Patents

Literature

33results about How to "Improve crushing precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Application by using carbon nanotube/urea formaldehyde resin carbon-coated spherical microcrystalline graphite as negative electrode material of lithium ion battery

InactiveCN107959028AImprove processing efficiencyImprove crushing precisionCell electrodesArgon atmosphereCarbon nanotube

The invention relates to application by using carbon nanotube / urea formaldehyde resin carbon-coated spherical microcrystalline graphite as negative electrode material of a lithium ion battery. Spherical microcrystalline graphite material is adopted as the lithium ion negative-electrode material to prepare the lithium ion battery, wherein the weight ratio of the negative electrode material, SBR (50% of solid content), CMC to Super-p is 97.5: 1.5: 2: 1, then moderate deionized water is added to mix to be syrup-like liquid, copper foil is coated with the liquid and dried in a vacuum drying oven for 12 h to prepare a negative electrode plate, an electrolyte of the lithium ion battery adopts 1MLiPF6 / EC+DEC+DMC=1: 1: 1, a separator is microporous polypropylene membrane, a counter electrode is alithium tablet, and the battery is assembled in a glove box with an airtight argon atmosphere. When the lithium ion battery is charged and discharged at the ratio of 0.1 C, a first charging and discharging cycle charging capacity is 390 mAh / g, and when the lithium ion battery is charged and discharged at the ratio of 5 C, after 500 times of cycles, the capacity retention ratio is 97.2%.

