Mixing device for soil remediation

A soil remediation and mixing device technology, which is applied in the field of soil remediation, can solve problems such as poor mixing effect and limited repair effect, and achieve the effect of avoiding screen hole clogging and improving crushing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

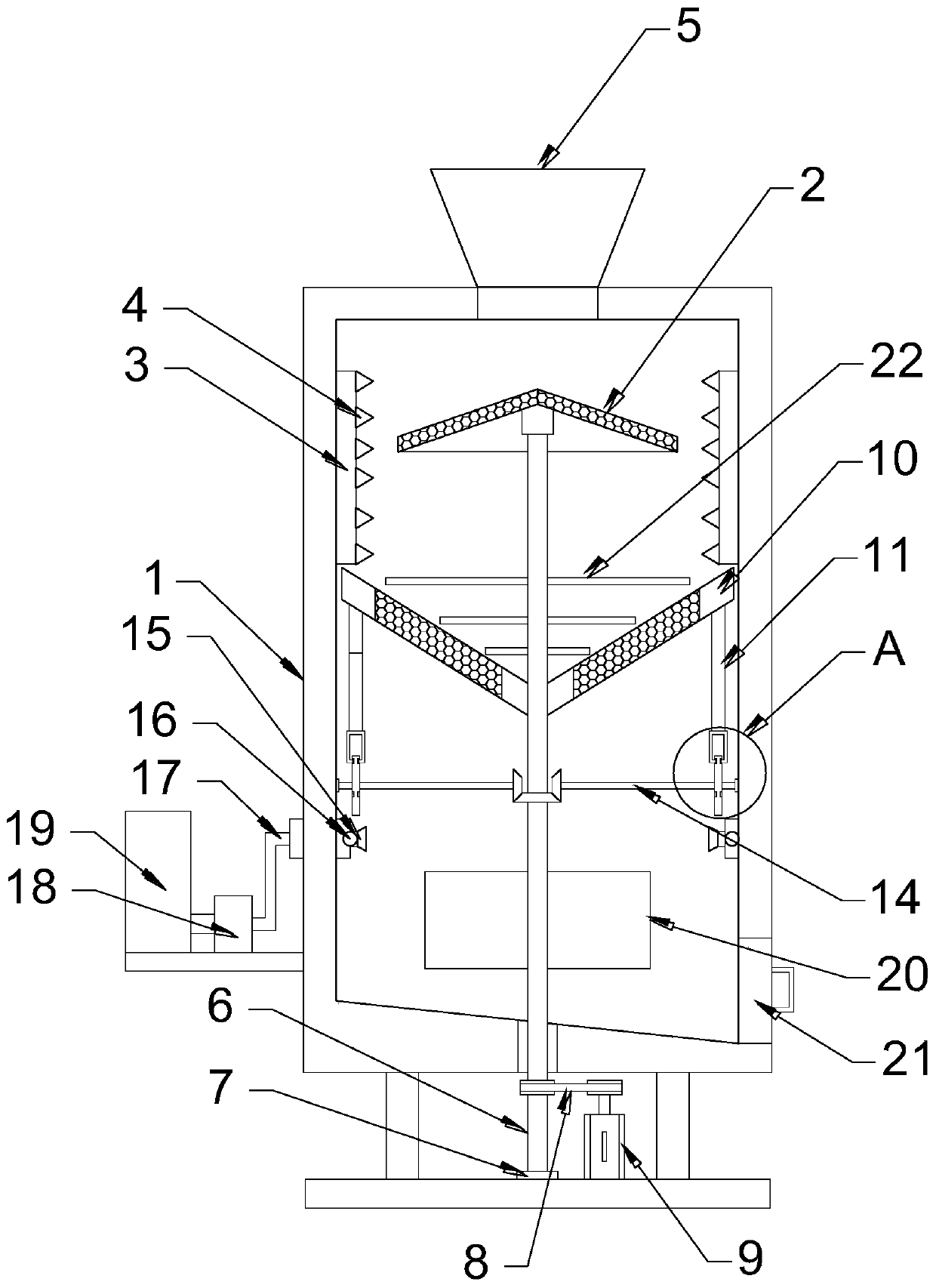

[0021] see Figure 1-4 , in an embodiment of the present invention, a soil remediation mixing device includes a box body 1; the upper end of the box body 1 is connected with a feed hopper 5; Cylinder 2 is a conical cylinder with sieve holes on the conical surface; an impact cylinder 3 is provided on the outside of the convex screen cylinder 2, and the impact cylinder 3 is fixedly connected with the inner wall of the box body 1, and the inner wall of the impact cylinder 3 is fixedly connected with a uniform Distributed impact teeth 4; the lower end of the convex screen cylinder 2 is fixedly connected with a central shaft 6, the central shaft 6 extends to the bottom of the box body 1, the central shaft 6 is rotationally connected with the base through the main bearing seat 7, and the central shaft 6 passes through the transmission The belt 8 is connected to the output shaft of the driving motor 9, and the driving motor 9 drives the central shaft 6 to rotate, and then drives the ...

