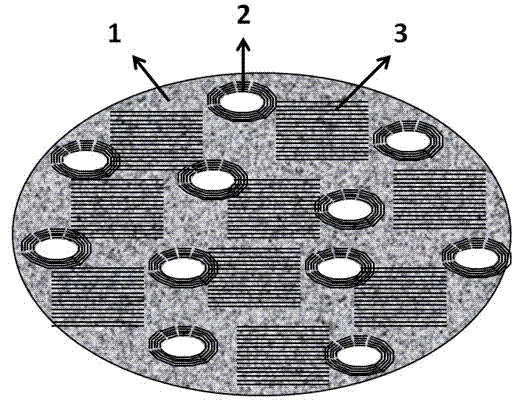

Preparation method of graphite negative electrode material containing hollow carbon nanostructure for lithium ion battery

A lithium-ion battery, carbon nanostructure technology, used in battery electrodes, structural parts, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

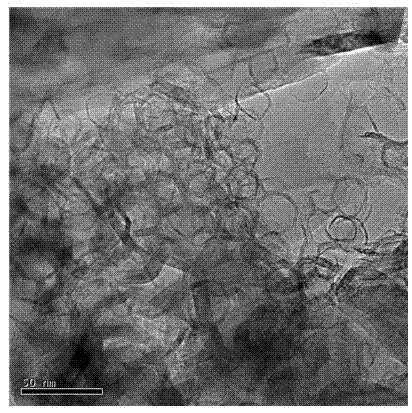

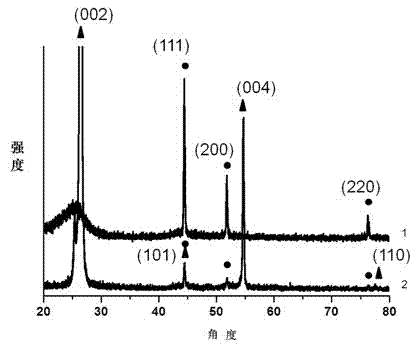

Embodiment 1

[0034] Embodiment 1: Using ethylene tar as the raw material for preparing asphalt, adding nickel nitrate and picric acid (explosive agent) in the tar by mass ratio (adding 5g nickel nitrate and 5g picric acid to 100g ethylene tar), during the heating process in the prepared asphalt During the heating process, the nickel nitrate decomposes (begins to decompose at 110°C), and then continues to heat up, and the picric acid reaches the decomposition temperature (about 300°C) and produces a slight explosion, which makes the nickel oxide more evenly dispersed, and the temperature rises to 420°C. Continue to stir for about 0.5 hour, stop, and finally prepare pitch with uniform dispersion of nano-metal nickel particles. Among them, the mass fraction of metal in the asphalt is 10%, and after being crushed, it is ground through a 100-mesh standard sieve for future use. Select natural flake graphite as the graphite source, wet ball mill through a 100-mesh standard sieve, and set aside. ...

Embodiment 2

[0048] Example 2, using coal tar as the raw material for preparing asphalt, adding nickel nitrate and picric acid (explosive agent) (100g coal tar with 1g nickel nitrate and 5g picric acid) in the coal tar by mass ratio, heating up in the prepared asphalt Stir continuously during the heating process. During the heating process, nickel nitrate decomposes (begins to decompose at 75°C) to obtain nickel oxide. After continuing to heat up, picric acid reaches the decomposition temperature (about 300°C) and produces a slight explosion, which makes the nickel oxide more evenly dispersed. The temperature rises To 420°C, continue to stir for about 0.5 hours, stop, and finally prepare asphalt with uniform dispersion of nano-metal nickel particles. Among them, the mass fraction of metal in the asphalt is 1%, and it is crushed and ground through a 300-mesh standard sieve for future use. Choose natural flake graphite as the graphite source, wet ball mill through a 300-mesh standard sieve,...

Embodiment 3

[0050] Use petroleum residue as the raw material for asphalt preparation, add ferric nitrate and picric acid (explosive agent) in the petroleum residue according to the mass ratio (add 30g ferric nitrate and 5g picric acid to 100g coal tar), during the heating process of the prepared asphalt Stir constantly, ferric nitrate decomposes to iron oxide during the heating process, then continue to heat up, picric acid reaches the decomposition temperature (about 300°C) and produces a slight explosion, which makes the iron oxide more uniformly dispersed, the temperature rises to 420°C, and continues to stir for about 0.5 Hours, stop, and finally modulated into asphalt with uniform dispersion of nano-metal iron particles. Among them, the mass fraction of metal in the asphalt is 20%, and after crushing, it is ground and passed through a 300-mesh standard sieve for future use. Select graphite microcrystals as the graphite source, wet ball milling through a 200-mesh standard sieve, and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com