Device for producing fine powder coating

A technology for fine powder and paint, applied in the field of devices for producing fine powder paint, can solve the problems of low production efficiency, large and complex structure, etc., and achieve the effects of simple structure, convenient use and low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

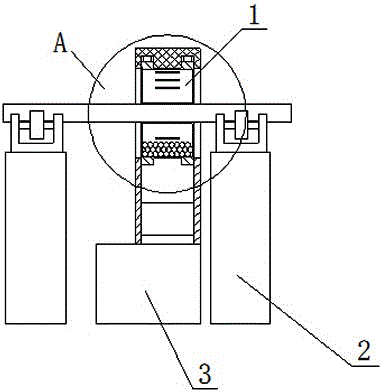

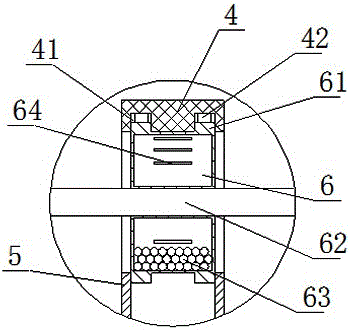

[0026] like figure 1 , figure 2 As shown, in this embodiment, a device for producing fine powder coatings includes a crushing structure 1 , a support structure 2 for supporting the crushing structure 1 and a powder collecting structure 3 communicating with the crushing structure 1 . The crushing structure 1 includes a cylindrical crushing barrel 6 with an annular cavity inside, a drive shaft 62 passing through the center of the crushing barrel 6 and connected to the crushing barrel 6, and a crushing ball 63 arranged in the cavity. The side wall of 6 is provided with several powder filter grooves 64, and powder filter screen is installed in described powder filter groove 64. The drive shaft 62 is connected to the drive system, and the drive system rotates the drive shaft 62, and then drives the crushing barrel 6 to rotate, so that the crushing ball 63 in the crushing barrel 6 can grind the material, so as to achieve the purpose of crushing, and The obtained powder has unifor...

Embodiment 2

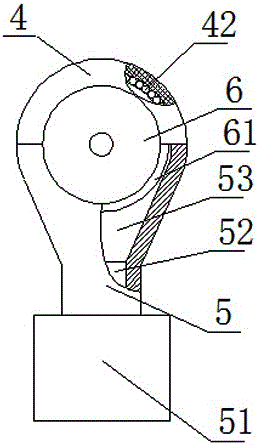

[0030] like Figure 4 , Figure 5 , Figure 8 As shown, on the basis of the above-mentioned embodiments, in this embodiment, an annular protrusion 61 is provided on the outside of the pulverizing barrel 6, and a semi-circular top cover 4 is installed above the powder collecting rack 5, and on the top cover 4 An annular groove 41 fitted with the annular protrusion 61 is provided, and the sealing connection between the top cover 4 and the powder collecting rack 5 can be realized by adding a sealing ring. Several rollers 42 are arranged between the annular protrusion 61 and the annular groove 41 . The use of the top cover 4 can protect the crushing barrel 6, thereby preventing other debris from entering the inside of the crushing barrel 6 through the filter powder tank 64, which is beneficial to avoid contamination of the material, and the sliding friction can be reduced by setting the roller 42. The frictional force is reduced for rolling friction, which is beneficial to redu...

Embodiment 3

[0032] like Figure 9 As shown, on the basis of the above-mentioned embodiments, in this embodiment, the support structure 2 includes two supports 21, a pair of auxiliary wheel brackets 22 arranged on the supports, and a pair of auxiliary wheel brackets 22 hinged on the auxiliary wheel brackets. The auxiliary wheel 23, the drive shaft 62 is placed on the auxiliary wheel. The supporting structures 2 are respectively arranged on both sides of the cylindrical crushing barrel 6 . The auxiliary wheel 23 can support the driving shaft 62 and can make the driving shaft 62 rotate more smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com