Owner:林荣铨

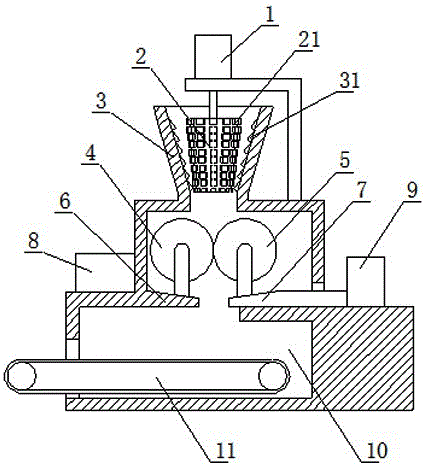

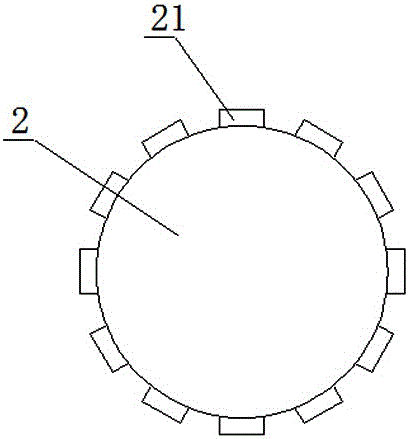

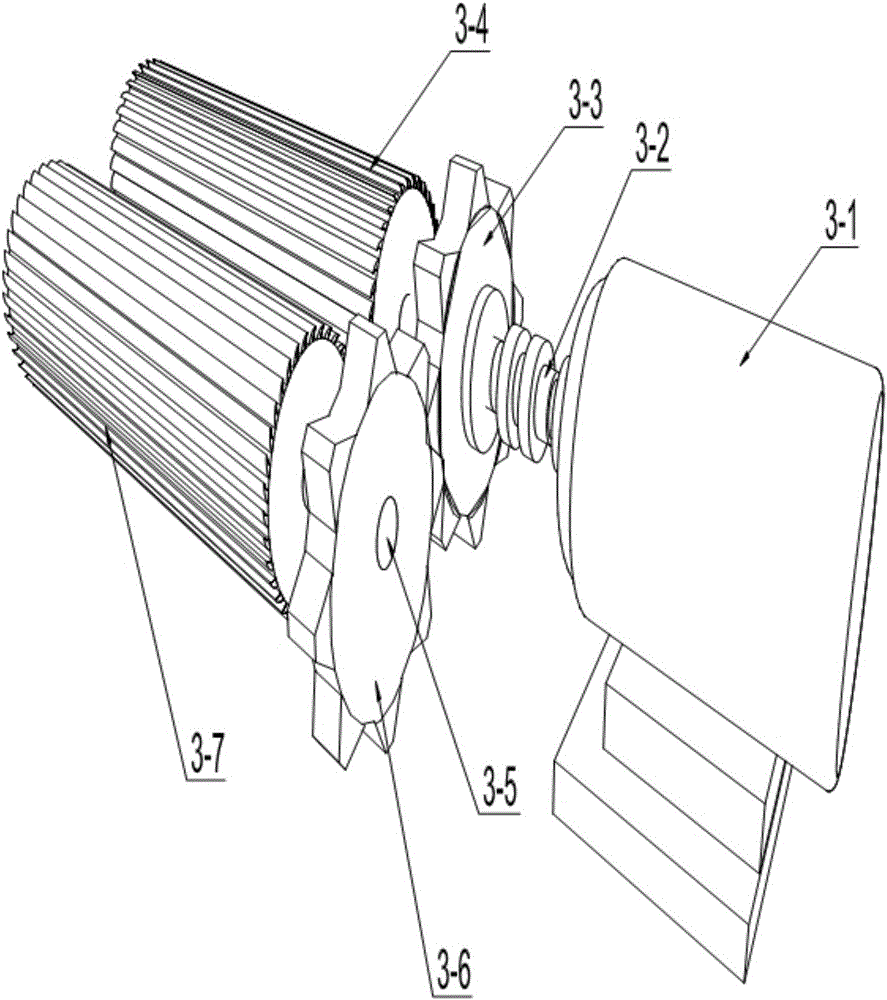

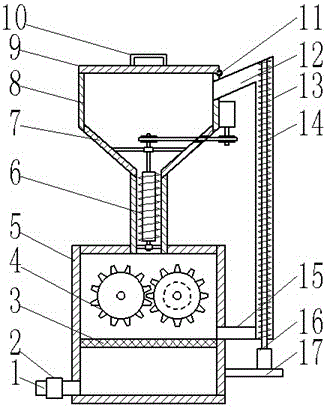

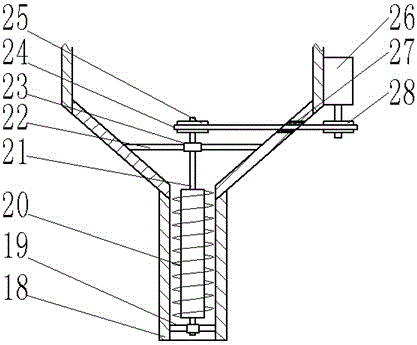

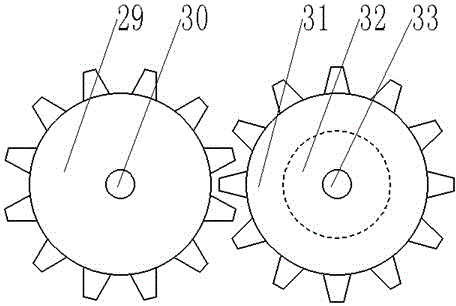

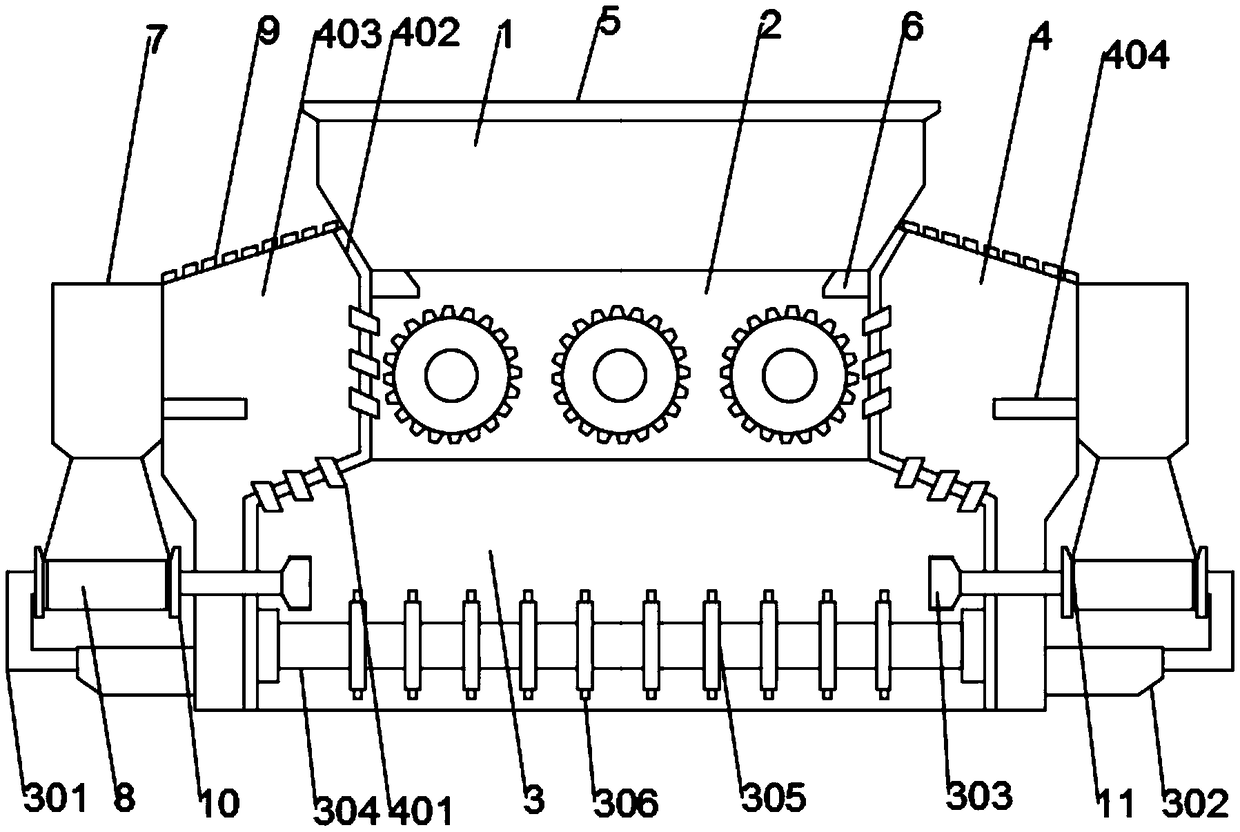

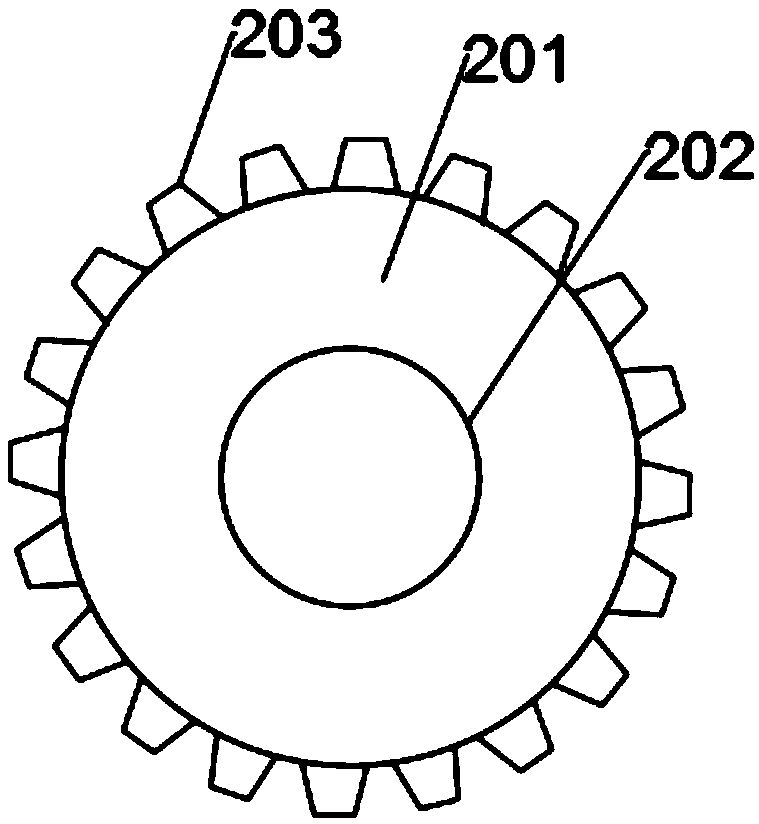

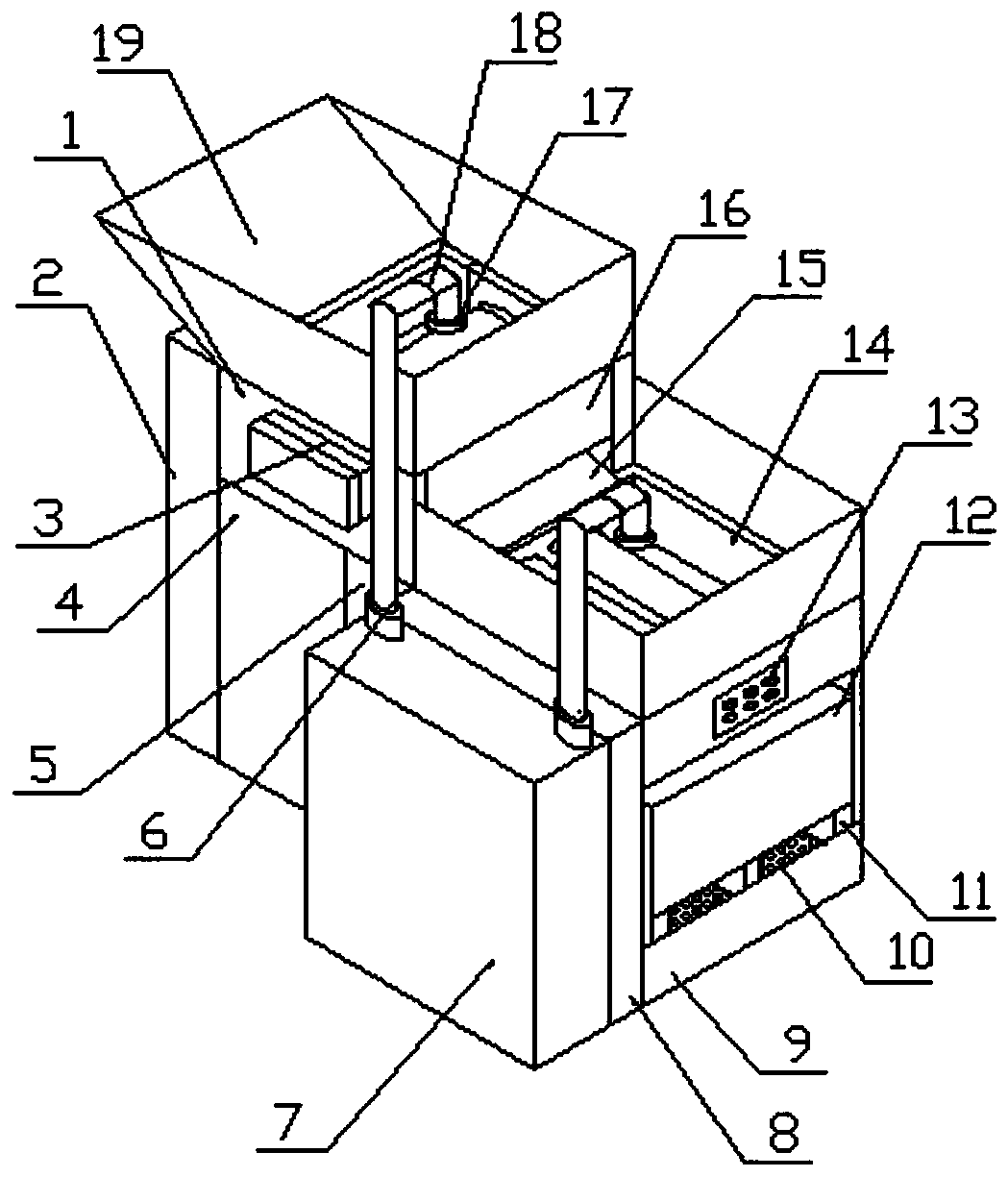

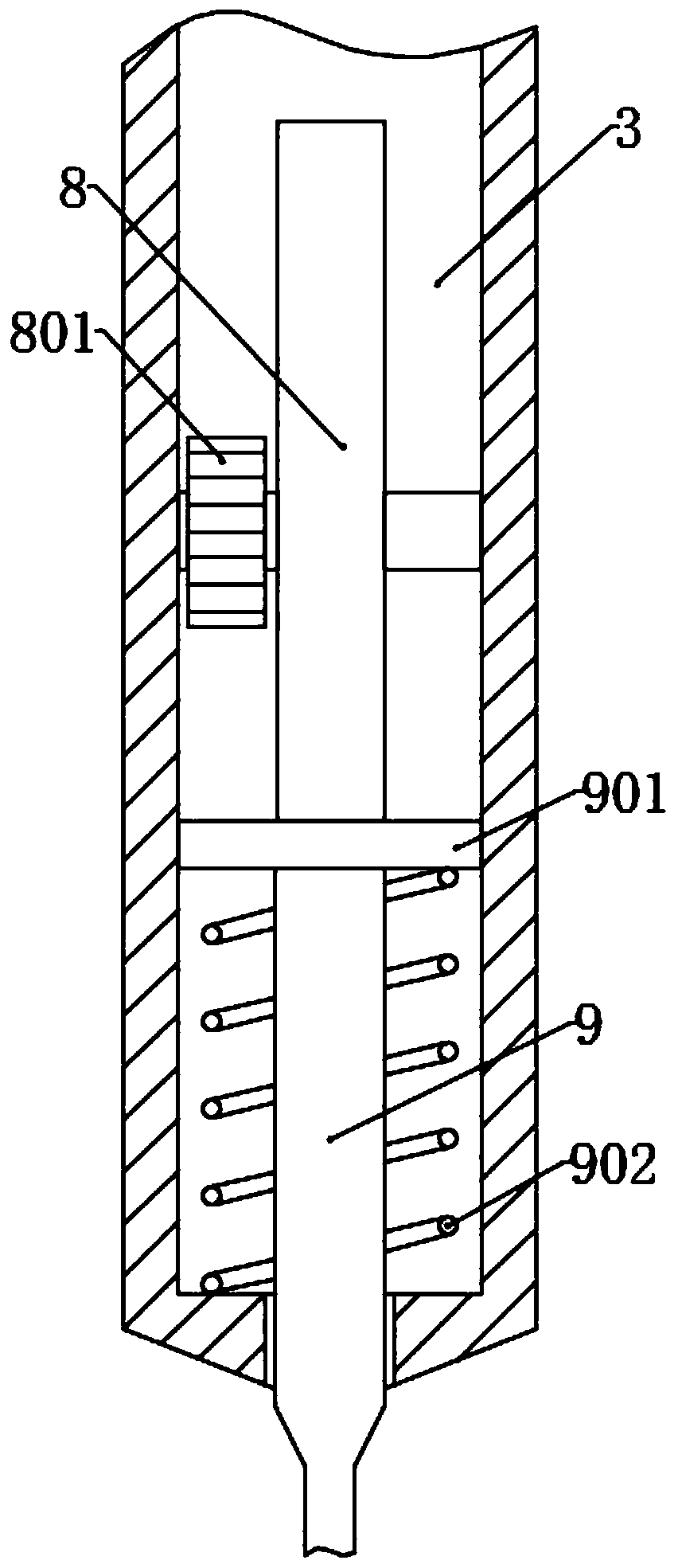

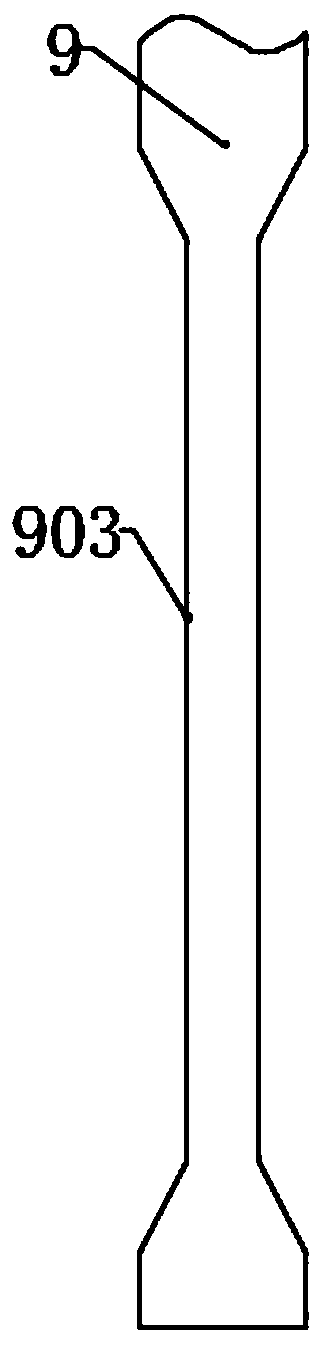

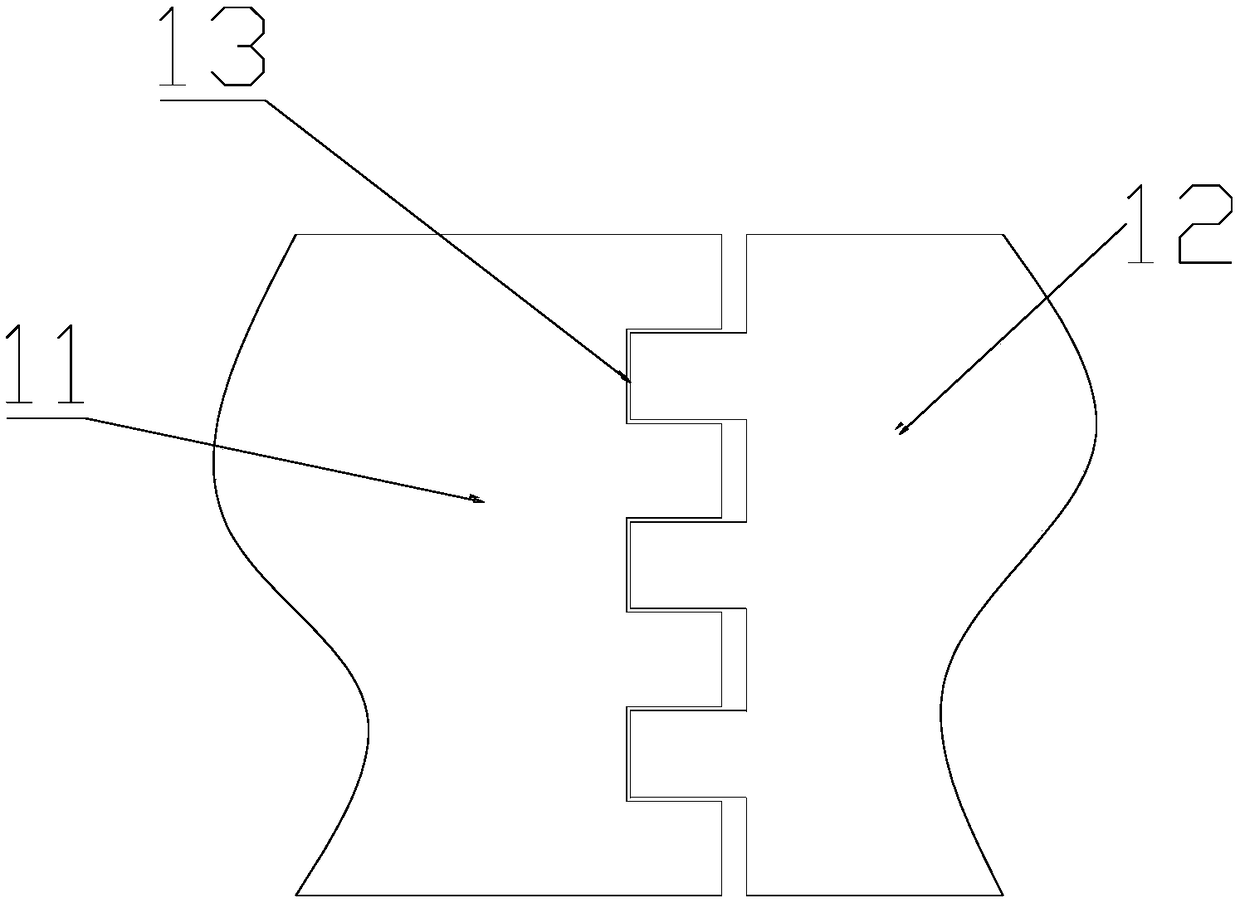

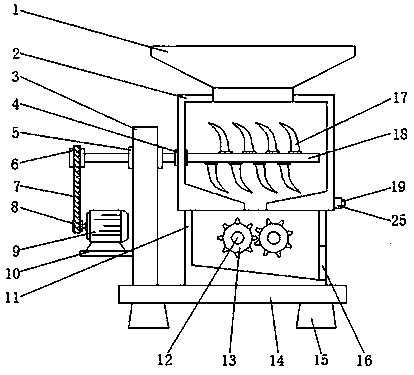

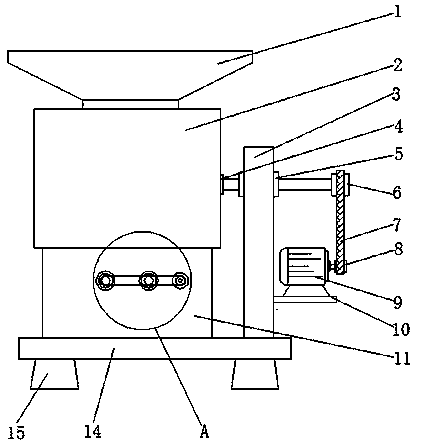

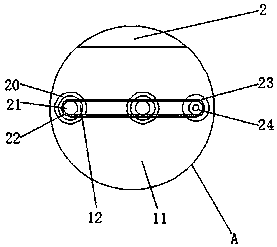

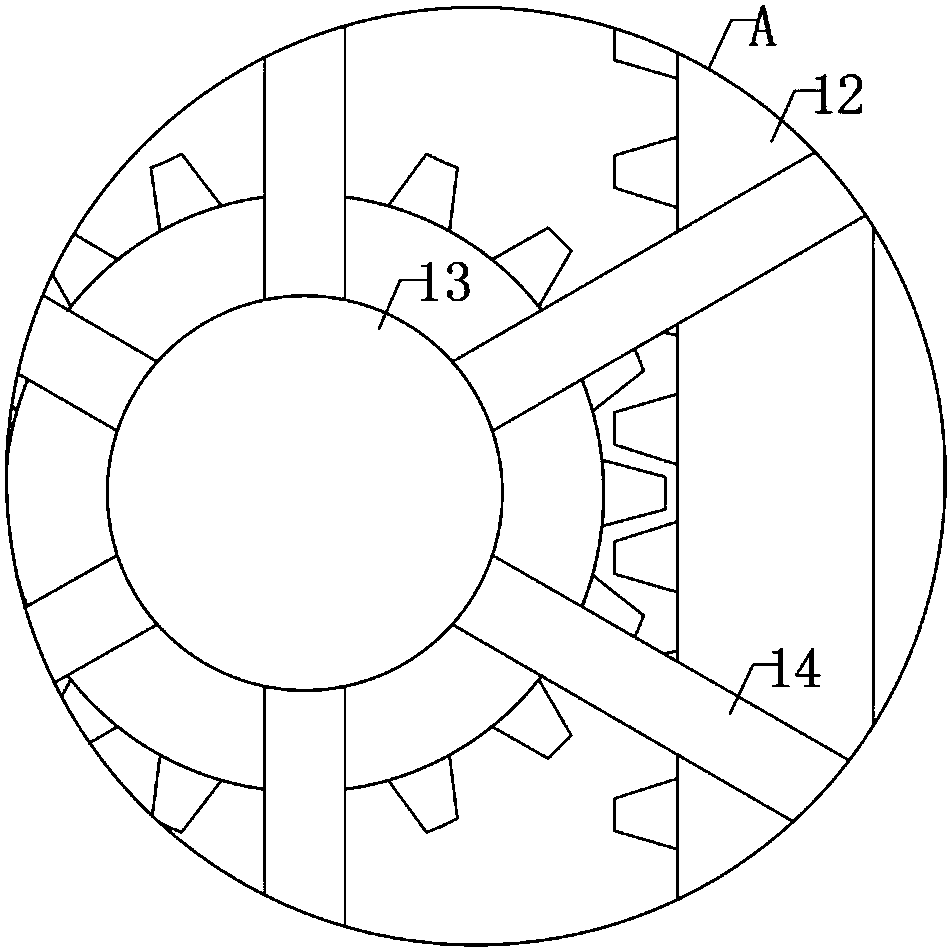

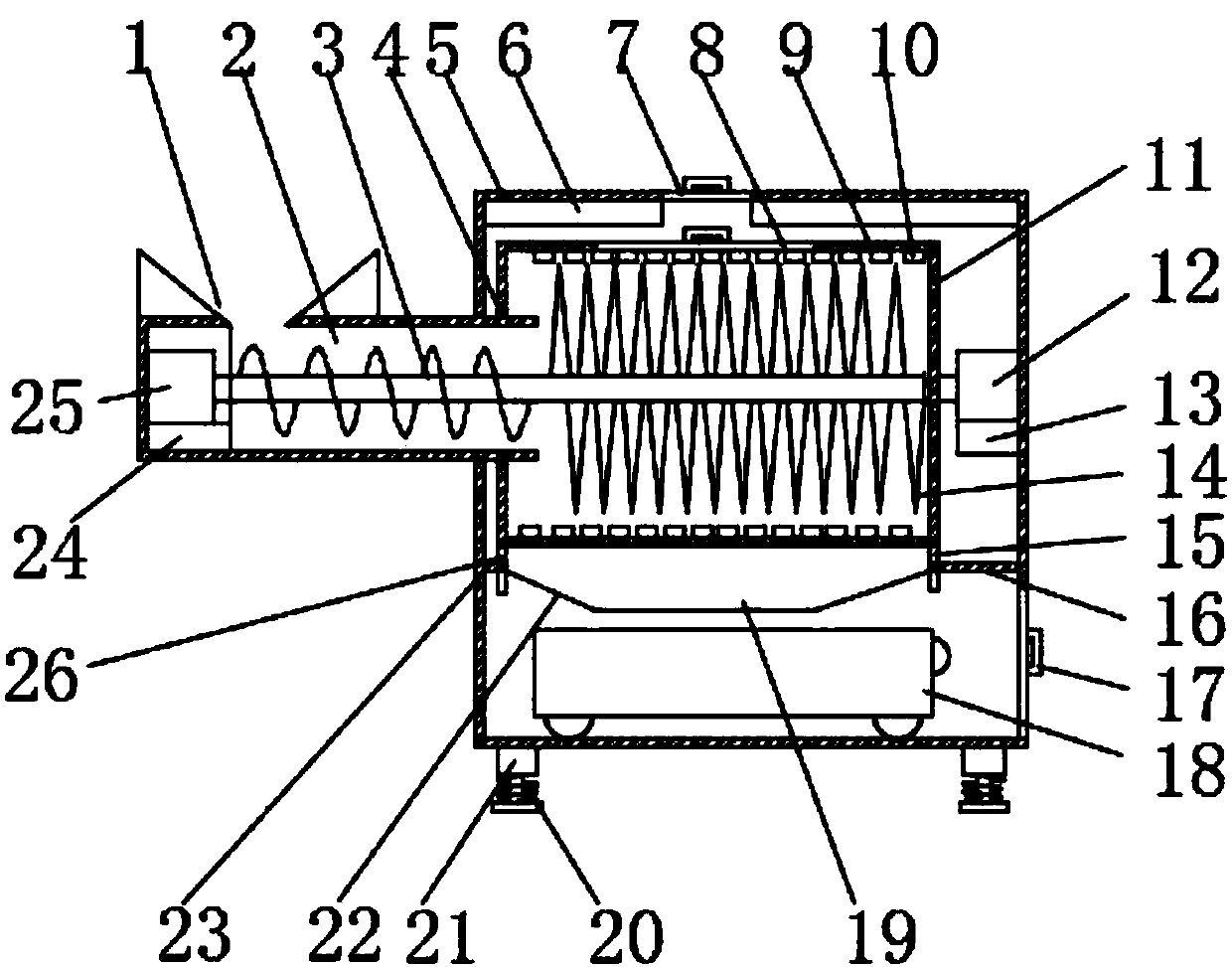

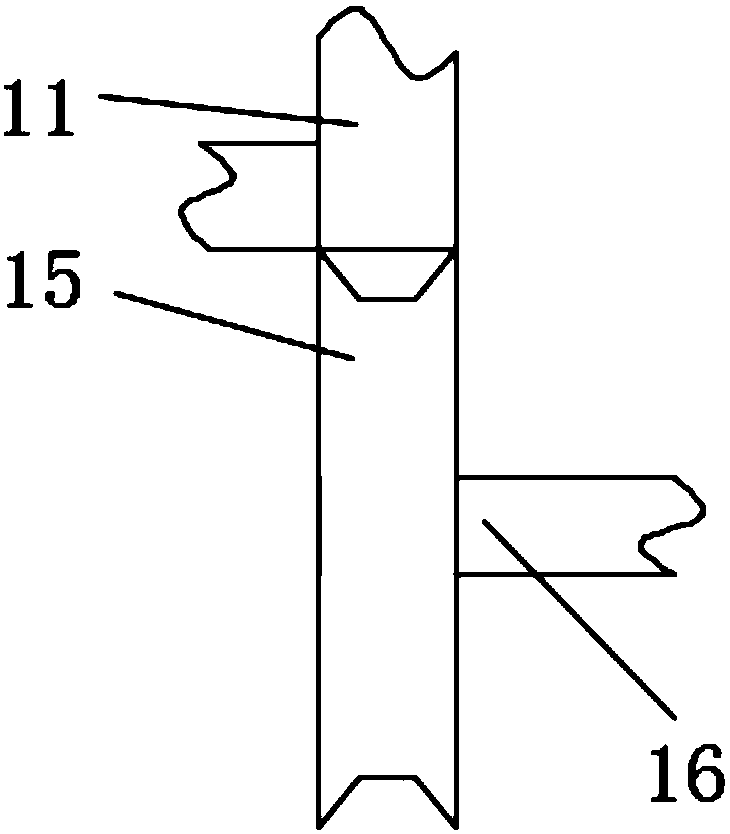

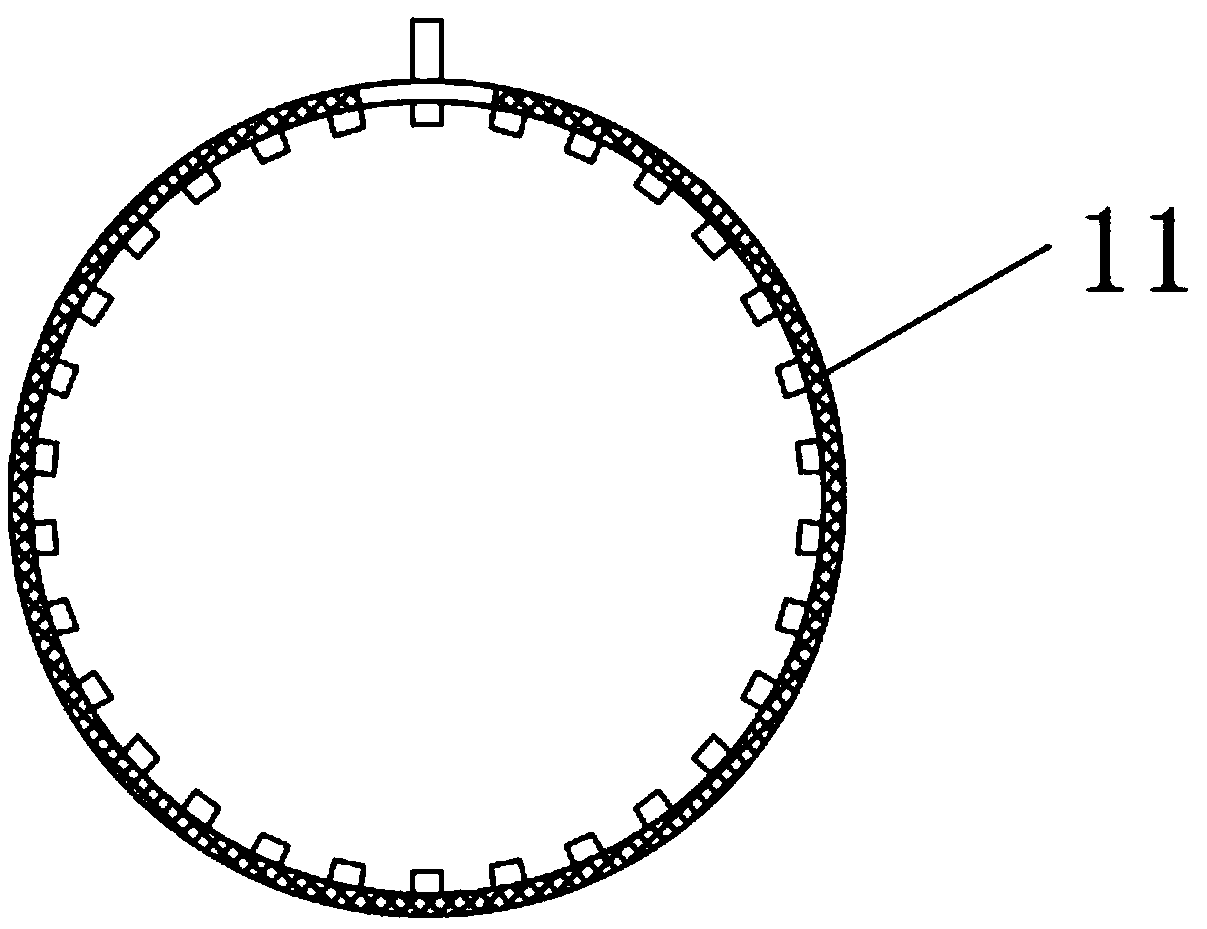

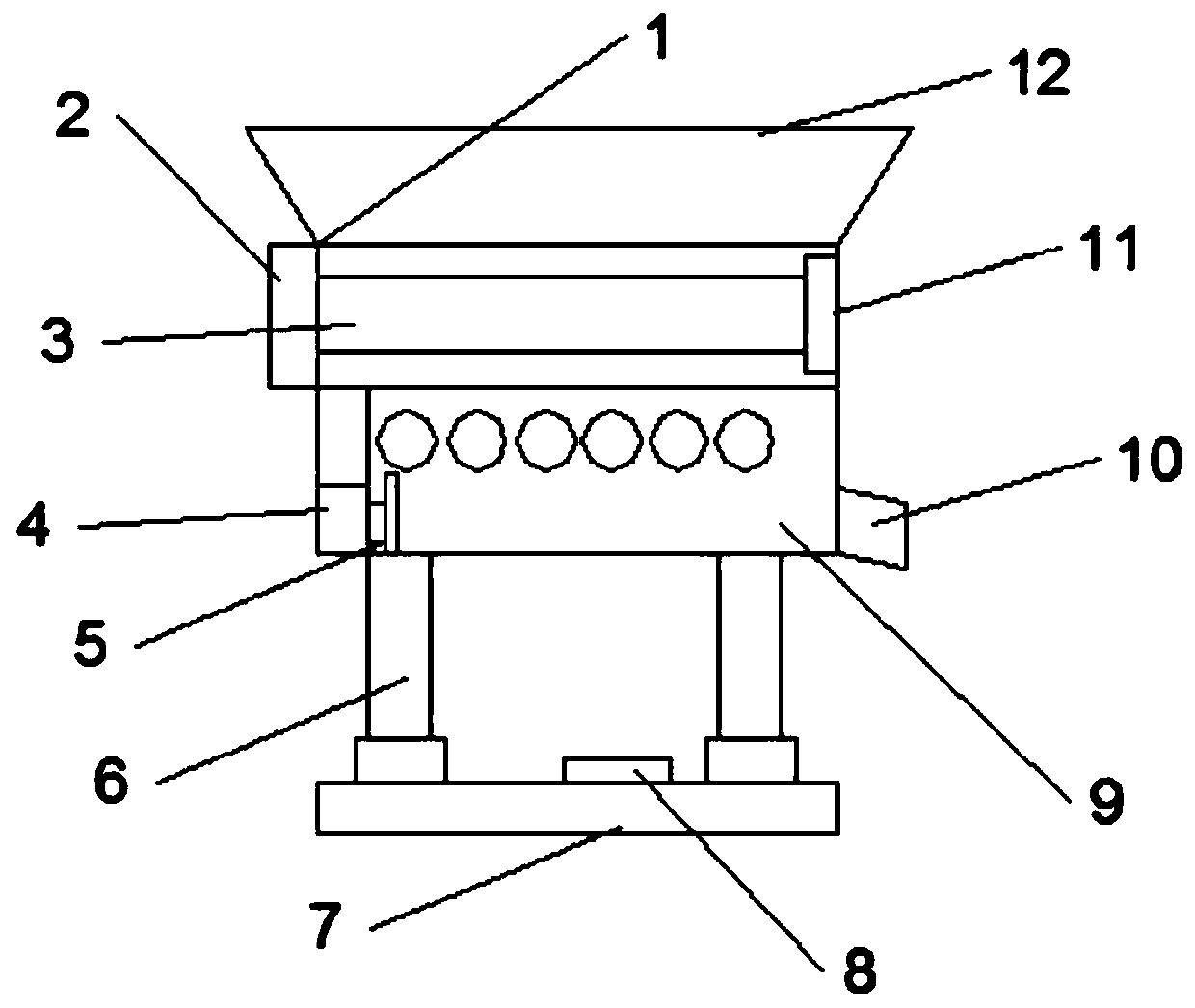

Ore crushing machine with multistage continuous crushing function

InactiveCN106732929ATimely supplementImprove crushing efficiencyGrain treatmentsEngineeringMachining

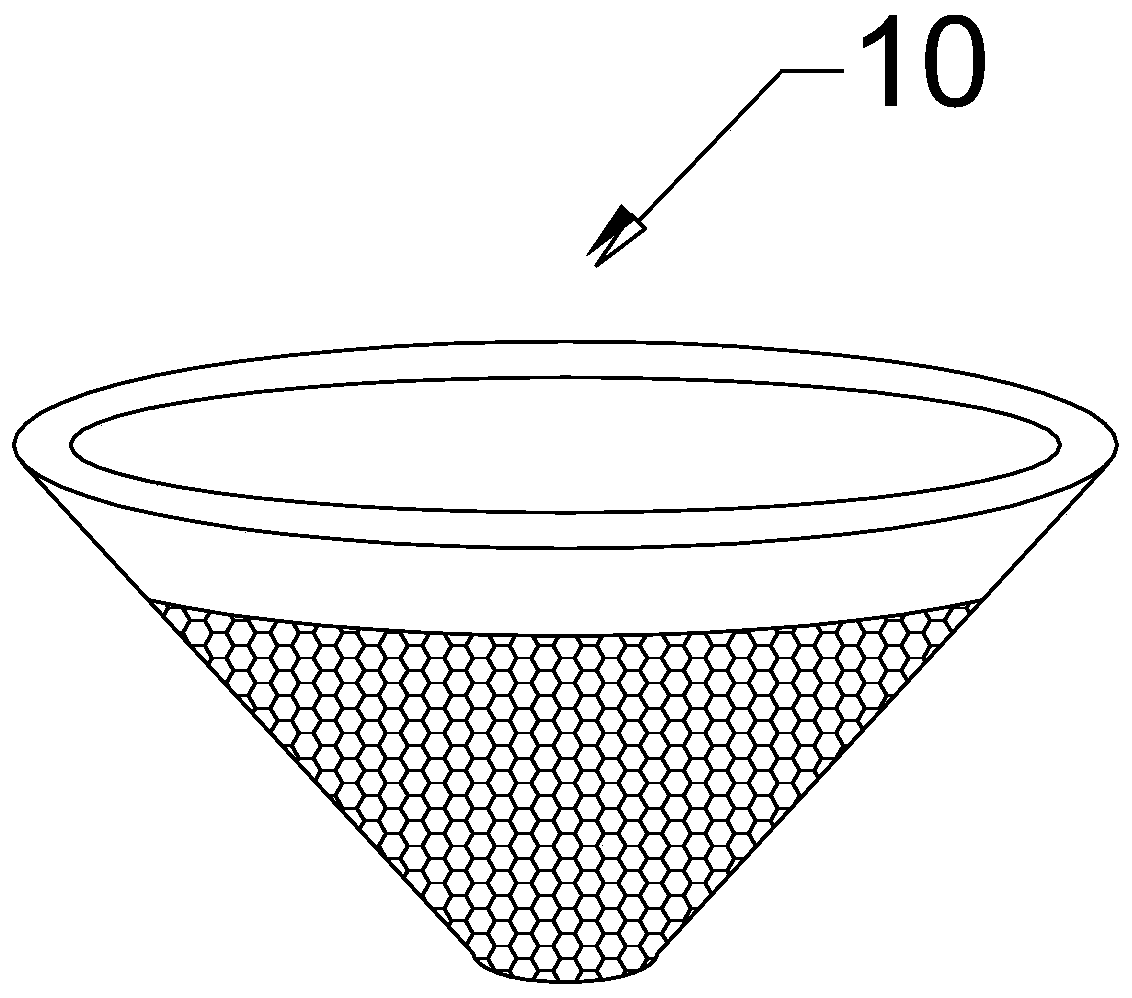

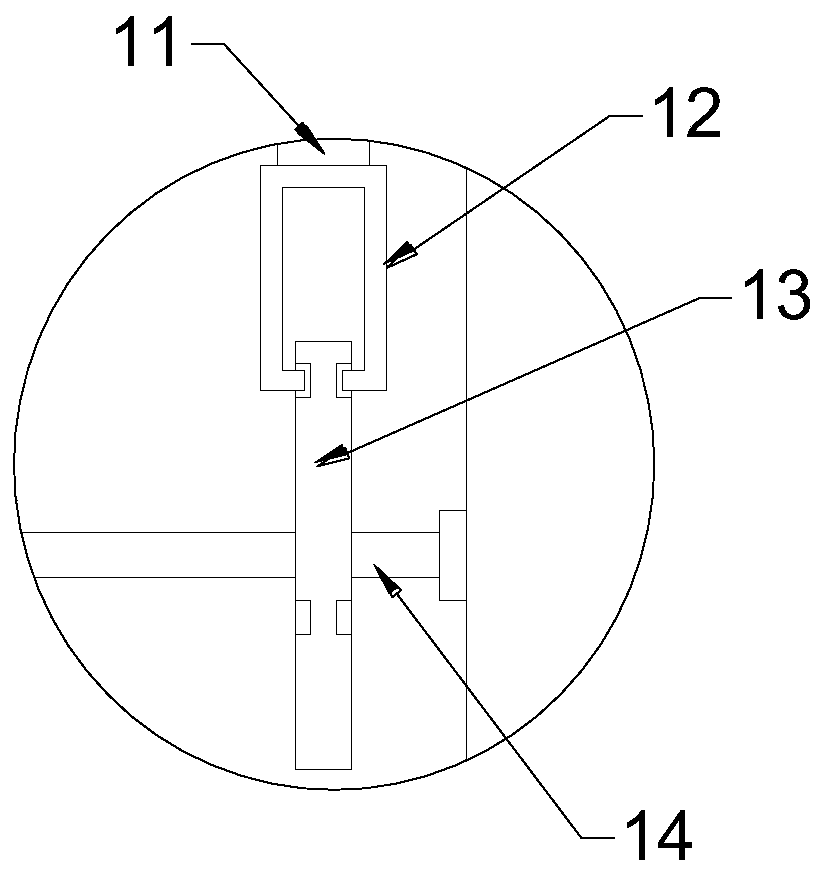

The invention discloses an ore crushing machine with a multistage continuous crushing function. The ore crushing machine comprises a first-stage crushing device, a second-stage crushing device and a collecting device which are sequentially arranged from up to bottom according to the ore flowing direction. The first-stage crushing device comprises an inverted conical channel and a crushing roller arranged in the channel. A plurality of layers of crushing teeth A are arranged on the inner surface of the channel. A plurality of layers of crushing teeth B are arranged on the outer surface of the crushing roller. The crushing roller is in transmission connection with a driving device A. The ore crushing machine has the beneficial effects that by the adoption of the ore crushing machine, multistage crushing can be achieved, and the crushing efficiency and crushing precision are high; by arranging the channel, materials can be added so that the materials can be supplemented in time, thus, the continuous machining function is achieved, and the crushing efficiency is improved; and by arranging the crushing teeth A and the crushing teeth B, the contact area between the ore crushing machine and the materials can be increased, and the crushing efficiency and crushing precision of the materials are improved.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

