Polyimide foam and preparation method thereof

A polyimide and foam technology, applied in the field of polymer materials, can solve the problems of complicated reaction and insufficient flexibility of foam, and achieve the effect of improving foam performance, increasing flexibility and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

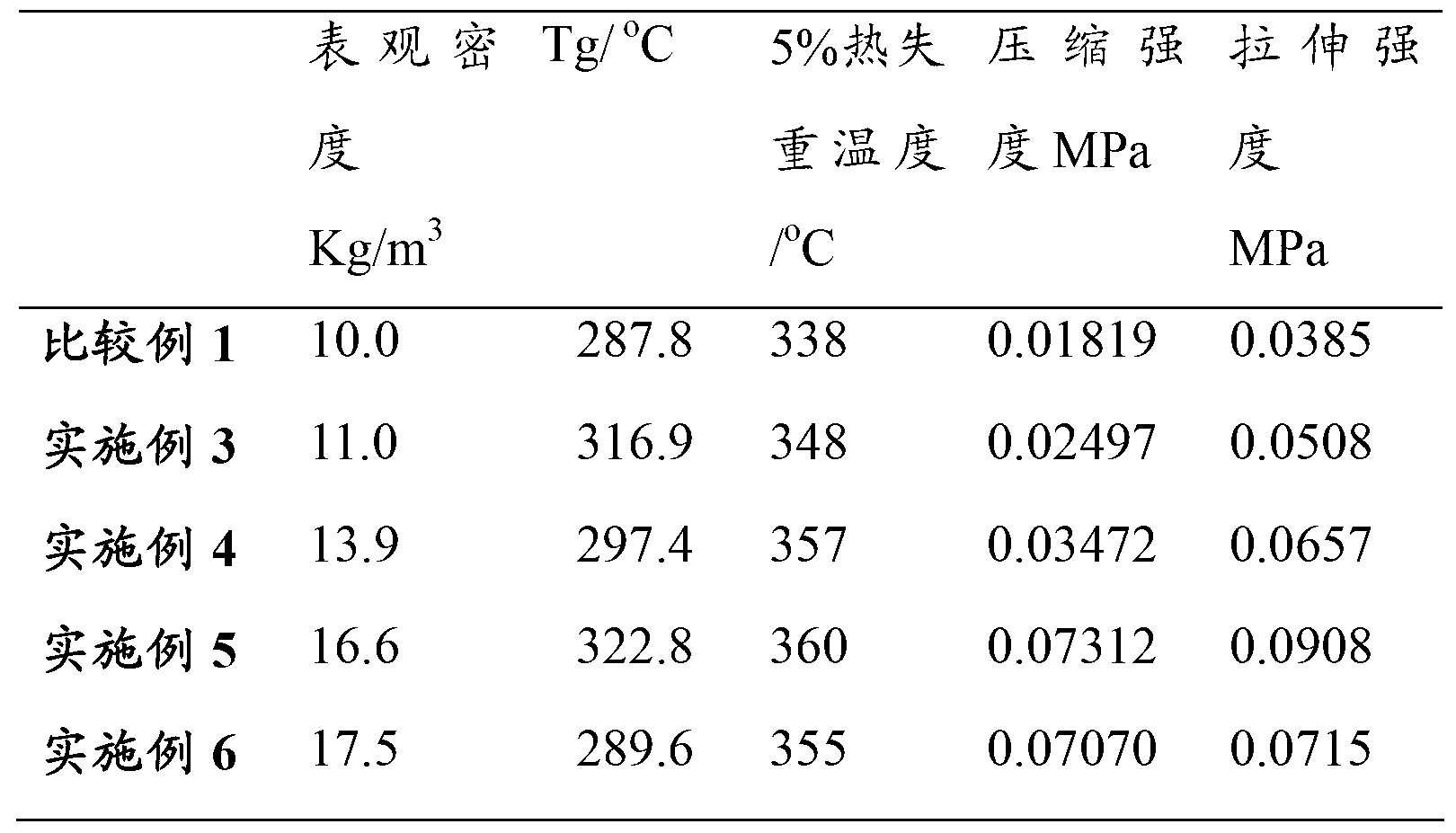

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of polyimide foam, it is characterized in that, comprises:

[0030] A) diamine and dianhydride are reacted in a solvent to obtain a first solution;

[0031] mixing dianhydride, foaming agent, catalyst and surfactant in a solvent to obtain a second solution;

[0032] B) mixing the first solution and the second solution, adding polyphenylpolymethylene polyisocyanate solution, stirring and foaming to obtain a foam intermediate;

[0033] C) Imidating the foam intermediate to obtain polyimide foam.

[0034] In the present invention, diamine and dianhydride are first reacted in a solvent to obtain a first solution. The molar ratio of the diamine to the dianhydride is preferably 1:0.95-1.05; the solid content of the first solution is preferably 9%-11%. The reaction temperature is preferably 20°C-30°C, and the reaction time is preferably 5-8h.

[0035] In the present invention, the dianhydride in the first solution is pref...

Embodiment 1

[0056] Weigh 8.400g (0.042mol) of 4,4'-diaminodiphenyl ether and add it to 187g of N,N'-dimethylformamide solution. After stirring and dissolving, add 12.349g (0.042mol) of 4,4 '-biphenyltetracarboxylic dianhydride, stirred at room temperature for 7 hours to obtain a first solution with a solid content of 10%.

Embodiment 2

[0058] 124g of 4,4'-benzophenone tetracarboxylic dianhydride, 10g of methanol, 12g of deionized water, 17g of DC-193, 6.5g of PEG, 0.1g of triethanolamine and 0.1g of dibutyltin dilaurate were added to 120g of N, In the N'-dimethylformamide solution, stir and dissolve evenly at room temperature to obtain the second solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com