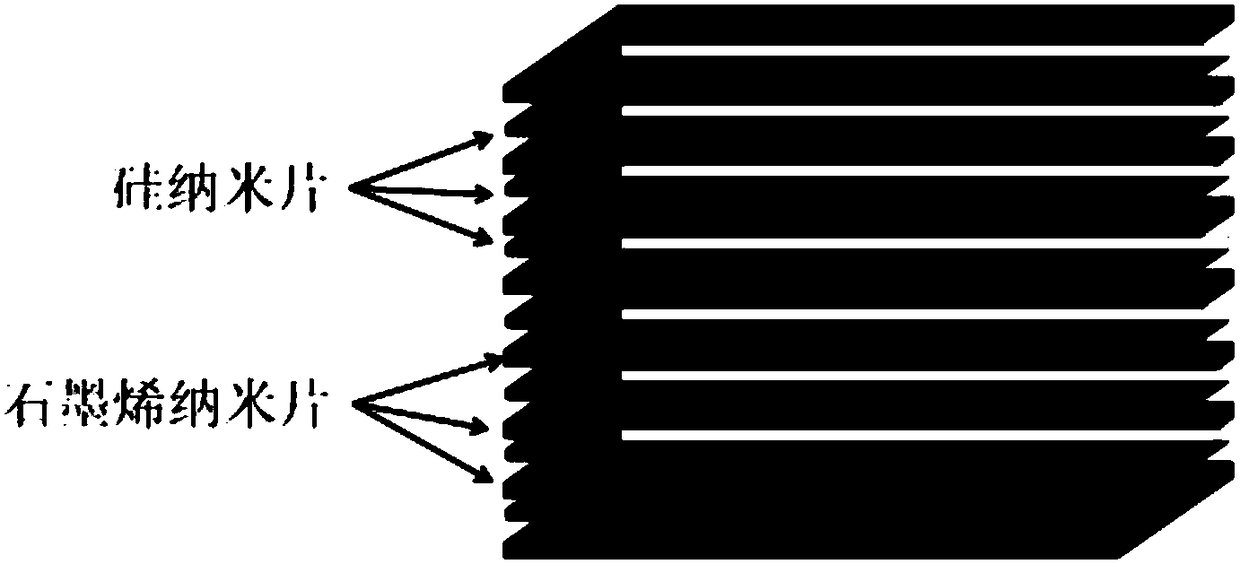

Silicon nanosheet-graphene nanosheet composite, preparation and application

A graphene nanosheet, silicon nanosheet technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of low cycle stability of composite materials, and achieve fast charge-discharge, cycle The effect of good performance and large lithium storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