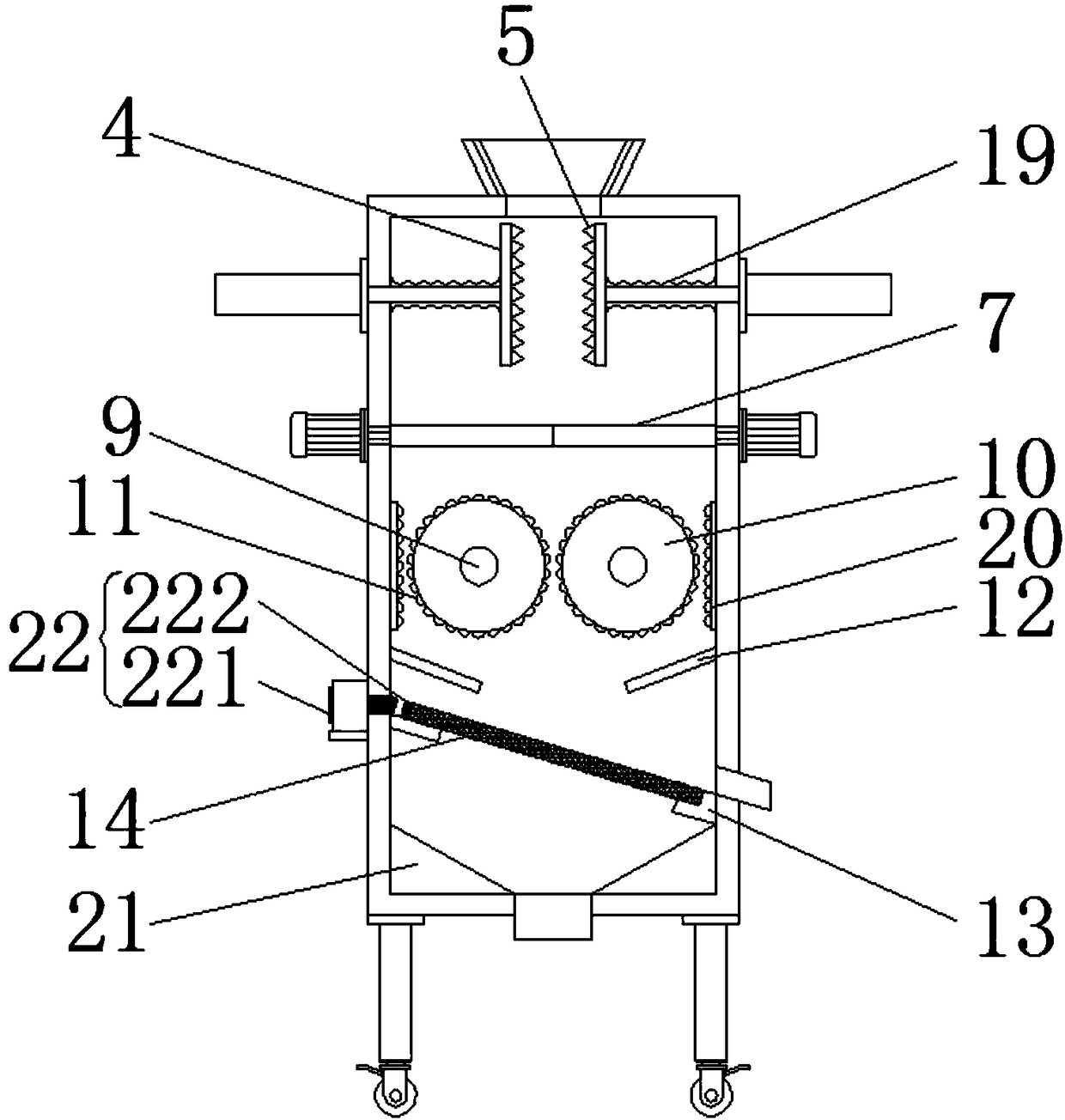

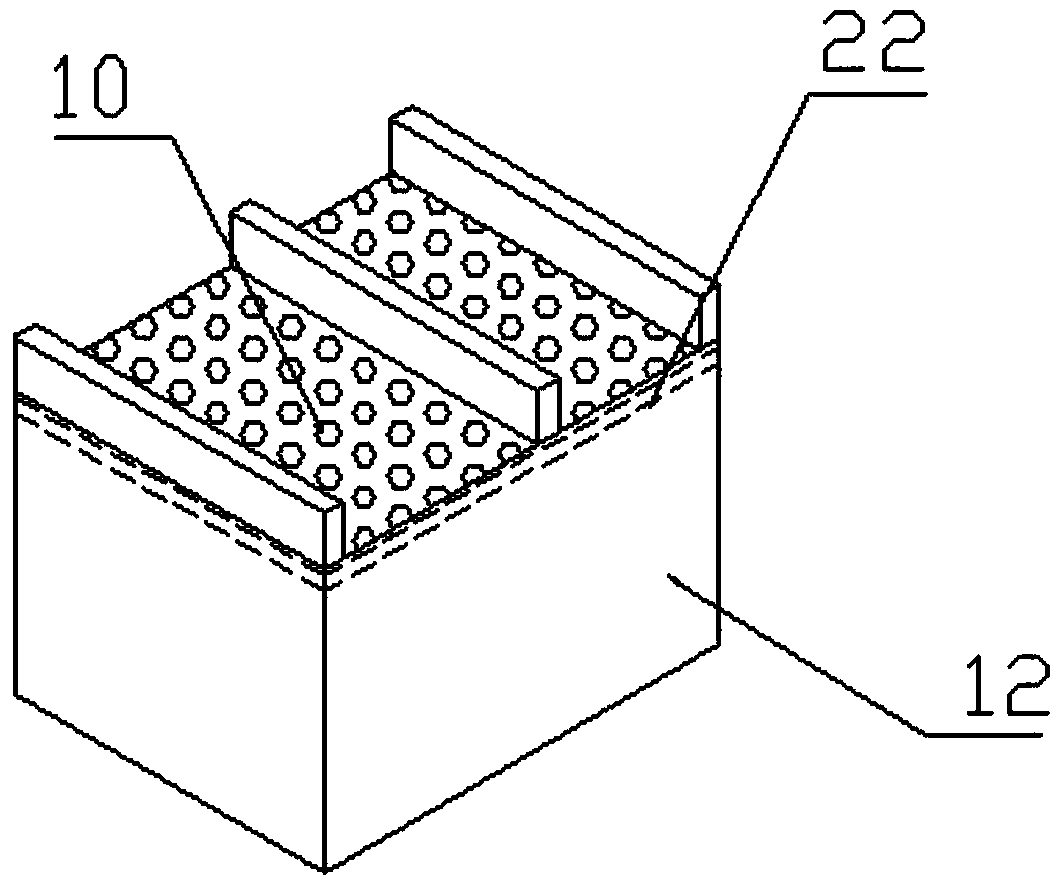

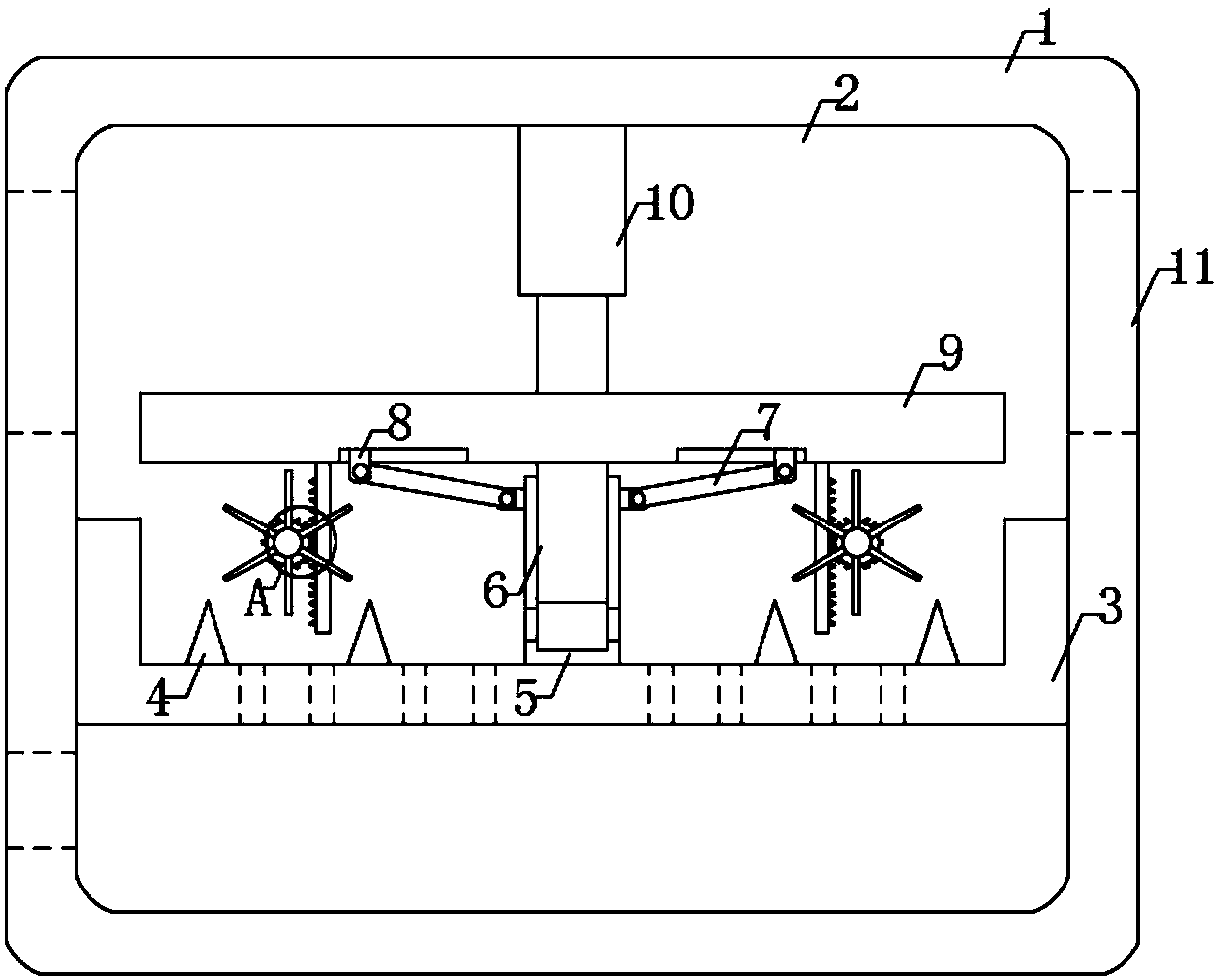

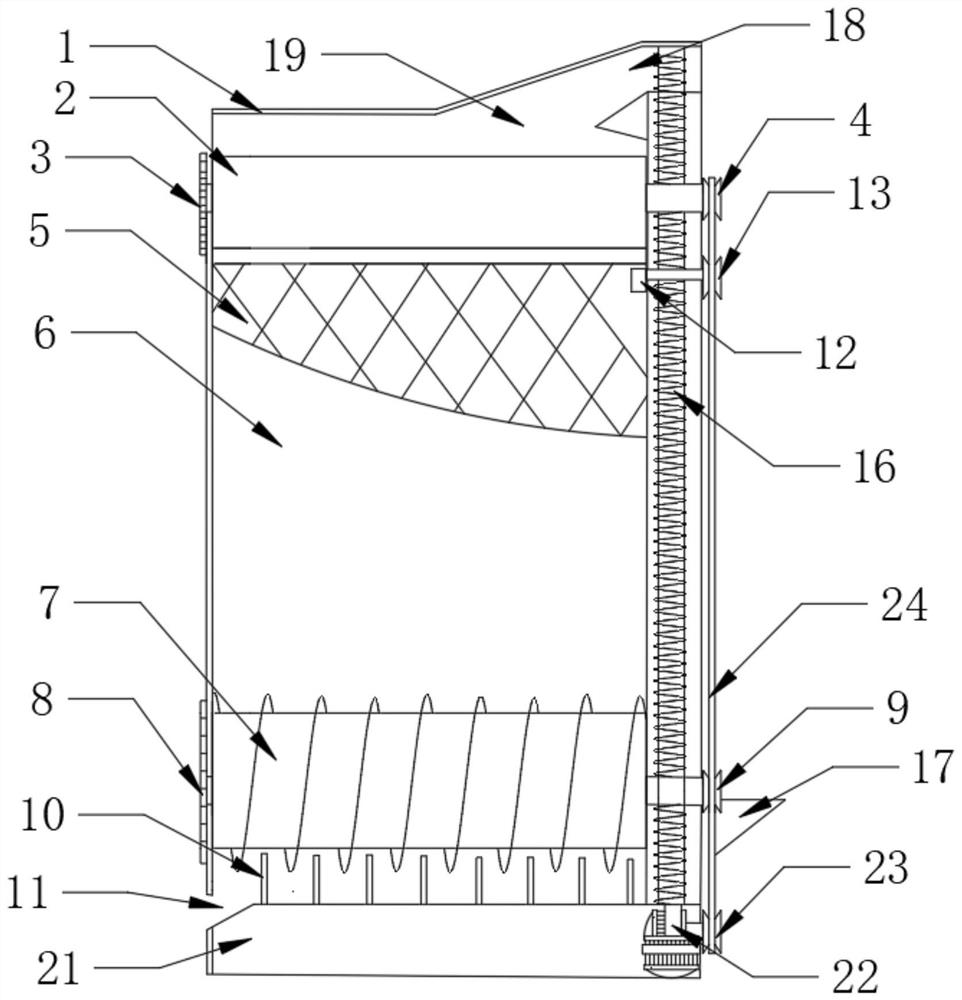

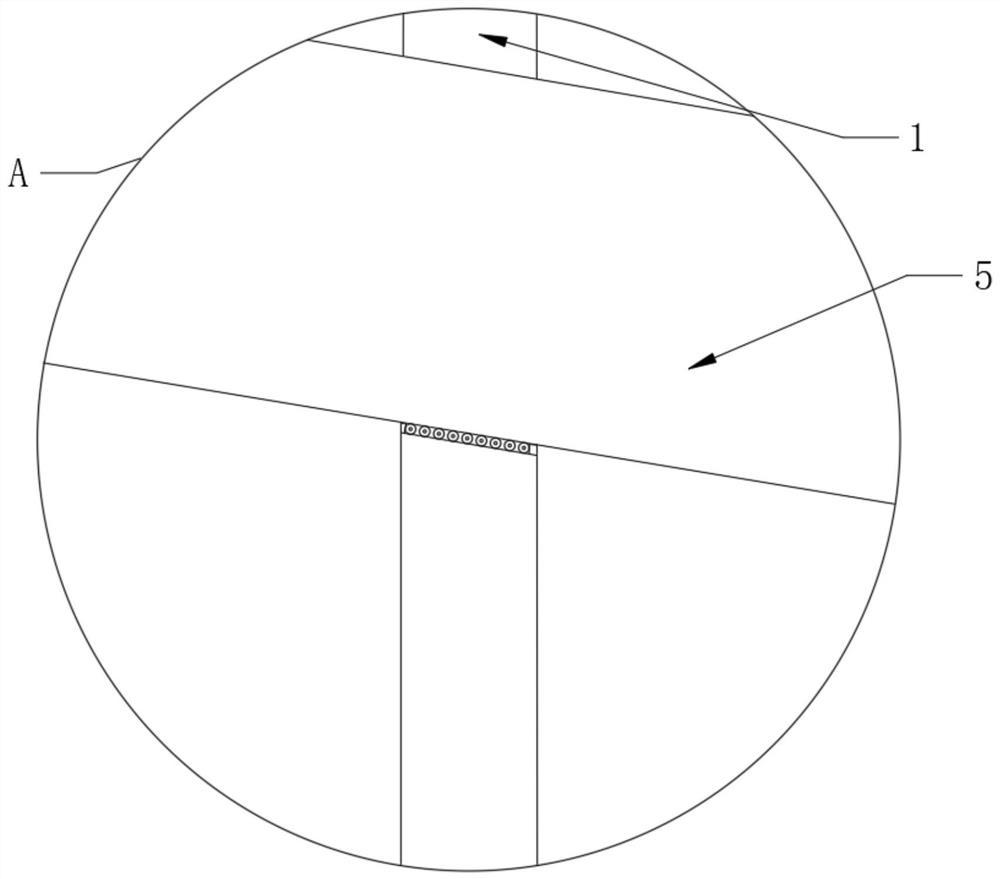

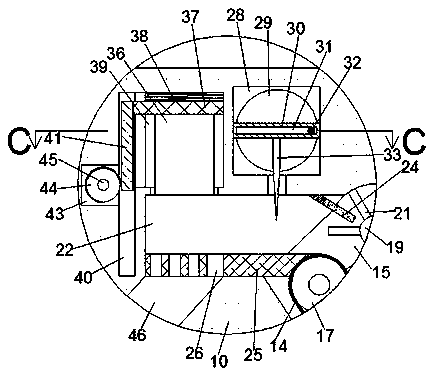

Waste coal slag smashing device for power plant

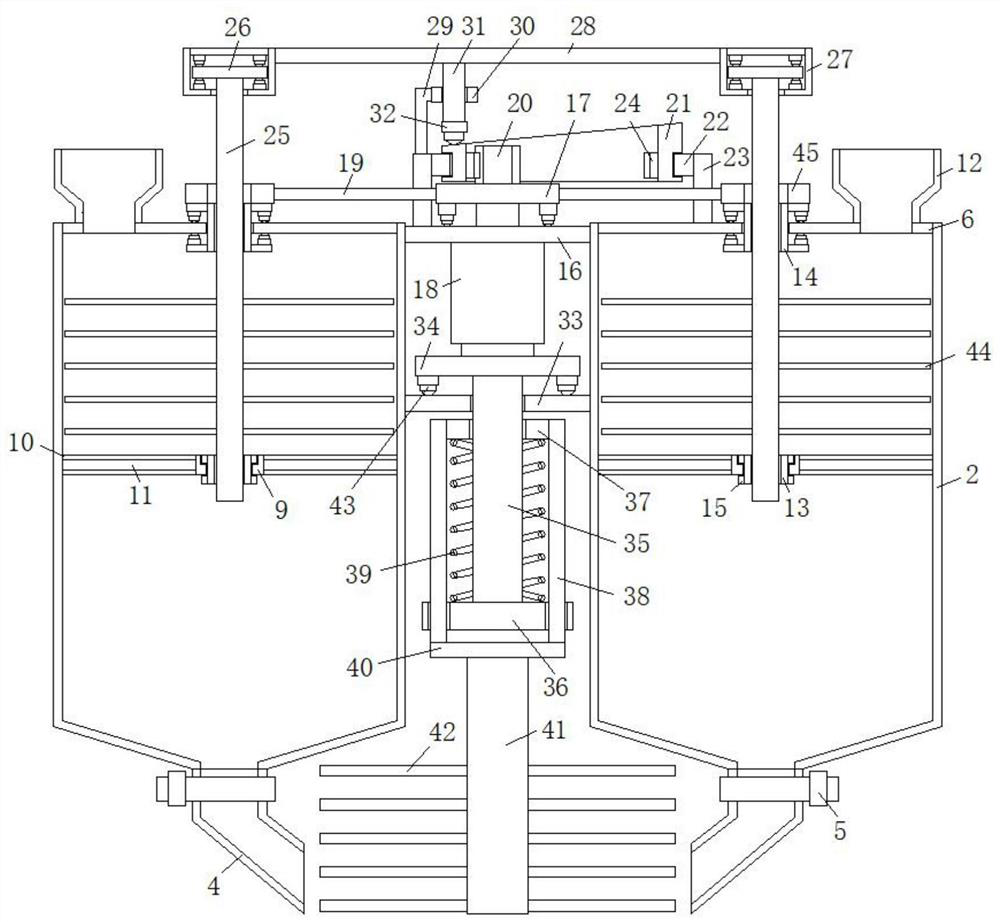

InactiveCN108405161AImprove crushing precisionImprove crushing effectSievingScreeningHydraulic cylinderSlag

The invention discloses a waste coal slag smashing device for a power plant. The waste coal slag smashing device comprises an outer shell. Two hydraulic cylinders are symmetrically and fixedly installed on the outer side wall of the upper portion of the outer shell; piston rods of the hydraulic cylinders penetrate through the side walls of the outer shell, extrusion plates are fixedly installed onthe piston rods of the hydraulic cylinders, and smashing teeth are arranged on the extrusion plates; output shafts of first motors penetrate through the side walls of the outer shell, and a turning-over plate is fixedly installed on the output shafts of the first motors through pin shafts and bearings; two second motors are fixedly installed on the outer side wall of the middle of the outer shell, output shafts of the second motors are in transmission connection with roller shafts through couplers, smashing rollers are arranged on the roller shafts, and hemispherical protruding blocks are arranged on the smashing rollers; and a filter net plate is erected on erecting plates. The smashing efficiency is high, the smashing precision of waste coal slag is improved, the fine waste coal slag meeting the requirement can be screened out, thus the screening speed is high, and the screening effect is good.

