Battery pack

A technology for battery packs and single cells, applied in battery electrodes, battery pack components, battery boxes/coatings, etc., can solve the problems of positive electrode thermal stability decline, lithium deintercalation, etc., and achieve simplified charge and discharge control and large tolerance , to ensure the effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

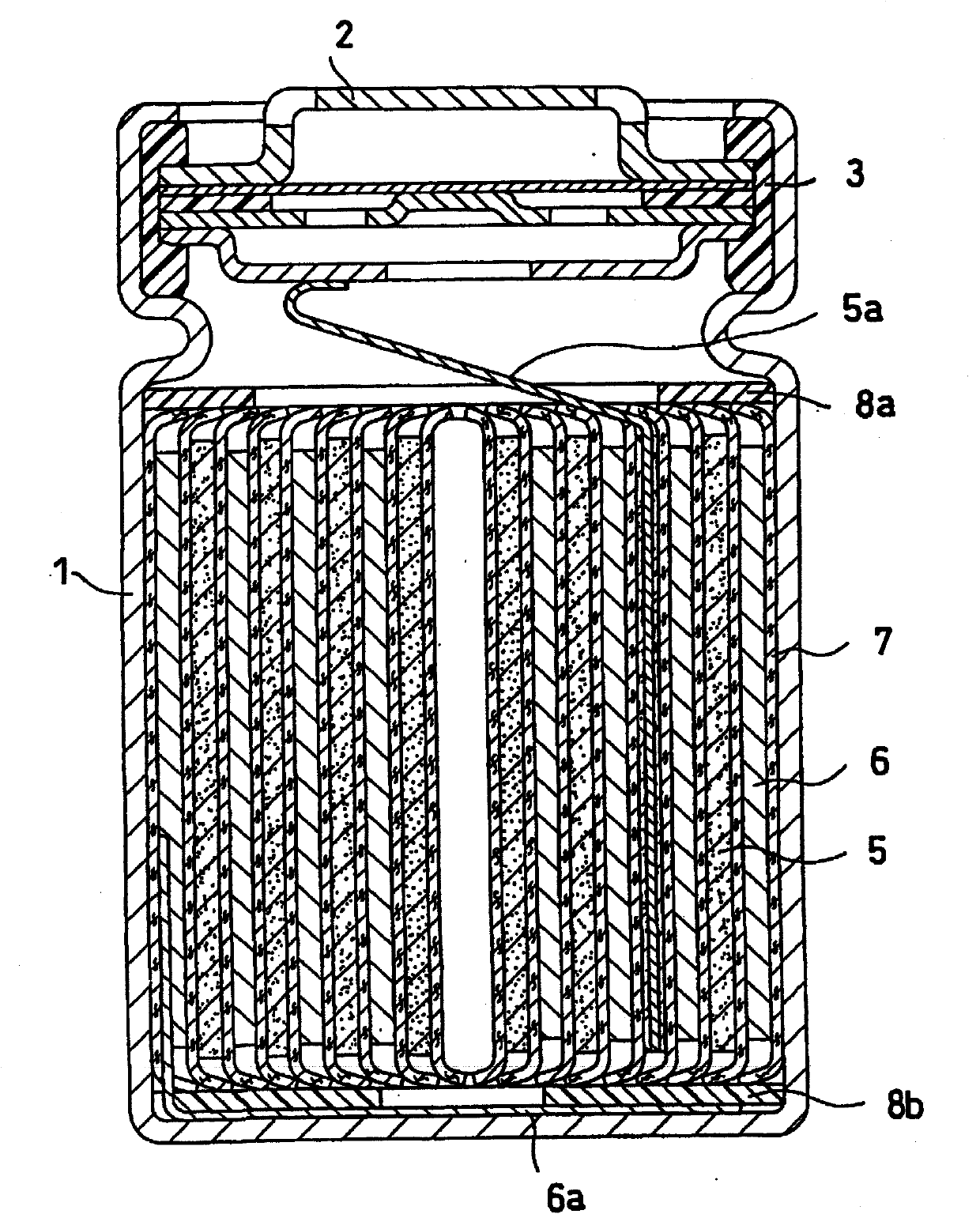

[0148] The first cell (battery P1 ) and the second cell (battery Q1 ) were manufactured in the following procedure.

