Anode active material for lithium cell and method for manufacturing same

A manufacturing method, lithium battery technology, applied to battery electrodes, non-aqueous electrolyte battery electrodes, batteries, etc., can solve problems such as poor structural stability, battery fire, rupture, etc., to achieve thermalization suppression, structural stability, and ensure thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

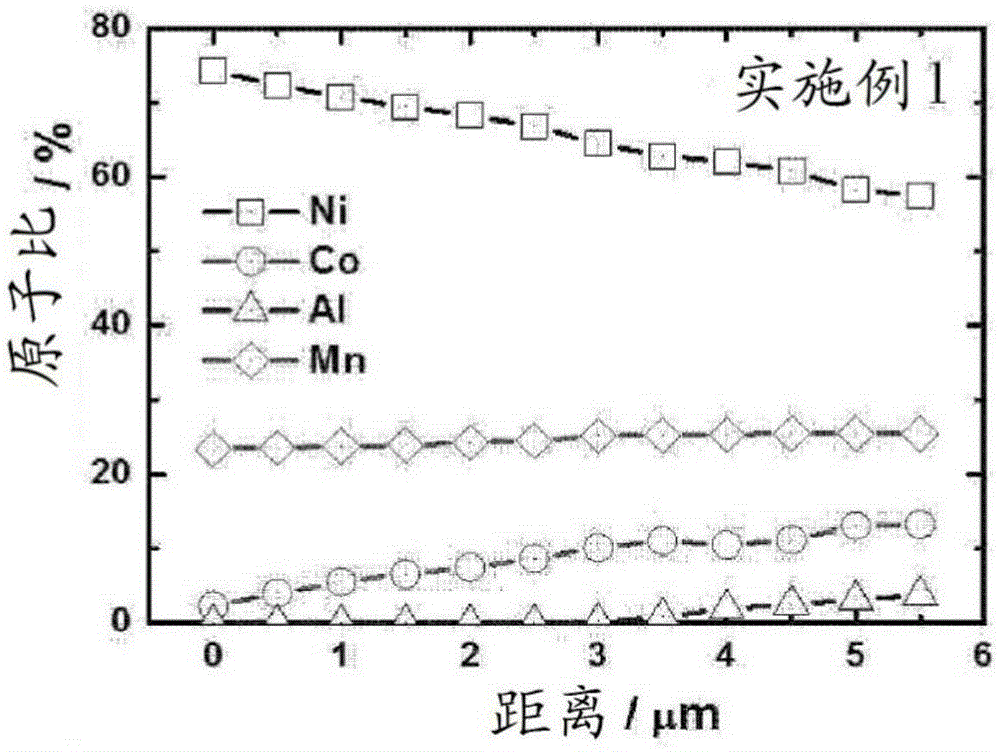

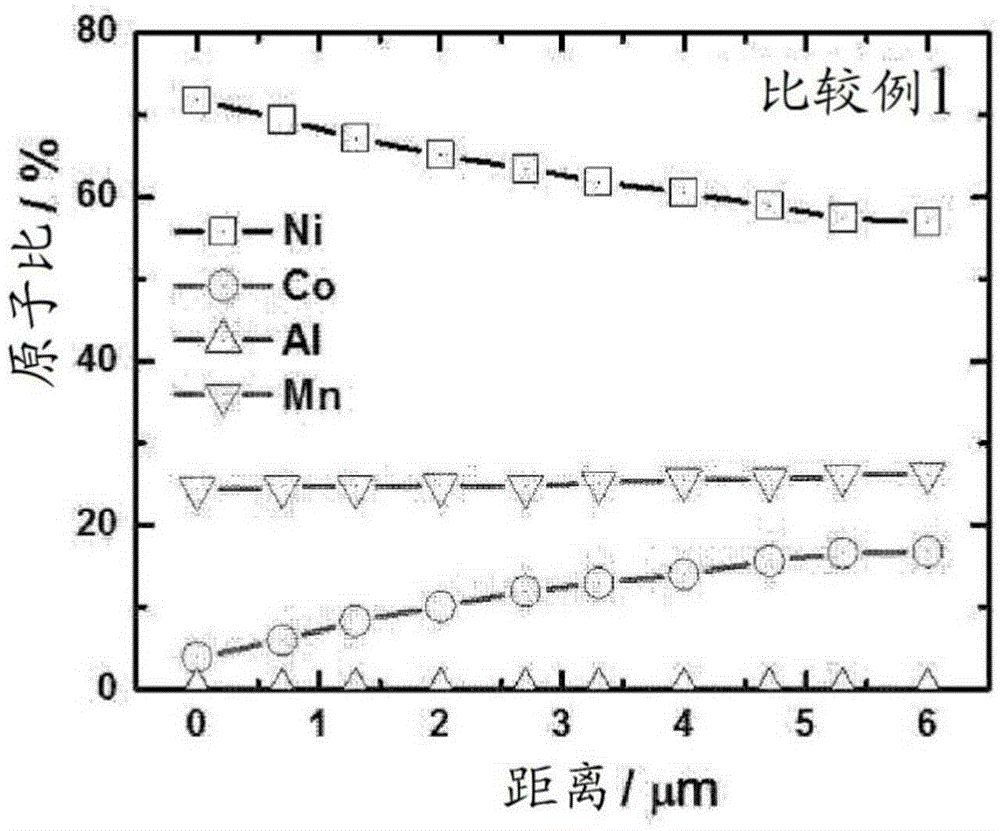

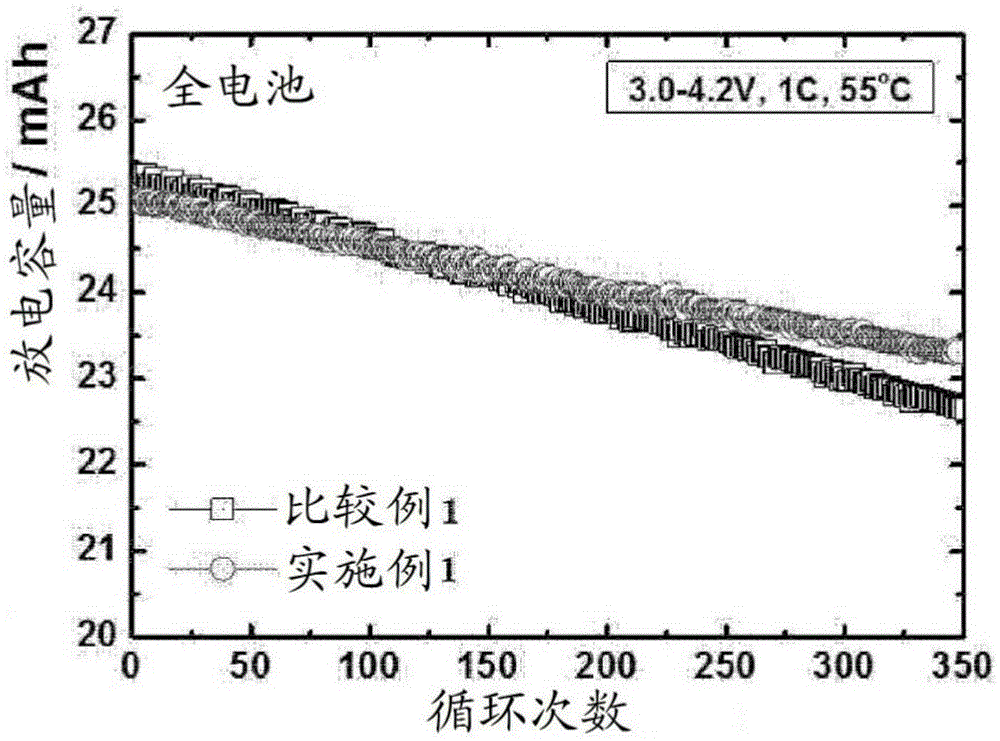

Embodiment 1

[0061] In order to produce an active material in which the concentration of nickel decreases continuously from the center to the surface, and the concentration of cobalt and manganese increases continuously from the center to the surface, and is doped with aluminum, first, as a metal salt solution for forming the center, the following 78:0:22 molar ratio mixed nickel sulfate: cobalt sulfate: manganese sulfate 2.4M concentration of metal aqueous solution, and prepared as the surface portion forming metal salt solution containing nickel sulfate: cobalt sulfate: manganese sulfate 54:19:27 Molar ratio of aqueous metal solutions.

[0062] After putting 4 liters of distilled water into the co-precipitation reactor (capacity 4L, rotating motor power 80W), hydrogen gas was supplied to the reactor at a rate of 0.5 liter / min to remove dissolved oxygen so that the temperature of the reactor was maintained at 50°C. and stirred at 1000 rpm.

[0063] The aqueous solution of the metal salt ...

Embodiment 2

