Preparation method of graphene-supported stannic oxide quantum dot negative electrode material for lithium ion battery

A technology of tin dioxide and graphene, applied in battery electrodes, circuits, electrical components, etc., can solve the problems that limit the wide application of tin dioxide negative electrode materials, complex synthesis process, harsh experimental conditions, etc., and achieve favorable electrochemical performance , The operation process is simple, and the effect of improving the contact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

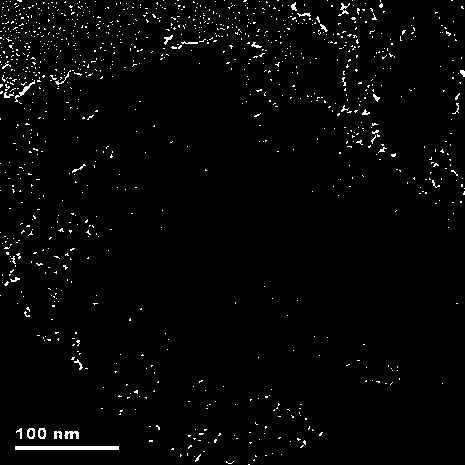

[0016] Add 2.3 g of sodium dodecylbenzenesulfonate into 70 mL of graphene oxide suspension aqueous solution (concentration: 10 g / L), stir until the surfactant is completely dissolved, and dilute the obtained suspension to 300 mL. The above suspension was added to 100 mL of 0.12 mol / L tin tetrachloride hydrochloric acid solution (the concentration of hydrochloric acid was 3.8 wt%), and 46 mL of urea aqueous solution (the concentration was 1 mol / L) was added dropwise to the above mixed solution, Add water to dilute the solution to 1000 mL at 88 o C under reflux for 16 hours, the precipitate obtained at 40 o Vacuum dried under C conditions, 420 in argon atmosphere o Calcining under the condition of C for 2 hours, the graphene / tin dioxide quantum dot composite material is obtained.

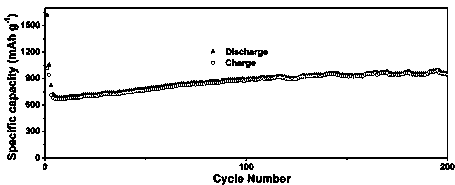

[0017] figure 1 The transmission electron microscope photo of the graphene / tin dioxide quantum dot composite material produced for this embodiment, the photo shows that the tin dioxide quantum dot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com