[0149] (A) Fabrication of battery P1

[0150] (1) Production of positive electrode

[0151] [Ni 1 / 3 mn 1 / 3 co 1 / 3 ](OH) 2 with LiOH·H 2 O After thorough mixing, form the mixture into granules. In the atmosphere, the particles were calcined at 1000 °C for 6 hours to obtain LiNi as the positive electrode active material 1 / 3 mn 1 / 3 co 1 / 3 o 2 .

[0152] Add N-methyl-2-pyrrolidine in the mixture of 88 parts by weight of positive electrode active material, 6 parts by weight of acetylene black as conductive material and 6 parts by weight of polyvinylidene fluoride (PVdF) as binder Ketone (NMP) to obtain positive electrode slurry. This positive electrode slurry was coated on a positive electrode current collector made of aluminum foil. After coating, it was dried at 100° C. for 30 minutes, and then dried at 85° C. for 14 hours under vacuum to obtain a pos...

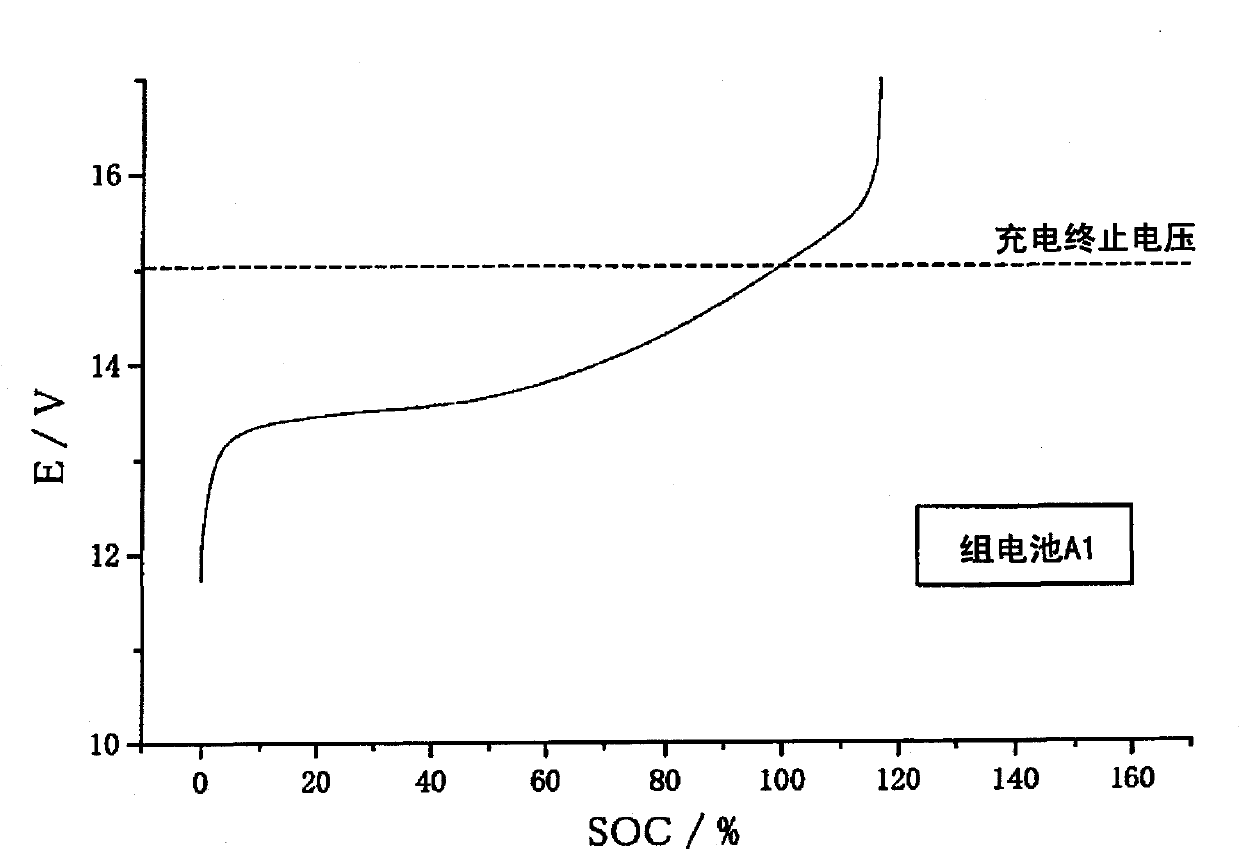

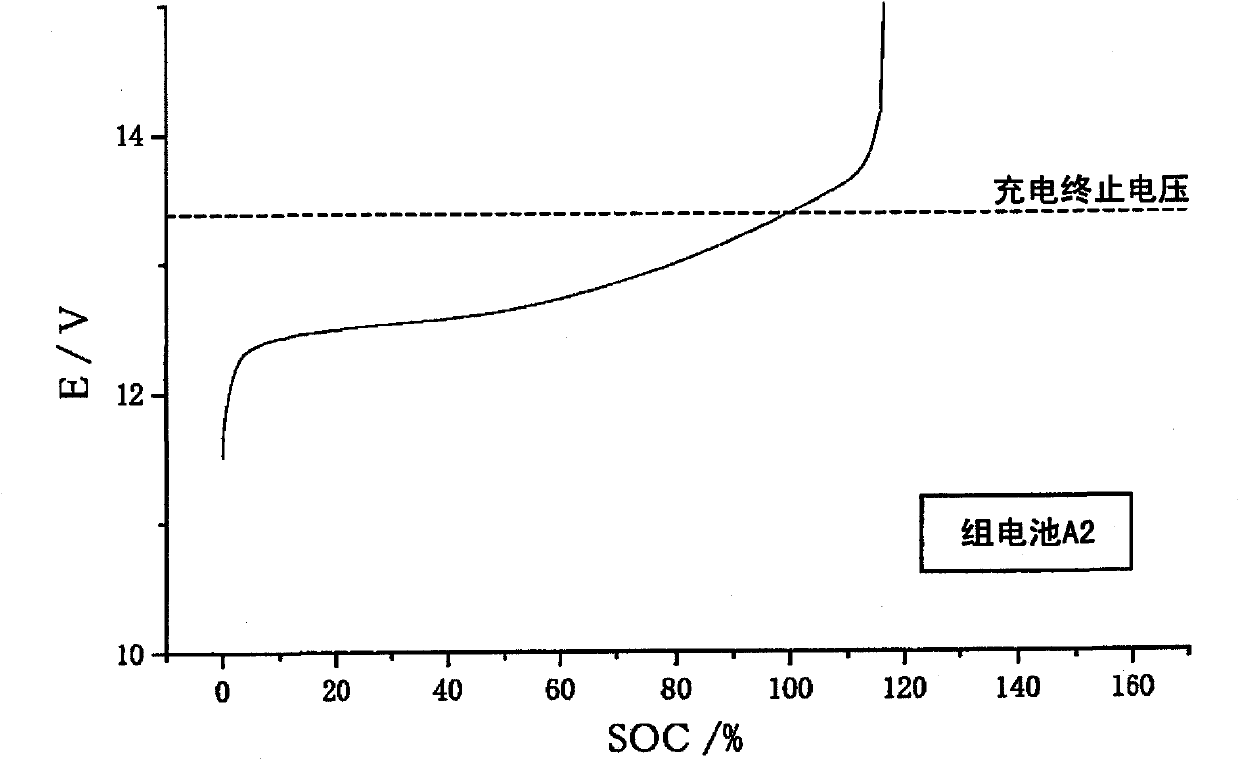

Embodiment 2

[0176] Artificial graphite is used as the negative active material, the thicknesses of the positive and negative electrodes are set to 0.140mm and 0.175mm respectively, and the densities of the positive and negative electrodes are set to 2.88g / cm 3 and 1.2g / cm 3 . The ratio (Q(p) / Q(n)) of the positive electrode capacity to the negative electrode capacity was 0.94. Copper foil was used as the negative electrode current collector. Except for the above, a battery P2 (first cell) was produced by the same method as the battery P1 of Example 1.

[0177] Artificial graphite is used as the negative active material, the thicknesses of the positive and negative electrodes are set to 0.150mm and 0.109mm respectively, and the densities of the positive and negative electrodes are set to 2.60g / cm 3 and 1.2g / cm 3 . The ratio (Q(p) / Q(n)) of the positive electrode capacity to the negative electrode capacity was 0.94. Copper foil was used as the negative electrode current collector. A ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com