Efficient crushing and screening machine for chemical production

A high-efficiency crushing and chemical production technology, applied in the field of screening machines, can solve the problems of high labor intensity, increased production costs, no screening and circular crushing, etc., and achieve the effects of reducing raw material accumulation, easy access, and high crushing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

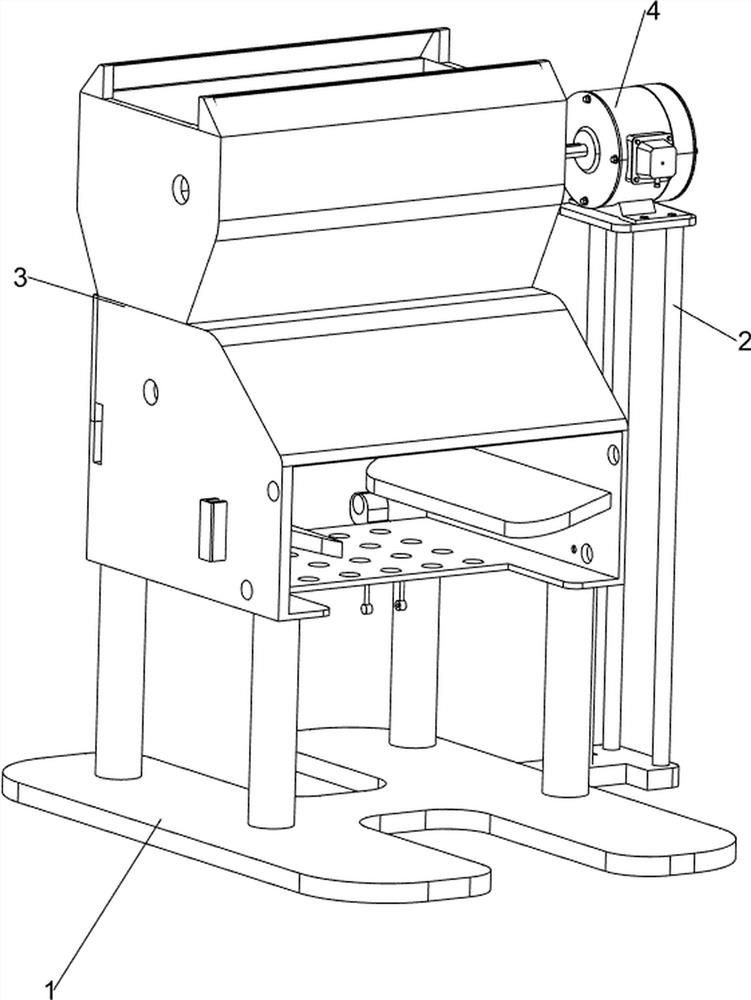

[0028]An efficient crushing and screening machine for chemical production, such asfigure 1 ,figure 2 ,image 3 ,Figure 4 withFigure 5 As shown, it includes a base 1, a bracket 2, a chassis 3, a motor 4, a crushing mechanism 5, and a screening mechanism 6. The base 1 is provided with a bracket 2 on the back side, a motor 4 is installed on the bracket 2, and the base 1 is provided on the left side. The case 3 is provided with a crushing mechanism 5 on the case 3, and a screening mechanism 6 is provided on the case 3.

[0029]First place the raw materials to be crushed on the crushing mechanism 5, and then turn on the motor 4. When the output shaft of the motor 4 rotates, the crushing mechanism 5 will be driven to drive the operation of the screening mechanism 6 to achieve crushing of the raw materials. After the pulverization is completed, the motor 4 is turned off. When the output shaft of the motor 4 stops rotating, the pulverizing mechanism 5 will stop operating, so that the screening ...

