An integrated device for pulverizing, compressing and removing water and its working method

A technology of crushing device and crushing bin, which is applied in the directions of drying solid materials, drying solid materials without heating, grain processing, etc. Simple and practical, good water removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

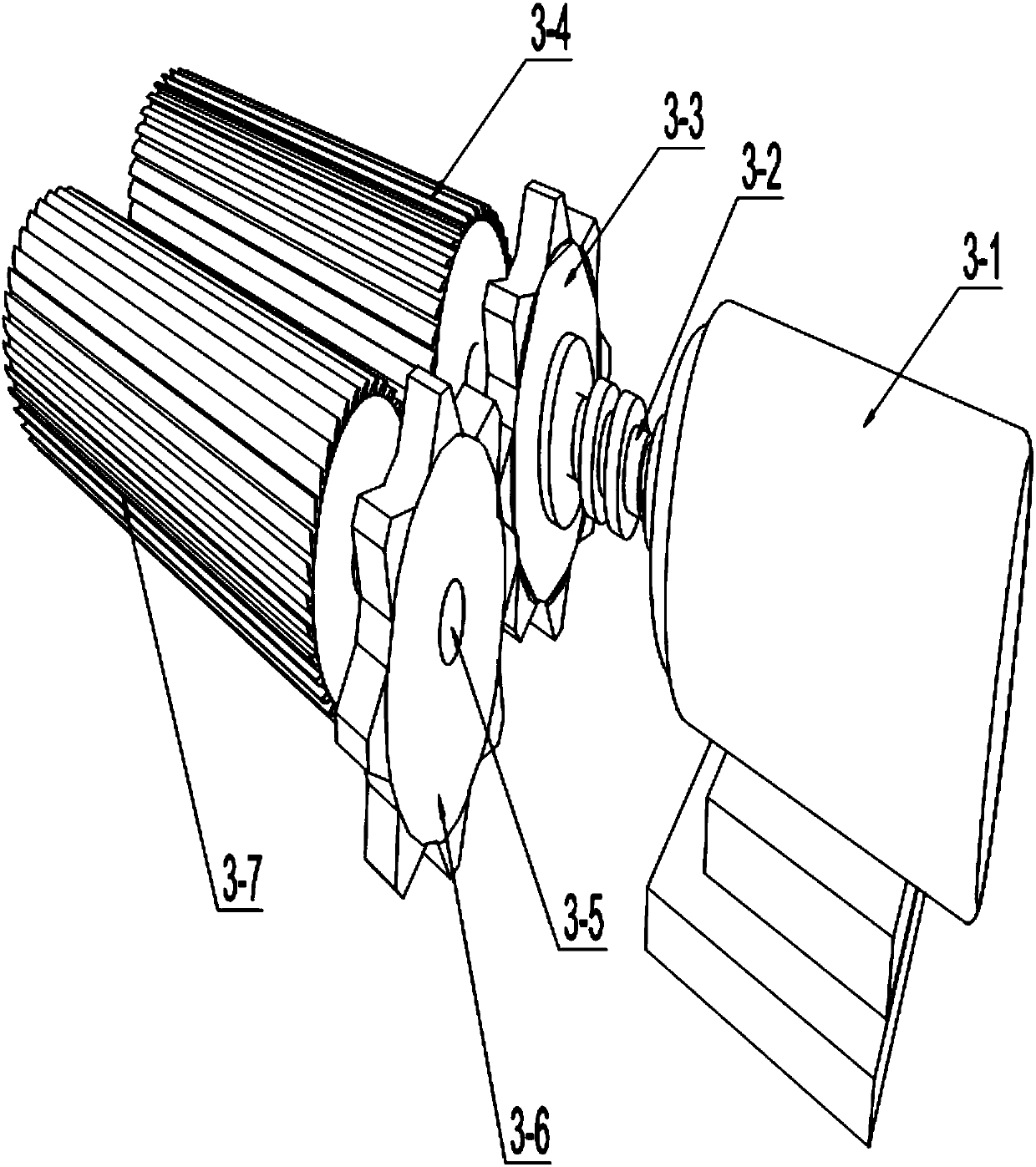

[0059] Follow the steps below to manufacture the crushing teeth 3-4-2 of the present invention in parts by weight:

[0060] Step 1. Add 500 parts of ultrapure water with a conductivity of 0.0005 μS / cm into the reactor, start the stirrer in the reactor at a speed of 135 rpm, and start the heating pump to raise the temperature in the reactor to 45 °C; Add 2 parts of cis-dichloroethylene, 1 part of propylene oxide, and 7 parts of o-nitrophenol, stir until completely dissolved, adjust the pH value to 3.0, adjust the speed of the stirrer to 65rpm, and the temperature is 40 ° C. Esterification reaction 2 Hour;

[0061] Step 2, take 6 parts of o-toluic anhydride, 3 parts of p-aminophenol hydrochloride and pulverize, the powder particle size is 380 mesh; add 15 parts of o-nitrochlorobenzene and mix evenly, spread in the tray, the thickness of the tile is 18 mm, irradiated with α-rays with a dose of 1.55 kGy and an energy of 1.55 MeV for 10 minutes;

[0062] Step 3: Dissolve the mixe...

Embodiment 2

[0066] Follow the steps below to manufacture the crushing teeth 3-4-2 of the present invention in parts by weight:

[0067] Step 1. Add 1,000 parts of ultrapure water with a conductivity of 0.03 μS / cm into the reactor, start the stirrer in the reactor at a speed of 180 rpm, and start the heating pump to raise the temperature in the reactor to 70 °C; Add 13 parts of cis-dichloroethylene, 15 parts of propylene oxide, and 19 parts of o-nitrophenol, stir until completely dissolved, adjust the pH value to 7.0, adjust the speed of the agitator to 95 rpm, and the temperature is 60 ° C, and the esterification reaction 10 hours;

[0068] Step 2, take 20 parts of o-toluic anhydride, 15 parts of p-aminophenol hydrochloride and pulverize, the powder particle size is 650 mesh; add 30 parts of o-nitrochlorobenzene and mix evenly, spread it in the tray, the thickness of the laying is 45 mm, irradiated with α-rays with a dose of 4.15 kGy and an energy of 9.55 MeV for 35 minutes;

[0069] St...

Embodiment 3

[0073] Follow the steps below to manufacture the crushing teeth 3-4-2 of the present invention in parts by weight:

[0074] Step 1. Add 508 parts of ultrapure water with a conductivity of 0.00056 μS / cm into the reactor, start the stirrer in the reactor at a speed of 138 rpm, and start the heating pump to raise the temperature in the reactor to 49 °C; Add 9 parts of cis-dichloroethylene, 9 parts of propylene oxide, and 9 parts of o-nitrophenol, stir until completely dissolved, adjust the pH value to 3.9, adjust the speed of the agitator to 69rpm, and the temperature is 49 ° C, the esterification reaction is 9 Hour;

[0075] Step 2, take 9 parts of o-toluic anhydride, 9 parts of p-aminophenol hydrochloride and pulverize, the particle size of the powder is 389 mesh; add 19 parts of o-nitrochlorobenzene and mix evenly, spread it in the tray, the thickness of the laying is 19 mm, irradiated with α-rays with a dose of 1.59 kGy and an energy of 1.59 MeV for 19 minutes;

[0076] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com