Preparation technology of nanomaterial

A preparation process and nano-material technology, which is applied in the field of nano-material preparation process, can solve the problems of weak adsorption, insignificant protection and filtration ability, lack of sterilization and antibacterial ability, etc., to achieve convenient operation and avoid attachment to equipment On the inner wall, the effect of the reasonable structure of the grinding device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

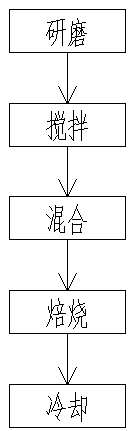

[0080] A preparation process for nanomaterials, the steps are as follows:

[0081] (1) Weigh in parts by weight: 32 parts of ferric oxide, 22 parts of titanium dioxide, 8-16 parts of magnesium oxide, 12 parts of aluminum oxide, 8 parts of expanded graphite and 5 parts of white carbon black are added to the grinding device and ground into Mixed particles A with particle diameter less than 150nm;

[0082] (2) Add 22% of mixed particles A, 6% of acetone, 5% of absolute ethanol and the rest of deionized water into the stirring device and mix uniformly to obtain mixed solution B;

[0083] (3) Mix 14% pottery clay powder, 10% red mud, 4% cenospheres, 18% zeolite powder and the rest of the mixed solution B by weight percentage, and inject it into the mold;

[0084] (4) Put the mold in a roasting furnace for roasting, the temperature of the combustion chamber is 700°C, and the roasting time is 2 hours;

[0085] (5) The nanomaterials can be obtained after natural cooling after calcin...

Embodiment 2

[0136] With the preparation technology of a kind of nanometer material described in embodiment one, its steps are as follows:

[0137] (1) Weigh in parts by weight: 25 parts of ferric oxide, 18 parts of titanium dioxide, 8 parts of magnesium oxide, 8 parts of aluminum oxide, 5 parts of expanded graphite and 3 parts of white carbon black are added to the grinding device and ground to a particle size Mixed particles A smaller than 150nm;

[0138] (2) Add 15% of mixed particles A, 5% of acetone, 3% of absolute ethanol and the rest of deionized water into the stirring device and mix evenly to obtain mixed solution B;

[0139] (3) Mix 15% pottery clay powder, 12% red mud, 3% hollow microspheres, 22% zeolite powder and the rest of the mixed solution B by weight percentage, and then inject it into the mold;

[0140] (4) Put the mold in a roasting furnace for roasting, the temperature of the combustion chamber is 700°C, and the roasting time is 2 hours;

[0141] (5) The nanomaterial...

Embodiment 3

[0143] With the preparation technology of a kind of nanometer material described in embodiment one, its steps are as follows:

[0144] (1) Weigh in parts by weight: 36 parts of ferric oxide, 24 parts of titanium dioxide, 16 parts of magnesium oxide, 16 parts of aluminum oxide, 10 parts of expanded graphite and 8 parts of white carbon black are added to the grinding device and ground to a particle size Mixed particles A smaller than 150nm;

[0145] (2) Add 28% of the mixed particles A, 5% of acetone, 6% of absolute ethanol and the rest of deionized water into the stirring device and mix evenly to obtain the mixed solution B;

[0146] (3) Mix 12% of clay powder, 8% of red mud, 5% of hollow microspheres, 16% of zeolite powder and the rest of the mixed solution B by weight percentage, and inject it into the mold;

[0147] (4) Put the mold in a roasting furnace for roasting, the temperature of the combustion chamber is 700°C, and the roasting time is 3 hours;

[0148] (5) The nan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com