Embodiment 2

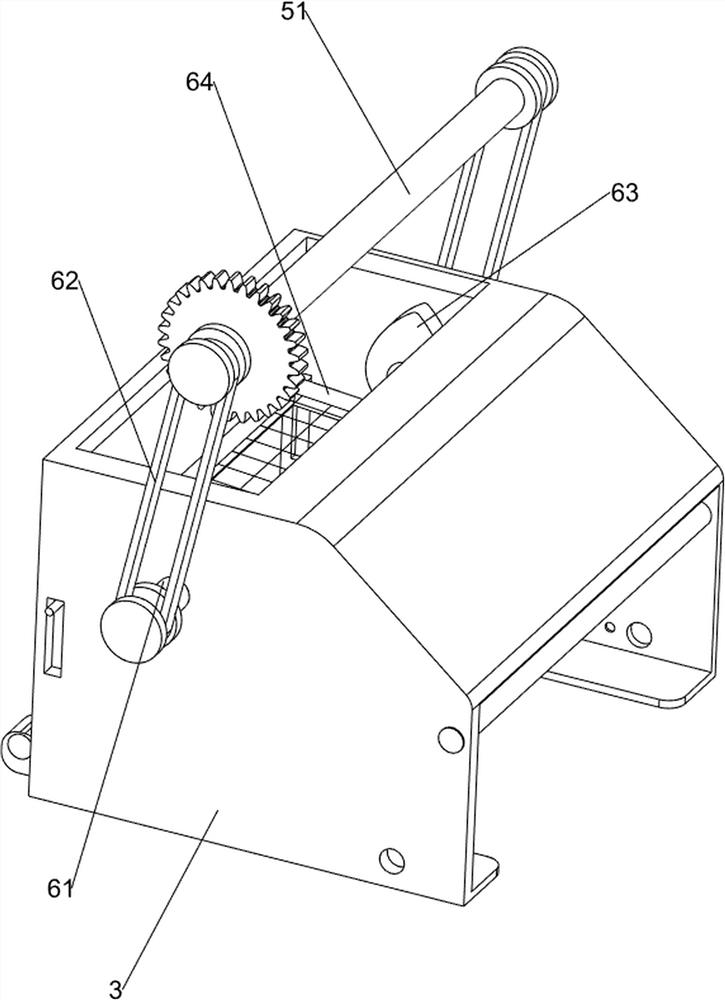

[0031]On the basis of Example 1, such asfigure 1 ,figure 2 ,image 3 ,Figure 4 withFigure 5 As shown, the pulverizing mechanism 5 includes a first transmission shaft 51, a first full gear 52 and an extrusion cylinder 53, a first transmission shaft 51 is provided on the chassis 3 to rotate symmetrically, and both ends of the first transmission shaft 51 are provided The first full gear 52, the two first full gears 52 on the same side of the front and rear mesh, and the first transmission shaft 51 is provided with a squeeze cylinder 53.

[0032]First, place the raw materials to be crushed on the squeeze cylinder 53, and when the output shaft of the motor 4 rotates, the first transmission shaft 51 on the right side of the belt is rotated, thereby driving the first full gear on the first transmission shaft 51 on the right side. The rotation of 52, because the two first full gears 52 mesh, will drive the rotation of the first full gear 52 on the left, thereby driving the rotation of the first...

Embodiment 3

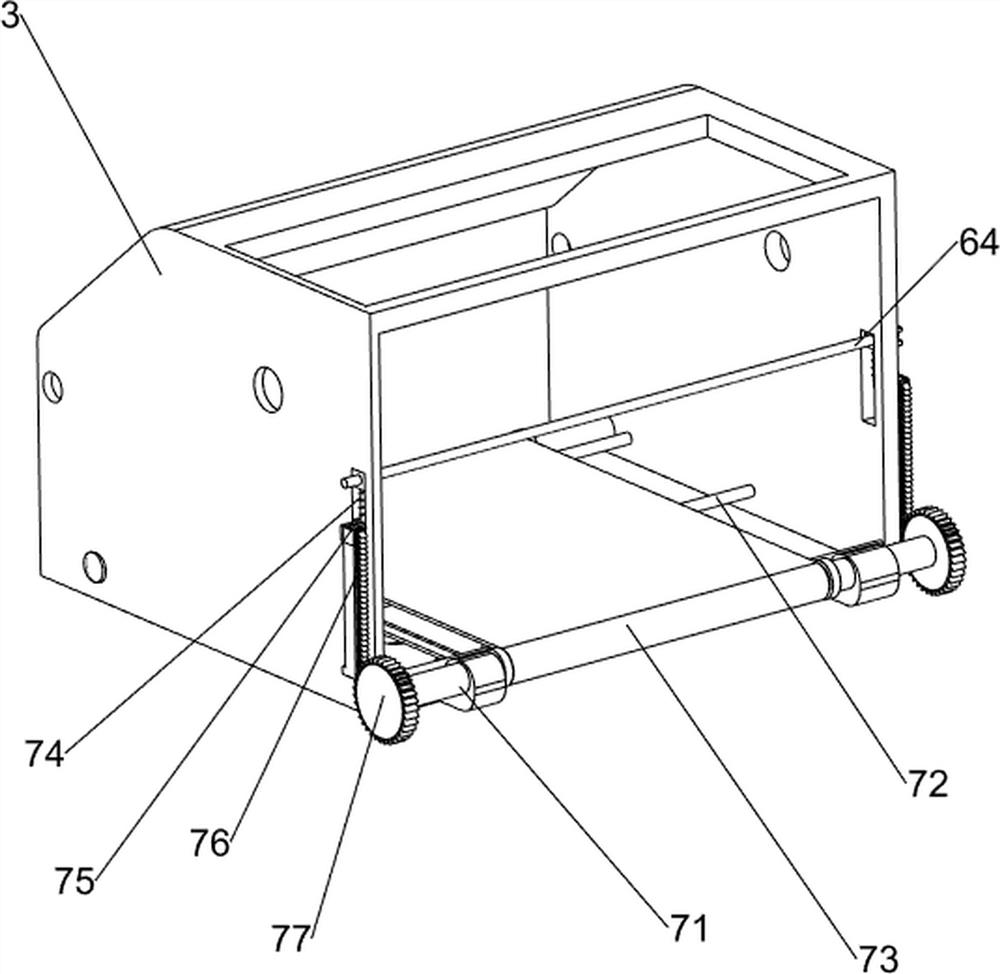

[0036]On the basis of Example 2, such asFigure 6 ,Figure 7 ,Figure 8As shown, it also includes a transportation mechanism 7, the chassis 3 is provided with a transportation mechanism 7, and the transportation mechanism 7 includes a third transmission shaft 71, an inner frame 72, a conveyor belt 73, a first connecting rod 74, a first compression spring 75, A spring rack compression rod 76 and a one-way gear 77 are provided on the vibration plate 64 symmetrically with a first connecting rod 74. The bottom of the first connecting rod 74 is slidably provided with a spring rack compression rod 76, and the first connecting rod 74 is sleeved There is a first compression spring 75. The bottom of the first compression spring 75 is connected to the spring rack compression rod 76. The case 3 is provided with a third transmission shaft 71 that rotates symmetrically, and the third transmission shaft 71 on the left is provided symmetrically. One-way gear 77, the one-way gear 77 meshes with the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com