Owner:高锦芳

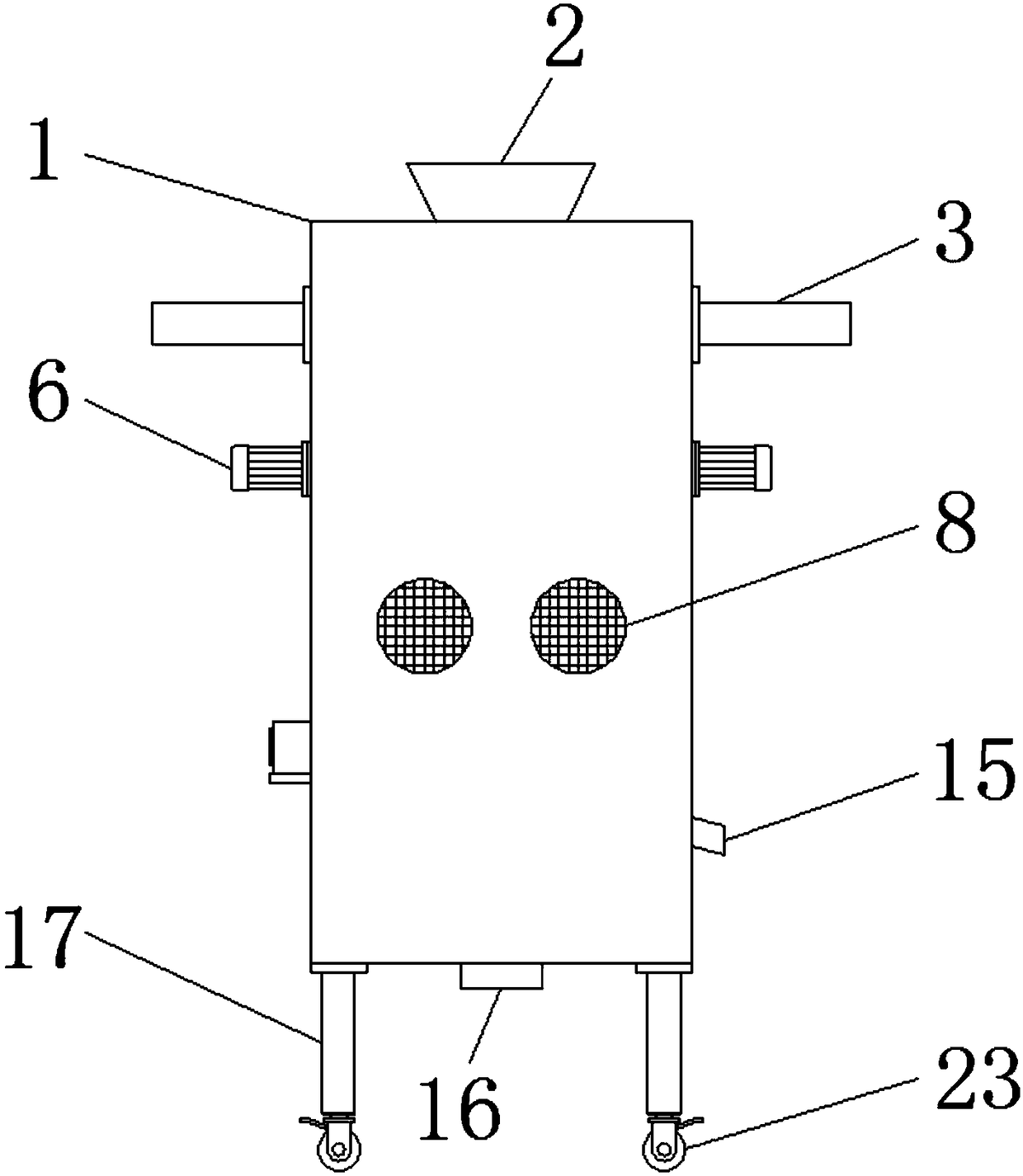

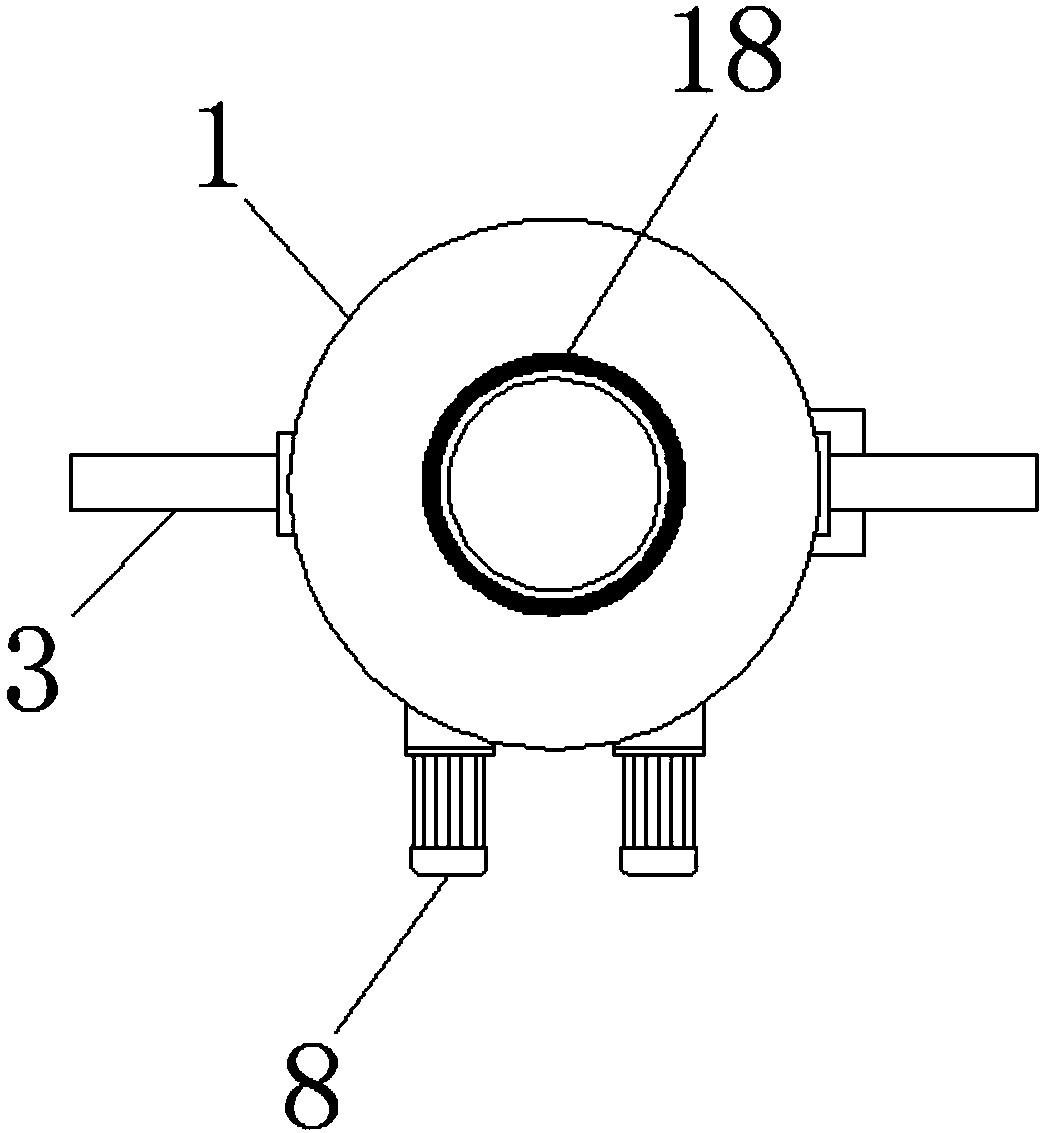

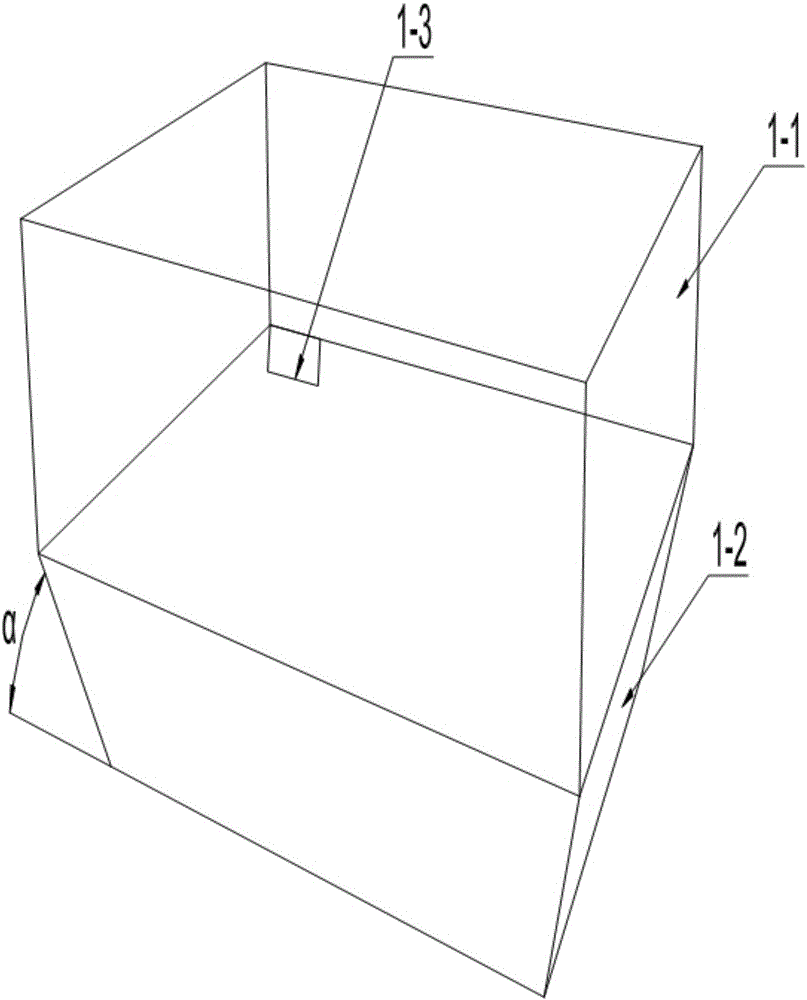

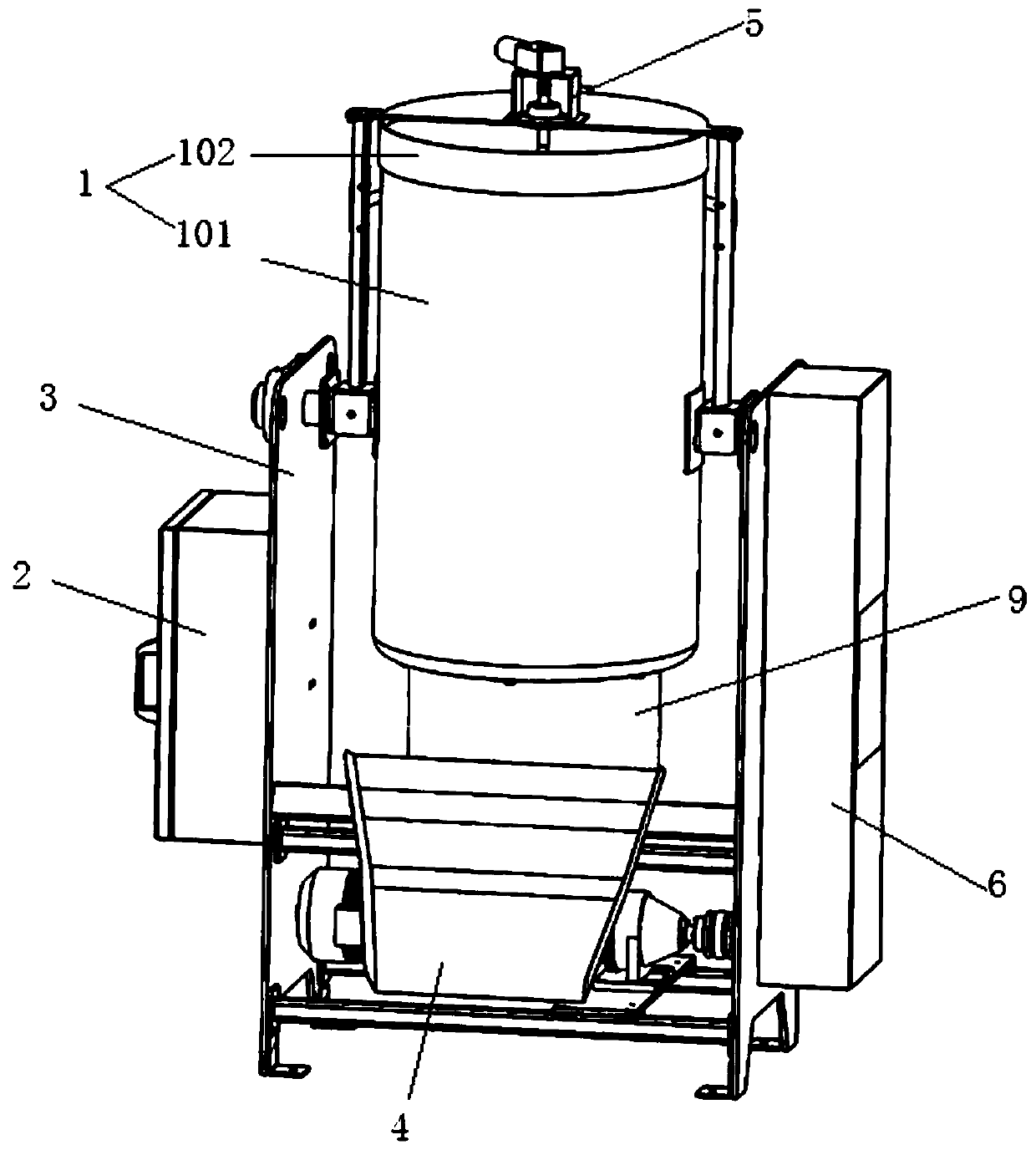

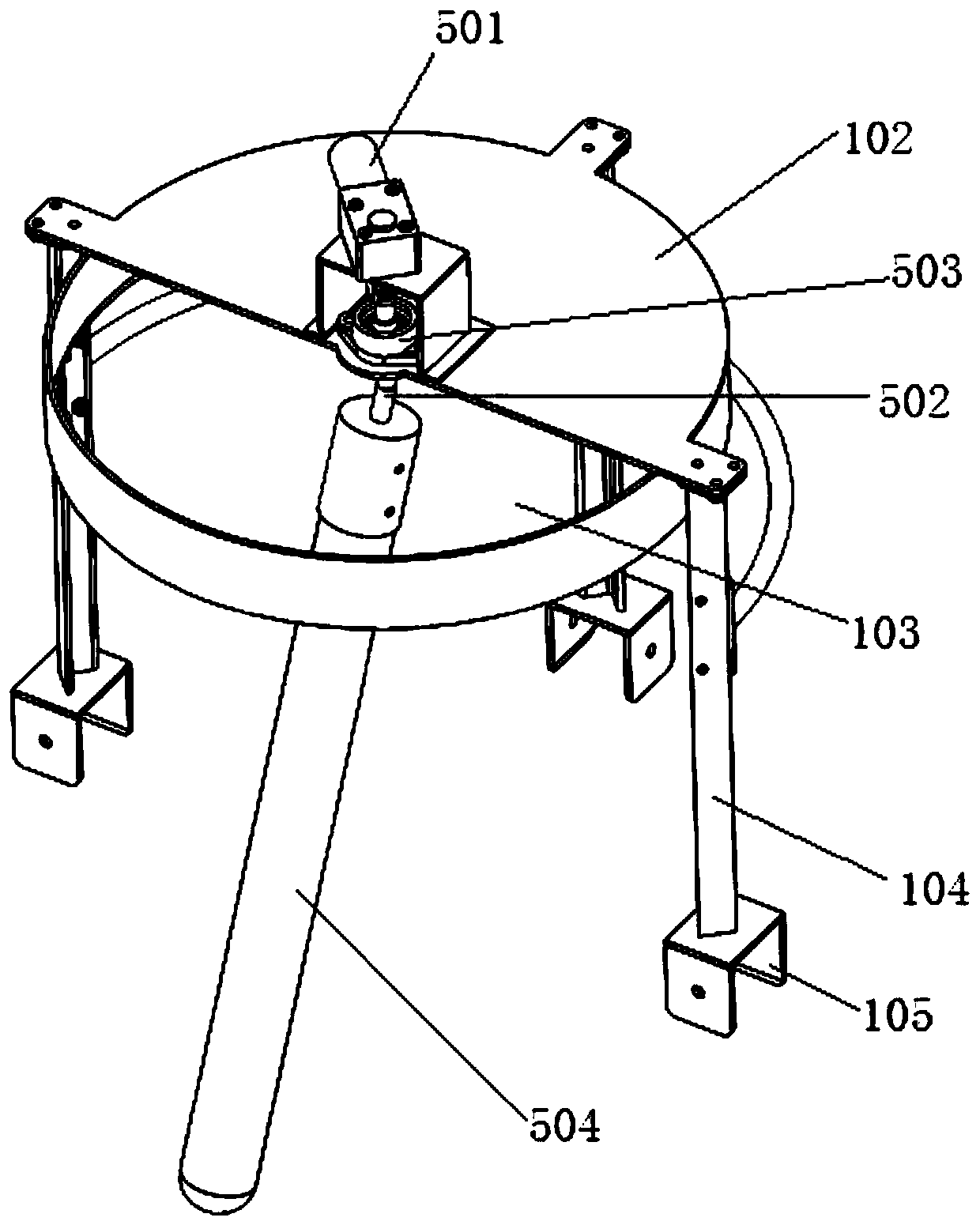

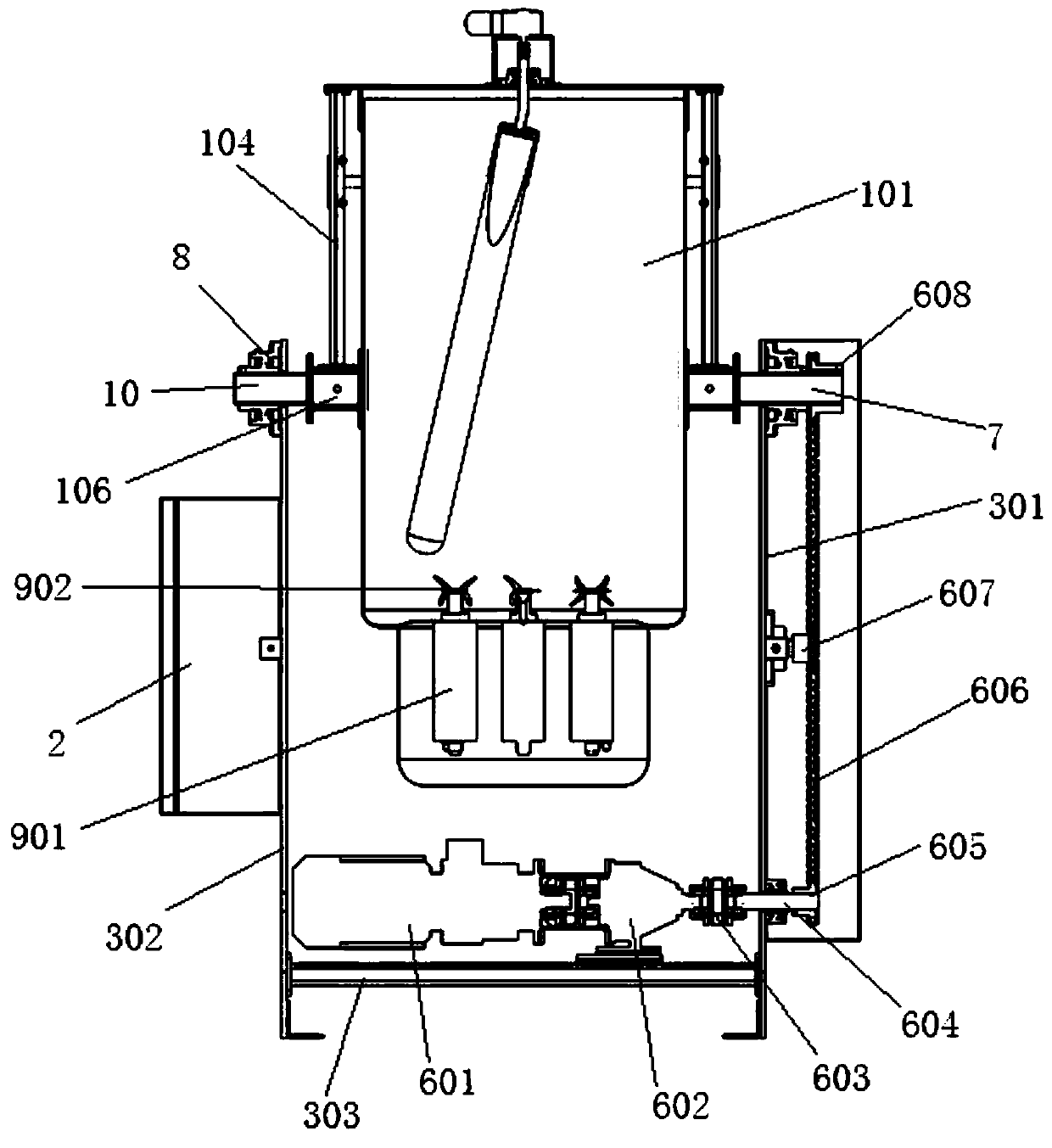

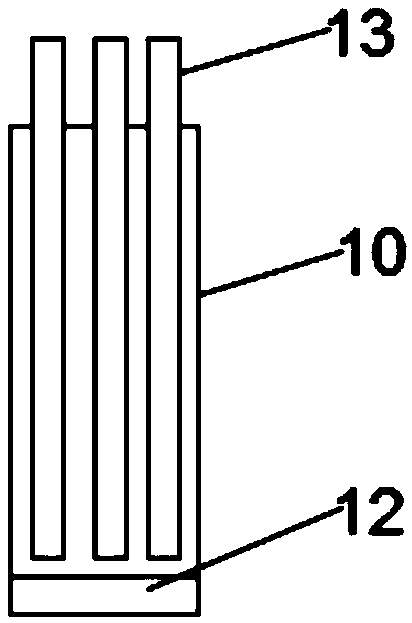

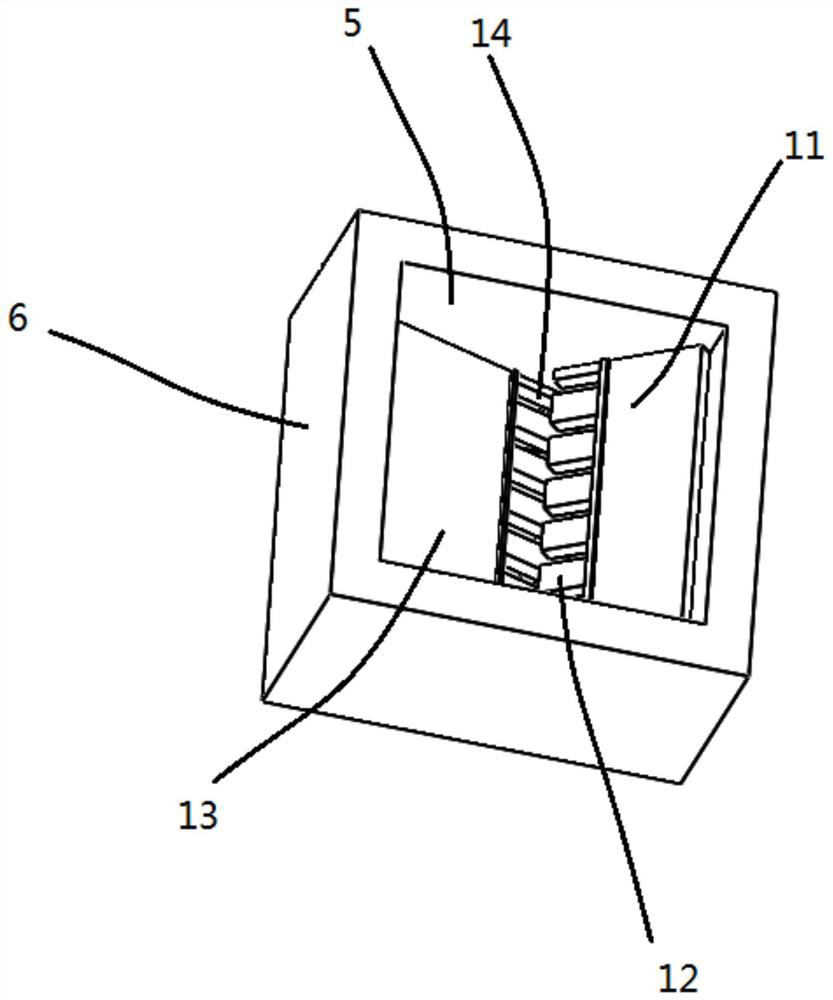

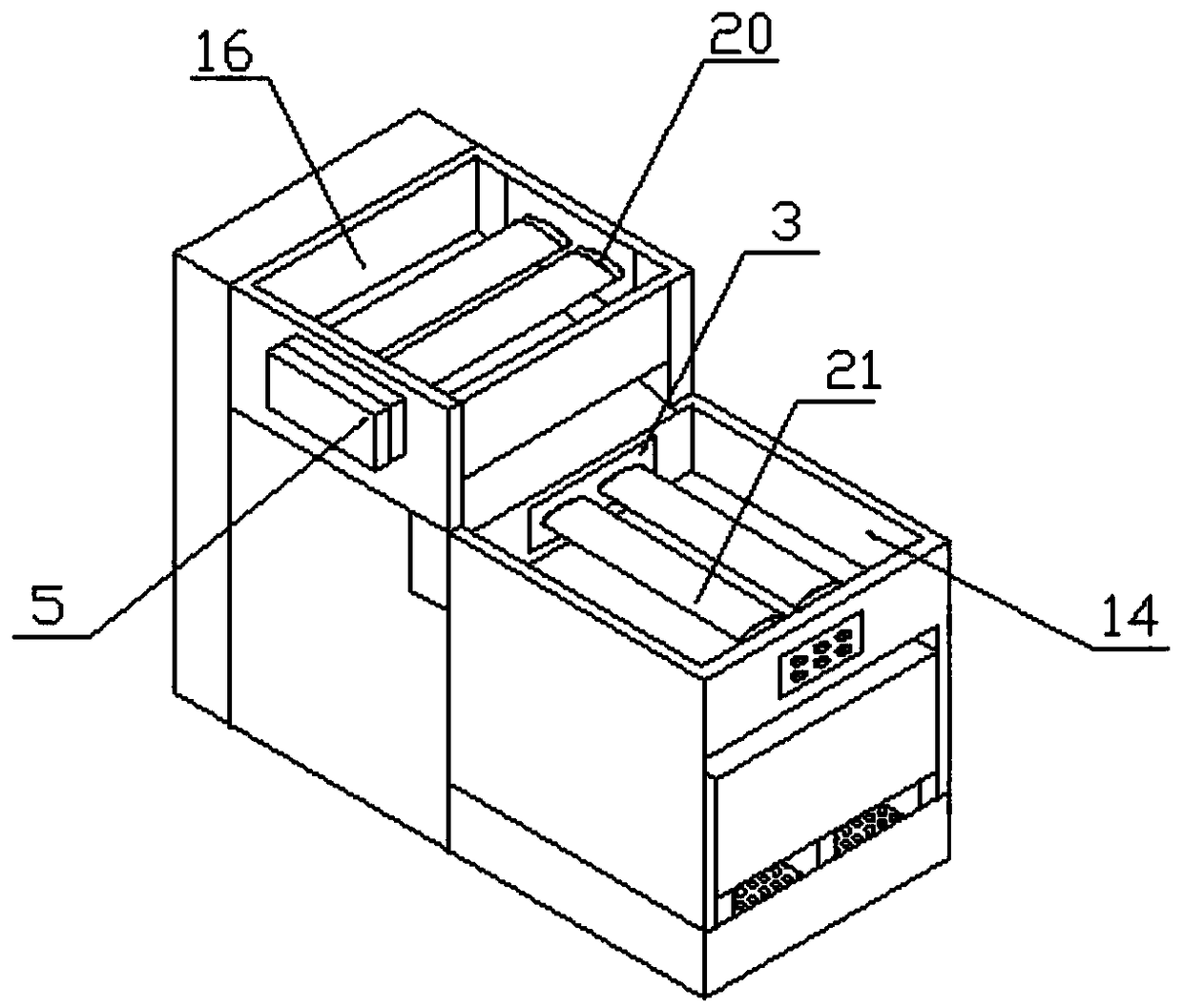

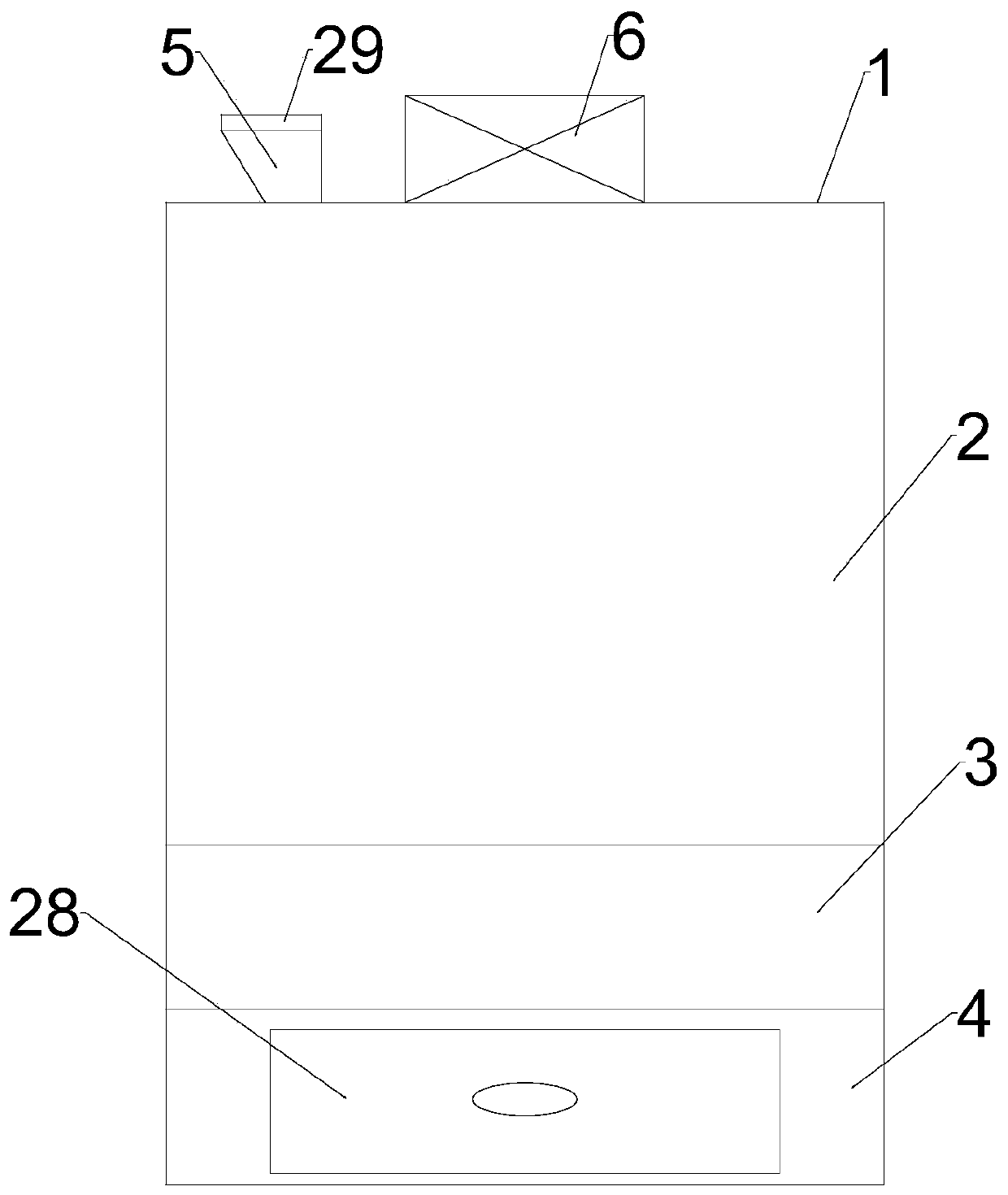

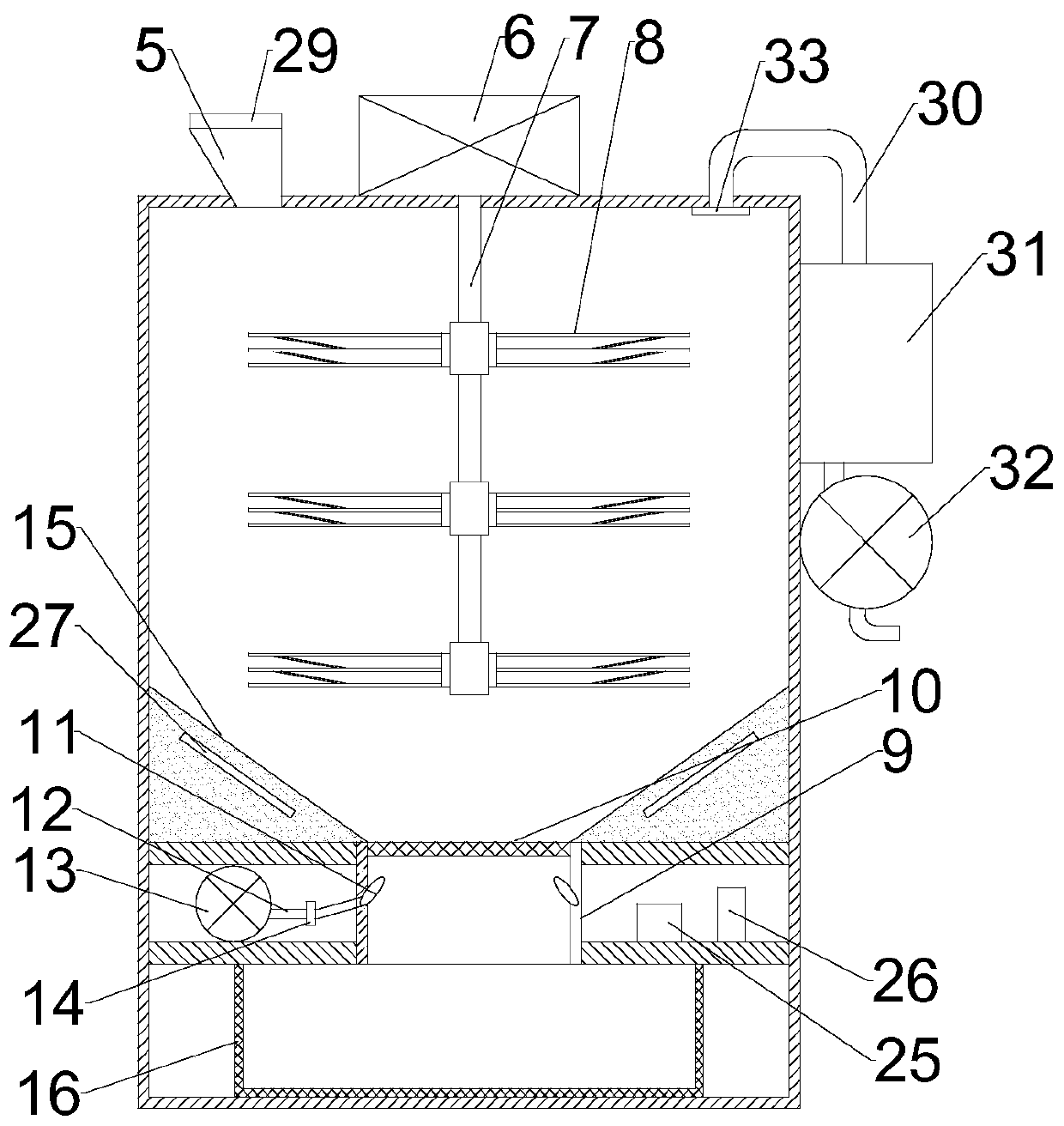

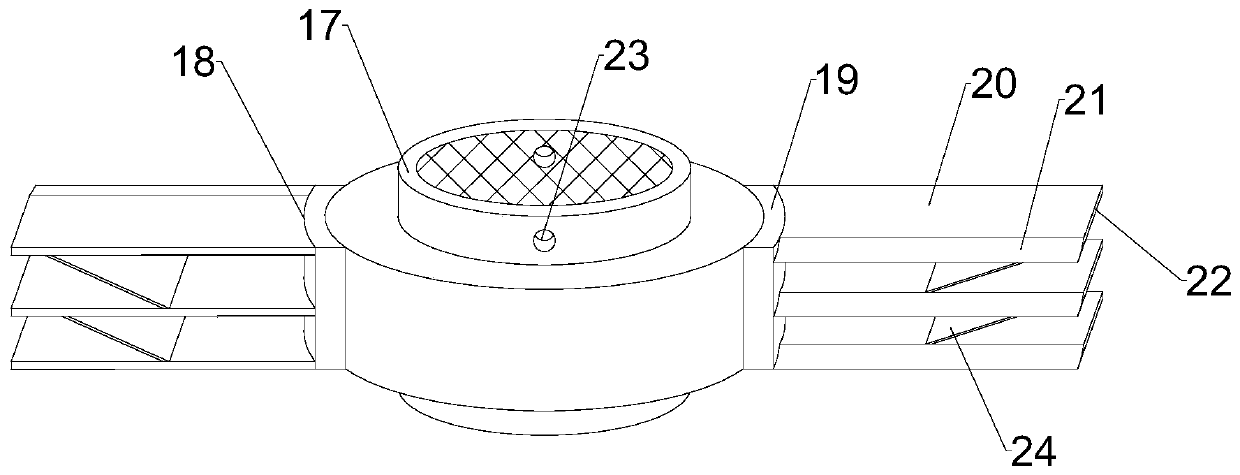

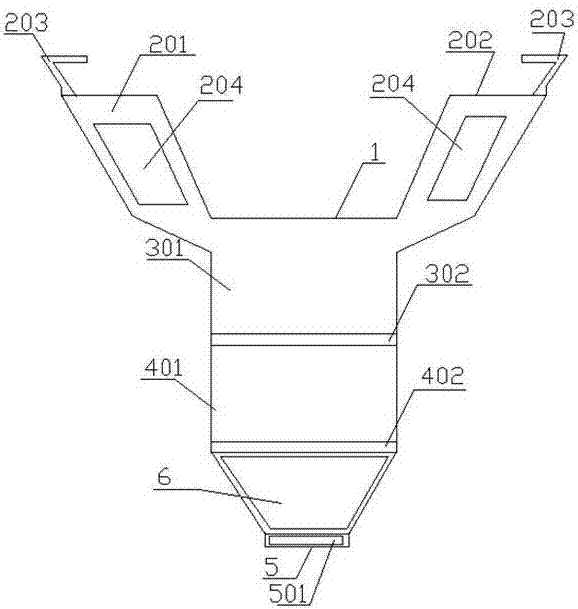

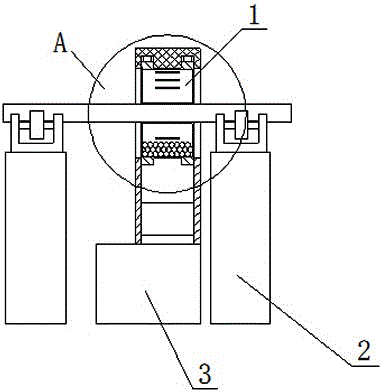

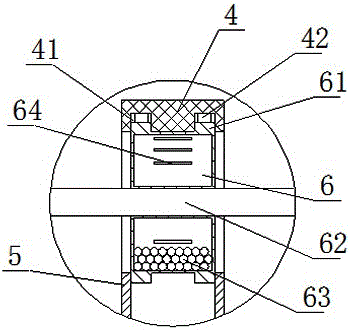

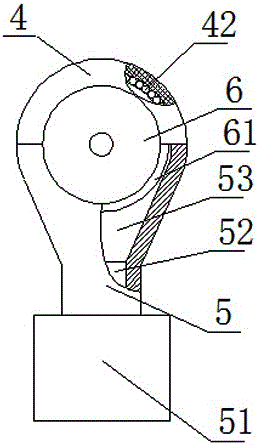

Crushing, compression and dehydration integrated device and working method thereof

