacitor, electrolytic capacitor and process for producing tetrafluoroaluminate salt of organic onium

A technology of electrolytic capacitors and aluminum electrolytic capacitors, which is applied in the direction of electrolytic capacitors, capacitors, circuits, etc., can solve the problems of high electrical conductivity of electrolytic capacitors, difficulty in maintaining thermal stability and voltage resistance for a long time, and large leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0245] 1) Fabrication of capacitor elements

[0246] As the anode foil, an aluminum foil obtained by enlarging the surface of an aluminum foil with a thickness of 120 μm and a purity of 99.9% by electrolytic etching, and then forming a dielectric made of aluminum oxide on the surface by anodizing at a chemical conversion voltage of 160 V was used. And cut into 190mm × 13.5mm.

[0247] As the cathode foil, an aluminum foil obtained by subjecting an aluminum foil having a thickness of 30 μm and a purity of 99.9% to a surface-expanding process by electrolytic etching and then cutting into 200 mm×13.5 mm was used.

[0248] As the separator, Manila paper cut into 218 mm×150 mm and having a thickness of 52 μm was used.

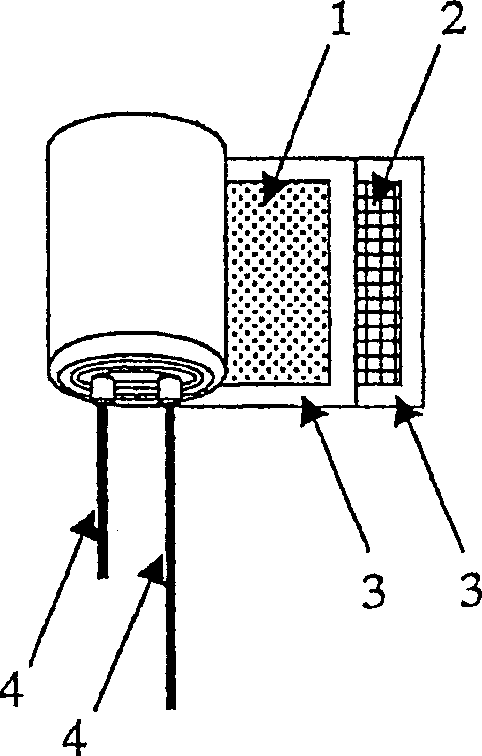

[0249] Such as figure 1 As shown, a separator 3 is placed between the anode foil 1 and the cathode foil 2, crimped, and fixed with an adhesive tape for fixing the capacitor element, wherein, the anode foil 2 is welded with a wire 4 installed by a fastening method ...

Embodiment 2

[0268] Carry out the drying of capacitor element under normal pressure, and in the atmosphere that relative humidity is 40%, carry out the cooling of capacitor element and the making of aluminum electrolytic capacitor, except this, carry out similarly with embodiment 1, make aluminum electrolytic capacitor, and evaluate. The collection results are shown in Table 1.

Embodiment 3

[0275] 1) Fabrication of capacitor elements

[0276] As the anode foil, an aluminum foil obtained by expanding the surface of an aluminum foil with a thickness of 120 μm and a purity of 99.9% by electrolytic etching, and then undergoing an anodic oxidation treatment with a chemical conversion voltage of 160 V in an aqueous solution of ammonium adipate to form The dielectric consisted of alumina and was cut to 190mm x 13.5mm.

[0277] As the cathode foil, an aluminum foil obtained by subjecting an aluminum foil having a thickness of 30 μm and a purity of 99.9% to a surface-expanding process by electrolytic etching and then cutting into 200 mm×13.5 mm was used.

[0278] As the separator, Manila paper cut into 218 mm×150 mm and having a thickness of 52 μm was used.

[0279] 2) Preparation of electrolyte

[0280] 25 parts by weight of dry 1-ethyl-2,3-dimethylimidazolinium tetrafluoroaluminate was dissolved in 75 parts by weight of low-moisture grade γ-butyrolactone, and this sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com