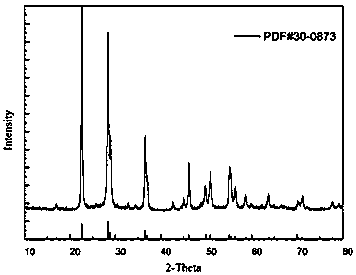

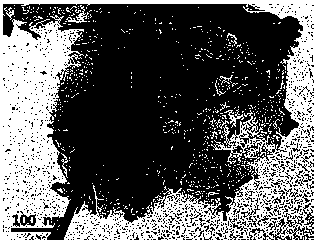

Preparation method of niobium pentoxide/reduced graphene oxide composite negative electrode material

A graphene composite and niobium pentoxide technology, which is applied in nanotechnology for materials and surface science, battery electrodes, secondary batteries, etc., can solve problems such as long time required, high energy consumption, and serious agglomeration. Achieve the effect of low cost, low energy consumption and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment includes the following steps:

[0031] (1) Mix 0.0435 g graphene oxide nanosheets with 40 ml deionized water, stir for 0.5 h, and ultrasonically disperse for 0.5 h to obtain a graphene oxide nano-dispersion;

[0032] (2) Disperse 0.872 g of niobium pentachloride in 40 mL of deionized water and stir for 0.5 h to obtain a suspension of niobium pentachloride; add 2 g of oxalic acid to the suspension obtained above and stir for 0.5 h to obtain a clear solution; 1.12 g of hexamethylenetetramine was added to the above clear solution and stirred for 0.5 h to obtain a white solution;

[0033] (3) Mix the white solution obtained in step (2) with the graphene oxide nano-dispersion obtained in step (1), stir for 0.5 h to obtain a mixed solution, put the mixed solution in a high-pressure reactor, and conduct 14 The hydrothermal reaction of h;

[0034] (4) After the completion of the hydrothermal reaction, the obtained precipitate was centrifuged and washed three t...

Embodiment 2

[0040] This embodiment includes the following steps:

[0041] (1) Mix 0.0435 g graphene oxide nanosheets with 40 mL deionized water, stir for 0.5 h, and ultrasonically disperse for 0.5 h to obtain graphene oxide nanodispersion;

[0042] (2) Disperse 0.872 g of niobium pentachloride in 40 mL of deionized water and stir for 0.5 h to obtain a suspension of niobium pentachloride; add 2 g of oxalic acid to the suspension obtained above and stir for 0.5 h to obtain a clear solution; 1.12 g of hexamethylenetetramine was added to the above clear solution and stirred for 0.5 h to obtain a white solution;

[0043] (3) Mix the white solution obtained in step (2) with the graphene oxide nano-dispersion obtained in step (1), stir for 0.5 h to obtain a mixed solution, put the mixed solution in a high-pressure reactor, and conduct 8 The hydrothermal reaction of h;

[0044] (4) After the completion of the hydrothermal reaction, the precipitate obtained from the hydrothermal reaction was cen...

Embodiment 3

[0049] This embodiment includes the following steps:

[0050] (1) Mix 0.0435 g of graphene oxide nanosheets with 40 ml of deionized water, stir for 0.5 h, and ultrasonically disperse for 0.5 h to obtain a graphene oxide nanodispersion;

[0051] (2) Disperse 0.872 g of niobium pentachloride in 40 ml of deionized water and stir for 0.5 h to obtain a suspension of niobium pentachloride; add 2 g of oxalic acid to the suspension obtained above and stir for 0.5 h to obtain a clear solution; 1.12 g of hexamethylenetetramine was added to the above clear solution and stirred for 0.5 h to obtain a white solution;

[0052] (3) The above white solution was mixed with the graphene oxide nano-dispersion, and stirred for 0.5 h to obtain a mixed solution. The mixed solution was put into an autoclave, and a hydrothermal reaction was carried out at 180 °C for 24 h.

[0053] (4) After the completion of the hydrothermal reaction, the precipitate obtained from the hydrothermal reaction was centr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com