Double-pipe feeding type graphite crushing system provided with pretreatment device

A technology of a pretreatment device and a crushing system, which is applied in the field of graphite crushing and graphite processing, can solve the problems of low processing efficiency of the crushing machine, secondary processing of graphite powder, and low crushing precision, and achieves low noise pollution, improved crushing precision, The effect of improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

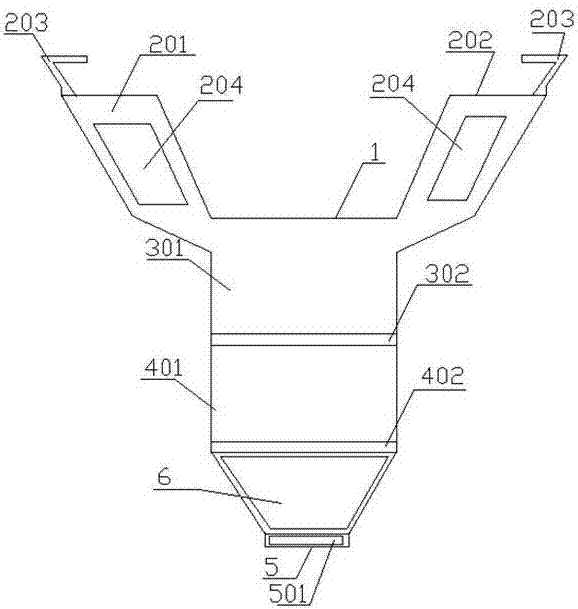

[0024] A double-pipe feeding graphite pulverization system with a pretreatment device, comprising: a pulverizer main body 1, a first feed port 201, a second feed port 202, a dust-proof baffle 203, a pre-crushing device 204, a first Crushing area 301, first filter screen 302, second crushing area 401, second filter screen 402, discharge port 5, dust density alarm device 501 and ultrasonic cleaner 6, the main body of the pulverizer 1, the first feed port 201, the second feeding port 202, the dust-proof baffle 203, the pre-crushing device 204, the first crushing area 301, the first filter screen 302, the second crushing area 401, the second filter screen 402 and the discharge port 5 are connected to each other , the pulverizer main body 1 includes a first pulverization zone 301 and a second pulverization zone 401, the first feeding port 201 and the second feeding port 202 are arranged on both sides of the top of the pulverizer main body 1, the Both the first feed port 201 and the...

Embodiment 2

[0028] A double-pipe feeding graphite pulverization system with a pretreatment device, comprising: a pulverizer main body 1, a first feed port 201, a second feed port 202, a dust-proof baffle 203, a pre-crushing device 204, a first Crushing area 301, first filter screen 302, second crushing area 401, second filter screen 402, discharge port 5, dust density alarm device 501 and ultrasonic cleaner 6, the main body of the pulverizer 1, the first feed port 201, the second feeding port 202, the dust-proof baffle 203, the pre-crushing device 204, the first crushing area 301, the first filter screen 302, the second crushing area 401, the second filter screen 402 and the discharge port 5 are connected to each other , the pulverizer main body 1 includes a first pulverization zone 301 and a second pulverization zone 401, the first feeding port 201 and the second feeding port 202 are arranged on both sides of the top of the pulverizer main body 1, the Both the first feed port 201 and the...

Embodiment 3

[0033] A double-pipe feeding graphite pulverization system with a pretreatment device, comprising: a pulverizer main body 1, a first feed port 201, a second feed port 202, a dust-proof baffle 203, a pre-crushing device 204, a first Crushing area 301, first filter screen 302, second crushing area 401, second filter screen 402, discharge port 5, dust density alarm device 501 and ultrasonic cleaner 6, the main body of the pulverizer 1, the first feed port 201, the second feeding port 202, the dust-proof baffle 203, the pre-crushing device 204, the first crushing area 301, the first filter screen 302, the second crushing area 401, the second filter screen 402 and the discharge port 5 are connected to each other , the pulverizer main body 1 includes a first pulverization zone 301 and a second pulverization zone 401, the first feeding port 201 and the second feeding port 202 are arranged on both sides of the top of the pulverizer main body 1, the Both the first feed port 201 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com