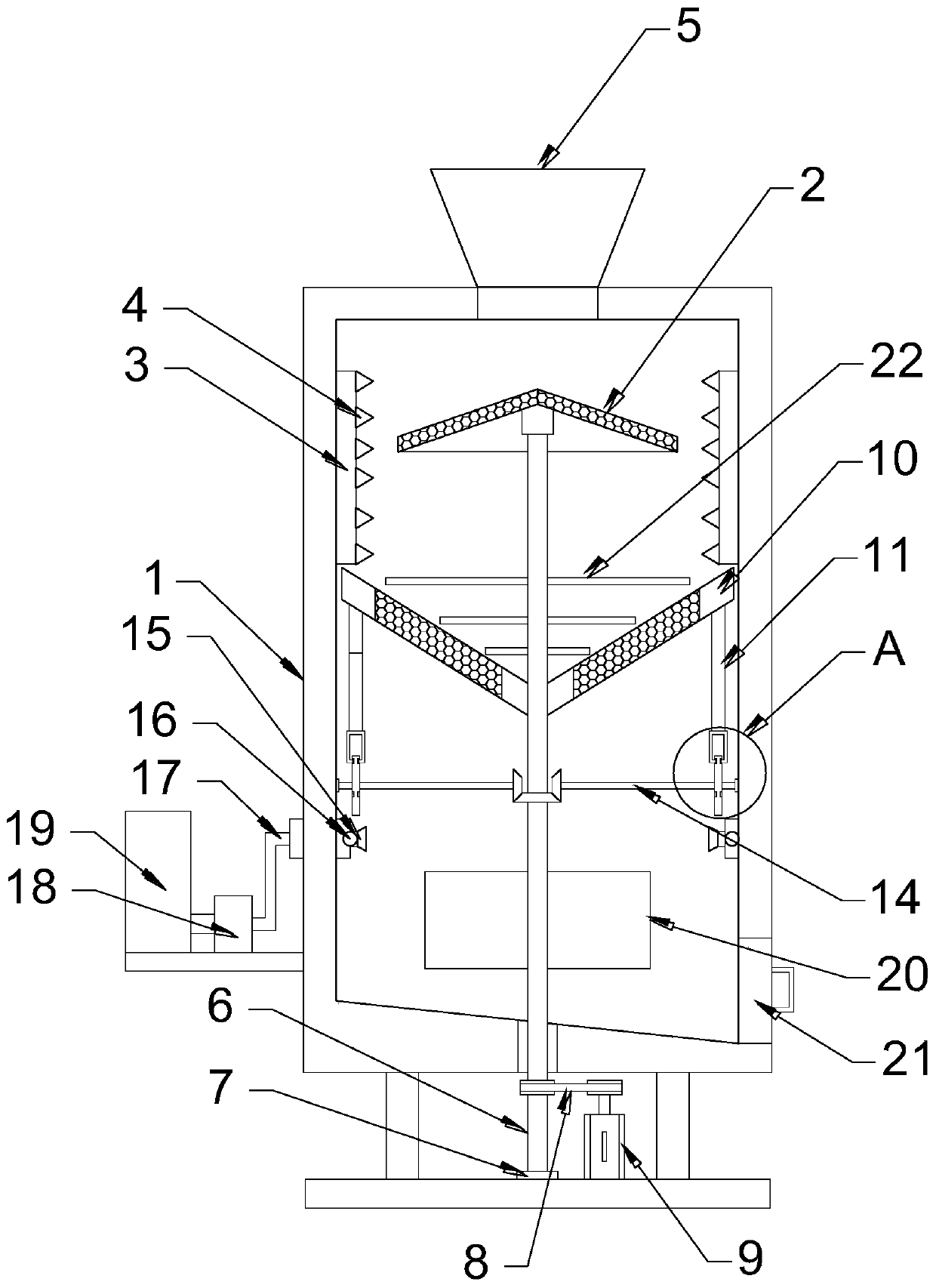

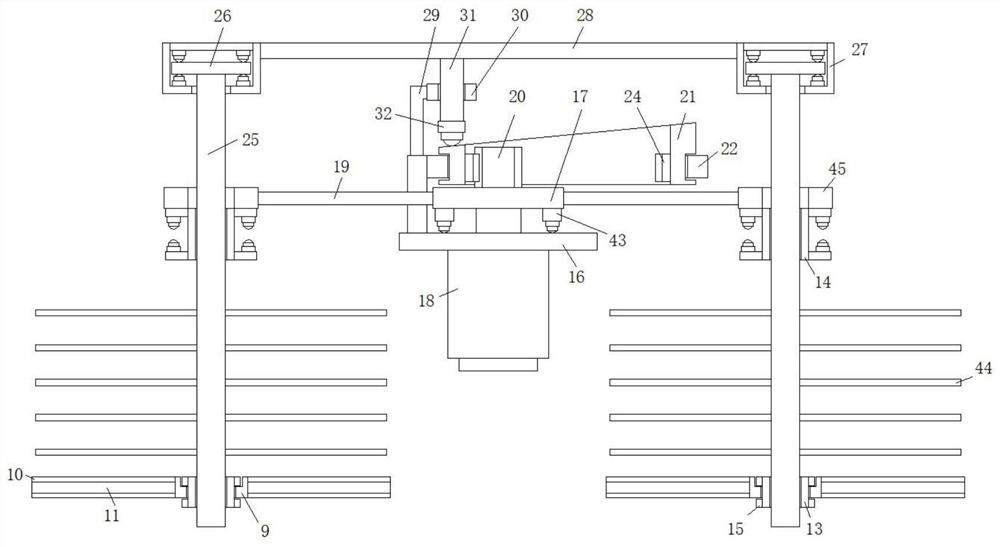

ActiveCN105728100AImprove crushing precisionHigh degree of automationDrying solid materials without heatGrain treatmentsControl systemDehydration

The invention discloses a crushing, compression and dehydration integrated device. The crushing, compression and dehydration integrated device consists of a feed bin, a crushing bin, a crushing device, a screening bin, a compression dehydration bin, an automatic sucking device, a drain pipe, a bracket and a control system; raw materials enter the feed bin through the automatic sucking device to drop into the crushing bin; fragments, crushed by the crushing device, vertically enter the screening bin, and are screened by the screening bin; the screened fragments enter the compression dehydration bin, and are discharged out of a bin body after compression; and compressed water is drained out of the device by the drain pipe. The crushing, compression and dehydration integrated device is novel and reasonable in shape, is convenient and fast in automatic sucking structure, is simple and practical in compression mechanism, is excellent in dehydration effect, and is wide in application range.

Owner:XUZHOU UNIV OF TECH

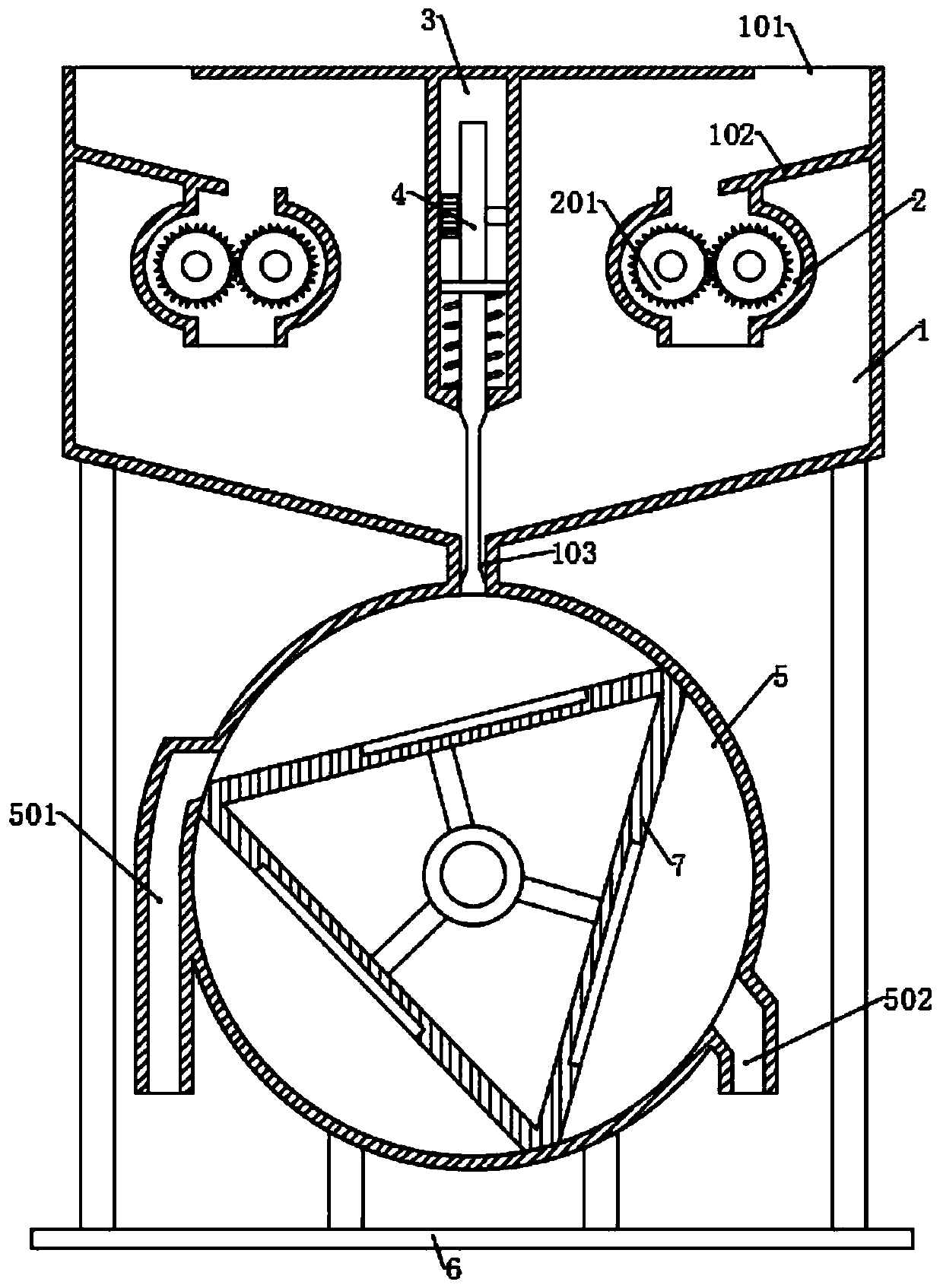

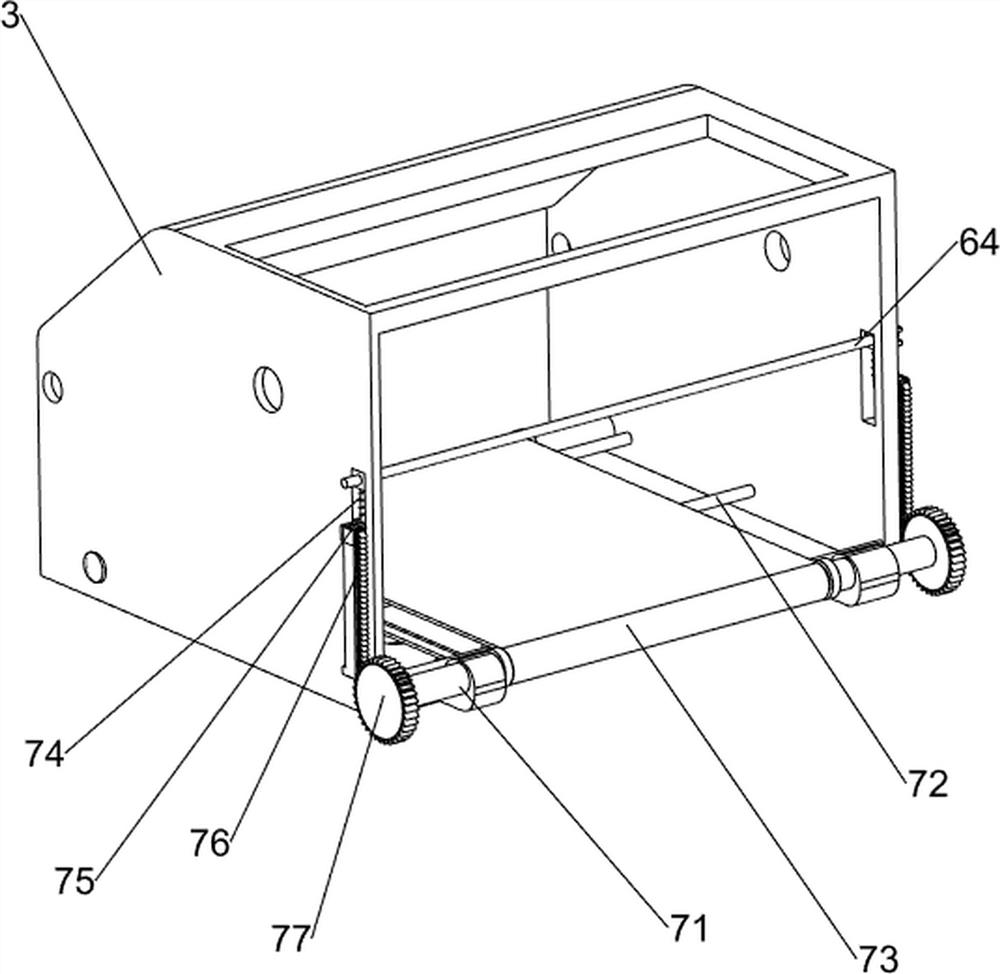

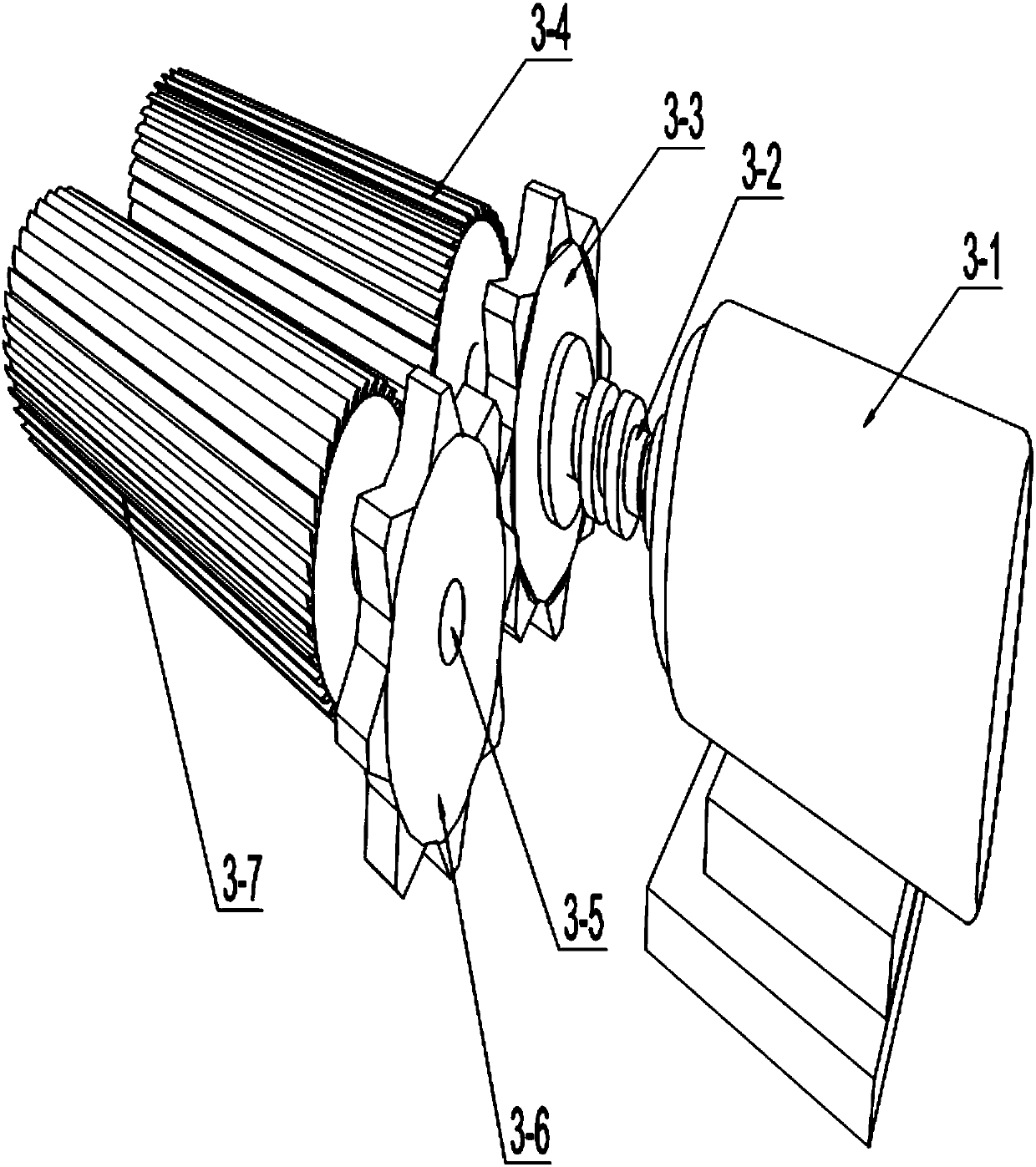

Smashing device with filtering function for battery cathode material

The invention provides a smashing device with a filtering function for a battery cathode material. The smashing device comprises a box body, a filling box, a first smashing device and a second smashing device. The first smashing device is arranged in the box body. A conveying pipe is arranged on the right portion of the box body. The second smashing device is arranged on the top of the box body. The right end of the conveying pipe is connected with a conveying cylinder. A spiral conveying device is mounted in the conveying cylinder. An inclined pipe is connected to the top of the conveying cylinder and connected to the right side of the filling box. The first smashing device is composed of a slave smashing wheel, a first mounting shaft, an active smashing wheel, a smashing motor and a second mounting shaft. The second smashing device is composed of a round cylinder, a first support, a spiral smashing device, a rotating shaft, a second support, a bearing, a belt, a slave wheel, a drive motor, a sealing ring and an active wheel. The smashing device can successively smash the materials twice, so that the smashing fineness and quality are improved; and the materials which are not smashed can be screened out and conveyed to the filling box to be smashed repeatedly.

Owner:SHENZHEN JUOCAN TECH CO LTD

Mixing device for soil remediation

PendingCN110125154APrevent screen cloggingImprove crushing precisionContaminated soil reclamationGrain treatmentsEngineeringKnife blades

The invention discloses a mixing device for soil remediation. The device comprises a box body; the upper end of the box body communicates with a material inlet hopper; and the interior of the box bodyis provided with an upwards-convex screen cylinder, the outer side of the upwards-convex screen cylinder is provided with an impact cylinder, the impact cylinder is fixedly connected with the inner wall of the box body, and the inner wall of the impact cylinder is fixedly connected with uniformly-distributed impact teeth. According to the device provided by the invention, the upwards-convex screen cylinder and the impact cylinder are arranged, so that soil is centrifugally screened, intercepted bulges are centrifugally thrown out, and crushing of the bulges is realized by cooperation of the upwards-convex screen cylinder and the impact cylinder; and a downwards-convex screen cylinder, connecting rods, clamping connection frames, eccentric disks and crushing blades are arranged, so that up-and-down movement of the downwards-convex screen cylinder is realized, the soil is further crushed by the crushing blades, clogging of screen holes is avoided, the crushing precision is improved, andsubsequent cooperation with a soil remediation liquid is facilitated.

Owner:王晶晶

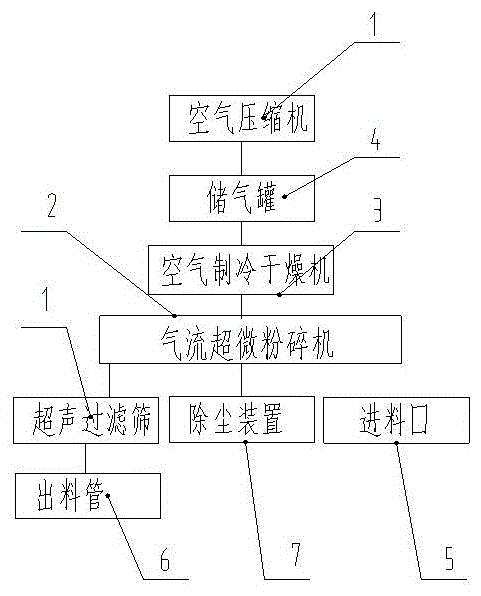

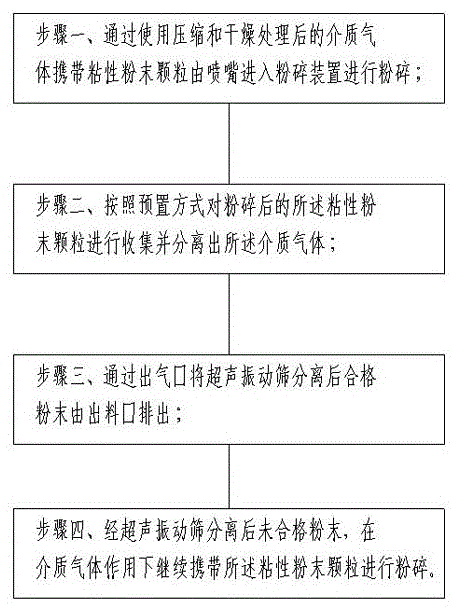

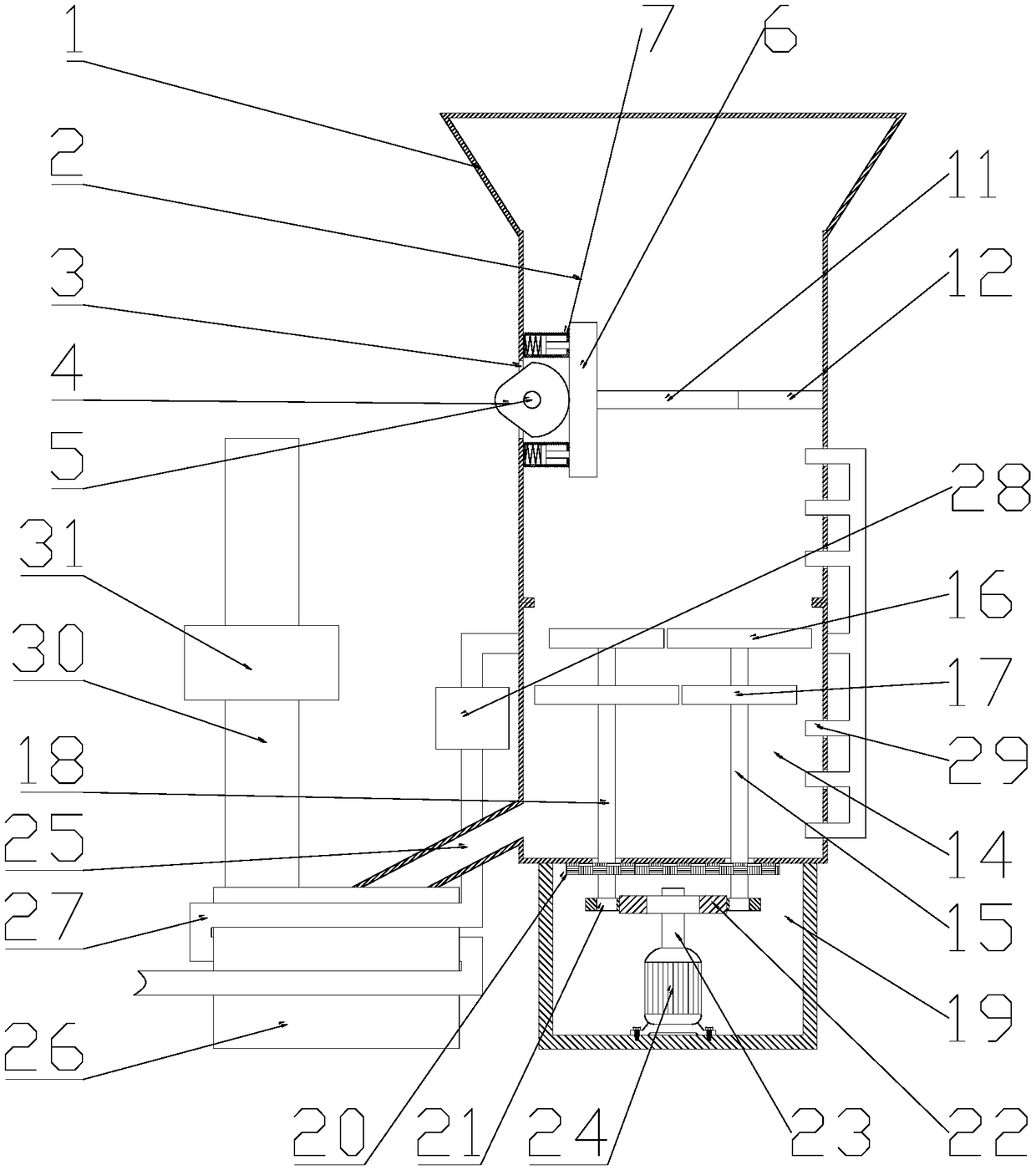

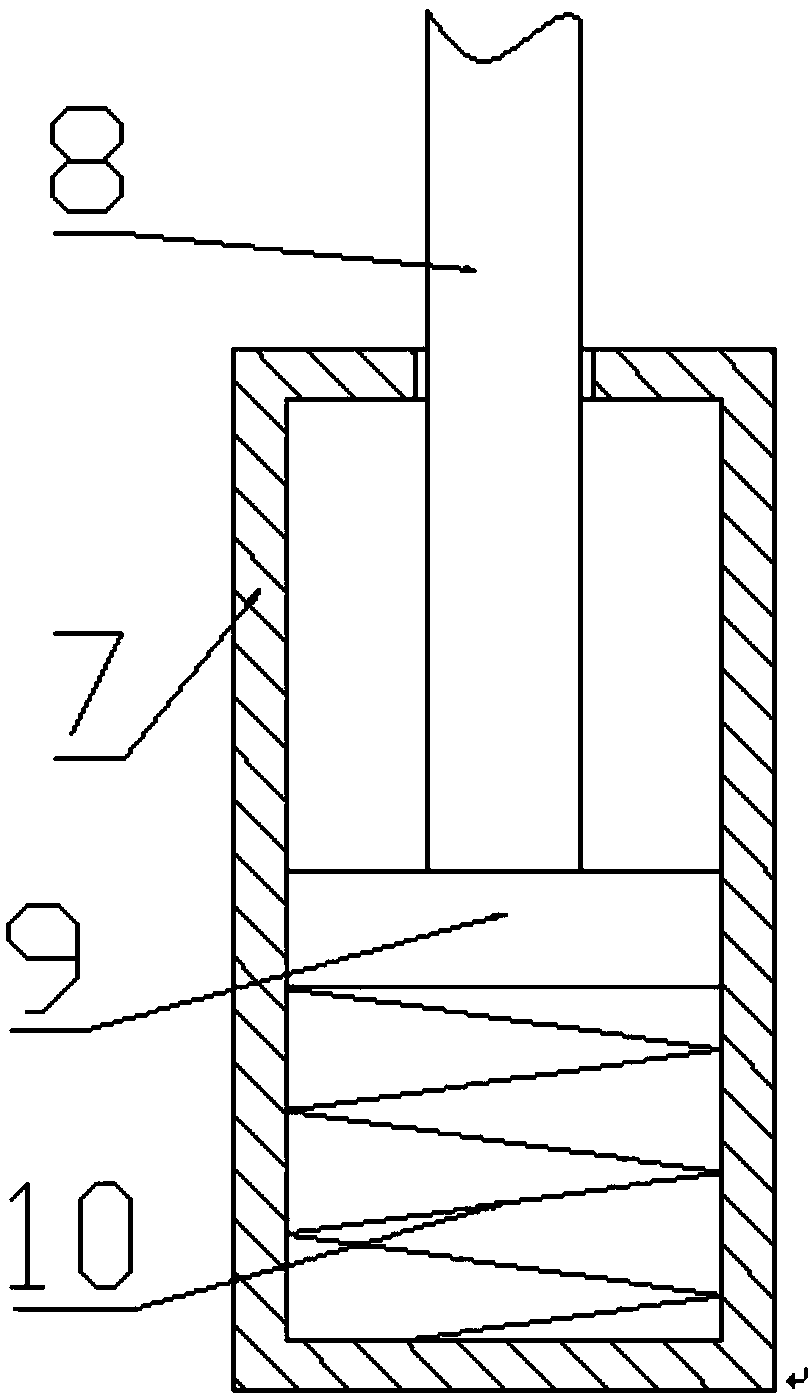

Airflow powder grinding system and powder treatment process

InactiveCN105080687AReduce the temperatureGuarantee that the efficacy of the ingredients remains unchangedGrain treatmentsGas compressorEngineering

The invention discloses an airflow powder grinding system and a powder treatment process. The airflow powder grinding system comprises an air compressor and an airflow ultrafine grinder which are sequentially connected. An air refrigerator is connected between the air compressor and the airflow ultrafine grinder. An air inlet of the air refrigerator is connected the air compressor, and an air outlet of the air refrigerator is connected with the airflow ultrafine grinder. An air storage tank is connected between the air compressor and the air refrigerator, and the airflow ultrafine grinder is connected with a dust removal device. By means of an airflow ultrafine grinding system, the temperature of compressed air can be lowered, and it is guaranteed that the components and effect of powder are not changed. An ultrasonic vibration screen is adopted, so that adhesion, friction, flat reducing, wedging in and other screen blocking factors can be restrained through ultrasonic vibration waves attached to the screen, screening efficiency and screen cleaning efficiency are improved, grinding precision is improved, and grinding cost is reduced.