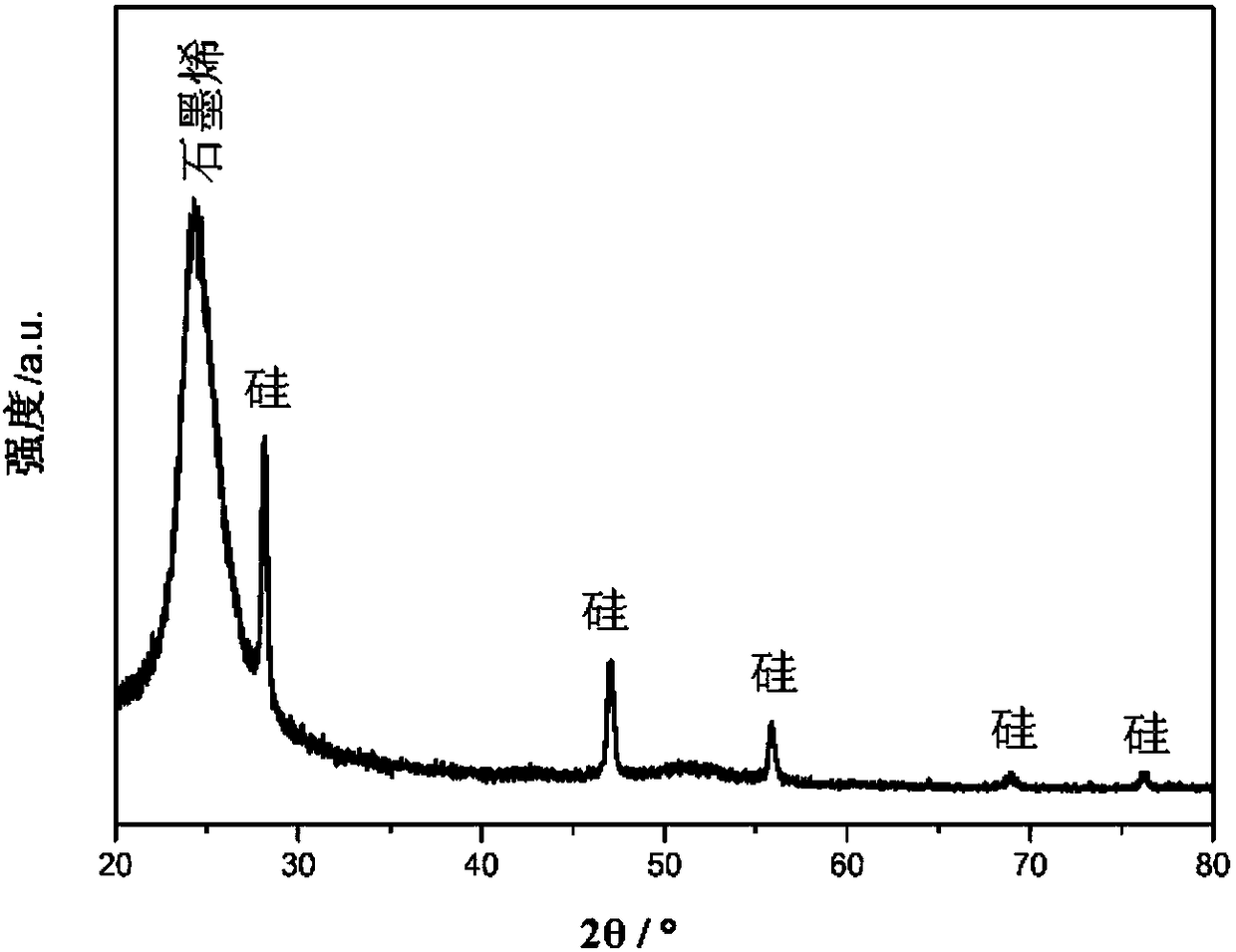

[0039] A kind of preparation method of silicon nanosheet-graphene nanosheet composite material of the present embodiment, concrete preparation steps are as follows:

[0040] (1) Add 3.0 g of graphite to a mixture of 360 mL of concentrated sulfuric acid and 40 mL of concentrated phosphoric acid, and cool in an ice-water bath. Very slowly 6.0 grams of potassium permanganate was added to the mixture. All operations should be done very slowly. The reaction was then heated to 50 °C and stirred mechanically for 24 h. The reaction was cooled to room temperature and poured slowly into a mixture of ice (400 mL) and 30 mL of 30% hydrogen peroxide. The solution was centrifuged, washed with 500 mL of 5% HCl, and then deionized water to a pH value of about 7, and the obtained product was vacuum-dried at 50° C. to remove water to obtain graphite oxide. Weigh an appropriate amount of graphite oxide and disperse it in deionized water, and ultrasonicate for 30 minutes to prepare a 1.0 mg / mL...

Embodiment 2

[0049] A kind of preparation method of silicon nanosheet-graphene nanosheet composite material of the present embodiment, concrete preparation steps are as follows:

[0050] Steps (1) and (2) are the same as in Example 1.

