Anti-clogging vortex screen solid-liquid separator for sewage treatment and separation method

A solid-liquid separator and sewage treatment technology, which is applied in the direction of separation methods, biological sludge treatment, chemical instruments and methods, etc., can solve the problems of high investment cost and low efficiency, achieve simple daily maintenance, good application prospects, overcome The effect of high investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

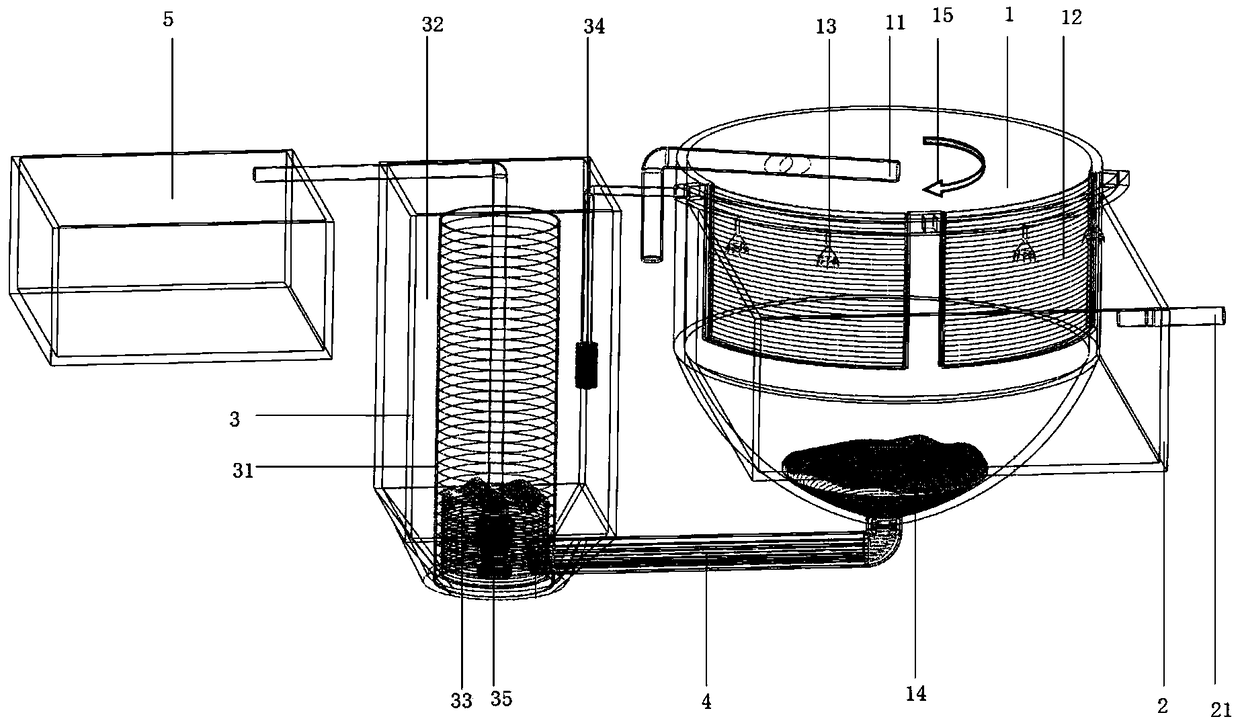

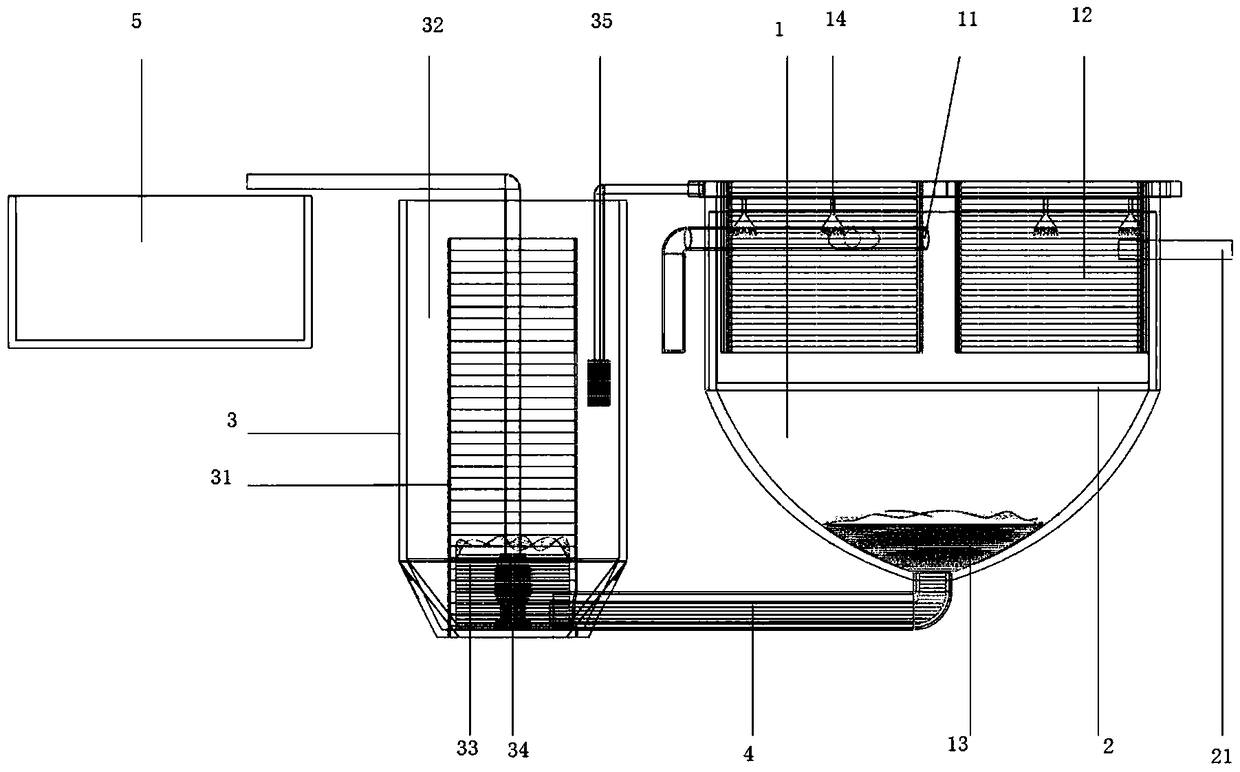

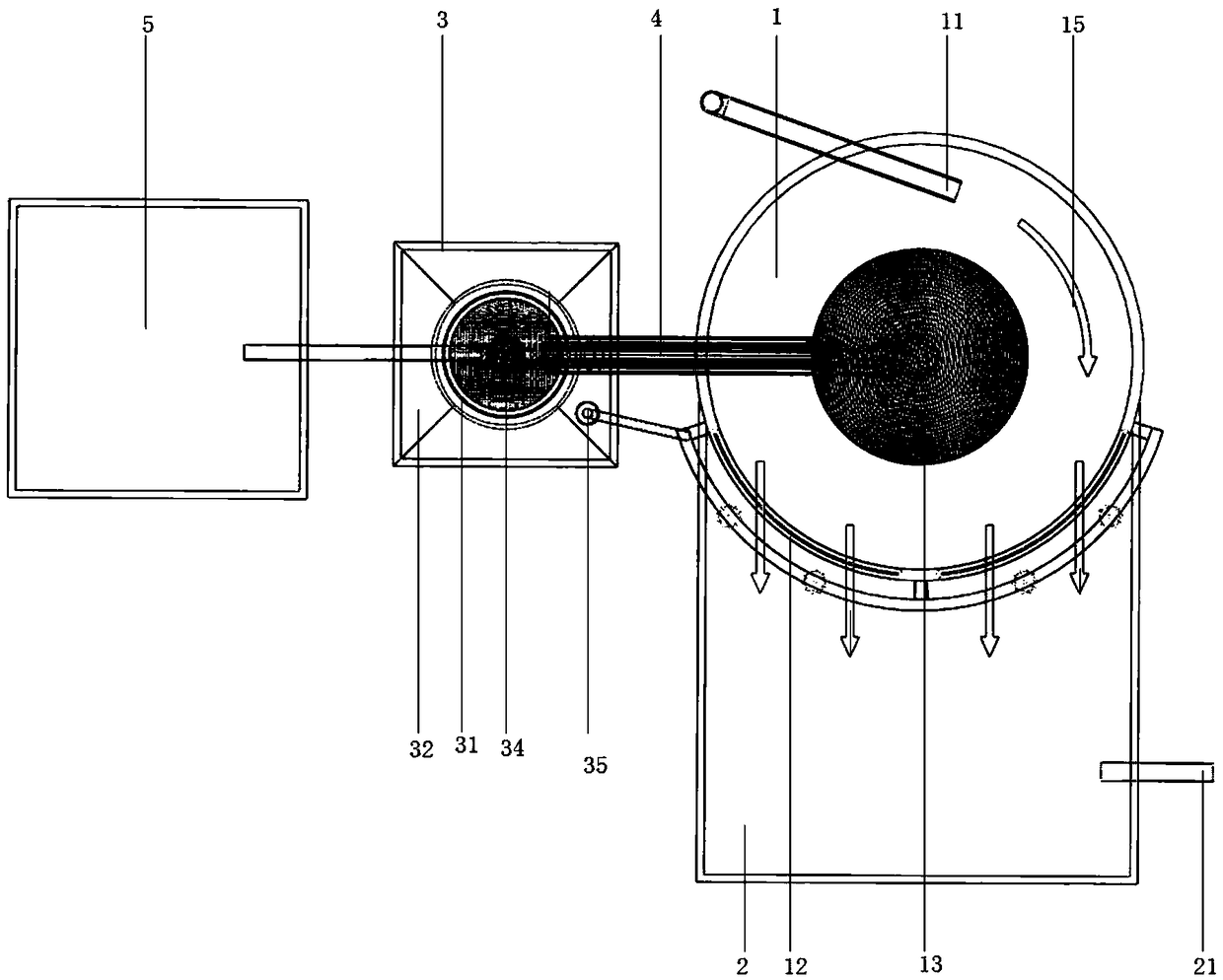

[0024] Anti-clogging cyclone screen solid-liquid separator for sewage treatment, see Figures 1 to 3 , including a screen solid-liquid separator 1, a clear water tank 2, a solid waste sedimentation tank 3, a bottom pipeline 4, and an organic fertilizer fermentation tank 5.

[0025] The bottom of the screen solid-liquid separator 1 is conical, and the upper part is provided with a group of screens 12 and a water inlet pipe 11. The screen 12 is an arc-shaped screen, and the water inlet pipe 11 is parallel to the tangent of the arc-shaped screen. Set, and located inside the curved screen. A screen