Owner:四川省有色冶金研究院有限公司

Fruit and vegetable puree making machine

Owner:合肥中农科泓智营养健康有限公司

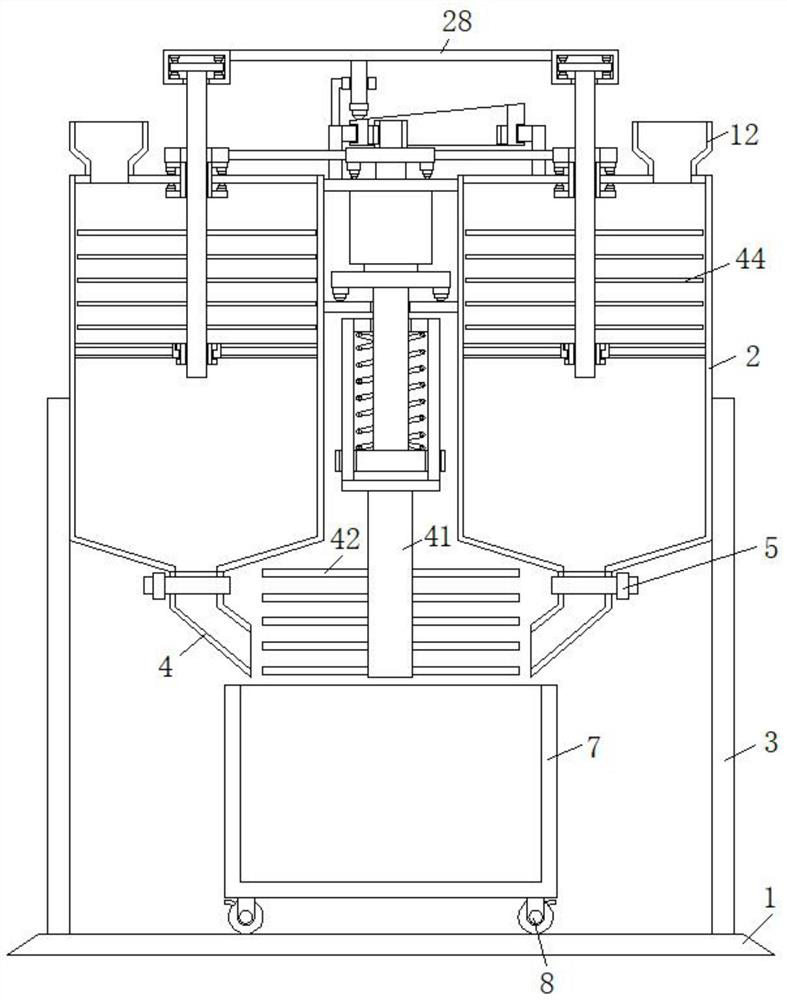

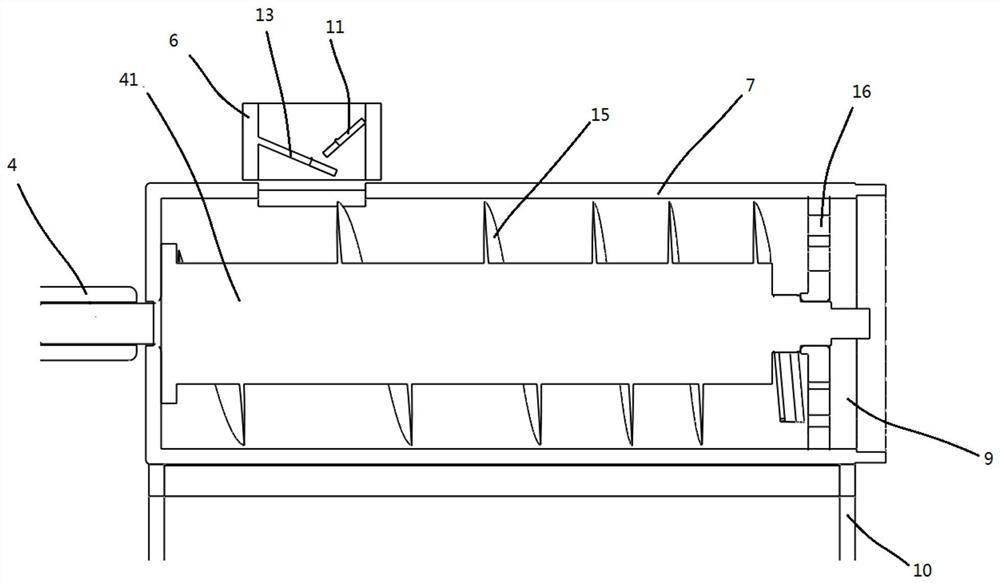

Feed crushing and processing device for wild duck breeding

InactiveCN111841407ARealize synchronous crushingImprove machining accuracyFeeding-stuffRotary stirring mixersAnimal scienceEngineering

The invention discloses a feed crushing and processing device for wild duck breeding. The feed crushing and processing device comprises a bottom plate, wherein a plurality of crushing boxes are vertically arranged above the bottom plate; the plurality of crushing boxes are arranged in a divergent manner; a support frame is arranged between the crushing box and the bottom plate; the bottom end of the crushing box is of a closing-up structure and communicates with a discharging folded pipe. A pipe body of the discharging folded pipe is provided with a valve; a collecting box is arranged on the top side of the bottom plate; an inner plate is fixedly connected to the inner wall of the top end of the crushing box, a middle shaft ring is arranged in the crushing box, a plurality of supporting rods are fixedly connected to the vertical outer side of the middle shaft ring in a diverging mode, a screen is arranged between the supporting rods, a plate body of the inner plate is provided with a feeding hole and communicates with a feeding hopper, and a first rotary drum rotationally penetrates through the middle shaft ring. The feed crushing and processing device is simple in structure and high in machining precision, the production cost is reduced, manpower is saved, the production efficiency is improved, and the use requirements of people in production and life are met.

Owner:ANHUI WANSHAN FOODS

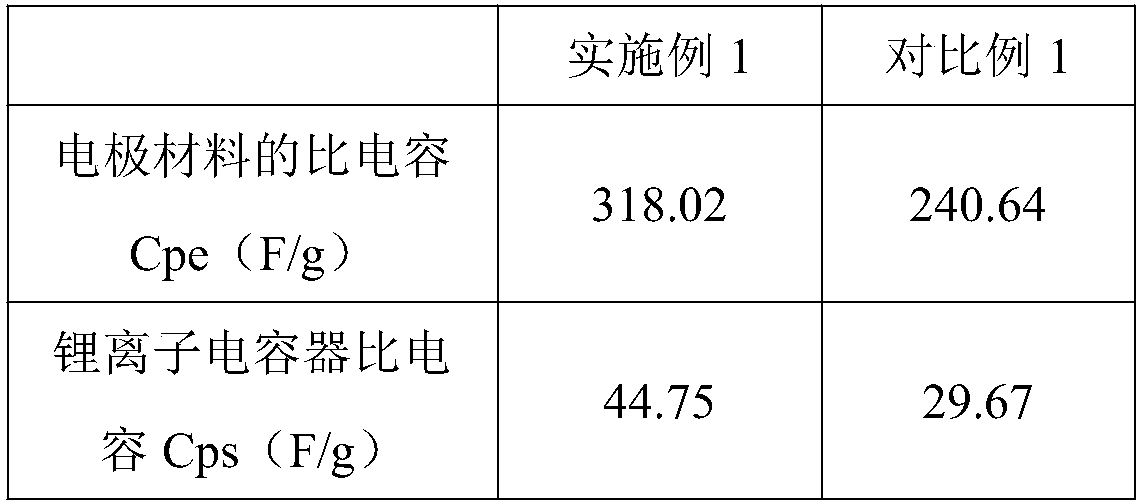

Method for preparing lithium ion capacitor using carbon nanotube/urea-formaldehyde resin carbon coated spherical microcrystalline graphite material

InactiveCN108155022AImprove processing efficiencyImprove crushing precisionHybrid capacitor electrodesCell electrodesCvd grapheneLithium-ion capacitor

The invention relates to a method for preparing a lithium ion capacitor using a carbon nanotube / urea-formaldehyde resin carbon coated spherical microcrystalline graphite material. According to the method, the carbon nanotube / urea-formaldehyde resin carbon coated spherical microcrystalline graphite material is adopted as a negative electrode, prepared lithium iron phosphate / expanded microcrystalline graphite / carbon composite material is made into an electrode tab to serve as a positive electrode, a polypropylene diaphragm is clamped between positive and negative electrode tabs, the lithium ioncapacitor is assembled, and lithium nitrate aqueous solution with the concentration of 1 mol / L is injected into the position between the positive and negative electrode tabs to use as electrolyte. According to the method, graphene is replaced by cheap and easy-to-obtain microcrystalline graphite as the raw material of the carbon nanotube / urea-formaldehyde resin carbon coated spherical microcrystalline graphite material, obtained composite material has excellent electrochemistry performance, under the condition that charge-discharge specific capacity does not drop, better circulation stabilityis achieved, economic benefits are high, and the method is suitable for industrialized application.

Owner:林荣铨

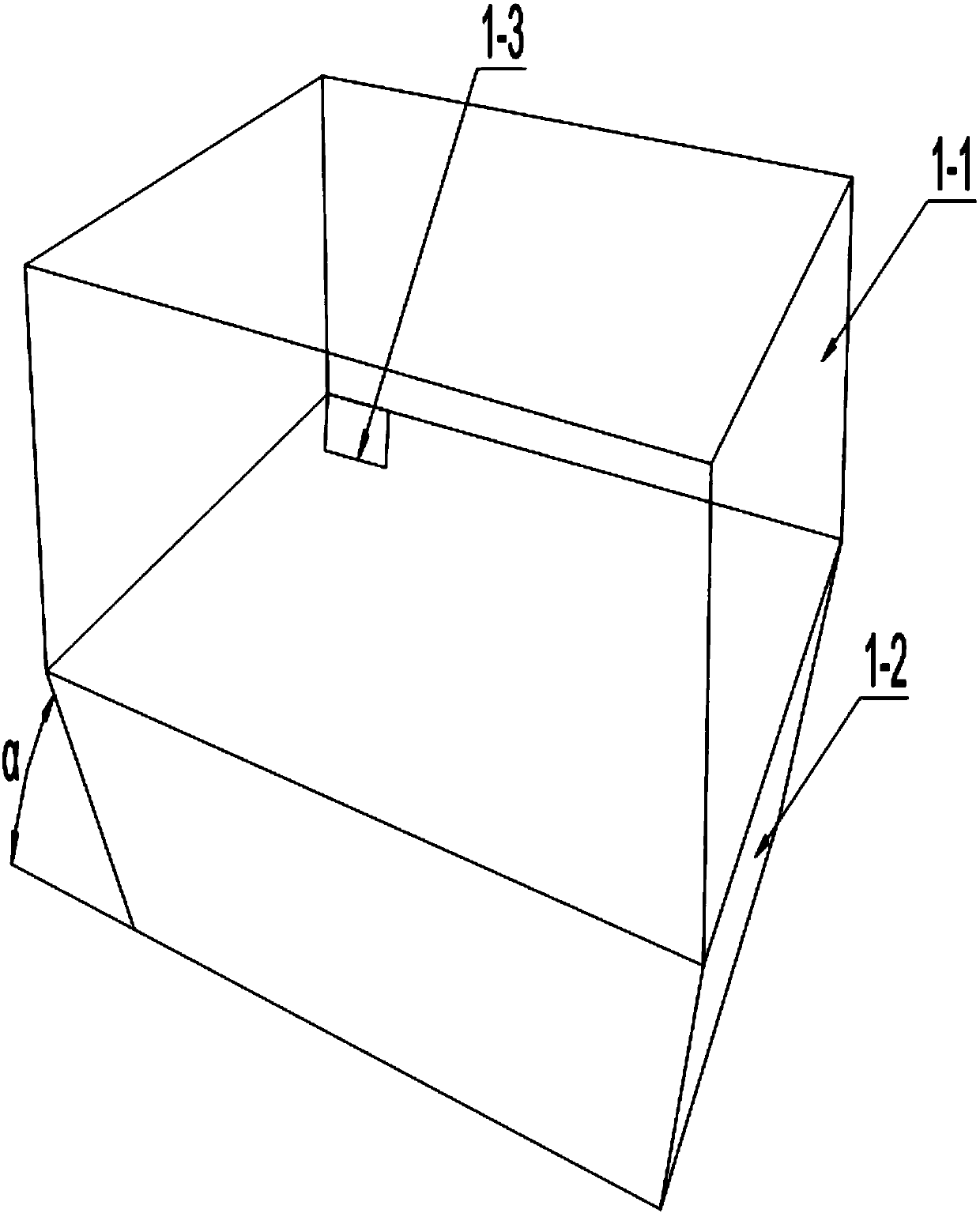

High-precision low-temperature crushing device for production of glass substrate frame

The invention discloses a high-precision low-temperature crushing device for production of a glass substrate frame. The high-precision low-temperature crushing device comprises a feeding drum, a coarse material crushing drum, a fine material crushing drum and cooling drums, wherein tapered material distribution trays are connected with and arranged at the bottom end of the feeding drum; a plurality of parallel crushing rollers are uniformly arranged in the interior of the coarse material crushing drum at equal intervals; air inlet pipes are respectively connected with and arranged on the sidesurfaces of the fine material crushing drum; external air compressed by air compressors is sucked into the fine material crushing drum by the air inlet pipes; the air outlet end of each air inlet pipeis provided with a metal air outlet seat; the inner wall of each cooling drum is provided with heat conducting plates which are in connection through connecting plates; a heat-dissipating groove is arranged between the connecting plates and each cooling drum; the interior of each heat-dissipating groove is provided with a communicating pipe; a liquid nitrogen drum is connected with and arranged at the external end of each communicating pipe; a hollow cooling seat is connected with and arranged at the bottom end of each liquid nitrogen drum; and each air inlet pipe penetrates through and is connected with a hollow cooling seat. Thus, through combination of multiple crushing manners, the high-precision low-temperature crushing device provided by the invention realizes high-precision low-temperature crushing, cools an air flow used for crushing at the same time, and improves the quality of low-temperature crushing.

Owner:芜湖良匠机械制造有限公司

Food material smashing device based on Internet of Things

The invention relates to a food material smashing device based on the Internet of Things. The food material smashing device comprises a smashing cylinder, a reamer and a discharging disc. A feeding chamber is arranged at the top of the smashing cylinder, a discharging opening is formed in the top of the feeding chamber, a first adjusting plate and a second adjusting plate are hinged to the symmetrical inner walls of the two sides of the feeding chamber, and the free end of the first adjusting plate and the free end of the second adjusting plate are partially overlapped. A rolling mechanism isarranged in the smashing cylinder in the axis direction, spiral pieces are arranged on the outer side of the rolling mechanism, a reamer is hinged to one end of the rolling mechanism, the dischargingdisc is connected to the end, close to the reamer, of the rolling mechanism in a matched mode, and a plurality of discharging holes are formed in the discharging disc at intervals. A transmission wheel is connected to the end, away from the reamer, of the rolling mechanism in a matched mode, and the transmission wheel can drive the rolling mechanism to rotate.

Owner:苏州众智诺成信息科技有限公司

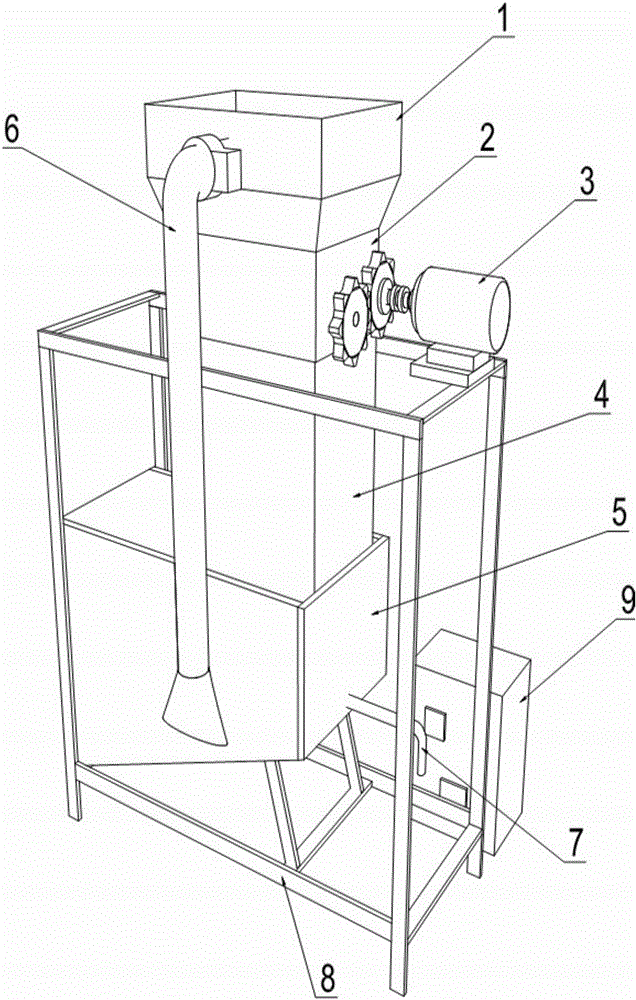

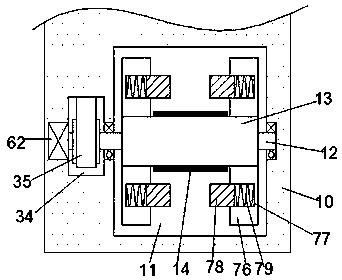

Smashing and feeding equipment for animal husbandry

The invention discloses smashing and feeding equipment for animal husbandry. The equipment comprises a feeding trough, a smashing device and a mixing device, the smashing device is composed of a floor-type stock bin, a fodder suction pipe, a fodder suction shell body, a fodder suction fan, a conveying pipe, an upper shell body, a smashing structure, a lower shell body, a transport mechanism and a fodder outlet pipe, the smashing device is arranged on the mixing device, the smashing device communicates with a fodder mixing box through the fodder outlet pipe, and the mixing device is composed of a motor, the fodder mixing box, a rotation shaft and stirring paddles; and a valve and a second weight sensor are connected between the fodder mixing box and the feeding trough, a control panel is arranged at the top of the fodder mixing box, and the left part of the top of the fodder mixing box is provided with an auxiliary-fodder inlet. The equipment has beneficial effects that the smashing accuracy is high, fodder can be smashed into various-size fodder particles, a fodder putting amount reaches an optimal value, stirring is more uniform, fodder quality is improved, timed and quantitative feeding to animals is realized, labor is saved, fodder waste is avoided, and economic benefits are improved.

Owner:ZHENGZHOU UNIV

Effective smashing device for processing ores and slag

InactiveCN108889369AAvoid stickingAvoid cloggingGrain treatmentsFiltration circuitsLeaking waterSlag

The invention discloses an effective smashing device for processing ores and slag. The effective smashing device for processing ores and slag comprises a device body, a storage battery, a gear box, abase, a motor case, a water delivering tube, a water tank, a filter, a sewage receiving box, a water leaking hole, supporting legs, ore and slag powder collecting box, a power control plate, a longitudinal smashing box, a discharging opening, a transverse smashing box, a sprayer, a water pump, a feeding hopper, a bearing, smashing rollers and a filer. The base is arranged on the bottom of the device body, the storage battery is arranged on one side of the base, the transverse smashing box is arranged on the top of the base, and the feeding hopper is arranged at the top end of the transverse smashing box. By the effective smashing device for processing ores and slag, the smashing precision is improved by secondary smashing, meanwhile, by arrangement of the sprayer, the smashing rollers aresprayed, adhesion and blockage of the smashing rollers are prevented, the smashing efficiency is improved, by arrangement of the filter screen on the bottom of the collecting box, water leaks out conveniently, the leaked water is filtered by the filter and then returns to the water tank again, resources are saved, and materials are recycled.

Owner:芜湖遥帆电子科技有限公司

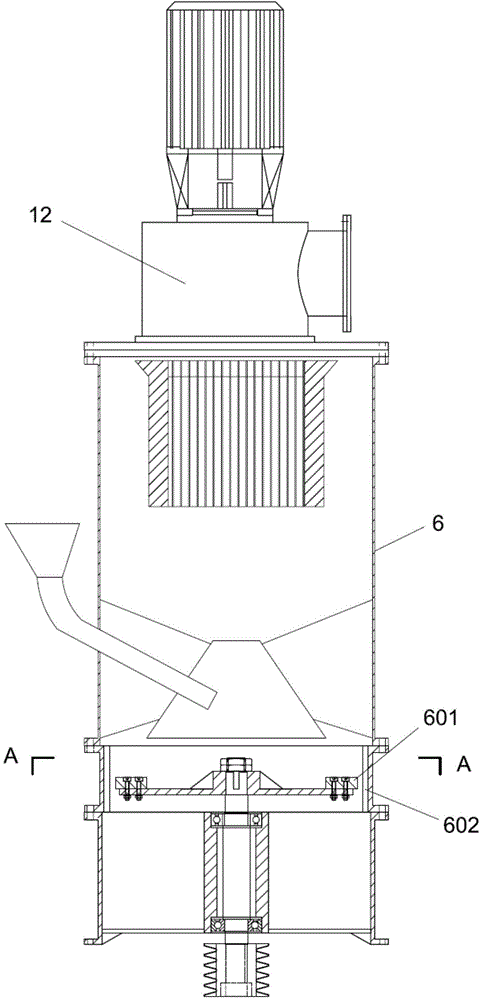

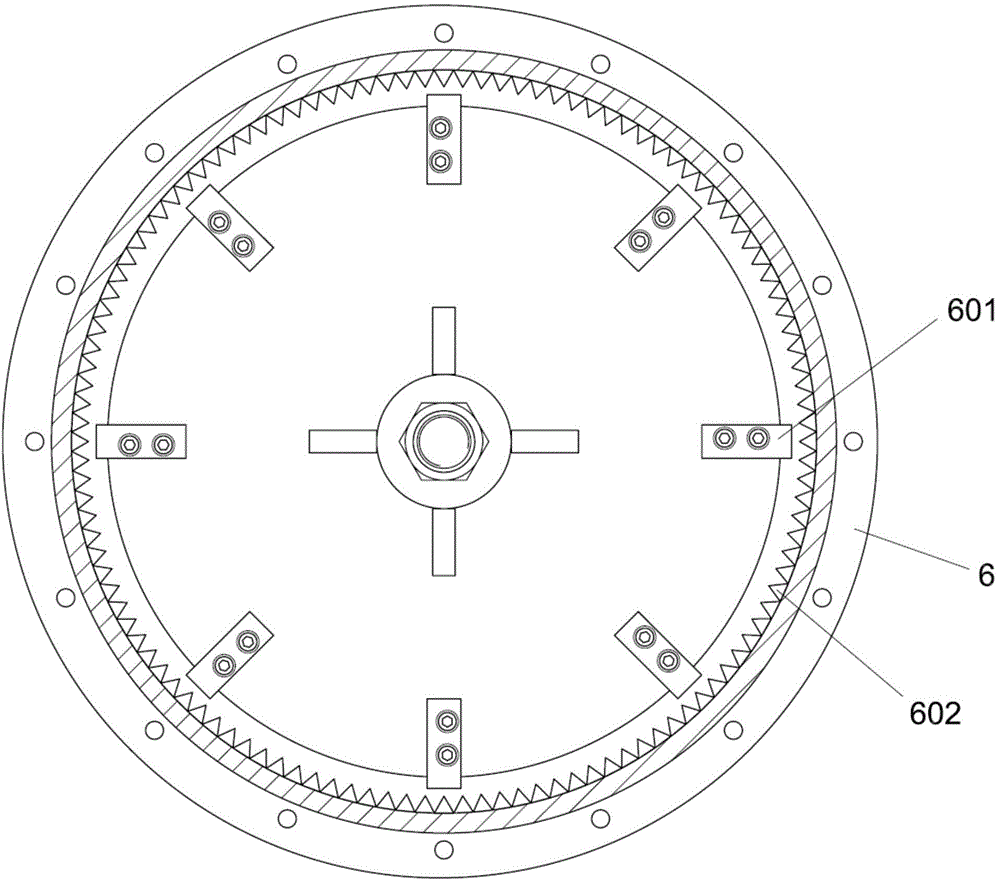

Ceramic raw material crushing equipment with iron removal function

InactiveCN111085300AImprove crushing precisionImprove crushing efficiencyMagnetic separationGrain treatmentsIron removalSlag

The invention discloses ceramic raw material crushing equipment with an iron removal function in the technical field of ceramic processing. The equipment comprises a base, an iron removal box, a storage box, a crushing assembly, a discharging assembly, an iron removal discharging mechanism and a recovery assembly. According to the ceramic raw material crushing equipment with the iron removal function, raw materials are added through a feeding opening of the storage box, and crushed through the crushing assembly and then enters the iron removal box; iron slag in the raw materials is separated out through the iron removal discharging mechanism, and powder and the iron slag are discharged and collected through a powder opening and an iron slag opening correspondingly; the powder screening process is added, the powder which does not pass through a screen enters a second crushing cavity through the recovery assembly, and secondary crushing is carried out through the crushing assembly; and when the raw materials move along a material guide plate, the raw materials are ground and crushed through a grinding assembly, so that the raw materials enter a first crushing cavity for primary crushing after being subjected to pre-crushing, and therefore the crushing efficiency and the crushing effect of the crushing assembly in the first crushing cavity can be improved.