[0071] In order to produce particles in which the metal concentration shows two concentration gradient gradients, first, as the first metal salt solution, a 2.4M concentration of metal was prepared by mixing nickel sulfate: cobalt sulfate: manganese sulfate at a molar ratio of 98:0:2. Aqueous solution, as the 2nd metal salt aqueous solution, has prepared the metal aqueous solution that comprises nickel sulfate: cobalt sulfate: manganese sulfate 91:3:6 mol ratio, and as the 3rd metal salt aqueous solution, has prepared nickel sulfate: cobalt sulfate: manganese sulfate 63:6:31 molar ratio of metal aqueous solution.

[0072] Change the mixing ratio of the 1st metal salt solution and the 2nd metal salt solution, drop into the reactor with 0.3 liters / hour, change the mixing ratio of the 2nd metal salt solution and the 3rd metal salt solution again, to the reaction Introduced into the container, the co-precipitation reaction was carried out, and the precursor particles with a metal ...

Embodiment 3

[0075] In order to produce particles containing a concentration gradient part on the outer surface of the chip part where the metal concentration is fixed, first, as the first metal salt solution, a 2.4M solution in which nickel sulfate: cobalt sulfate: manganese sulfate was mixed at a molar ratio of 95:1:4 was prepared. Concentration of the metal aqueous solution, and as the 2nd metal salt aqueous solution, prepared the metallic aqueous solution that comprises nickel sulfate: cobalt sulfate: manganese sulfate 55:15:30 molar ratio.

[0076] and supply the first metal salt solution for a predetermined time, and after manufacturing a chip part with a fixed metal concentration, change the mixing ratio of the first metal salt solution and the second metal salt solution, and introduce them into the reactor to perform Co-precipitation reaction was used to produce particles including a concentration gradient part on the outer surface of the chip part where the metal concentration was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com