cleaning nozzle 13 is provided near the inner side wall of the screen 12 , and the screen solid-liquid separator 1 communicates with the clean water tank 2 through the screen 12 . The screen 12 is a 60-100 mesh screen.

[0026] The solid waste sedimentation tank 3 is provided with a columnar screen dirt collector 31, and the columnar screen dirt collector 31 divides the solid waste se...

Embodiment 2

[0034] Embodiment 2 is used for the solid-liquid separation system of livestock and poultry breeding wastewater

[0035] Livestock and poultry breeding wastewater enters the screen solid-liquid separator 1 through the water inlet pipe 11 to form a swirl 15, and the clean water flows out through the screen 12, enters the clean water tank 2, and flows out from the water outlet 21 of the clean water tank 2, with a mesh size of 60- 100; the solid waste 14 sinks with the swirling flow and is deposited at the bottom of the vertebral body. The bottom of the vertebral body is connected to the external solid waste settling tank 3 by the bottom pipeline 4. The solid waste settling tank 3 is equipped with a columnar screen dirt collector 31, and the water purification area 32 of the solid waste settling tank 3 is provided with a low-lift water pump 34. The lift water pump 34 is connected with the screen cleaning nozzle 13 . When pumping water, the bottom of the cone of the screen solid-...

Embodiment 3

[0037] Embodiment 3 is used for the solid-liquid separation system of aquaculture industrialization wastewater

[0038] The solid waste in the wastewater discharged from the aquaculture factory is mainly composed of residual bait and fish feces. The content of solid waste is relatively low, but the particles are finer and need to be filtered with a finer screen.

[0039]The waste water discharged from the factory breeding workshop enters the screen solid-liquid separator 1 through the water inlet pipe 11 to form a swirl 15, and the clean water flows out through the screen 12, enters the clean water tank 2, and flows out from the water outlet 21 of the clean water tank 2. The mesh of the screen is 80-120 mesh; the solid waste 14 sinks with the swirling flow and is deposited at the bottom of the vertebral body. The bottom of the vertebral body is connected to the external solid waste settling tank 3 by the bottom pipeline 4. The solid waste settling tank 3 is equipped with a col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com