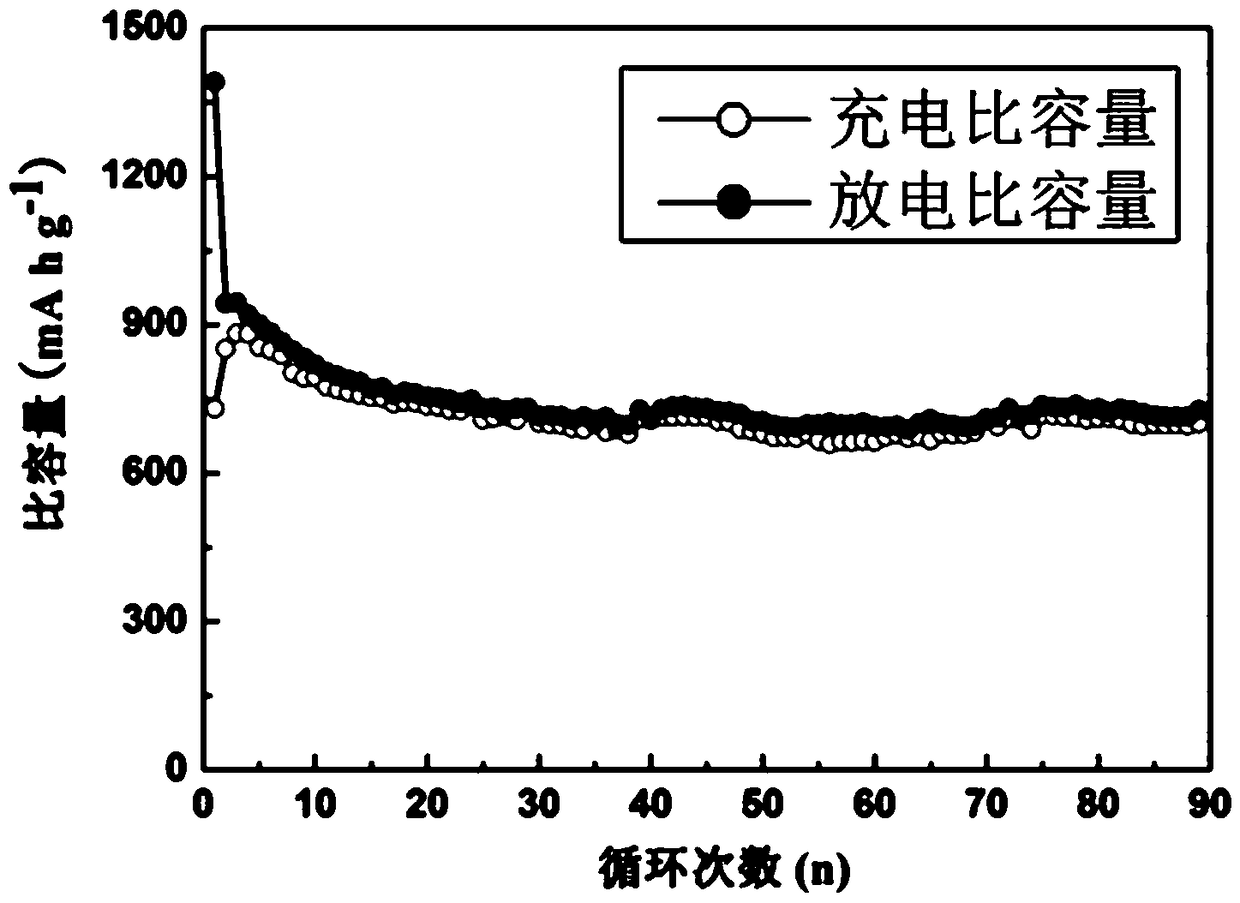

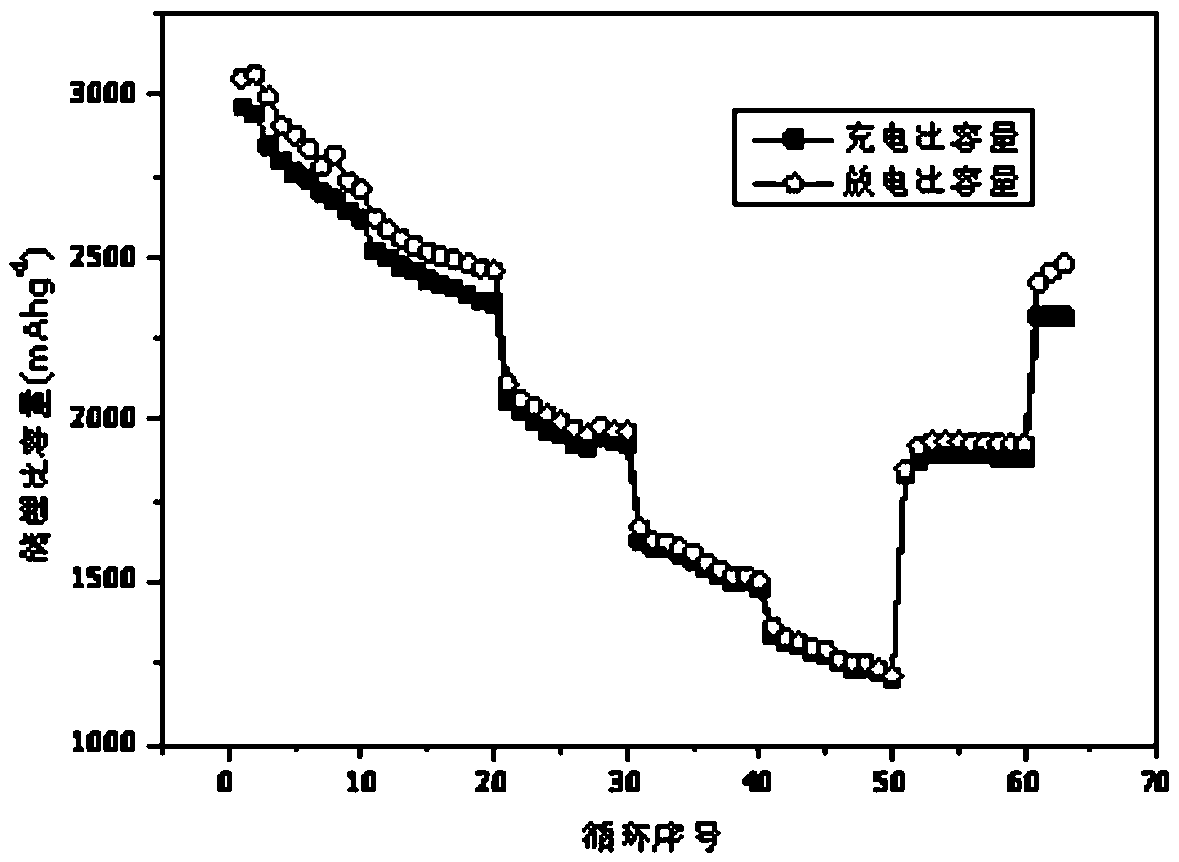

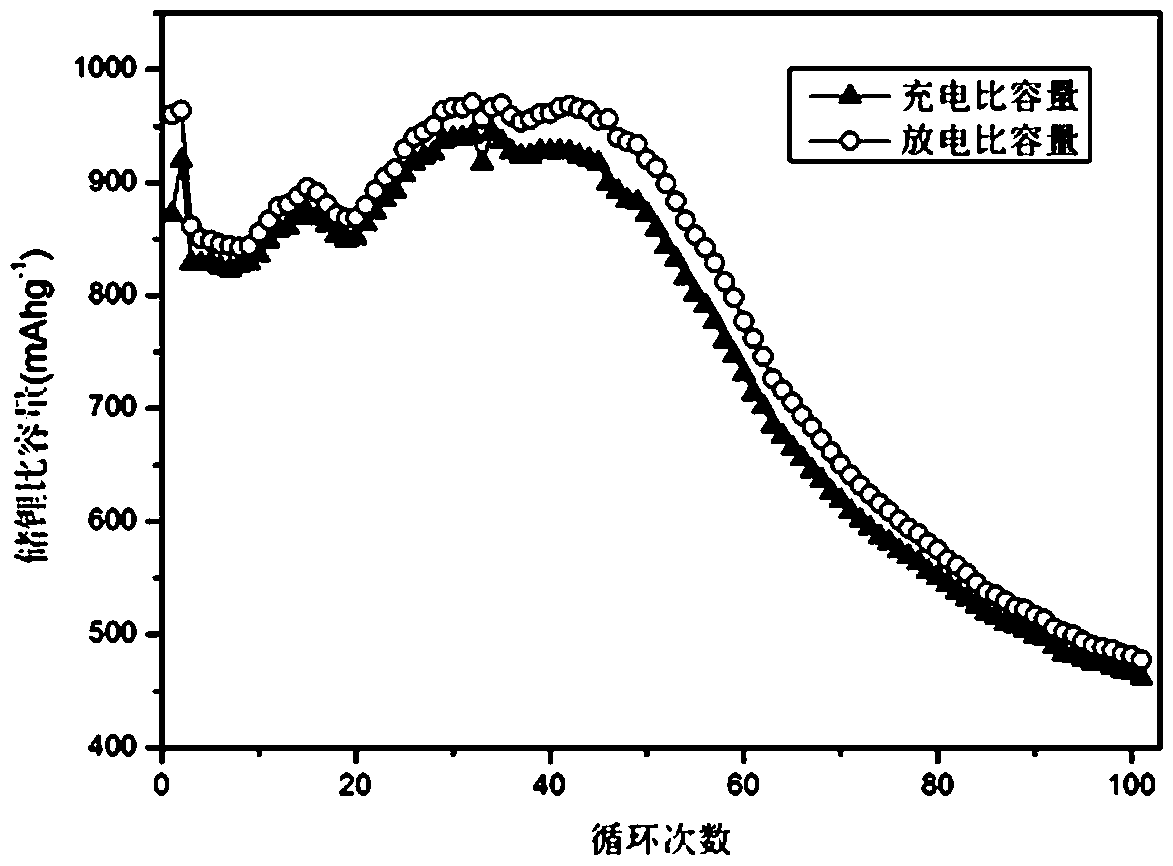

Preparation method of 3D porous graphite/carbon nanotube-nanometer silicon aerogel lithium ion battery cathode material

A nano-silicon aerogel and porous graphene technology, which can be used in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In the first step, the surfactant polyvinylpyrrolidone is added to deionized water at 0.1%, and stirred for 2 hours to fully dissolve the surfactant in the water;

[0050] In the second step, carbon nanotubes and nano-silicon are added to the solution in the first step at a mass ratio of carbon nanotubes and nano-silicon of 1:1, and ultrasonicated until they are uniformly dispersed to obtain a certain concentration of carbon nanotubes and nano-silicon mixed Dispersion solution A;

[0051] The third step is to prepare a graphene oxide aqueous solution with a solution concentration of 2 mg / mL according to the mass ratio of graphene oxide and nano-silicon at a ratio of 1:0.1, and ultrasonically until it is uniformly dispersed to obtain solution B;