Embodiment 2

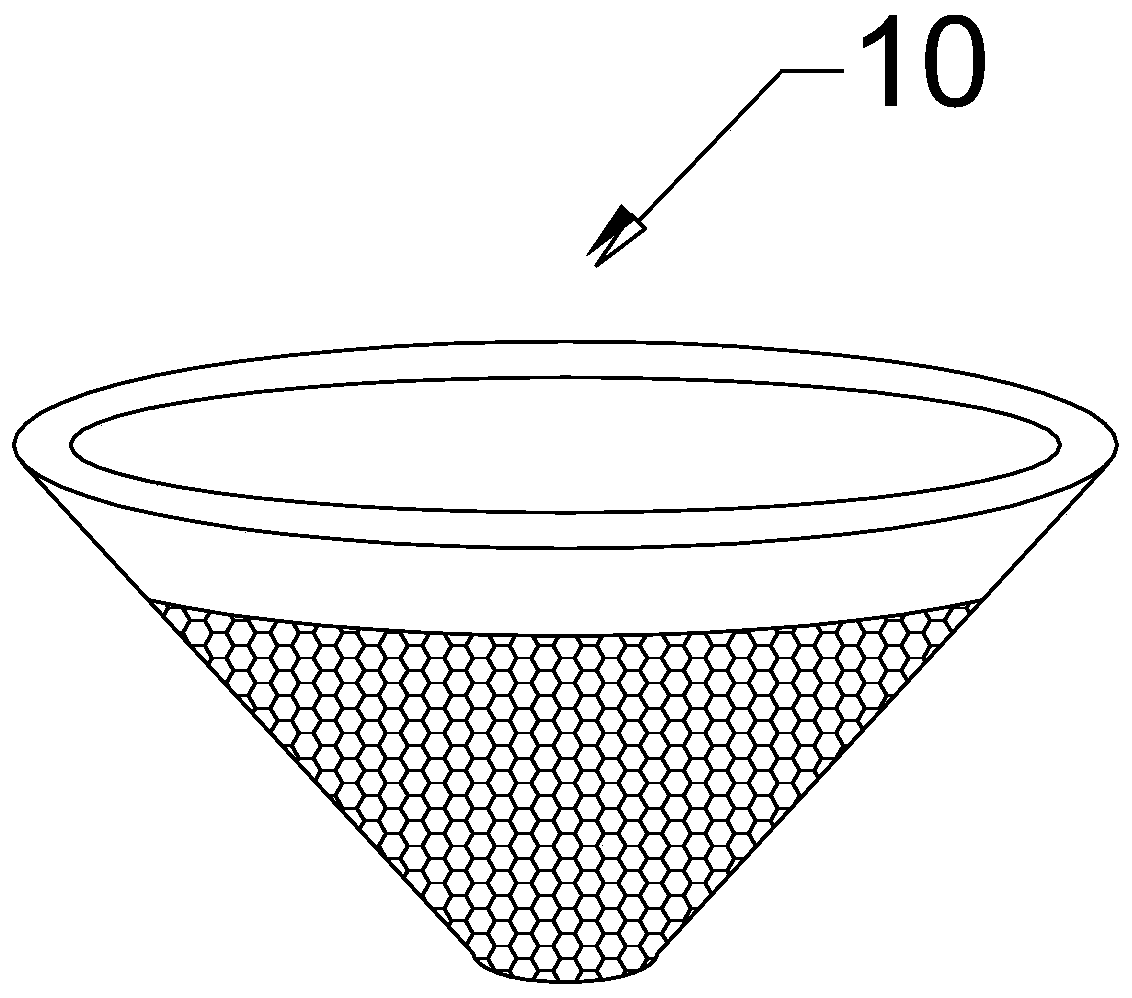

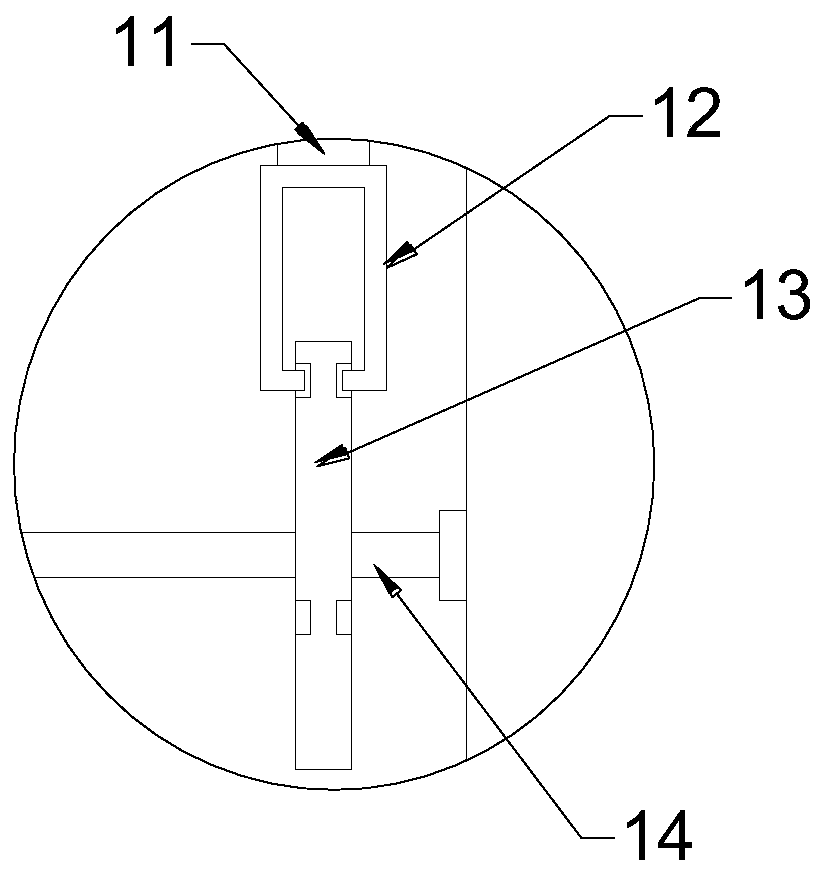

[0024] The difference between this embodiment and Embodiment 1 is that: the convex screen cylinder 2 is provided with a convex screen cylinder 10, and the convex screen cylinder 10 is a conical cylinder with evenly distributed sieve holes on the conical surface. And the tip of the tapered cylinder is facing downward; the edge of the convex screen cylinder 10 is fixedly connected with a connecting rod 11, and the lower end of the connecting rod 11 is fixedly connected with a clamping frame 12, and the clamping frame 12 is clamped with an eccentric disc 13, and the eccentric disc 13 is provided with a circular groove, and the lower end of the clamping frame 12 is nested in the circular groove and is slidably connected with the circular groove; the eccentric disc 13 is fixedly connected with a transmission shaft 14, and the transmission shaft 14 is rotationally connected with the inner wall of the box body 1. The inner side of the transmission shaft 14 is connected with the centra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com