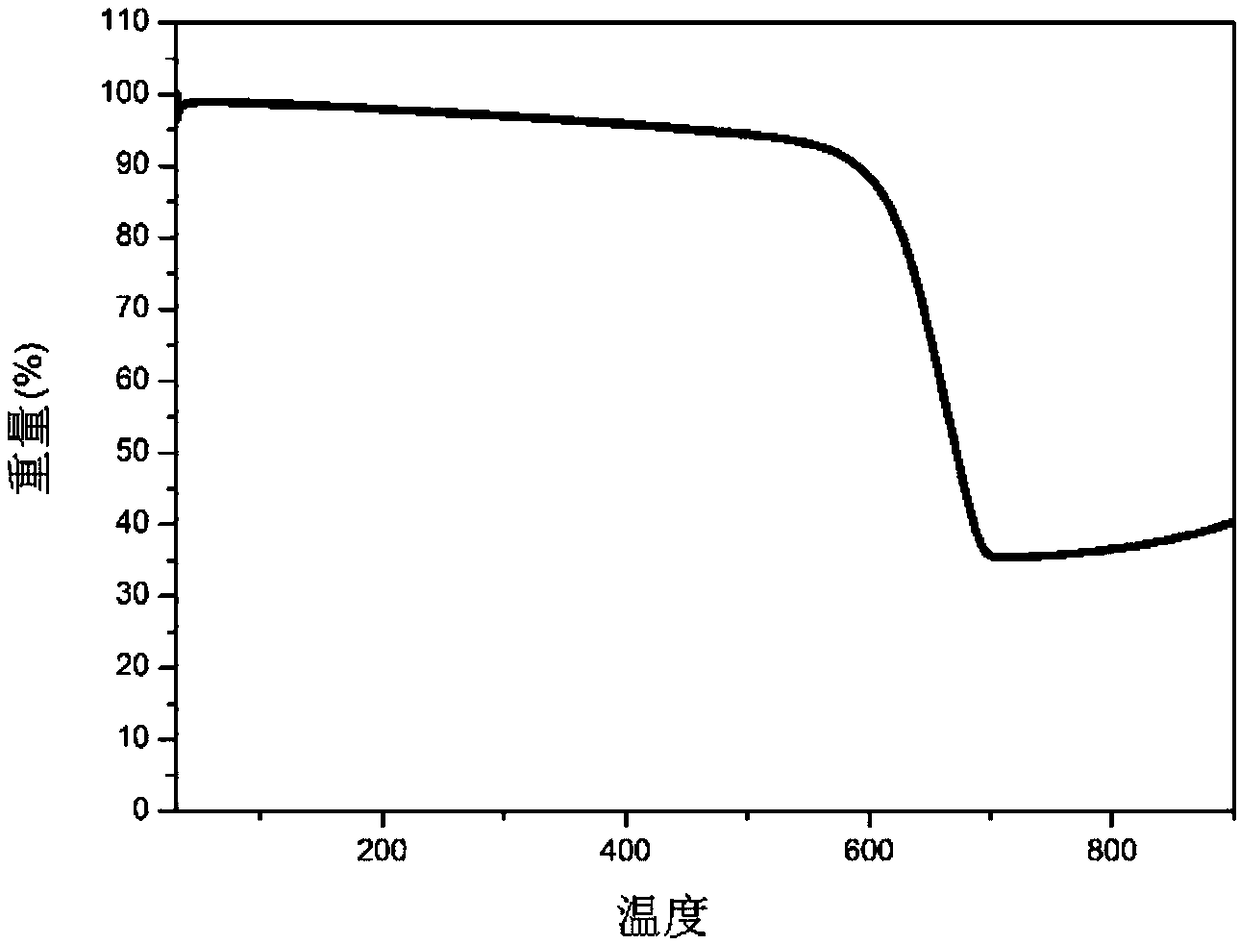

[0051] (3) Mix 400mL of 1.0mg / mL graphene oxide nanosheet suspension with 200mL of 0.5mg / mL silicon nanosheet suspension, stir evenly, evaporate to dryness at 50°C, and treat at 750°C under vacuum for 2h to obtain silicon nanosheets. sheet-graphene nanosheet composites.

[0052] The cycle performance curve of silicon nanosheet-graphene nanosheet composite material obtained in this example at 0.01~3.0V, 200mA / g current density is as follows Image 6 shown. from Image 6 It can be seen that the first discharge specific capacity of the material reaches 1673.5mAh / g at 0.01-3.0V, 200mA / g current density, and the discharge specific capacity remains at 816mAh / g after 50 cycles, indicating that the material has a good cycle stability.

Embodiment 3

[0054] A kind of preparation method of silicon nanosheet-graphene nanosheet composite material of the present embodiment, concrete preparation steps are as follows:

[0055] Steps (1) and (2) are the same as in Example 1.

[0056] (3) Mix 200mL of 1.0mg / mL graphene oxide nanosheet suspension with 200mL of 0.5mg / mL silicon nanosheet suspension, stir evenly, evaporate to dryness at 50°C, and treat at 750°C under vacuum for 2h to obtain silicon nanosheets. sheet-graphene nanosheet composites.

[0057] The cycle performance curve of silicon nanosheet-graphene nanosheet composite material obtained in this example at 0.01~3.0V, 200mA / g current density is as follows Figure 7 shown. from Figure 7 It can be seen that the first discharge specific capacity of the material reaches 1673.5mAh / g at 0.01-3.0V, 200mA / g current density, and the discharge specific capacity remains at 816mAh / g after 50 cycles, indicating that the material has a good cycle stability. Its cycle performance c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com