[0052] The 4th step, according to the mass ratio of graphene oxide and nickel nitrate is the ratio of 1:0.1, nickel nitrate is added in the solution B, stirs 1h, obtains mixed solution C;

[0053] In the fifth step, mix the mi...

Embodiment 2

[0058] In the first step, the surfactant polyvinylpyrrolidone is added to deionized water at 0.01%, and stirred for 1 hour to fully dissolve the surfactant in the water;

[0059] In the second step, carbon nanotubes and nano-silicon are added to the solution in the first step at a mass ratio of carbon nanotubes and nano-silicon of 1:5, and ultrasonicated until they are uniformly dispersed to obtain a certain concentration of carbon nanotubes and nano-silicon mixed Dispersion solution A;

[0060] The third step is to prepare a graphene oxide aqueous solution with a solution concentration of 0.5 mg / mL according to the mass ratio of graphene oxide and nano-silicon at a ratio of 1:10, and ultrasonically until it is uniformly dispersed to obtain solution B;

[0061] The 4th step, according to the mass ratio of graphene oxide and nickel nitrate is the ratio of 1:1, ferric chloride is added in the solution B, stirs 1h, obtains mixed solution C;

[0062] In the fifth step, mix the mi...

Embodiment 3

[0067] In the first step, the surfactant polyvinylpyrrolidone is added to deionized water at 1%, and stirred for 12 hours to fully dissolve the surfactant in the water;

[0068] In the second step, carbon nanotubes and nano-silicon are added to the solution in the first step at a mass ratio of carbon nanotubes and nano-silicon of 1:0.1, and ultrasonicated until they are uniformly dispersed to obtain a certain concentration of carbon nanotubes and nano-silicon mixed Dispersion solution A;

[0069] The third step is to prepare a graphene oxide aqueous solution with a solution concentration of 1 mg / mL according to the mass ratio of graphene oxide and nano-silicon at a ratio of 1:2, and ultrasonically until it is uniformly dispersed to obtain solution B;

[0070] The 4th step, according to the mass ratio of graphene oxide and nickel nitrate is the ratio of 1:1, cobalt oxalate is added in the solution B, stirs 1h, obtains mixed solution C;

[0071] In the fifth step, mix the mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com