Owner:安徽米物通讯科技有限公司

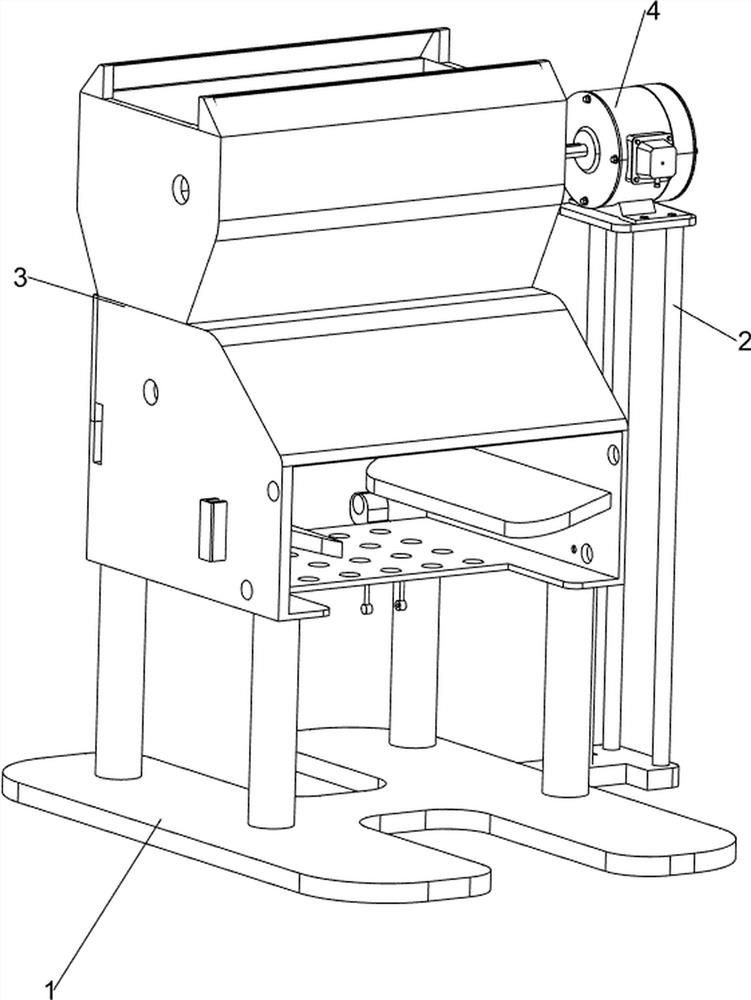

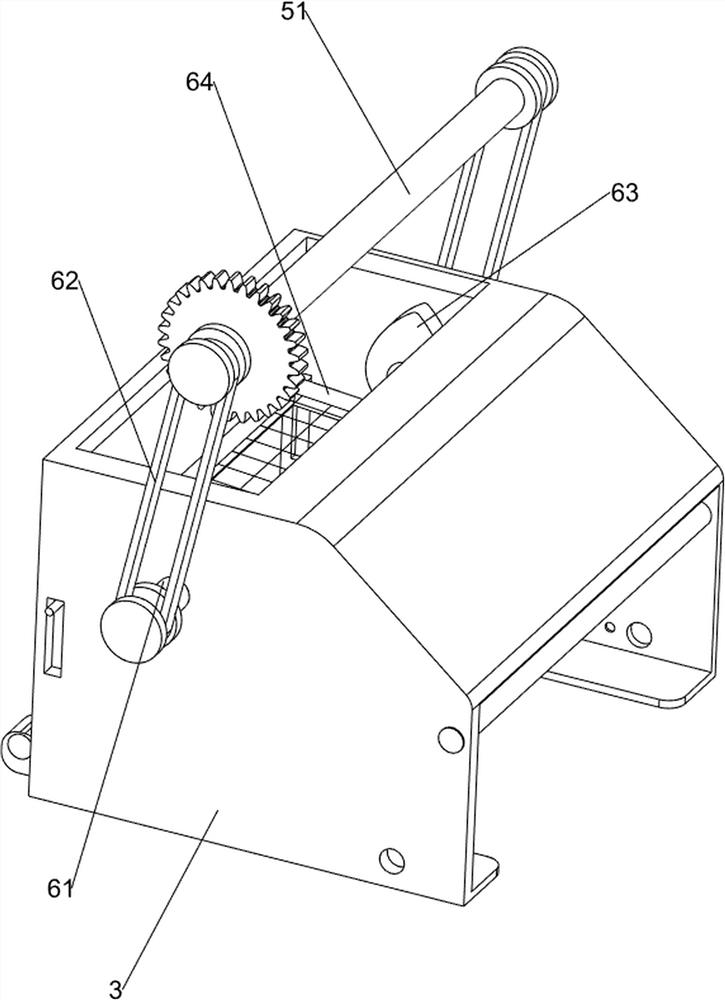

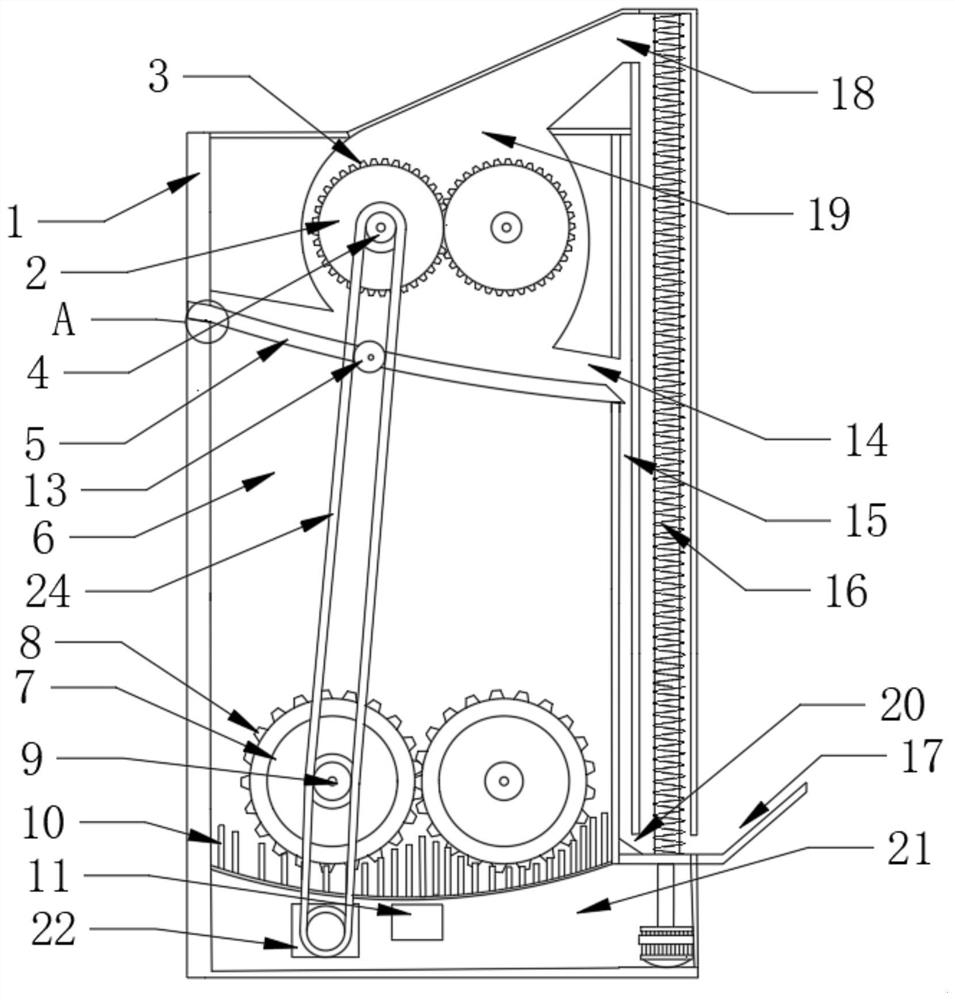

Efficient crushing and screening machine for chemical production

PendingCN112237959AImprove crushing precisionReduce raw material accumulationSievingScreeningElectric machineryProcess engineering

The invention relates to a screening machine, in particular to an efficient crushing and screening machine for chemical production. The efficient crushing and screening machine for the chemical production can automatically crush raw materials and can transport the raw materials. The efficient crushing and screening machine for the chemical production comprises a base, a support arranged on the base, a motor mounted on the support, a machine box, arranged on the base, and a crushing mechanism, wherein the crushing mechanism is arranged on the machine box, and a screening mechanism is arranged on the machine box. According to the machine, through the design of the crushing mechanism, the raw materials can be crushed, the raw materials do not need to be crushed manually with a knife through manpower, and thus the risk that workers are accidentally injured by the knife is reduced, and meanwhile the raw materials are crushed more thoroughly; and through the design of a pushing mechanism, the raw materials falling into a first storage plate can be continuously moved rightwards, accumulation of the raw materials in the first storage plate is reduced, and meanwhile people can take the rawmaterials in the first storage plate conveniently.

Owner:徐荣强

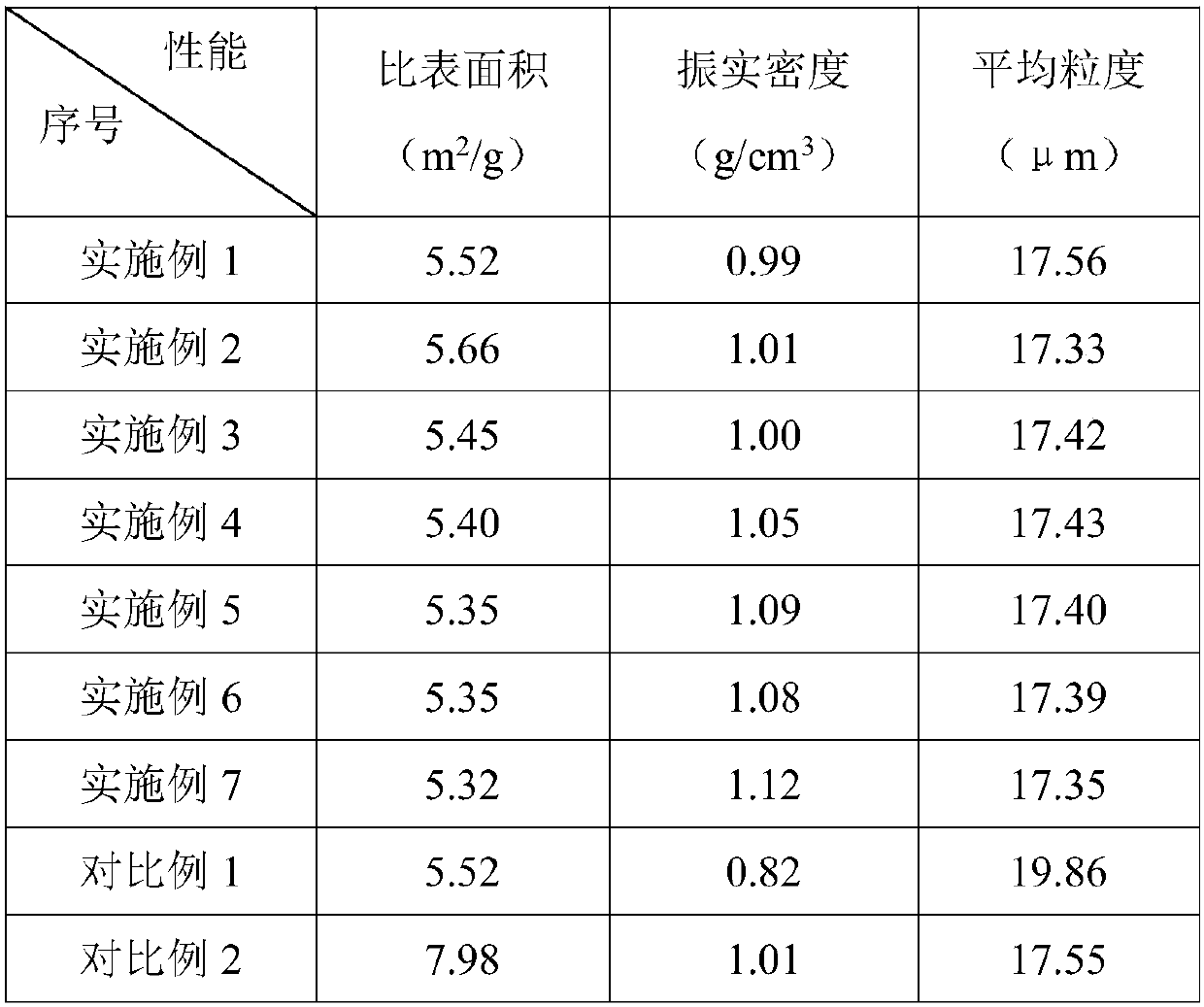

Preparation method of spherical microcrystalline graphite

InactiveCN107673347APreparation and Release AdvantagesFacilitates cleaning removalGraphiteGrain treatmentsGraphiteSpherical shaped

The invention belongs to the technical field of graphite processing and discloses a preparation method of spherical microcrystalline graphite. The preparation method of the spherical microcrystallinegraphite, provided by the invention, comprises the steps of pre-treating, shaping, purifying and carrying out drying treatment. The step of pre-treating comprises the step of treating microcrystallinegraphite dry concentrate by adopting a shearing machine; the step of purifying is carried out in an ultrasonic reaction kettle by adopting an acidic water solution and a material. According to the preparation method of the spherical microcrystalline graphite, provided by the invention, the problems in a spherical graphite preparation process that the crushing is not complete and the prepared spherical graphite has low spherical degree and low purity are innovatively solved; the microcrystalline graphite is mechanically crushed and a physical collision process also can be generated, so that the raw material of the microcrystalline graphite is effectively crushed and purified; a preparation technology is simple, the specific surface area of the prepared spherical graphite is remarkably reduced and the tap density of the prepared spherical graphite is improved.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

Environment-friendly straw burning device

InactiveCN109099430AGuaranteed working environmentImprove crushing precisionCuttersIncinerator apparatusAir pumpEngineering

The invention discloses an environment-friendly straw burning device which includes a hopper, a second cavity, a first cutter shaft, long blades, a sliding rail, an incinerator, an exhaust pipe and apurification device. A second cutter shaft is symmetrically arranged on the left side of the first cutter shaft, the first cutter shaft and the second cutter shaft are fixed with long blades and shortblades, the bottoms of the first cutter shaft and the second cutter shaft are welded and fixed with driven gears, a driving gear is arranged in the middle of the driven gears on the left and right, the driving gear is mounted on a motor, the motor is fixed on the inner wall of the lower side of a transmission box through bolts, an air pipe is wound outside the incinerator, an air pump is arrangedon the air pipe, and an air outlet is arranged on the right side of the air pipe. According to the environment-friendly straw burning device, straw cutting-crushing can be realized, meanwhile the heat produced by burning straw is used for drying the straw in the process of cutting-crushing, thus straw burning is more complete, smoke dust is greatly reduced, and green and environmental protectionare achieved.

Owner:龙娇

Rubber raw material pulverizing device with good pulverizing effect

InactiveCN109012954AEasy to useImprove crushing efficiencyGrain treatmentsMechanical engineeringRaw material

The invention discloses a rubber raw material pulverizing device with a good pulverizing effect. The rubber raw material pulverizing device comprises a feeding hopper; the feeding hopper is mounted onthe upper surface of a first box body; a first bearing is clamped and connected to the side surface of the first box body; the first bearing is internally provided with a pulverizing rotating shaft in a sleeving mode; the outer surface of the pulverizing rotating shaft is sleeved with a second bearing; the second bearing is clamped and connected to the side surface of a supporting rod; the left end of the pulverizing rotating shaft is fixedly connected with a first rotating wheel; the outer surface of the first rotating shaft is fixedly connected with a pulverizing blade; the pulverizing blade is located in the first box body; the first rotating wheel is in transmission connection with a second rotating wheel through a rubber belt; and a first motor is fixedly connected to the side surface of the second rotating wheel. The rubber raw material pulverizing device with the good pulverizing effect pulverizes materials twice, the pulverization precision and quality are improved, and unpulverized materials can be screened out and conveyed into a second box body to be pulverized again.

Owner:HUANGSHAN QUANSHENG SEALING TECH

Cereal crop livestock feed processing pulverizing machine

ActiveCN109201225AImprove the efficiency of grain processingGuaranteed service lifeGrain treatmentsCrop livestockAgricultural engineering

The invention discloses a cereal crop livestock feed processing pulverizing machine, comprising a pulverizing cylinder, a guiding chamber, a pressurizing chamber and a pulverizing mechanism, wherein the pressurizing chamber is fixedly mounted on a support seat by bolts, the upper side of the pressurizing chamber is connected with a high-speed motor through a second belt, the high-speed motor is connected to the lower side of the pulverizing cylinder through a first belt, the pulverizing cylinder is fixedly mounted above the pressurizing chamber by bolts, the diameter of the pulverizing cylinder is 1.2 times that of the pressurizing chamber, the guiding chamber is arranged above the pulverizing cylinder by bolts, a feeding hole is installed above the guiding chamber by welding, a discharging hole is installed at the lower side of the pulverizing cylinder by welding, and a pulverizing mechanism is installed inside the pulverizing cylinder and is used for cutting and pulverizing grains. In the pulverizing machine, the pulverizing mechanism and the pressurizing chamber work in cooperation, the pulverizing mechanism limits the size of the pulverized grains, and the pressurizing chamberincreases the speed of the discharging hole, improves the pulverization precision, accelerates the production rhythm, and improves the pulverization efficiency.

