Biomass tar cracking catalyst

A technology of tar cracking and biomass pyrolysis, which is applied in the field of biomass renewable energy utilization, can solve the problems of cumbersome preparation methods, and achieve the effects of simple preparation process, prevention of sintering, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

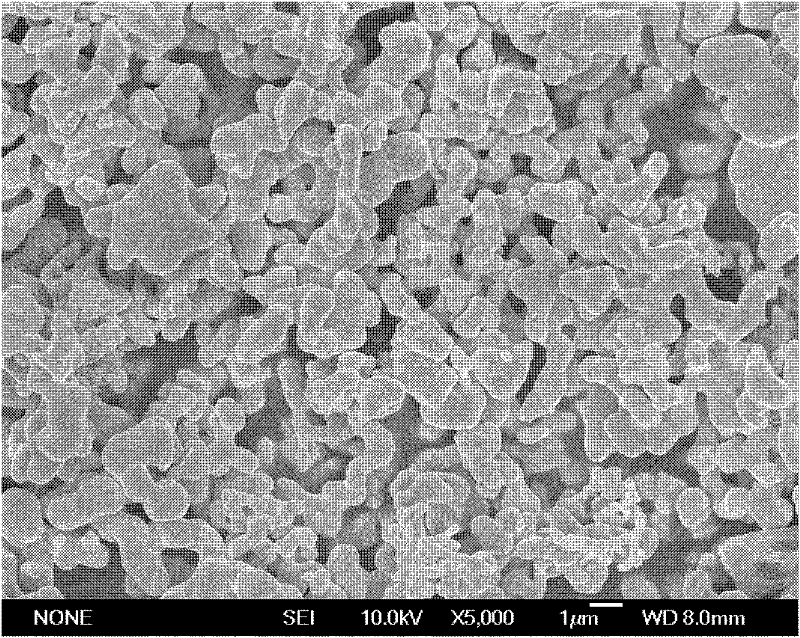

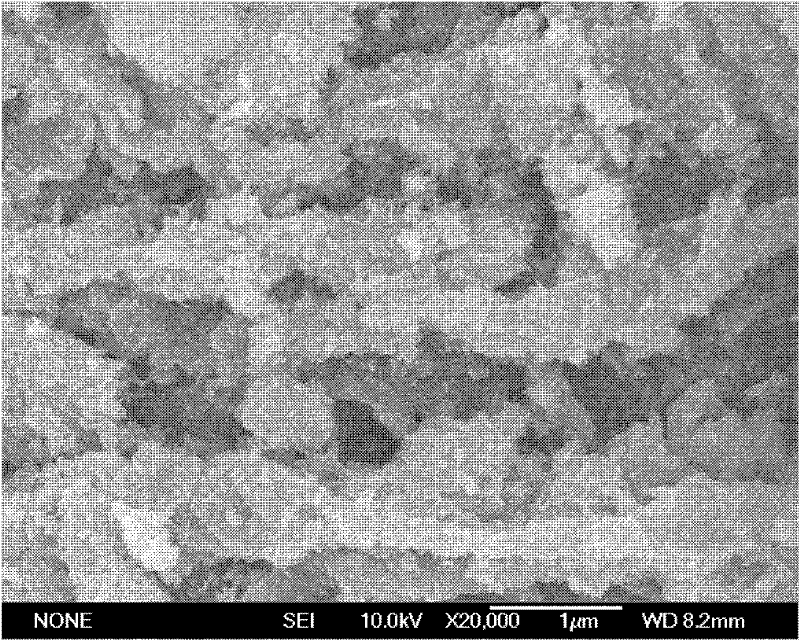

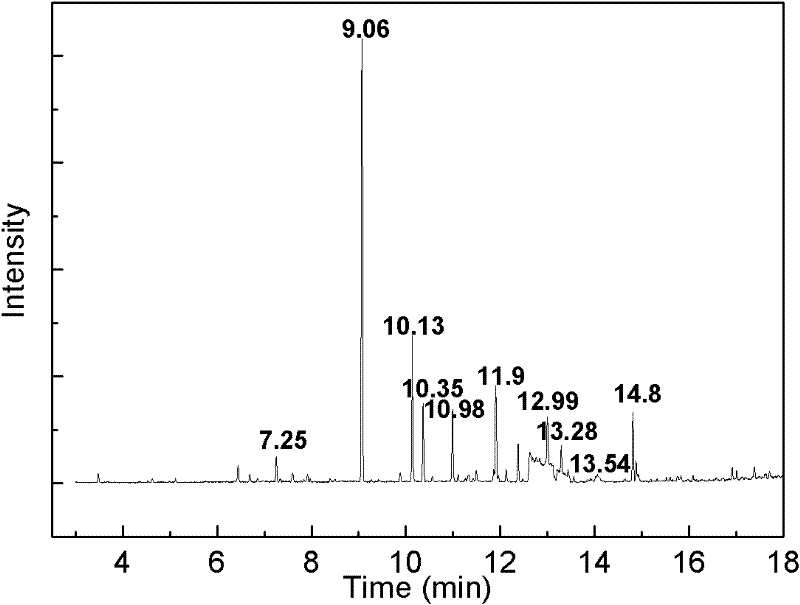

Image

Examples

Embodiment 1

[0027] Embodiment 1: Take by weighing 100.45g charcoal after dry distillation pyrolysis by wood block, after crushing, mix with 28.23g metal cobalt oxide Co 2 o 3 After mixing evenly, process it into a 2-3mm spherical shape, and put it in a fixed bed in a catalytic evaluation device as a catalyst for catalytic cracking of tar. The catalytic evaluation device is produced by Tianjin Xianquan Industry and Trade Development Co., Ltd., model WFS-3015 , the inner diameter of the fixed bed is 15mm, the length is 270mm, and the loading amount of the catalyst is 50g. At the beginning of the experiment, nitrogen is used as the carrier gas, and the flow rate is 50ml / min. In the vaporizer of the evaluation device, after being gasified, it enters the fixed catalytic bed together with the carrier gas to undergo a catalytic cracking reaction. The gas generated after the reaction is cooled and then emptied. If there is uncracked tar, it will be condensed and collected. The quality of tar and...

Embodiment 2

[0029] Example 2: Weigh 148.60g of biomass pyrolytic carbon, crush it to 0.5-0.8mm, mix it with 27.88g of metal elemental Co evenly, process it into a 2-3mm spherical shape, and put it in the fixed bed of the catalytic evaluation device , a catalyst for catalytic cracking of tar, when the bed reaches a temperature of 650°C, start adding tar for catalytic cracking reaction. The experimental results are listed in Table 2.

Embodiment 3

[0030] Example 3: Weigh 200.72g of CaO and 37.50g of metallic elemental Co, mix them uniformly physically, process them into 2-3mm spheres and place them in a fixed bed in a catalytic evaluation device, as a catalyst for catalytic cracking of tar, as a bed After the layer reaches a temperature of 650°C, tar is added for catalytic cracking reaction. The experimental results are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com