Owner:FENGTAI COUNTY RUIPU AGRI DEV

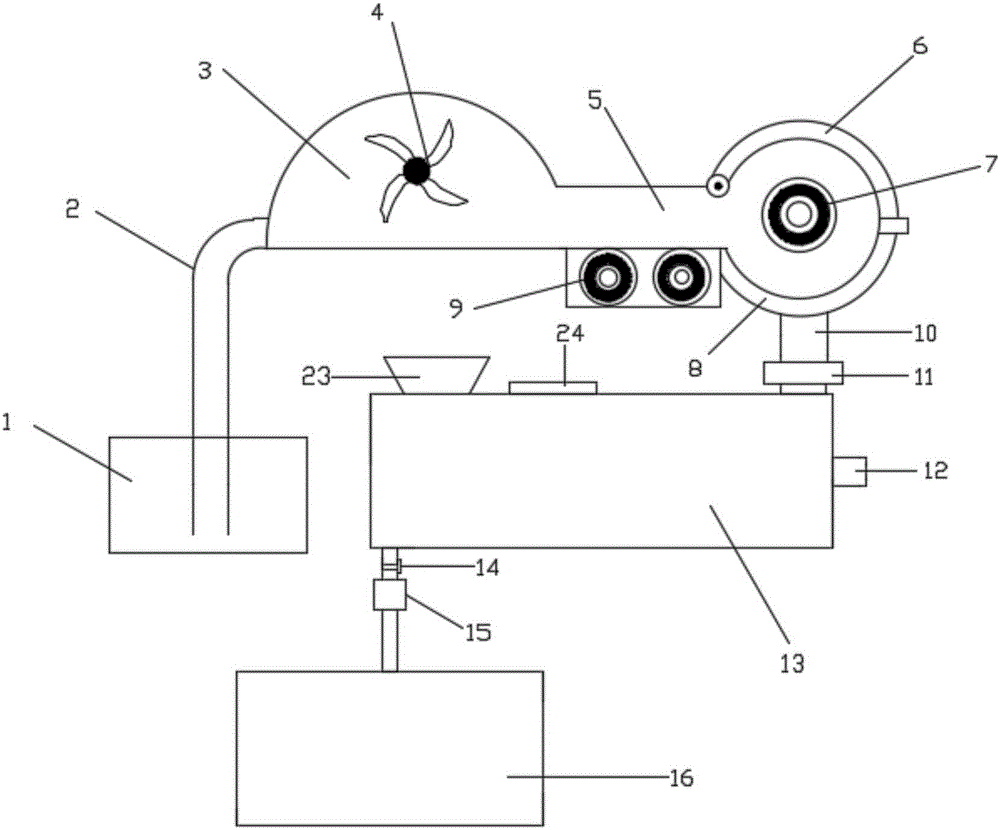

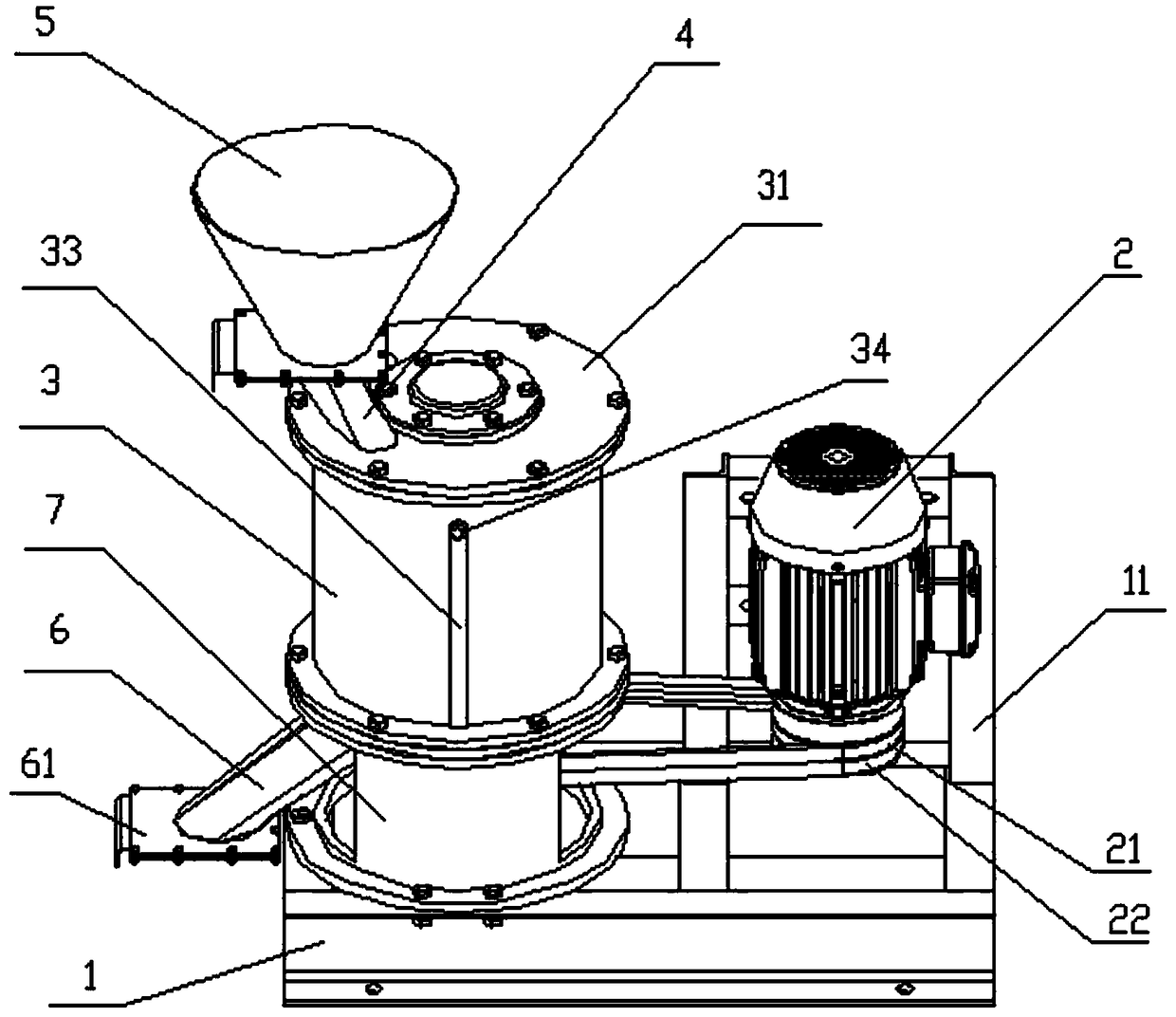

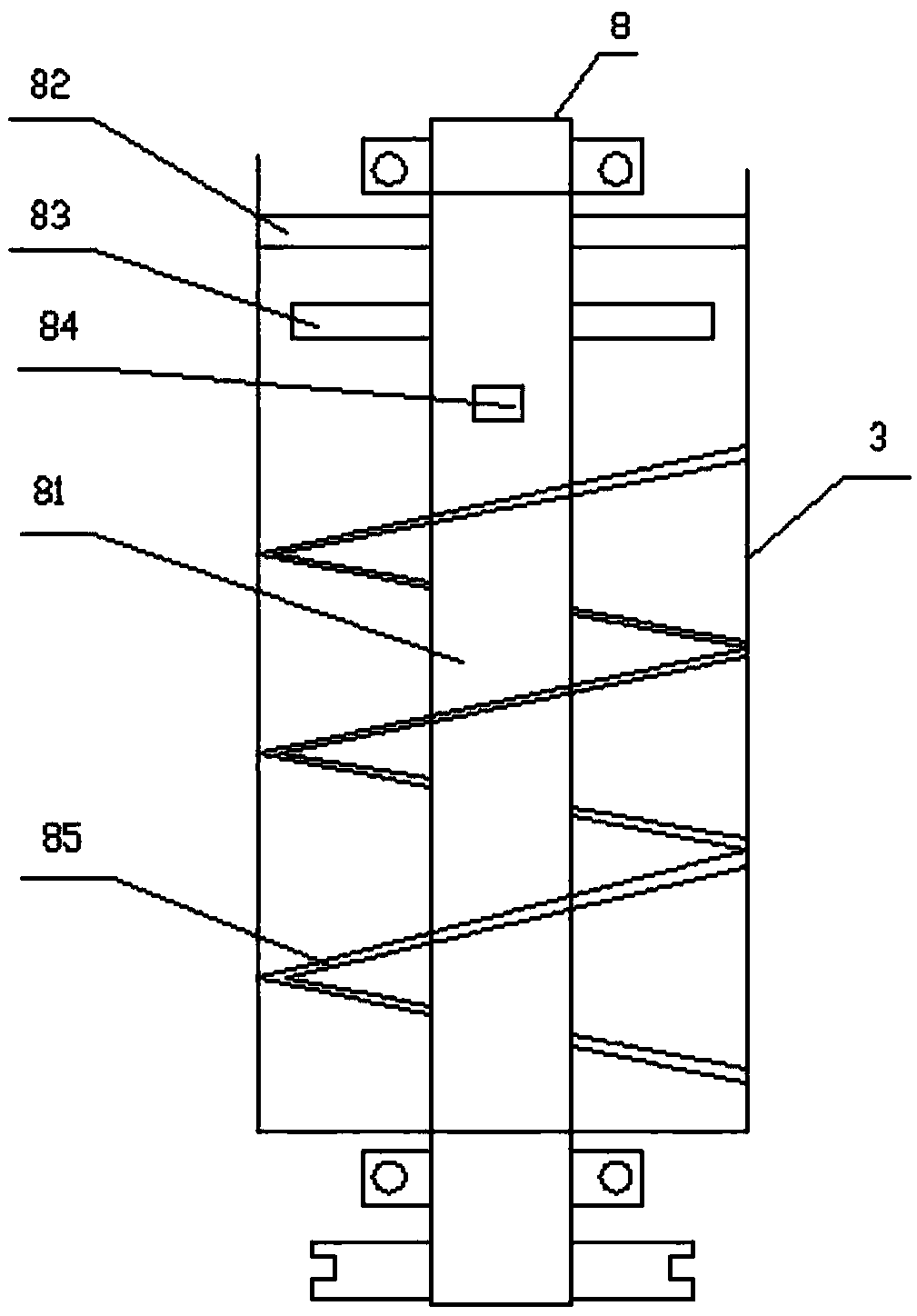

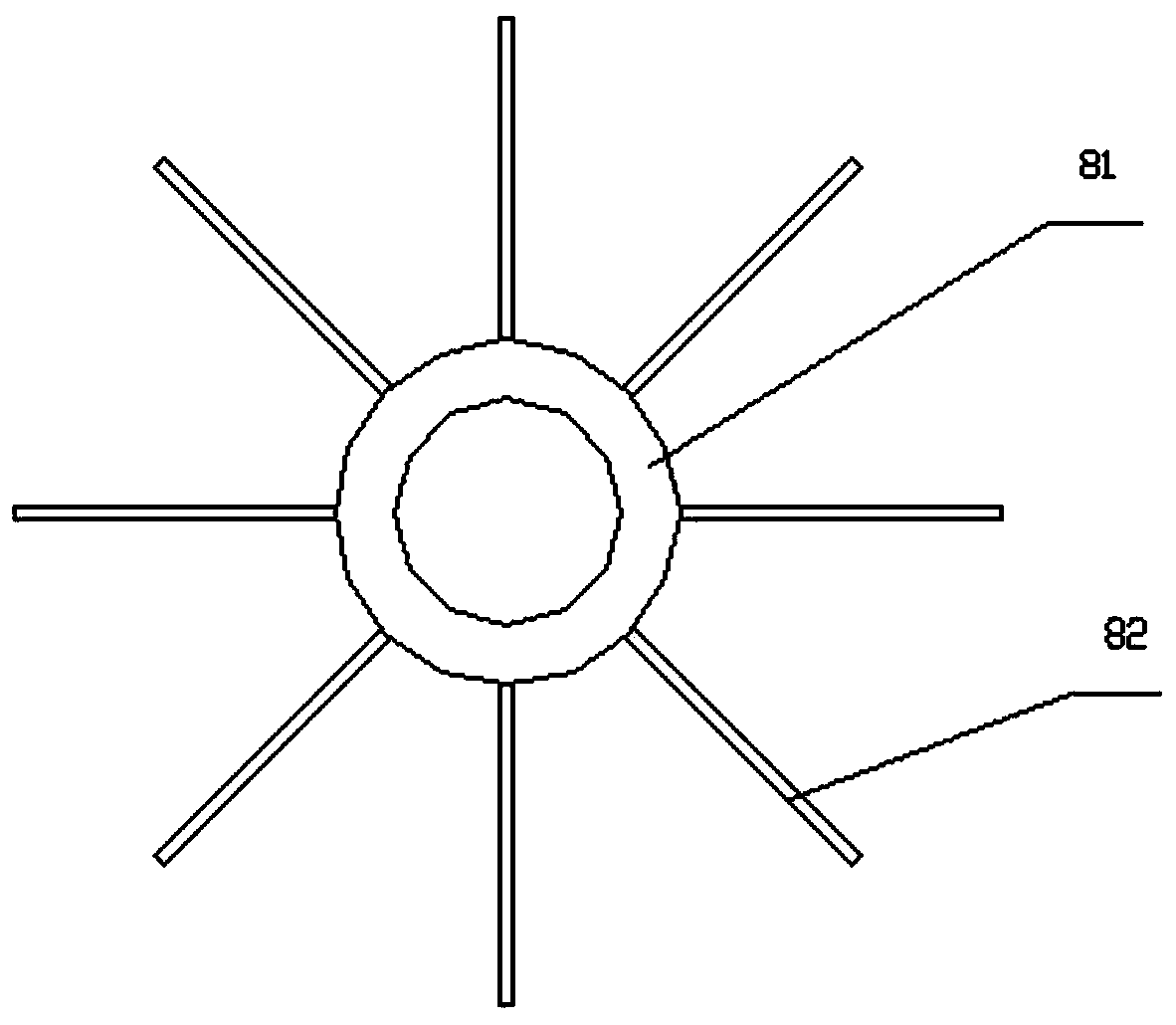

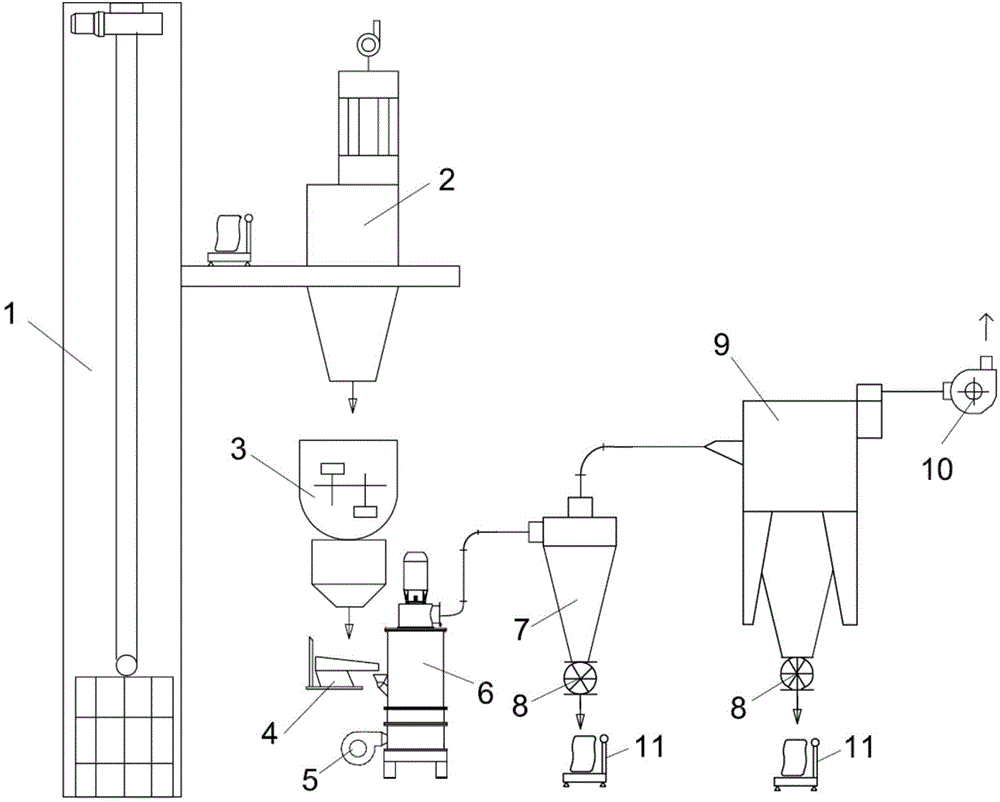

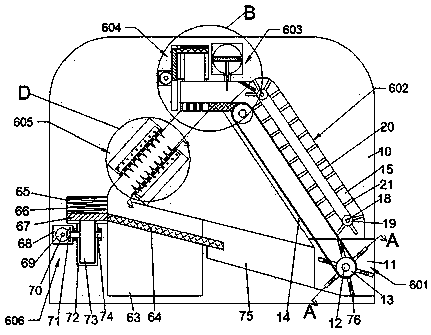

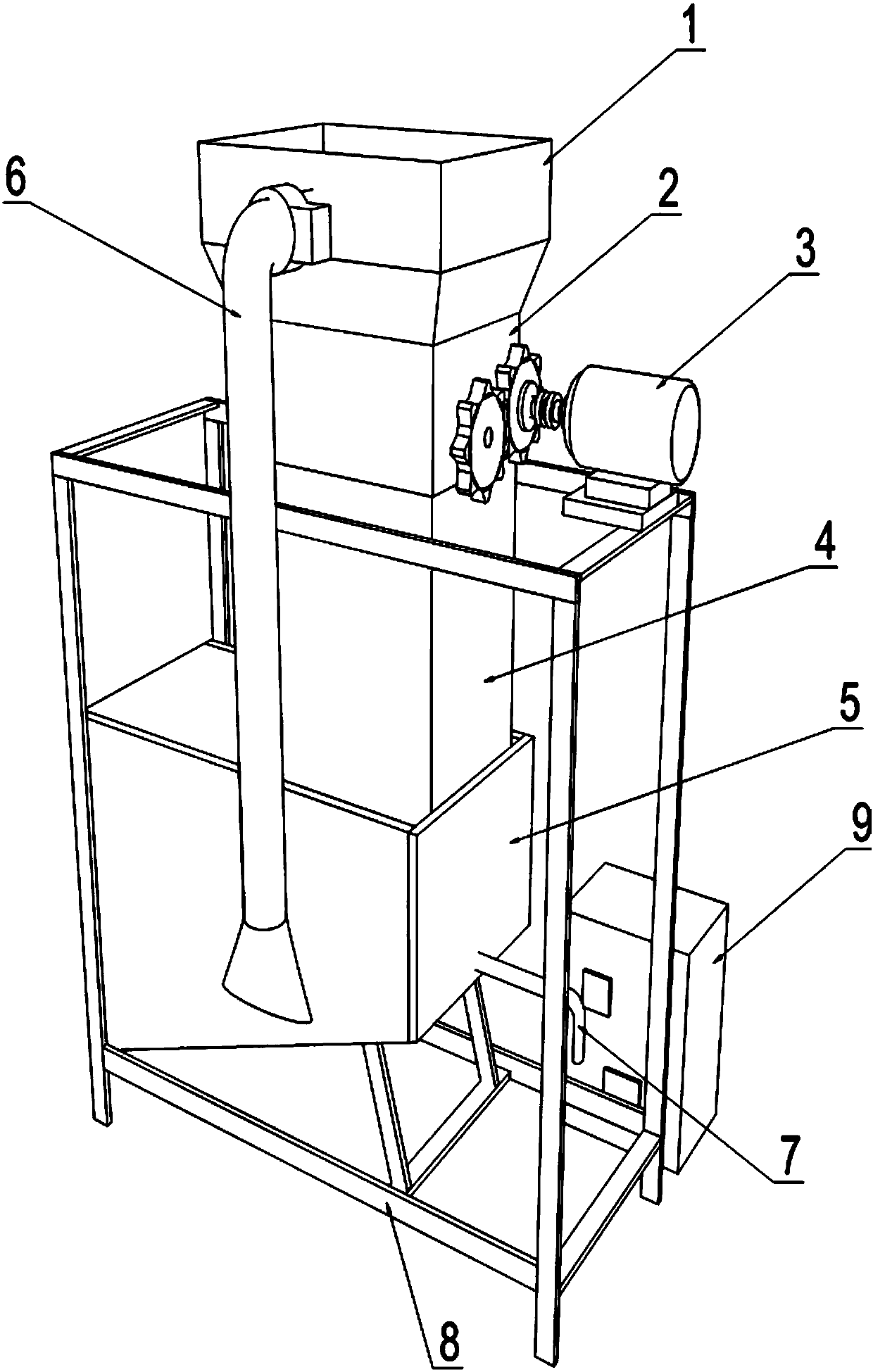

Superfine crushing device and superfine crushing method for preparing mixed feed

InactiveCN104643272AImprove crushing precisionSmall particle sizeFeeding-stuffGrain treatmentsPulverizerMixed feed

The invention discloses a superfine crushing device and a superfine crushing method for preparing mixed feed. The superfine crushing device comprises a lifting machine, a first pulse dust collector, a mixing machine, a vibration feeding machine, a crushing machine, a cyclone separator, a second pulse dust collector and an induced draught fan which are arranged sequentially, wherein the first pulse dust collector is fixedly arranged at the outer wall of the lifting machine, a material outlet of the first pulse dust collector is positioned above a material inlet of the mixing machine, the vibration feeding machine is positioned between a material outlet of the mixing machine and a material inlet of the crushing machine, a grading machine is arranged at a material outlet of the crushing machine, the material outlet of the crushing machine is connected with a material inlet of the cyclone separator through the grading machine, and a dust outlet of the cyclone separator is sequentially connected with the second pulse dust collector and the induced draught fan. The superfine crushing method comprises the following steps of material feeding, material mixing, crushing, and dedusting and collecting. The superfine crushing method has the advantages that the crushing temperature is controlled below 60 DEG C, the dissolving of the material in the crushing machine can be effectively prevented, the crushing effect is better, and the material mixing is uniform.

Owner:CHENGDU SHUXING FEED

Bean germ smashing device

InactiveCN108126789AAchieve dispersionReasonable structureGrain treatmentsBiochemical engineeringPiston cylinder

The invention discloses a bean germ smashing device which comprises a device body. The device body is of a hollowed structure, and a smashing cavity is formed in the device body. A U-shaped bearing plate is arranged in the smashing cavity. The left side and the right side of the U-shaped bearing plate are both fixedly connected with the side wall of the smashing cavity. A concave placing groove isformed in the upper end of the U-shaped bearing plate. The middle of the upper end of the concave placing groove is fixedly connected with the lower end of a guide pillar. A guide groove is formed inthe other end of the guide pillar. One end of a piston cylinder is inserted into the guide groove, and the other end of the piston cylinder is fixedly connected with the middle of the lower end of adrive plate. An arranged electric push rod can drive the drive plate to move up and down, the piston cylinder can move up and down in the guide groove and further play an air blowing effect on bean germs on the U-shaped bearing plate via through holes, and thus the purpose of dispersing the bean germs is achieved. Arranged stirring rods can stir and smash the bean germs, the phenomenon of uneven smashing is avoided, and the smashing quality of the whole device is improved to a great extent.

Owner:重庆鑫果味食品有限公司

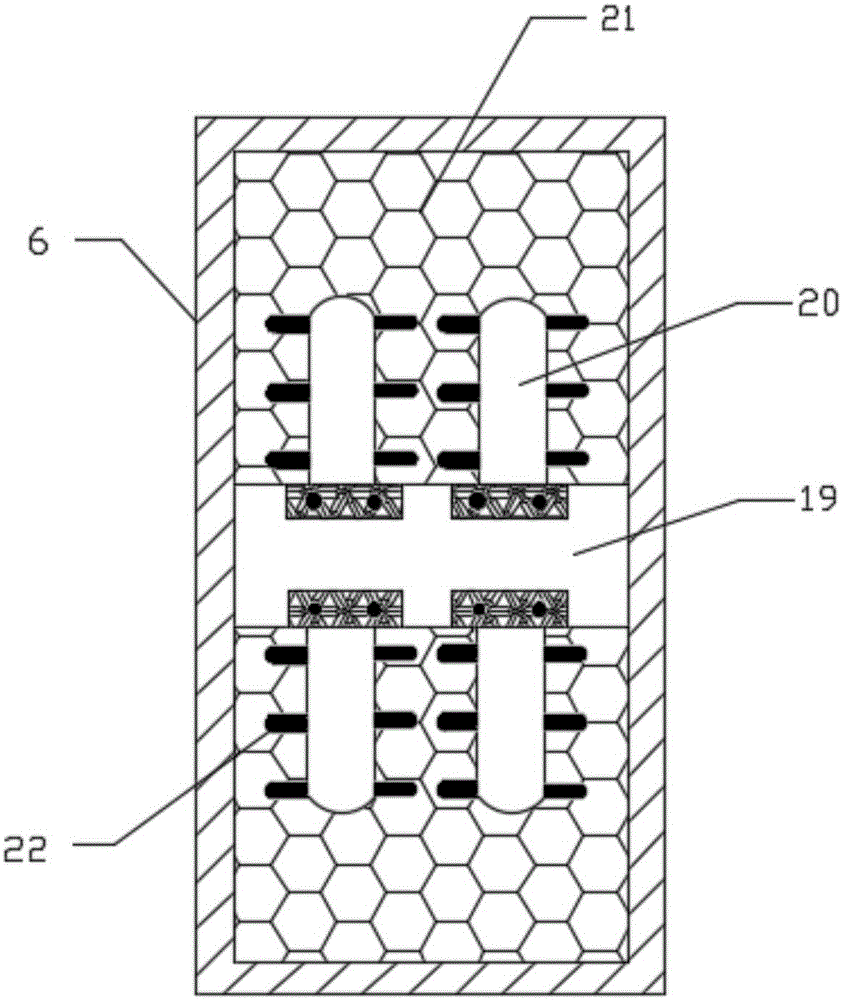

High-efficiency feed grinder with ultrasonic sterilization

InactiveCN107638932AImprove crushing precisionGood effect of removing bacteriaFeeding-stuffLavatory sanitoryEngineeringUltrasound

The invention provides a high-efficiency feed grinder with ultrasonic sterilization, and belongs to the technical field of feed machinery. The high-efficiency feed grinder with the ultrasonic sterilization comprises a coarse grinding box, a shell body and a fine grinding box; the coarse grinding box is arranged on the left side of the shell body; the fine grinding box is arranged inside of the shell body; a feed port is formed above the coarse grinding box; a first fixing plate is arranged on the lower side of the left end of the coarse grinding box; a first motor is fixed above the first fixing plate; a first door is arranged above the shell body; the middle cylinder wall of the coarse grinding box is served as a cylindrical screen; a second gate is arranged on the outer side of the upperpart of the cylindrical screen; according to the invention, a coarse feed box and a concentrate feed box are arranged, so that feed is ground twice; a cylindrical screen on the concentrate feed box makes ground feed consistent in particles; an ultrasonic device can remove miscellaneous bacteria from the feed; a feed vehicle can directly remove ground concentrate feed; the whole equipment is simple and reliable, high in grinding precision, good in miscellaneous bacteria removal effect and strong in practicability.

Owner:伍超群

Stirring machine for ceramic granulation

InactiveCN114454333ACrushed fullyStir wellClay mixing apparatusClay processing apparatusOxide ceramicAuger

The invention discloses a stirrer for ceramic granulation, and belongs to the technical field of aluminum oxide ceramic granulation production, the stirrer comprises a shell, a spiral conveyor for upward conveying is mounted in the shell, two crushing rollers capable of relatively rotating are rotatably mounted at the upper end in the shell, a filter screen is mounted right below the crushing rollers, and the upper end of the shell is fixedly connected with the shell. A stirring cavity is formed in the portion, below the filter screen, of the interior of the shell, an auger capable of relatively rotating is rotationally installed in the stirring cavity, and a plurality of stirring rods are installed in the portion, below the auger, of the interior of the stirring cavity. The raw materials are smashed through the smashing rollers, then the filter screen arranged below the smashing rollers is used for screening the smashed raw materials, the raw materials which are not smashed cannot enter the stirring cavity below the smashing rollers, and the raw materials entering the stirring cavity can be stirred more sufficiently through the two packing augers which rotate relatively and the multiple stirring rods which are arranged in the stirring cavity.

Owner:新化县瑞晨电子陶瓷有限公司

A device for crushing medicinal materials

InactiveCN108435348BRealize filtration and purification treatmentImprove efficiencyGrain treatmentsEngineeringHigh pressure gas

The invention relates to the technical field of medicine production equipment, and specifically relates to a medical material crushing device. The device comprises a housing and a crushing mechanism,wherein a crushing chamber, a screening chamber and a collecting chamber are arranged in the housing; a feeding port is formed in the top part of the crushing chamber; the crushing mechanism comprisesa driving device, a crushing stirring shaft and a plurality of crushing cutters; the screening chamber is provided with a screening tube and an injection mechanism; the injection mechanism comprisesa nozzle, a gas injection pipe and a high-pressure gas storing tank; and a collecting bucket is arranged in the collecting chamber. According to the medical material crushing device, the crushing cutters with special structures are adopted, so that the crushing accuracy can be improved, and guidance is certainly supplied to the crushed materials, and the materials are easily discharged; in addition, the nozzle is arranged in the screening pipe and is capable of injecting pulse gas to regularly impact the materials on a screening net, so that the materials of which the particle size meeting thestandard can fall down, and the materials of which the particle size does not meet the standard are injected back into the crushing chamber to be crushed again, and as a result, the material crushingeffect is improved.

Owner:BOZHOU QIANCAO PHARMA

Anti-blockage stone crusher

The invention discloses an anti-blockage stone crusher. A first crushing box and a second crushing box are included. A motor box is arranged on one side of each of the first crushing box and the second crushing box. A plurality of crushing rollers are arranged on one side of the motor box. Bearings are arranged at one ends of the crushing rollers. An electric telescopic rod is arranged at the bottom of the second crushing box. A push plate is arranged at one end of the electric telescopic rod. A discharging port is formed in one side of the second crushing box. Hydraulic damping devices are arranged on the periphery of the bottom of the second crushing box. A load bearing base is arranged at the bottoms of the hydraulic damping devices and provided with a power source control board. When the stone crusher is used, the transverse and longitudinal crushing rollers in the first crushing box and the second crushing box are used for secondary machining of stone, the crushing precision is improved, and blockage is avoided; the electric telescopic rod is used for driving the push plate for automatic discharging, and manpower is saved; and the hydraulic damping devices are arranged, vibration and noise are reduced, and the environment quality is improved.

Owner:湖南永利建设工程有限公司蓝山县分公司

Straw brick raw material preparation device

InactiveCN110574557ACuts evenly and across the boardImprove crushing precisionCuttersMaterials preparationBrick

The invention discloses a straw brick raw material preparation device. The straw brick raw material preparation device comprises a machine body, wherein the machine body is internally provided with afeed port, the feed port is internally provided with a feed device, the feed device comprises stirring plates and a feed rotating wheel, the stirring plates are uniformly arranged on the feed rotatingwheel, the upper side of the feed port is provided with a conveying cavity, and the conveying cavity is internally provided with a conveying device. According to the straw brick raw material preparation device, through the feed device, straw is automatically conveyed into the machine body for smashing and material preparation, the straw is uniformly and comprehensively cut in the machine body through the combined action of a longitudinal cutting device and a transverse cutting device, then the cut straw is smashed through a smashing device, then broken straw slag achieving the requirements iscollected through a screening device, the unqualified straw is circularly smashed until reaching standards, and the device is arranged circularly, so that the smashing precision of the straw is high.

Owner:JINHUA LUORI NEW ENERGY TECH CO LTD

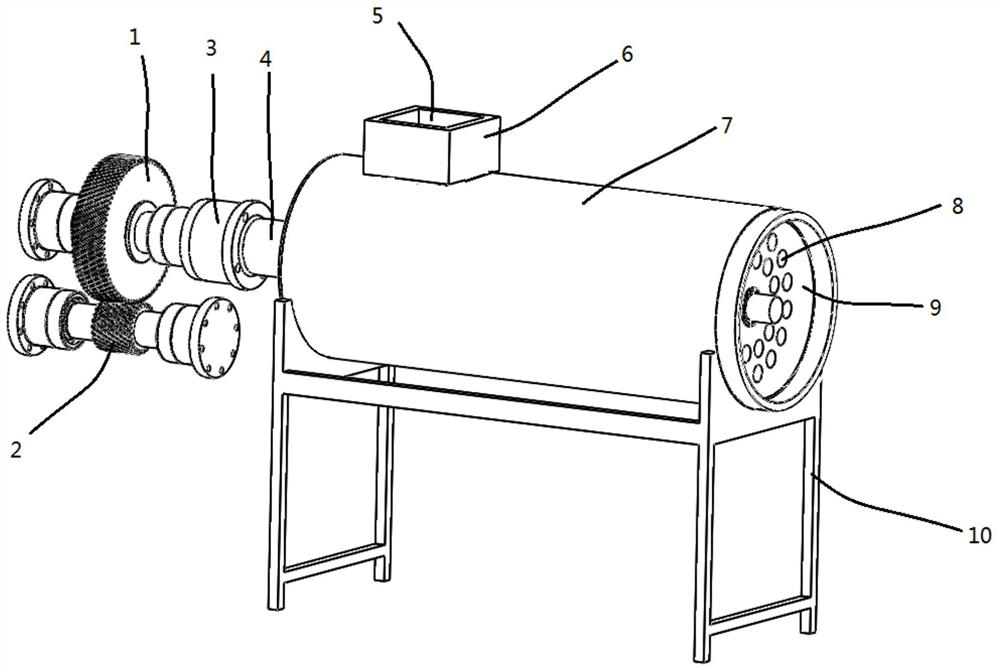

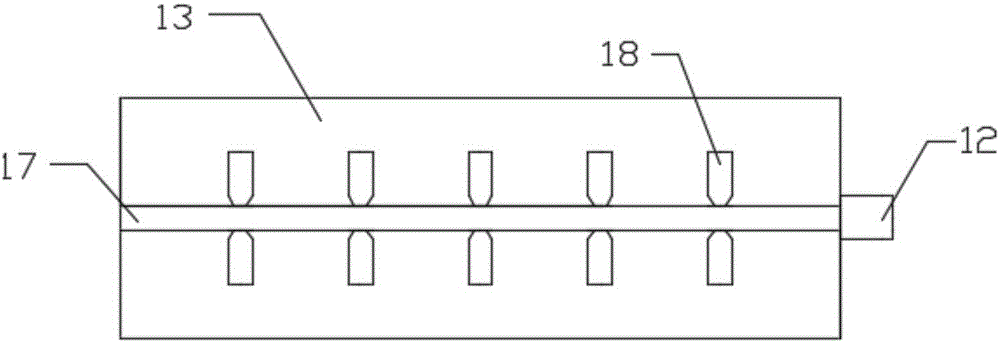

Double-pipe feeding type graphite crushing system provided with pretreatment device

InactiveCN106964473AImprove crushing precisionReduce noise pollutionGrain treatmentsPulverizerPre treatment

The invention discloses a double-pipe feeding graphite pulverization system with a pretreatment device, comprising: a pulverizer main body, a first feeding port, a second feeding port, a dust-proof baffle, a pre-crushing device, a first pulverizing area, the first filter screen, the second crushing area, the second filter screen, the discharge port, the dust density alarm device and the ultrasonic cleaner, the main body of the pulverizer includes the first crushing area and the second crushing area, the first The feed inlet and the second feed inlet are arranged on both sides of the top of the pulverizer main body, the first feed inlet and the second feed inlet are provided with pre-crushing devices, the first crushing area and the second The crushing area is provided with a first filter screen, the bottom of the second crushing area is provided with a second filter screen, the discharge port is provided with a dust density alarm device for detecting the dust density, and the discharge port is internally provided with a An ultrasonic cleaner for cleaning graphite powder attached to the inside of the outlet.

Owner:王家银

An integrated device for pulverizing, compressing and removing water and its working method

ActiveCN105728100BImprove crushing precisionHigh degree of automationDrying solid materials without heatGrain treatmentsControl systemDehydration

Owner:XUZHOU UNIV OF TECH

Device for producing fine powder coating

InactiveCN106732976AUniform particle sizeImprove crushing precisionGrain treatmentsDrive shaftGranularity

The invention discloses a device for producing fine powder coating. The device comprises a crushing structure, a supporting structure used for supporting the crushing structure, and a powder collection structure communicating with the crushing structure. The crushing structure comprises a cylindrical crushing barrel, a driving shaft and crushing balls, wherein an annular cavity is formed in the cylindrical crushing barrel, the driving shaft penetrates through the center of the crushing barrel and is in transmission connection with the crushing barrel, the crushing balls are arranged in the cavity, and a plurality of powder filtering grooves are formed in the side wall of the crushing barrel. The powder collection structure is arranged below the crushing barrel. The device for producing fine powder coating has the beneficial effect that materials can be ground through the crushing balls, and thus powder coating which is uniform in granularity and high in crushing precision is obtained; and the device for producing fine powder coating has the advantages that the structure is simple, using is convenient, loading and unloading are convenient, and the processing difficulty is low.

Owner:成都佳欣诚信科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com